- DL manuals

- Banner

- Accessories

- Q4X

- Instruction manual

Banner Q4X Instruction manual

Summary of Q4X

Page 1

Q4x stainless steel laser sensor with dual discrete outputs and io-link instruction manual original instructions 190074 rev. D 17 january 2017 © banner engineering corp. All rights reserved 190074.

Page 2

Contents 1 product description ............................................................................................................................................. 3 1.1 models .....................................................................................................................

Page 3

1 product description class 1 laser cmos sensor with dual outputs and io-link. Patent pending. Figure 1. Flush mount (left) and threaded barrel (right) models • the ultimate problem solver: reduce sensor inventory with a reliable, durable sensor that solves the most challenging applications • solves...

Page 4

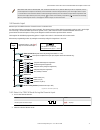

1.3 features 1 2 3 figure 2. Sensor features 1. Output indicator (amber) 2. Display 3. Buttons 1.3.1 display and indicators the display is a 4-digit, 7-segment led. The main screen is the run mode screen. For 2-pt, bgs, fgs, and dyn teach modes, the display shows the current distance to the target i...

Page 5

(select)(teach) • press to select menu items in setup mode • press and hold for longer than 2 seconds to start the currently selected teach mode (the default is two- point teach) (+)(ch1/ch2) • press to navigate the sensor menu in setup mode • press to change setting values; press and hold to increa...

Page 6

2 installation 2.1 install the safety label the safety label must be installed on q4x sensors that are used in the united states. Note: position the label on the cable in a location that has minimal chemical exposure. 1. Remove the protective cover from the adhesive on the label. 2. Wrap the label a...

Page 7

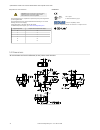

3. Check the sensor alignment. 4. Tighten the mounting screws to secure the sensor (or the sensor and the bracket) in the aligned position. 2.4 wiring diagram 4 1 3 2 10-30v dc ch1 ch2 + – push-pull load load figure 10. Channel 2 as pnp discrete or pfm output 4 1 3 2 10-30v dc ch1 ch2 + – push-pull ...

Page 8

3 sensor programming program the sensor using the buttons on the sensor or the remote input (limited programming options). In addition to programming the sensor, use the remote input to disable the buttons for security, preventing unauthorized or accidental programming changes. See locking and unloc...

Page 9

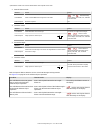

No: do not reset to factory defaults yes: reset to factory defaults two-point static teach dynamic teach background suppression foreground suppression top menu sub menu off: no delays enabled on: enable on and/or off delay (set value in delay timer menu) 1 shot, fixed output pulse duration totalizer...

Page 10

Two-point static teach dynamic teach background suppression foreground suppression top menu sub menu off: no delays enabled on: enable on and/or off delay (set value in delay timer menu) 1 shot, fixed output pulse duration total end: exit setup teach selection ch2 output ch2 window size ch2 ** outpu...

Page 11

• —complementary to output 1 • —remote teach input • —laser off when pulled high • —laser on when pulled high • —master sync line output for two-sensor cross-talk avoidance • —slave sync line output for two-sensor cross-talk avoidance • —pulse frequency modulation (pfm) output (see pulse frequency m...

Page 12

This setting is automatically applied during any subsequent teach operation. The window size value represents a +/- mm value, so the total window size is twice this value. For example, a window set of 10 mm gives a 20 mm window centered around the taught point. The window size can also be changed di...

Page 13

• —standard excess gain mode with increased noise immunity 3.2.8 output timing delays use this menu to select the output timing delay to be set. On and off delay timers can be used together. The default is no delay. For channel 2, this menu is available when the output is set to light operate or dar...

Page 14

• 10 milliseconds for 10, 15, 25, and 50 millisecond response speeds • 1 millisecond for 1.5, 2, 3, and 5 milliseconds response speeds use and to scroll through the values. Millisecond values do not include the decimal point; seconds values include the decimal point. • 1 to 999 ms (when is selected,...

Page 15

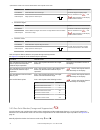

Zero = near (default setting) shift = off = = zero = far shift = off = = zero = far shift = on = = display reference display reference 50 mm 50 mm 50 mm display reference display reference display reference 100 0 200 300 mm 0 -100 100 200 mm 0 -100 100 200 mm 100 0 200 300 mm 200 0 100 300 mm 200 0 ...

Page 16

3.2.12 display view use this menu to select the display view. The default is right-reading. • —right-reading • —inverted • —right-reading and the display enters sleep mode after 60 seconds • —inverted and the display enters sleep mode after 60 seconds when the sensor is in sleep mode, the display wa...

Page 17

Note: when dual mode is selected (dyn, fgs, and bgs indicators are on), after the teach process is completed, use the manual adjustment to adjust the sensitivity of the thresholds around the taught reference point. The taught reference point is a combination of the measured distance and returned sig...

Page 18

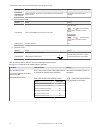

Action result pulses teach mode 1 t two-point static background suppression 2 t t t dynamic background suppression 3 t t t t t one-point window (foreground suppression) 4 t t t t t t t one-point background suppression 5 t t t t t t t t t dual (intensity + distance) the selected teach method displays...

Page 19

Action result four-pulse the remote input. T t t t t t t the sensor is ready to have the button state defined and displays. 2. Lock or unlock the sensor buttons. Action result single-pulse the remote input to unlock the sensor. T displays and the sensor returns to run mode. Double-pulse the remote i...

Page 20

2. Start the teach mode. Method action result push button press and hold teach for longer than 2 seconds. And flash alternately on the display. The dyn, fgs, and bgs indicators flash. Remote input no action required. N/a 3. Teach the sensor. Method action result push button press teach to teach the ...

Page 21

Condition teach result display two invalid teach points sets a switch point at the following location: model switch point 100 mm threaded barrel models 99 300 mm threaded barrel models 290 600 mm threaded barrel models 590 110 mm flush mount models 109 310 mm flush mount models 300 610 mm flush moun...

Page 22

Method action result push button press teach to teach the target. The sensor begins sampling target distance information and and flash alternately on the display. The dyn indicator flashes. Remote input single-pulse the remote input. T 4. Present the targets. Method action result push button present...

Page 23

Switch point value a switch point value -a 2 press and hold > 2s 1 3 press again figure 19. One-point window (foreground suppression) in order to reliably detect changes from the taught background, if multiple laser reflections are returning to the sensor, the output status is treated as though the ...

Page 24

Condition teach result display one valid teach point with both switch points in range (with offset, if applicable) sets a window (two switch points) centered around the taught distance. The ± window size is the vertical minimum object separation. The two switch points always stay within the specifie...

Page 25

Condition teach result display one valid teach point that, after the offset, results in a both switch points outside of the range sets a window (two switch points) centered around the following location: model window center point 100 mm threaded barrel models 80 300 mm threaded barrel models 250 600...

Page 26

Method action result push button present the target. The sensor-to-target distance must be within the sensor's range. The target's measurement value displays. Remote input 2. Start the teach mode. Method action result push button press and hold teach for longer than 2 seconds. Light operate and flas...

Page 27

Condition teach result display one valid teach point that, after offset, becomes invalid sets a switch point at the following location: model switch point 100 mm threaded barrel models 75 300 mm threaded barrel models 200 600 mm threaded barrel models 400 110 mm flush mount models 85 310 mm flush mo...

Page 28

Method action result push button press and hold the teach button for more than 2 seconds. Light operate: and flash on the display. The dyn, fgs, and bgs indicators flash. Dark operate: and flash on the display. The dyn, fgs, and bgs indicators flash. Remote input no action required. N/a 3. Teach the...

Page 29

4 io-link interface io-link is a point-to-point communication link between a master device and sensor. It can be used to automatically parameterize sensors and transmit process data. For the latest io-link protocol and specifications, please visit the web site at http://www.Io- link.Com . The io-lin...

Page 30

5 specifications sensing beam visible red class 1 laser, 655 nm supply voltage (vcc) 10 to 30 v dc (class 2 supply) (10% max ripple within limits) power and current consumption, exclusive of load sensing range—threaded barrel models 600 mm models: 25 mm to 600 mm (0.98 in to 23.62 in) 300 mm models:...

Page 31

Beam spot size—100/110 mm models table 11: beam spot size—100/110 mm models distance (mm) size (horizontal × vertical) threaded barrel models flush mount models 25 35 2.4 mm × 1.0 mm 50 60 2.2 mm × 0.9 mm 100 110 1.8 mm × 0.7 mm beam spot size—300/310 mm and 600/610 mm models table 12: beam spot siz...

Page 32

Required overcurrent protection warning: electrical connections must be made by qualified personnel in accordance with local and national electrical codes and regulations. Overcurrent protection is required to be provided by end product application per the supplied table. Overcurrent protection may ...

Page 33

Figure 22. Flush mount models q4x stainless steel laser sensor with dual discrete outputs and io-link www.Bannerengineering.Com - tel: 763.544.3164 33.

Page 34

5.2 performance curves—threaded barrel models minimum separation distance between target and background for: uniform and non-uniform targets 100 mm models 300 mm models minimum separation t arget to background (mm) dimension y distance to target (mm) dimension x target switch point distance backgrou...

Page 35

5.3 performance curves—flush mount models minimum separation distance between target and background for: uniform and non-uniform targets 110 mm models 310 mm models minimum separation t arget to background (mm) dimension y distance to target (mm) dimension x 0 2 4 6 8 10 12 14 16 18 20 22 0 25 50 75...

Page 36

6 additional information 6.1 dual (intensity + distance) mode in background suppression (dyn, 1-pt, 2-pt) and foreground suppression (fgs) teach modes, the q4x sensor compares changes in the measured distance between the sensor and target to control the output state. Dual teach mode, dual intensity ...

Page 37

The q4x sensor can be taught non-ideal reference surfaces, such as surfaces outside of the sensor range or very dark surfaces. Teaching non-ideal reference surfaces may enable applications other than transparent or clear object detection, but best results for transparent or clear object detection re...

Page 38

6.4 abbreviations the following table describes the abbreviations used on the sensor display and in this manual. Abbreviation description no valid signal in range the sensor has not been taught one-shot first multiple light reflections second two-point teach (static background suppression) automatic...

Page 39

Abbreviation description lock/locked laser off master near zero reference location—the front of the sensor is 0 and the measurement increase as the target moves further away from the sensor object , off delay timer (channel 1, channel 2) off , offset (channel 1, channel 2) an applied offset resulted...

Page 40

7 troubleshooting table 15: error codes error code description resolution no valid signal in range reposition the sensor or the target the signal is saturated (too much light) reposition the sensor or the target to increase the detection distance, or increase the angle of incidence between the senso...

Page 41

8 accessories 8.1 cordsets 4-pin threaded m12/euro-style cordsets model length style dimensions pinout (female) mqdc-406 1.83 m (6 ft) straight 44 typ. ø 14.5 m12 x 1 2 3 4 1 1 = brown 2 = white 3 = blue 4 = black mqdc-415 4.57 m (15 ft) mqdc-430 9.14 m (30 ft) mqdc-450 15.2 m (50 ft) mqdc-406ra 1.8...

Page 42

4-pin threaded m12/euro-style cordsets—double ended, oil resistant model length style dimensions pinout mqdec-401ss-pur 0.3 m (1 ft) male straight/ female straight 40 typ. [1.58"] ø 14.5 [0.57"] m12 x 1 44 typ. [1.73"] ø 14.5 [0.57"] m12 x 1 female 2 3 4 1 male 1 4 3 2 1 = brown 2 = white 3 = blue 4...

Page 43

8.2 brackets all measurements are listed in millimeters, unless noted otherwise. Smbq4x.. • swivel bracket with tilt and pan movement for precision adjustment • easy sensor mounting to extruded rail t-slots • metric and inch size bolts available • side mounting of some sensors with the 3 mm screws i...

Page 44

8.3 aperture kits—threaded barrel models apg18s kit with glass lens to protect plastic sensor lens from chemical environments and weld splatter damage. Used with s18, m18, t18, tm18, and q4x housing Ø 22.4 mm 12.7 mm lens o-ring additional information • borosilicate glass window protects the pmma wi...

Page 45

9 contact us corporate headquarters address: banner engineering corporate 9714 tenth avenue north minneapolis, minnesota 55441, usa phone: +1 763 544 3164 website: www.Bannerengineering.Com europe address: banner engineering emea park lane culliganlaan 2f diegem b-1831, belgium phone: +32 (0)2 456 0...

Page 46

10 banner engineering corp. Limited warranty banner engineering corp. Warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner engineering corp. Will repair or replace, free of charge, any product of its manufacture which, at the t...