- DL manuals

- Lawn Solutions

- Lawn and Garden Equipment

- TR2009HOF1

- Operator's Manual

Lawn Solutions TR2009HOF1 Operator's Manual

Summary of TR2009HOF1

Page 1

Turf revitalizer model: tr2009hof1 lawn solutions commercial products, inc. 502-968-3188 serial no. Ls02001 and up form no. 3370-861 operator’s manual g016883.

Page 2: Introduction

Warning california proposition 65 warning the engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects, or other reproductive harm. This spark ignition system complies with canadian ices-002. Important: this engine is not equipped with a spa...

Page 3: Contents

Contents introduction................................................................. 2 safety ........................................................................... 3 safe operating practices ....................................... 3 slope indicator...............................................

Page 4

– never refuel or drain the machine indoors. • check that the operator presence controls, safety switches, and shields are attached and functioning properly. Do not operate unless they are functioning properly. Operation • never run an engine in an enclosed area. • only operate in good light, keepin...

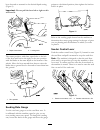

Page 5: Slope Indicator

Slope indicator g01 1841 figure 3 this page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 20 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 20 degrees. Fold a...

Page 6

Safety and instructional decals safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 119-4655 112-9028 1. Warning—stay away from moving parts; keep all guards in place. 93-7321 1. Cutting/disme...

Page 7: Setup

Setup unfolding the handle 1. Raise the handle to the operating position. G016884 figure 4 2. Slide the oval locking rings down each side of the upper handle over the lower handle, locking the handle sections together. Checking the engine oil level the machine comes from the factory with oil in the ...

Page 8

Recoil starter pull the recoil starter handle to start engine (figure 6). Fuel shut-off valve close the fuel shut-off valve when transporting or storing the machine (figure 6). Choke lever before starting a cold engine, move the choke lever forward. After the engine starts, regulate the choke to kee...

Page 9

Lever forward or rearward to the desired depth setting (figure 9). Important: do not pull the lever left or right as this will bend it. 2 figure 9 1. Depth control lever 2. Locking knob the center position, with three open holes to the left of the lever and four to the right) is the zero position wi...

Page 10: Specifications

Specifications note: specifications and design are subject to change without notice. Width 30 inches (76 cm) length (operating) 54 inches (137 cm) length (with handle stored) 37.5 inches (95.25 cm) height (operating) 44.5 inches (113 cm) height (with handle stored) 29 inches (73.5 cm) weight 265 lbs...

Page 11: Cleaning Debris From The

Cleaning debris from the machine service interval: before each use or daily 1. Put the traction control in neutral, disengage the cutting blades, stop the engine, wait for all moving parts to stop, and turn off the engine switch. 2. Brush dirt and debris away from the air cleaner and engine openings...

Page 12: Starting And Stopping The

3. Clean around the fuel tank cap and remove it (figure 14). Note: the cap is tethered to the fuel tank. G013315 figure 14 4. Add unleaded gasoline to the fuel tank, until the level is just inside the mesh filter basket. Important: this space in the tank allows gasoline to expand. Do not fill the fu...

Page 13

The machine over the yard with the seeder control lever turned off. Note: dethatch a newly seeded lawn the following spring or fall to allow the grass to thicken and reduce the chance of fungus. Power raking/renovation to break new ground or till an existing lawn, set the cutting blades to be 1/4 to...

Page 14: Maintenance

Maintenance recommended maintenance schedule(s) maintenance service interval maintenance procedure before each use or daily • check the engine oil level. • clean debris from the air cleaner and seed basket. • inspect the air cleaner elements. • check the tire pressure. • ensure that the machine does...

Page 15: Wire

Disconnecting the spark plug wire before performing any maintenance on the engine, belts, or cutting blades, disconnect the spark plug wire from the spark plug (figure 16). Figure 16 1. Spark plug wire engine maintenance servicing the air cleaner service interval: before each use or daily—inspect th...

Page 16: Servicing The Engine Oil

8. If the paper element is excessively dirty, replace it. Note: never try to brush dirt off the paper element; brushing forces the dirt into the fibers. 9. Clean the foam element in warm, soapy water or in a nonflammable solvent. Note: do not use gasoline to clean the foam element because it could c...

Page 17: Drive System

Figure 19 1. Center electrode insulator 2. Side electrode 3. Air gap (not to scale) 6. Carefully install the spark plug by hand (to avoid cross threading) until it is hand tight. 7. Tighten the spark plug an additional 1/2 turn if it is new; otherwise, tighten it an additional 1/8 to 1/4 turn. Impor...

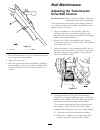

Page 18: Belt Maintenance

G016888 1 2 figure 21 1. Jam nut 2. Cable 3. Move the cable down to stop forward movement or up to stop reverse movement. 4. Tighten the jam nuts. 5. Start the engine and test the adjustment, repeating this procedure as necessary until the machine does not move when the traction control handle is in...

Page 19: Seeder Maintenance

G016900 1 1 2 3 4 2 5 figure 23 1. Nut and washer 4. C-washer 2. Pulley carriage 5. Bolt 3. Machine frame c. Move the carriage to the left, tightening the belt, then secure the four mounting nuts and bolts. 5. Install the belt cover using the fasteners you removed previously. Seeder maintenance adju...

Page 20: Replacing Worn Cutting

Replacing worn cutting blades service interval: before each use or daily—check the blades for wear or damage. When the cutting blades are worn down and no longer functioning properly, replace them, as follows: important: perform this procedure when the fuel tank is empty or nearly empty. 1. Stop the...

Page 21: Storage

Storage 1. Raise the cutting blades, stop the machine, stop the engine, and disconnect the spark plug wire. 2. Remove dirt and grime from the entire machine. Important: you can wash the machine with mild detergent and water. Do not pressure wash the machine. Avoid excessive use of water, especially ...

Page 22: Notes:

Notes: 22.

Page 23: Notes:

Notes: 23.

Page 24: Notes:

Notes: 24.

Page 25

Lawn solutions warranty limited warranty for turf revitalizer the product carries a 1-year limited warranty from the date of purchase for the original purchaser. Lawn solutions will replace for the original purchaser free of charge any part or parts found to be defective in material or workmanship e...