- DL manuals

- Makita

- Trimmer

- EM2650LH

- Instruction Manual

Makita EM2650LH Instruction Manual

Summary of EM2650LH

Page 1

Em2650uh em2651uh em2650lh em2651lh petrol brushcutter em2650uh em2651uh em2650lh em2651lh instruction manual important: read this instruction manual carefully before putting the petrol brushcutter into operation and strictly observe the safety regulations! Preserve instruction manual carefully!.

Page 2

2 thank you very much for purchasing the makita petrol brushcutter. We are pleased to recommend to you the makita petrol brushcutter which is the result of a long development programme and many years of knowledge and experience. Please read this booklet which refers in detail to the various points t...

Page 3

General instructions – to ensure correct operation, user has to read this instruction manual to make himself familiar with the handling of the petrol brushcutter. Users insufficiently informed will risk danger to themselves as well as others due to improper handling. – it is recommended only to lend...

Page 4

Start the petrol brushcutter only in accordance with the instructions. – do not use any other methods for starting the engine! – use the petrol brushcutter and the tools only for such applications as specified. – only start the petrol brushcutter engine, after the entire assembly is done. Operation ...

Page 5

5 method of operation – only use the petrol brushcutter in good light and visibility. During the winter season beware of slippery or wet areas, ice and snow (risk of slipping). Always ensure a safe footing. – never cut above waist height. – never stand on a ladder and run the petrol brushcutter. – n...

Page 6

6 never straighten or weld damaged cutting tools. – operate the petrol brushcutter with as little noise and contamination as possible. In particular check the correct setting of the carburetor. – clean the petrol brushcutter at regular intervals and check that all screws and nuts are well tightened....

Page 7

Technical data em2650uh, em2650lh model em2650uh em2650lh bike handle loop handle dimensions: length x width x height (without cutting blade) mm 1,765 x 620 x 474 1,765 x 330 x 264 mass (without plastic guard and cutting blade) kg 5.5 5.1 volume (fuel tank) l 0.6 volume (oil tank) l 0.08 engine disp...

Page 8

Technical data em2651uh, em2651lh model em2651uh em2651lh bike handle loop handle dimensions: length x width x height (without cutting blade) mm 1,765 x 620 x 474 1,765 x 330 x 264 mass (without plastic guard and cutting blade) kg 5.6 5.2 volume (fuel tank) l 0.6 volume (oil tank) l 0.08 engine disp...

Page 9

⑬ ⑭ ⑮ ④ ⑤ ⑰ ⑦ ⑨ ⑪ ⑩ ⑫ ⑯ em2650lh em2651lh em2650uh em2651uh 22 21 designation of parts gb designation of parts 1 fuel tank 2 rewind starter 3 air cleaner 4 i-o switch (on/off) 5 spark plug 6 exhaust muffler 7 clutch case 8 rear grip 9 hanger 10 handle 11 control lever 12 control cable 13 shaft 14 pr...

Page 10

10 caution: before doing any work on the petrol brushcutter, always stop the engine and pull the spark plug connector off the spark plug. Always wear protective gloves! Caution: start the petrol brushcutter only after having assembled it completely. For machines with bike handle models – loosen knob...

Page 11

11 to meet the applicable safety provisions, only the tool/ protector combinations as indicated in the table must be used. Be sure to use genuine makita cutter blades or nylon cutting head. – the cutter blade must be well polished, free of cracks or breakage. If the cutter blade hits against a stone...

Page 12

12 turn the machine upside down, and you can replace the cutter blade or nylon cutting head easily. – insert the hex wrench through the hole in the gear case and rotate the receiver washer (4) until it is locked with the hex wrench. – loosen the nut (1) (left-hand thread) with the socket wrench and ...

Page 13

1 inspection and refill of engine oil – perform the following procedure, with the engine cooled down. – set the engine level, remove oil cap (fig. 1), and check to see whether or not there is oil in the range between the upper limit and lower limit marks of the oil pipe (fig. 2). – top up with oil t...

Page 14

1 refueling handling of fuel it is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refueling must be performed in a sufficiently ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a...

Page 15

15 correct handling of machine attachment of shoulder strap – adjust the strap length so that the cutter blade will be kept parallel with the ground. For em2650uh, em2651uh note: be careful not to trap clothing, etc., in the buckle. Observe the applicable accident prevention regulations! Starting mo...

Page 16

16 3) primer pump continue to push the primer pump until fuel enters into the primer pump. (in general, fuel enters into the primer pump by 7 to 10 pushes.) if the primer pump is pushed excessively, an excess of gasoline returns to the fuel tank. Note: in case of excessive fuel intake, remove the sp...

Page 17

1 caution: the cutting tools mentioned below must only be resharpened by an authorized facility. Manual resharpening will result in imbalances of the cutting tool causing vibrations and damage to the equipment. – cutter blade an expert resharpening and balancing service is provided by authorized ser...

Page 18

1 cover latches press press 80 mm (3 - 1/8”) spool for left hand rotation spool 100 mm (3 - 15/16”) notches eyelets replacing the nylon cord – first, stop the engine. – press on the housing latches inward to lift off the cover, then remove the spool. – hook the center of new nylon cord into the notc...

Page 19

1 caution: before doing any work on the petrol brushcutter, always stop the engine and pull the plug cap off the spark plug (see “checking the spark plug”). Always wear protective gloves! To ensure a long service life and to avoid any damage to the equipment, the following servicing operations shoul...

Page 20

20 cleaning of air cleaner danger: inflammables strictly prohibited interval of cleaning and inspection: daily (every 10 operating hours) – turn the choke lever to the full close side, and keep the carburetor off from dust or dirt. – loosen air cleaner cover mounting bolt. – pull the cover and detac...

Page 21

21 cleaning of fuel filter warning: inflammables strictly prohibited interval of cleaning and inspection: monthly (every 50 operating hours) suction head in the fuel tank – the fuel filter (1) of the suction head is used to filter the fuel required by the carburetor. – a periodical visual inspection...

Page 22

22 warning: when draining the fuel, be sure to stop the engine and confirm that the engine cools down. Just after stopping the engine, it may still hot with possibility of burns, inflammability and fire. Attention: when the machine is kept out of operation for a long time, drain up all fuel from the...

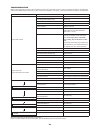

Page 23

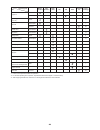

2 *1 perform initial replacement after 20h operation. *2 for the 200 operating hour inspection, request authorized service agent or a machine shop. *3 after emptying the fuel tank, continue to run the engine and drain fuel in the carburetor. Operating time item before operation after lubrication dai...

Page 24

2 troubleshooting before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact authorized service agent or local de...

Page 28

Makita corporation anjo, aichi, japan 884951a229 www.Makita.Com ala.