- DL manuals

- Oki

- Printer Accessories

- B6500 Series

- Service Manual

Oki B6500 Series Service Manual

Summary of B6500 Series

Page 1

Laser printer oki b6500 service manual 060810a.

Page 2: Cautions For Operation

I cautions for operation contents of this document may be subjected to modification without previous notice.Oki data will not assume any responsibilities for accidental or incidental damages resulting from technical or editorial errors or omission in this manual, issue of this manual, execution of d...

Page 3

Ii 1. About this manual this manual is a standard service manual containing information required for maintenance of this laser printer (standard specifications). 2. Cautions, warnings and notes maintenance operations requiring special cautions or additional information for procedures in this manual ...

Page 4

Iii 4. Safety to prevent possible accidents during maintenance activities, you must pay attention to the "warning" and "caution" information in this manual. Performing any dangerous operations, or procedures not included in this manual, should be avoided. Occasionally, it may be required to perform ...

Page 5

Iv 4.2 drive units when servicing gears or other drive units, be sure to turn them off and disconnect the power plug from the receptacle. Whenever possible, drive them manually. Never touch the gears or other moving parts while the printer is running. 4.3 high-temperature units when servicing high-t...

Page 6

V 4.4 laser beams • direct exposure to a laser beam can damage the eyes and cause blindness. • never open a cover that has a laser warning label attached. • before disassembling and reassembling this laser printer, be sure to turn the printer power off. • when servicing this laser printer while it i...

Page 7

Vi 4.5 warning/caution labels warning labels and caution labels are attached to this laser printer to prevent accidents. These labels should be clear and easy to read. Check the labels for any damage such as peeling or stains when servicing the printer. 4.5.1 caution label for high-temperature units...

Page 8

Vii 5. Installation 5.1 power source do not plug too many leads into a single socket. Use a dedicated electric outlet and confirm that the power is within specifications. Connect the single power cord to an electric outlet capable of supplying more power than the maximum power consumption of this la...

Page 9

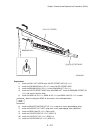

Viii 5.4 unpacking 5.4.1 unpacking laser printer the printer must be carried horizontally with two or more persons. Extreme care must be taken to avoid personal injuries. Unpack the carton and confirm that the part numbers of the laser printer and all components are correct. Ensure that all componen...

Page 10

Ix 5.4.3 unpacking option face up tray unpack the carton and confirm that the part numbers of the face up tray and all components are correct. Ensure that all components are undamaged. 5.4.4 unpacking option 550 paper feeder unpack the carton and confirm that the part numbers of the option 550 paper...

Page 11

X 5.5 installation procedures 5.5.1 installing laser printer for details, refer to the instruction manual supplied with the main unit. When holding up the later printer, be sure to grasp the handles with both hands. Grasping a part other than the handles result in fall or damage of the laser printer...

Page 12

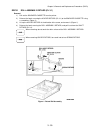

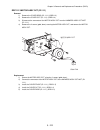

Xi 5.5.2 installing option duplex for details, refer to the instruction manual supplied with the main unit or chapter 3 rrp 21.1 option duplex. Before the installation, turn off the power and plug off the power cord. 1) unpack the option duplex, remove cushioning materials, and confirm that all atta...

Page 13

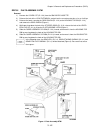

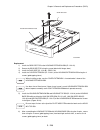

Xii 5.5.4 installing option 550 paper feeder for details, refer to the instruction manual supplied with the main unit or chapter 3 rrp 20.1 option 550 paper feeder. Before the installation, turn off the power, plug off the power cord, and remove the paper tray from the laser printer. 1) unpack the o...

Page 14

Xiii 6. Dismantlement 6.1 dismantlement procedures 6.1.1 dismantling laser printer and option units for details, refer to the instruction manual or chapter 3 removal and replacement procedures. The dismantlement process is performed by following installation procedures in reverse sequence. When hold...

Page 15

Xiv chapter 1 troubleshooting .............................................................................................1 - 1 chapter 2 diagnostics ................................................................................................... 1 - 1 chapter 3 removal and replacement procedure...

Page 16

Xv blank page.

Page 17

Chapter 1 troubleshooting chapter 1 troubleshooting contents chapter 1 troubleshooting ............................................................................................ 1 - 1 1. Progressing with the troubleshooting ........................................................................ 1...

Page 18

Chapter 1 troubleshooting chapter 1 troubleshooting contents fip1.37 motor assy exit ............................................................................................................. 1 - 58 fip1.38 clutch regi .................................................................................

Page 19

Chapter 1 troubleshooting chapter 1 troubleshooting contents fip4.3 low paper in tray/tray 3, 4 .................................................................................................. 1 - 100 fip4.4 no recognition of option 550 paper feeder ...................................................

Page 20

Chapter 1 troubleshooting chapter 1 troubleshooting contents blank page.

Page 21

1 – 1 chapter 1 troubleshooting the fip makes the assumption that the printer controller (pwba ess) is functioning normally. If the problem cannot be corrected by using the fip, replace the printer controller with a new one and check for proper operation. Any oem with unique specifications, or the d...

Page 22

1 – 2 chapter 1 troubleshooting 1.2 preparatory requirements be sure to check the following items before beginning the troubleshooting procedures: 1) voltage of the power supply is within specifications (measure the voltage at the electric outlet). 2) power cord is free from breakage, short-circuit,...

Page 23

1 – 3 chapter 1 troubleshooting 1.3 cautions for service operations 1) when servicing the printer, be sure to remove the power cord from the power outlet except when absolutely necessary. Unless specifically indicated, whenever the printer power is on, never touch any of the electrical components. T...

Page 24

1 – 4 chapter 1 troubleshooting 1.4 cautions for fip use 1) the fip makes the assumption that the printer controller (pwba ess) is functioning normally. If the problem cannot be corrected by using the fip, replace the printer controller with a new one and check for proper operation. If the trouble i...

Page 25

1 – 5 chapter 1 troubleshooting 14) "replacement" in the fip indicates replacement of parts which are considered to be the source of trouble. These parts are sometimes components of assemblies containing them, or of a higher- level assembly. In such an instant, the higher-level assembly must be repl...

Page 26

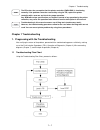

1 – 6 chapter 1 troubleshooting 2. Level 1 fip 2.1 level 1 fip the level 1 fip is the first step for problem resolution. The level 1 fip isolates the presence of various troubles including error codes. The level 2 fip provides a guide for proceeding with the troubleshooting. 2.2 flow of level 1 fip.

Page 27

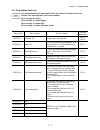

1 – 7 chapter 1 troubleshooting 2.3 error/status code list for information about the following fip items described in “fip to be referenced” column in the following table, refer to the following: fip1.1 through 45: printer fip2.1 through 11: option duplex fip3.1 through 15: option oct fip4.1 through...

Page 28

1 – 8 chapter 1 troubleshooting status 3-6 paper size mismatch - paper size detected by the paper size switch or set in the nvram does not match the paper length obtained from on time of regi sensor at feeding. Fip1.12 status 15-1 xero warning - remaining toner in ep cartridge became low. Fip1.16 st...

Page 29

1 – 9 chapter 1 troubleshooting js4 js3 js2 js1 js0 contents of jam error description fip to be referred 1 0 0 0 1 exit jam 1 paper jam/exit -when the paper was not fed to exit sensor within the specified time. - when exit sensor turned on in warming up. Fip1.8 1 1 0 0 1 exit jam 2 paper jam/exit - ...

Page 30

1 – 10 chapter 1 troubleshooting 3. Level 2 fip 3.1 level 2 fip the level 2 fip is the diagnostic procedure to sort various troubles in addition to the error codes. When troubleshooting, executing the steps given in the fip or checkout procedure allows you to quickly find the cause of a problem..

Page 31

1 – 11 chapter 1 troubleshooting 4. Error code fip 4.1 level 1 fip fip1.1 nvm error *1: though some kind of foreign noise would be possible cause, go to [fip1.42 electrical noise] and check, to make sure. Step check yes no possible causes: hvps/mcu (pl12.1.19) 1 does error occur when the power is tu...

Page 32

1 – 12 chapter 1 troubleshooting fip1.2 ros error step check yes no possible causes: ros assy (pl8.1.1) hvps/mcu (pl12.1.19) ep cartridge harness assy ros (pl8.1.2) lvps (pl12.1.5) 1 checking nvram for data setup value. Are the values of nv03 (resolution) and the value of nv04 (laser diode output) s...

Page 33

1 – 13 chapter 1 troubleshooting fip1.3 fuser error step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy fuser (pl8.1.17) harness assy lvps (pl12.1.1) 1 checking the thermistor for operation. Does error occur soon after the power is turned on? Er...

Page 34

1 – 14 chapter 1 troubleshooting fip1.4 fan error step check yes no possible causes: fan main (pl1.1.14) fan sub (pl8.1.5) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking fan main for rotation (1). Does fan main rotate, when the power is turned on? Go to step 2. Go to step 5. 2 checking fan sub for ...

Page 35

1 – 15 chapter 1 troubleshooting fip1.5 main motor error step check yes no possible causes: main motor (pl11.1.2) gear assy housing (pl11.1.3) gear assy plate (pl11.1.10) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking main motor installation are main motor, gear assy housing and gear assy plate ins...

Page 36

1 – 16 chapter 1 troubleshooting fip1.6 cover error step check yes no possible causes: interlock s/w 24v (pl8.1.11) interlock s/w 5v (pl8.1.12) interlock s/w rear (pl12.1.7) switch i/l assy (pl1.1.11) cover open (pl1.1.2) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking cover open and cover rear are ...

Page 37

1 – 17 chapter 1 troubleshooting fip1.7 fip paper jam/regi to fuser step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) clutch regi (pl5.1.23) btr assy (pl8.1.21) ep cartridge gear assy housing (pl11.1.3) harness assy fuser (pl8.1.17) lvps (pl12.1.5) 150 feeder assy (pl5.1....

Page 38

1 – 18 chapter 1 troubleshooting 10 checking harness assy fuser for continuity warning; start the operation after the fuser assy have cooled down. Disconnect p/j46 from lvps. Remove fuser assy. (rrp8.8) is there continuity between p/j46 and p/j4647? Go to step 11. Replace har- ness assy fuser. 11 ch...

Page 39

1 – 19 chapter 1 troubleshooting 20 checking glutch regi for function does clutch regi function appropriately? Check using chapter 2 diagnostic [regi. Roll clutch test]. Go to step 21. Go to fip1.38 clutch regi. 21 checking gear assy housing operation (1) remove ep cartridge. Install cover assy and ...

Page 40

1 – 20 chapter 1 troubleshooting fip1.8 paper jam/exit step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) harness assy fuser (pl8.1.17) motor assy exit (pl10.1.15) lvps (pl12.1.5) roll pinch exit (pl10.1.23) 500 exit assy (pl10.1.2) 150 paper cassette (pl2.1.50) 550 paper ...

Page 41

1 – 21 chapter 1 troubleshooting 11 checking exit sensor for operation (2). Remove ep cartridge. Is the voltage across p/j46-5(+) and p/j46-4(-) on lvps, 0vdc when actuator exit is pushed, and 3.3vdc when released? Go to step 14. Go to step 12. 12 checking the power to exit sensor. Is the voltage ac...

Page 42

1 – 22 chapter 1 troubleshooting fip1.9 paper jam/tray to regi step check yes no possible causes: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) chute assy fdr1 (pl5.1.3) hvps/mcu (pl12.1.19) lvps (pl12.1.5) chute assy fdr2 (pl7.1.21, pl20.2.2) c...

Page 43

1 – 23 chapter 1 troubleshooting 10 checking chute assy fdr1/2 (pl5.1.3, pl7.1.21) for operation does each gear and roller of chute assy fdr1/2 rotate smoothly? Turn each gear and roller with a finger to check. Go to step 11. Replace chute assy fdr1/2. 11 checking a paper feeding tray when running a...

Page 44

1 – 24 chapter 1 troubleshooting fip1.10 paper jam/misfeed step check yes no possible causes: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) lvps (pl12.1.5) hvps/mcu (pl12.1.19) clutch regi (pl5.1.23) chute assy fdr1 (pl5.1.3) gear assy housing (...

Page 45

1 – 25 chapter 1 troubleshooting 7 checking paper position remove ep cartridge. Does the front end of paper touch actuator b of sensor regi? Go to step 8. Go to fip1.28 sensor regi. 8 checking roll assy retard is roll assy retard clean and installed correctly? Check roll assy retard installed to eac...

Page 46

1 – 26 chapter 1 troubleshooting fip1.11 ep cartridge step check yes no possible causes: hvps/mcu (pl12.1.19) ep cartridge guide assy cru r (pl8.1.25) 1 checking ep cartridge (1) is the ep cartridge appropriate model? Remove the ep cartridge to check the model. Go to step 2. Replace ep car- tridge. ...

Page 47

1 – 27 chapter 1 troubleshooting fip1.12 paper size error step check yes no possible causes: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) 550 feeder assy (pl7.1.10) 550 paper cassette (pl4.1.50) 1 ...

Page 48

1 – 28 chapter 1 troubleshooting fip1.13 no tray/tray 1, 2 step check yes no possible causes: guide tray left (pl7.1.7) 150 paper cassette (pl2.1.50) hvps/mcu (pl12.1.19) 550 paper cassette (pl4.1.50) 1 does error occur with tray 3 or tray 4? Go to fip4.1 "no tray/tray 3.4". Go to step 2. 2 does err...

Page 49

1 – 29 chapter 1 troubleshooting fip1.14 no paper/tray 1, 2 step check yes no possible causes: sensor no paper (pl5.1.38, pl7.1.38) actuator no paper (pl5.1.6, pl7.1.14) hvps/mcu (pl12.1.19) lvps (pl12.1.5) plate assy btm (pl2.1.10, pl4.1.10) rack btm lock 550 (pl4.1.21) housing base 550(pl4.1.44) 1...

Page 50

1 – 30 chapter 1 troubleshooting fip1.15 low paper in tray/tray 2 step check yes no possible causes: sensor low paper (pl7.1.4) actuator low paper (pl7.1.5) plate assy btm (pl4.1.10) hvps/mcu (pl12.1.19) 550 paper cassette (pl4.1.50) 550 feeder assy (pl7.1.10) 1 checking the sensor for operation doe...

Page 51

1 – 31 chapter 1 troubleshooting fip1.16 drum life step check yes no possible causes: ep cartridge guide assy cru r (pl8.1.25) hvps/mcu (pl12.1.19) 1 checking ep cartridge does error still occur, after installing a new ep car- tridge? Go to step 2. End of work 2 checking guide assy cru r for continu...

Page 52

1 – 32 chapter 1 troubleshooting fip1.17 fuser life step check yes no possible causes: fuser assy (pl8.1.20) harness assy fuser (pl8.1.17) hvps/mcu (pl12.1.19) 1 checking fuser assy does error still occur, after installing a new fuser assy and sending reset fuser life warning command? Checks by send...

Page 53

1 – 33 chapter 1 troubleshooting fip1.18 no power step check yes no possible causes: power cord (pl12.1.23) lvps (pl12.1.5) hvps/mcu (pl12.1.19) operation panel (pl1.1.1) harness assy panel (pl1.1.10) interlock s/w 24v (pl8.1.11) interlock s/w 5v (pl8.1.12) interlock s/w rear (pl12.1.7) fan main (pl...

Page 54

1 – 34 chapter 1 troubleshooting 7 checking clutch regi (pl5.1.23) remove shield plate hvps (pl12.1.18). Disconnect p/j243. Remove ep cartridge. Does fan main rotate, when the power is turned on? Go to fip1.38 clutch regi. Go to step 8. 8 checking operation panel disconnect harness assy panel from p...

Page 55

1 – 35 chapter 1 troubleshooting 17 checking fan sub replace fan sub. (rrp8.2) remove ep cartridge. Does the fan sub rotate, when the power is turned on? End of work replace hvps/ mcu. (rrp12.10) step check yes no.

Page 56

1 – 36 chapter 1 troubleshooting fip1.19 lcd/led display error step check yes no possible causes: operation panel (pl1.1.1) harness assy panel (pl1.1.10) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking 3.3vdc power line is the voltage across the harness of operation panel, 3.3 vdc? Go to step 2. Go ...

Page 57

1 – 37 chapter 1 troubleshooting fip1.20 inoperative keypad step check yes no possible causes: operation panel (pl1.1.1) harness assy panel (pl1.1.10) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking 3.3 vdc power line is the voltage across the harness of operation panel, 3.3 vdc? Go to step 2. Go to...

Page 58

1 – 38 chapter 1 troubleshooting fip1.21 other printer error step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 run a test print. Is the printer able to test print? Check using chapter 2 diagnostic [test pattern mode menu]. Go to step 4. Go to step 2. 2 checking lvps (1) remov...

Page 59

1 – 39 chapter 1 troubleshooting fip1.22 face up tray error step check yes no possible causes: hvps/mcu (pl12.1.19) sensor face up open (pl10.1.25) gate fu (pl10.2.6) lever gate fu (pl10.2.17) 1 checking actuator for operation does actuator full stack in gate fu move smoothly, when moving lever gate...

Page 60

1 – 40 chapter 1 troubleshooting fip1.23 full stack error/500 paper exit step check yes no possible causes: sensor full stack (pl10.1.26) actuator full stack (pl10.1.10) hvps/mcu (pl12.1.19) 1 checking actuator full stack for operation does actuator full stack in paper feed out sec- tion move smooth...

Page 61

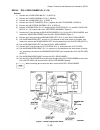

1 – 41 chapter 1 troubleshooting 4.2 level 2 fip fip1.24 lvps step check yes no possible causes: lvps (pl12.1.5) hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) 1 checking lvps (pl12.1.5) control power remove shield plate lvps. (rrp12.1) disconnect p/j41 from lvps. Turn the power on. Check the vol...

Page 62

1 – 42 chapter 1 troubleshooting fip1.25 main motor step check yes no possible causes: main motor (pl11.1.2) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking main motor remove ep cartridge. Close cover open (pl1.1.2). Does main motor rotate, when the power is turned on? C...

Page 63

1 – 43 chapter 1 troubleshooting fip1.26 ros assy step check yes no possible causes: ros assy (pl8.1.1) harness assy ros (pl8.1.2) interlock s/w 5v (pl8.1.12) harness assy lvps (pl12.1.1) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking the power to laser diode of ros assy remove cover top assy (pl1....

Page 64

1 – 44 chapter 1 troubleshooting 9 checking /rosmot on signal of scanner motor install ep cartridge. Close cover open (pl1.1.2). Is p/j13-3(+) and p/j13-2(-) on hvps/mcu, 0 v just after when the power is turned on, and 5vdc 10 sec- onds after stopping main motor? Go to step 11. Go to step 10. 10 che...

Page 65

1 – 45 chapter 1 troubleshooting fip1.27 fuser assy step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) interlock s/w 24v (pl8.1.11) harness assy fuser 100v/200v (pl8.1.17) harness assy ac100v/200v (pl12.1.8) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1 checking heater ci...

Page 66

1 – 46 chapter 1 troubleshooting 7 checking the resistance of thermistor of temperature sensor disconnect p/j46 from lvps. Is the resistance between p/j46-6 and p/j46-7 and p/ j46-1 and p/j46-2 about 480 k-ohm in the normal tem- perature (about 20 °c)? Go to step 8. Replace fuser assy. (rrp8.8) 8 ch...

Page 67

1 – 47 chapter 1 troubleshooting fip1.28 sensor regi step check yes no possible causes: sensor regi (pl5.1.30) actuator b (pl5.1.17) 150 feeder assy (pl5.1.1) harness assy tray1 (pl5.1.37) harness assy chute (pl12.1.17) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking actuator b for operation and sha...

Page 68

1 – 48 chapter 1 troubleshooting 6 checking harness assy tray1 for continuity remove sensor regi. (rrp5.7) disconnect p/j245. Is there continuity between p/j245-4 and p/j241-3? P/j245-5 and p/j241-2? P/j245-6 and p/j241-1? Go to step 8. Replace har- ness assy tray1. 7 checking hvps/mcu for continuit...

Page 69

1 – 49 chapter 1 troubleshooting fip1.29 sensor no paper step check yes no possible causes: sensor no paper (pl5.1.38, pl7.1.38) actuator no paper (pl5.1.6, pl7.1.14) 150 feeder assy (pl5.1.1) harness assy tray1 (pl5.1.37) harness assy tray2 (pl7.1.36) harness assy chute (pl12.1.17) hvps/mcu (pl12.1...

Page 70

1 – 50 chapter 1 troubleshooting 6 checking harness assy chute for continuity disconnect p/j24 from hvps/mcu. Disconnect p/j245 and p/j248. Is there continuity between j24-6 and j245-13? J24-7 and j245-12? J24-8 and j245-11? J24-1 and j248-5? J24-2 and j248-4? J24-3 and j248-3? Go to step 7. Replace...

Page 71

1 – 51 chapter 1 troubleshooting fip1.30 sensor low paper step check yes no possible causes: sensor low paper (pl7.1.4) actuator low paper (pl7.1.5) plate assy btm (pl4.1.10) harness assy low1 (pl7.1.2) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking actuator low paper for operation install paper ca...

Page 72

1 – 52 chapter 1 troubleshooting fip1.31 sensor toner step check yes no possible causes: sensor toner (pl5.1.46) sensor toner assy (pl5.1.45) harness assy toner1 (pl5.1.50) harness assy toner2 (pl12.1.28) ep cartridge hvps/mcu (pl12.1.19) 1 checking ep cartridge (1) does sufficient toner in ep cartr...

Page 73

1 – 53 chapter 1 troubleshooting fip1.32 interlock s/w 24v step check yes no possible causes: interlock s/w 24v (pl8.1.11) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w 24v disconnect p/j45 from lvps. Is p/j45-1 and p/j45-3 continuous, when interlock s/w 24v is pushed, and not when r...

Page 74

1 – 54 chapter 1 troubleshooting fip1.33 interlock s/w 5v, switch i/l assy step check yes no possible causes: interlock s/w 5v (pl8.1.12) switch i/l assy (pl1.1.11) harness assy ros (pl8.1.2) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w 5vl remove interl...

Page 75

1 – 55 chapter 1 troubleshooting fip1.34 interlock s/w rear step check yes no possible causes: interlock s/w rear (pl12.1.7) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w rear for continuity disconnect p/j44 from lvps. Is p/j44-1 and p/j44-3 continuous, when interlock s/w rear is pus...

Page 76

1 – 56 chapter 1 troubleshooting fip1.35 switch i/l assy (interlock s/w front r) step check yes no possible causes: switch i/l assy (pl1.1.11) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking switch i/l assy for continuity disconnect p/j411. Is p/j411-1 and p/j411-2 continuous, when switch i/ l assy ...

Page 77

1 – 57 chapter 1 troubleshooting fip1.36 pwba exit motor step check yes no possible causes: pwba exit motor (pl12.1.4) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking harness assy lvps for continuity disconnect p/j27, p/j10, p/j102 and p/j101 from harness assy lvps. Is t...

Page 78

1 – 58 chapter 1 troubleshooting fip1.37 motor assy exit step check yes no possible causes: motor assy exit (pl10.1.15) pwba exit motor (pl12.1.4) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking motor assy exit for operation. Not using diag tool- replace motor assy exit....

Page 79

1 – 59 chapter 1 troubleshooting fip1.38 clutch regi step check yes no possible causes: clutch regi (pl5.1.23) harness assy chute (pl12.1.17) harness assy tray1 (pl5.1.37) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy chute for continuity disconnect p/j24 from hvps/mcu. Is there conti...

Page 80

1 – 60 chapter 1 troubleshooting fip1.39 clutch assy ph step check yes no possible causes: clutch assy ph (pl5.1.21, pl7.1.20) harness assy tray1 (pl5.1.37) harness assy tray2 (pl7.1.36) harness assy chute (pl12.1.17) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy chute for continuity ...

Page 81

1 – 61 chapter 1 troubleshooting fip1.40 guide tray left step check yes no possible causes: guide tray left (pl7.1.7) harness assy lvps (pl12.1.1) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy lvps for continuity disconnect p/j18 from hvps/mcu. Disconnect p/j1821. Is each cable betwee...

Page 82

1 – 62 chapter 1 troubleshooting fip1.41 hvps/mcu step check yes no possible causes: hvps/mcu (pl12.1.19) guide assy cru r (pl8.1.25) ep cartridge harness assy ant (pl8.1.24) harness assy lvps (pl12.1.1) 1 checking the power by guide assy cru r is guide assy cru r installed appropriately? Does the c...

Page 83

1 – 63 chapter 1 troubleshooting fip1.42 electrical noise step check yes no possible causes: hvps/mcu (pl12.1.19) guide assy cru r (pl8.1.25) fuser assy (pl8.1.20) ep cartridge harness assy ant (pl8.1.24) harness assy ac100v/200v (pl12.1.8) harness assy lvps (pl12.1.1) option 550 paper feeder pwba f...

Page 84

1 – 64 chapter 1 troubleshooting 8 checking pwb ground remove shield plate lvps (pl12.1.3) and shield plate hvps (pl12.1.8). (rrp12.1, 12.9) is the ground normal? Are screws for ground of the following pwbs firmly tightened? All screws of hvps/mcu (pl12.1.19) all screws of lvps (pl12.1.5) when optio...

Page 85

1 – 65 chapter 1 troubleshooting fip1.43 motor assy exit step check yes no possible causes: motor assy exit (pl10.1.15) harness assy lvps (pl12.1.1) pwba exit motor (pl12.1.4) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking motor assy exit. Not using diag tool: replace motor assy exit (rrp10.5) is t...

Page 86

1 – 66 chapter 1 troubleshooting fip1.44 sensor face up open step check yes no possible causes: sensor face up open (pl10.1.25) gate fu (pl10.2.6) lever gate fu (pl10.2.17) harness assy exit snr (pl10.1.27) hvps/mcu (pl12.1.19) 1 checking gate fu for operation open cover assy rear 500. Move lever ga...

Page 87

1 – 67 chapter 1 troubleshooting fip1.45 sensor full stack step check yes no possible causes: sensor full stack (pl10.1.26) actuator full stack (pl10.1.10) harness assy exit snr (pl10.1.27) hvps/mcu (pl12.1.19) 1 checking actuator full stack open cover assy rear 500. Move actuator full stack with a ...

Page 88

1 – 68 chapter 1 troubleshooting blank page.

Page 89: Duplex Option

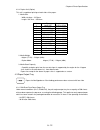

1 – 69 chapter 1 troubleshooting duplex option 4.3 error/status code list 4.4 table 1 status code error contents error description fip to be referred status 3-1 js0 status 3-1 to 3-5 indicates jam by combination of table 1-1. Status 3-2 js1 status 3-3 js2 status 3-4 js3 status 3-5 js4 status 17-3 du...

Page 90

1 – 70 chapter 1 troubleshooting 4.5 level 1 fip fip2.1 option duplex cover error step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) hsg lower dup (pl21.1.6) cover hsg dup (pl21.1.18) switch duplex (pl21.1.27) pwba duplex (pl21.1.32) 1 checking cover hsg dup open cover hsg dup. ...

Page 91

1 – 71 chapter 1 troubleshooting fip2.2 option duplex error step check yes no possible causes: hvps/mcu (pl12.1.19) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) 1 checking option duplex installation does error still occur, after removing option duplex once, reinstalling, and then turning the ...

Page 92

1 – 72 chapter 1 troubleshooting fip2.3 paper jam/exit to dup step check yes no possible causes: hvps/mcu (pl12.1.19) sensor dup (pl21.1.34) actuator dup (pl21.1.37) roll dup (pl21.1.17) roll pinch (pl21.1.4) motor duplex (pl21.1.29) 1 does error occur, when the power is turned on? Go to step 2. Go ...

Page 93

1 – 73 chapter 1 troubleshooting fip2.4 paper jam/dup to regi step check yes no possible causes: hvps/mcu (pl12.1.19) fdr1 as sub 150 a4 (pl5.1.2) sensor dup (pl21.1.34) actuator dup (pl21.1.37) roll dup (pl21.1.17) roll pinch (pl21.1.4) motor duplex (pl21.1.29) 1 checking option duplex installation...

Page 94

1 – 74 chapter 1 troubleshooting fip2.5 paper jam/duplex misfeed step check yes no possible causes: fdr1 as sub 150 a4 (pl5.1.2) hvps/mcu (pl12.1.19) roll dup (pl21.1.17) roll pinch (pl21.1.4) motor duplex (pl21.1.29) 1 checking option duplex installation remove option duplex, and then reinstall. Do...

Page 95

1 – 75 chapter 1 troubleshooting fip2.6 paper size error/duplex step check yes no 1 possible causes: hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) pwba feeder 550 (pl20.1.34) checking paper size is the paper size capable for duplex printing? Go to step 2. Replace the paper. 2 checking the paper siz...

Page 96

1 – 76 chapter 1 troubleshooting fip2.7 no recognition of option duplex step check yes no possible causes: hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) 1 checking option duplex detection signal (1) remove pwba duplex. (rrp21.5) remove harness ...

Page 97

1 – 77 chapter 1 troubleshooting 4.6 level 2 fip fip2.8 pwba duplex step check yes no possible causes: pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) 1 checking harness assy dup for continuity remove option duplex. Disconnect p/j50 from pwba dup...

Page 98

1 – 78 chapter 1 troubleshooting fip2.9 motor duplex step check yes no possible causes: motor duplex (pl21.1.29) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1 checking harness assy dup for continuity remove option duplex. Disc...

Page 99

1 – 79 chapter 1 troubleshooting fip2.10 sensor dup step check yes no possible causes: sensor dup (pl21.1.34) actuator dup (pl21.1.37) harness assy dup snr (pl21.1.35) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1 checking act...

Page 100

1 – 80 chapter 1 troubleshooting fip2.11 switch duplex step check yes no possible causes: switch duplex (pl21.1.27) harness assy lvps (pl12.1.1) harness assy dup cover (pl21.1.31) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking switch duplex for co...

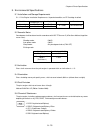

Page 101: Oct Option

1 – 81 chapter 1 troubleshooting oct option 4.7 error/status code list table 1-1 status code error contents error description fip to be referred status 3-1 js0 status 3-1 to 3-5 indicates jam by combina- tion of table 1-1. Status 3-2 js1 status 3-3 js2 status 3-4 js3 status 3-5 js4 status 16-5 full ...

Page 102

1 – 82 chapter 1 troubleshooting 4.8 level 1 fip fip3.1 option oct cover error step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) pwba oct (pl23.1.22) cover rear (pl23.1.4) cover oct (pl23.1.1) s/w rear cover (pl23.1.18) harness assy rear cover (pl23.1.29) 1 checking cover rear ...

Page 103

1 – 83 chapter 1 troubleshooting fip3.2 option oct error step check yes no possible causes: harness assy oct1 (pl12.1.26) hvps/mcu (pl12.1.19) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) 1 checking option oct installation remove option oct, reinstall and turn the power on. Does error still oc...

Page 104

1 – 84 chapter 1 troubleshooting fip3.3 paper jam/exit to oct step check yes no possible causes: hvps/mcu (pl12.1.19) sensor oct (pl23.1.30) actuator oct (pl23.1.31) roll oct lower (pl23.1.16) roll oct upper (pl23.1.36) roll pinch (pl23.1.34) motor assy oct (pl23.1.6) 1 does error occur, when the po...

Page 105

1 – 85 chapter 1 troubleshooting fip3.4 paper jam/oct step check yes no possible causes: hvps/mcu (pl12.1.19) sensor oct (pl23.1.30) actuator oct (pl23.1.31) roll oct lower (pl23.1.16) roll oct upper (pl23.1.36) roll pinch (pl23.1.34) motor assy oct (pl23.1.6) 1 does error occur, when the power is t...

Page 106

1 – 86 chapter 1 troubleshooting fip3.5 paper size error/oct step check yes no possible causes: hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) pwba feeder 550 (pl20.1.34) 1 checking the paper size setup does the size of paper in use match the size set by guide assy end? Go to step 2. Change the pape...

Page 107

1 – 87 chapter 1 troubleshooting fip3.6 full stack error/oct step check yes no possible causes: sensor full stack (0n pwba oct) hvps/mcu (pl12.1.19) pwba oct (pl23.1.22) actuator full stack (pl23.1.15) 1 checking actuator full stack for operation does actuator full stack move smoothly, when you move...

Page 108

1 – 88 chapter 1 troubleshooting fip3.7 no recognition of option oct step check yes no possible causes: hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) 1 checking option oct detection signal (1) disconnect p/j70 on pwba oct. Is the voltage across...

Page 109

1 – 89 chapter 1 troubleshooting 4.9 level 2 fip fip3.8 pwba oct step check yes no possible causes: pwba oct (pl23.1.22) harness assy oct1 (pl12.1.26) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy oct2 for continuity remove option oct. (rrp23.1) disconnec...

Page 110

1 – 90 chapter 1 troubleshooting fip3.9 motor assy oct step check yes no possible causes: motor assy oct (pl23.1.6) pwba oct (pl23.1.22) harness assy oct mot (pl23.1.46) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking harness assy oct mot for continuity re...

Page 111

1 – 91 chapter 1 troubleshooting fip3.10 motor assy offset step check yes no possible causes: motor assy offset (pl23.1.20) motor assy oct (pl23.1.6) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking motor assy offset not using diag tool...

Page 112

1 – 92 chapter 1 troubleshooting fip3.11 solenoid assy gate step check yes no possible causes: solenoid assy gate (pl23.1.27) p wba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking solenoid assy gate not using diag tool: replace solenoid ass...

Page 113

1 – 93 chapter 1 troubleshooting fip3.12 s/w rear cover step check yes no possible causes: s/w rear cover (pl23.1.18) harness assy rear cover (pl23.1.29) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy oct1 (pl12.1.26) 1 checking s/w rear cover fo...

Page 114

1 – 94 chapter 1 troubleshooting fip3.13 sensor oct step check yes no possible causes: sensor oct (pl23.1.30) actuator oct (pl23.1.31) harness assy oct snr (pl23.1.26) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking actuator oct for op...

Page 115

1 – 95 chapter 1 troubleshooting fip3.14 sensor full stack (on pwba oct) step check yes no possible causes: sensor full stack (mounted on pwba oct) actuator full stack (pl23.1.15) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking actuato...

Page 116

1 – 96 chapter 1 troubleshooting fip3.15 sensor offset (on pwba oct) step check yes no possible causes: sensor offset (mounted on pwba oct) chute offset assy (pl23.1.35) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking the actuator of c...

Page 117: 550 Paper Feeder Option

1 – 97 chapter 1 troubleshooting 550 paper feeder option 4.10 error/status code list status code error contents error description fip to be referred status 1-5 cassette fail - paper size is not specified. Fip4.1 status 15-3 near end of paper in tray 4 - remaining paper in tray 4 became low. Fip4.3 s...

Page 118

1 – 98 chapter 1 troubleshooting 4.11 level 1 fip fip4.1 no tray/tray 3, 4 step check yes no possible causes: hvps/mcu (pl12.1.19) opt assy size (pl20.1.8) option 550 paper feeder 550 paper cassette (pl20.3.50) 1 does error still occur, after removing and reinstalling the 550 paper cassette of optio...

Page 119

1 – 99 chapter 1 troubleshooting fip4.2 no paper/tray 3, 4 step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) sensor no paper (pl20.2.33) actuator no paper (pl20.2.6) option 550 paper feeder 550 paper cassette (pl20.3.50) plate assy btm (pl20.3.10) rack btm lock 550 (pl20.3.21) ...

Page 120

1 – 100 chapter 1 troubleshooting fip4.3 low paper in tray/tray 3, 4 step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) sensor low paper (pl20.1.30) actuator low paper (pl20.1.31) plate assy btm (pl20.3.10) option 550 paper feeder 550 paper cassette (pl20.3.50) 1 checking the se...

Page 121

1 – 101 chapter 1 troubleshooting fip4.4 no recognition of option 550 paper feeder the description below is on the assumption that option 550 paper feeder's are installed to tray 3 and tray 4. Step check yes no possible causes: lvps (pl12.1.5) hvps/mcu (pl12.1.19) pwba feeder 550 (pl20.1.34) harness...

Page 122

1 – 102 chapter 1 troubleshooting fip4.5 inappropriate option 550 paper feeder step check yes no possible causes: pwba feeder 550 (pl20.1.34) 1 checking option 550 paper feeder is option 550 paper feeder for correct jigen2 installed? Go to fip4.6, 4.7 pwba feeder 550. Replace option 550 paper feeder...

Page 123

1 – 103 chapter 1 troubleshooting 4.12 level 2 fip fip4.6 pwba feeder 550 it is stated here as option 550 paper feeder is set as tray 3. When it is set as tray 4, refer to the statement in fip2.21 pwba feeder 550 for the circuit usage condition. Step check yes no possible causes: harness assy fdr1 (...

Page 124

1 – 104 chapter 1 troubleshooting fip4.7 pwba feeder 550 it is stated here as option 550 paper feeder is set as tray 4. When it is set as tray 3, refer to the statement in fip2.20 pwba feeder 550 for the circuit usage condition. Step check yes no possible causes: pwba feeder 550 (pl20.1.34) harness ...

Page 125

1 – 105 chapter 1 troubleshooting fip4.8 sensor no paper step check yes no possible causes: sensor no paper (pl20.2.33) actuator no paper (pl20.2.6) harness assy clsnr1 (pl20.2.31) harness assy clsnr2 (pl20.1.36) 550 paper cassette (pl20.3.50) option 550 paper feeder pwba feeder 550 (pl20.1.34) hvps...

Page 126

1 – 106 chapter 1 troubleshooting 6 checking hvps/mcu for continuity disconnect p/j11 and p/j20 from hvps/mcu. Is there continuity between p11-16 and p20-5? Go to step 7. Replace hvps/ mcu. (rrp12.10) 7 checking after replacing sensor no paper (3) replace sensor no paper. (rrp20.16) does the problem...

Page 127

1 – 107 chapter 1 troubleshooting fip4.9 sensor low paper step check yes no possible causes: sensor low paper (pl20.1.30) actuator low paper (pl20.1.31) harness low paper (pl20.1.33) harness assy fdr2 (pl20.1.5) option 550 paper feeder 550 paper cassette pwba feeder 550 (pl20.1.34) plate assy btm (p...

Page 128

1 – 108 chapter 1 troubleshooting fip4.10 opt assy size step check yes no possible causes: opt assy size (pl20.1.18) harness assy size fdr1 (pl20.1.19) harness assy size fdr2 (pl20.1.35) option 550 paper feeder 550 paper cassette pwba feeder 550 (pl20.1.34) hvps/mcu (pl12.1.19) 1 checking harness as...

Page 129

1 – 109 chapter 1 troubleshooting fip4.11 clutch assy ph step check yes no possible causes: clutch assy ph (pl20.2.21) option 550 paper feeder 550 paper cassette (pl20.3.50) pwba feeder 550 (pl20.1.34) harness assy clsnr1 (pl20.2.31) harness assy clsnr2 (pl20.1.36) harness assy fdr2 (pl20.1.5) hvps/...

Page 130

1 – 110 chapter 1 troubleshooting fip4.12 clutch pr-regi step check yes no possible causes: clutch pr-regi (pl20.2.22) option 550 paper feeder 550 paper cassette (pl20.3.50) pwba feeder 550 (pl20.1.34) harness assy clsnr1 (pl20.2.31) harness assy clsnr2 (pl20.1.36) harness assy fdr2 (pl20.1.5) hvps/...

Page 131

1 – 111 chapter 1 troubleshooting 5. Image quality defects 5.1 entry chart for image quality troubleshooting it is assumed that the printer controller is functioning normally. By running a test print with the engine only, if the trouble is on the printer controller side or the engine side, diagnosis...

Page 132

1 – 112 chapter 1 troubleshooting when an image quality problem occurs, run a test print to clearly define the defect. Next, troubleshoot using the image quality fip table accordingly. If the problem cannot be resolved using the image quality fip, check again with the image quality fip. Next, replac...

Page 133

1 – 113 chapter 1 troubleshooting 5.2 image quality fip fip- 1.P1 faint print before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the density of the im...

Page 134

1 – 114 chapter 1 troubleshooting 7 checking the image development process operate test print, and turn off the power of the printer while printing. Remove the ep cartridge with care, and check the toner image formed on the drum, right before the tran- scribe part (btr). Is the image on the drum com...

Page 135

1 – 115 chapter 1 troubleshooting fip- 1.P2 blank print (no print) before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the entire paper is printed pure...

Page 136

1 – 116 chapter 1 troubleshooting 5 checking btr assy remove btr assy. (rrp8.10) check if any stains and/or wear on btr assy. Are there any stains and/or wear on btr? Go to step 6. Replace btr assy. (rrp8.10) 6 checking the image development process operate test print, and turn off the power of the ...

Page 137

1 – 117 chapter 1 troubleshooting fip- 1.P3 solid black before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the entire paper is printed jet-black. Ess ...

Page 138

1 – 118 chapter 1 troubleshooting fip- 1.P4 vertical blank lines (white stripes in paper transport direction) before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on pri...

Page 139

1 – 119 chapter 1 troubleshooting 6 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? ...

Page 140

1 – 120 chapter 1 troubleshooting fip- 1.P5 horizontal band cross out before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are some extremely fain...

Page 141

1 – 121 chapter 1 troubleshooting 6 checking the image transcribe process check the toner image formed on the drum, right after the transcribe part (btr). Is the toner image on the drum completely transcribed on the paper? Go to step 7. Go to fip1.41 hvps/mcu. 7 checking drive assy and gear assy hou...

Page 142

1 – 122 chapter 1 troubleshooting fip- 1.P6 vertical stripes before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are vertical black stripes along...

Page 143

1 – 123 chapter 1 troubleshooting fip- 1.P7 horizontal stripes before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are horizontal black stripes a...

Page 144

1 – 124 chapter 1 troubleshooting 6 checking drum ground check the plate earth of guide assy cru r. Are there any stains or deformation on the plate earth? Go to step 7. Restore or clean the plate earth, or replace guide assy cru r. (rrp8.13) 7 checking btr assy remove btr assy. (rrp8.10) check if a...

Page 145

1 – 125 chapter 1 troubleshooting fip- 1.P8 partial deletion before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are some extremely faint or comp...

Page 146

1 – 126 chapter 1 troubleshooting fip- 1.P9 spots before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are toner spots all over the paper disorder...

Page 147

1 – 127 chapter 1 troubleshooting fip- 1.P10 ghosting before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the ghost appears on the paper. The ghost may...

Page 148

1 – 128 chapter 1 troubleshooting 6 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? ...

Page 149

1 – 129 chapter 1 troubleshooting fip- 1.P11 background (fog) before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there is toner stain all over or a pa...

Page 150

1 – 130 chapter 1 troubleshooting fip- 1.P12 skew before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the printed image is not paralleled with both sid...

Page 151

1 – 131 chapter 1 troubleshooting fip- 1.P13 paper damage before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the paper comes out from the printer crum...

Page 152

1 – 132 chapter 1 troubleshooting 6 checking ep cartridge install a new ep cartridge. Carry out a test printing. Is the paper still damaged? Go to step [ess and possible causes]. End of work step check yes no.

Page 153

1 – 133 chapter 1 troubleshooting fip- 1.P14 unfused image before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the printed image is not fixed on the pa...

Page 154

1 – 134 chapter 1 troubleshooting 4 checking fuser assy turn the gear of the heater roller with a finger. Check the contact condition of heat roll and pressure roll when rotating. Do heat roll and pressure roll contact evenly? Go to step [ess and possible causes]. Replace fuser assy. (rrp8.8) step c...

Page 155

1 – 135 chapter 1 troubleshooting 6. Judgment of print consistency it is stated here how to judge simply the main print consistency printing with the standard paper (letter size). Keep the paper packaged in the operating environment for 12 hours, and then use the paper just after it has been unpacke...

Page 156

1 – 136 chapter 1 troubleshooting 6.2 side edge registration measure the amount of shift from the ideal point 108.0 mm away from the left end at center of front and- back of the paper. Reference: less than +/-2.5 mm.

Page 157

1 – 137 chapter 1 troubleshooting 6.3 skew measurement of the inclined paper feeding measure the vertical distance of two points 190 mm away each other on the top horizontal line. Reference: less than +/-1.2 mm.

Page 158

1 – 138 chapter 1 troubleshooting 6.4 perpendicularity measurement of the perpendicularity for suppressing inclines of ros and opc. Check the perpendicular line to the horizontal line to measure the horizontal distance at the point 114.5 mm away vertically from center of top horizontal line. Referen...

Page 159

1 – 139 chapter 1 troubleshooting 6.5 parallelism the parallelism is difference of feeding speed between left and right sides of the paper. Measure the difference of length between two 234 mm long vertical lines 190 mm away each other. Reference: less than +/-1.2 mm.

Page 160

1 – 140 chapter 1 troubleshooting blank page.

Page 161

1 – 141 chapter 1 troubleshooting 7. Preventive maintenance when visiting the customer for a service call, perform the maintenance work to prevent any additional problems. Procedure for preventive maintenance 1) check how the customer is using the machine. 2) write down the cumulative print count. U...

Page 162

1 – 142 chapter 1 troubleshooting blank page.

Page 163

Chapter 2 printer diagnostics chapter 2 diagnostics contents chapter 2 diagnostics ....................................................................................................2 - 1 1. Diagnostics ...................................................................................................

Page 164

Chapter 2 printer diagnostics chapter 2 diagnostics contents 11. Print summary.........................................................................................................2 - 16.

Page 165

2 - 1 chapter 2 diagnostics chapter 2 diagnostics 1. Diagnostics 1.1 overview diagnostics enable you to run various test on printer components. You can run motors forward and reverse and at different speeds, the actuation and de-actuation of sensors or switches, energize and de-energize solenoids, e...

Page 166

2 - 2 chapter 2 diagnostics 2. Entering diagnostics to enter diagnostics, perform the following: 1. Switch the printer power off. 2. Press and hold both the “menu” and “ x” buttons on the operator panel 3. Switch the printer power on. 4. Continue to hold the “menu” and “ x” buttons until “initializi...

Page 167

2 - 3 chapter 2 diagnostics 3. Main menu 3.1 navigating through the diagnostic menus four buttons are used to navigate through the diagnostic menus and sub-menus, ( w, x, s, t). From the initial menu selection “output tests” (see 3.2), pressing the “ t” button moves down the menu to “input tests” th...

Page 168

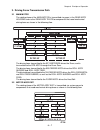

2 - 4 chapter 2 diagnostics 4. Output tests with “output tests” displayed on the lcd, pressing the “ x” button will enter the “output tests” menu and display the first menu selection. The complete output tests menu is displayed in the figure below. None of the menu selections in the output tests hav...

Page 169

2 - 5 chapter 2 diagnostics 5. Input tests input tests are used to test cover interlocks, paper path sensors, paper size switches, etc., fuser tem- perature and rom checksum. With “input tests” displayed on the lcd, pressing the “ x” button will enter the “input tests” menu and display the first men...

Page 170

2 - 6 chapter 2 diagnostics 6. Alignment the image registration alignment allows each tray to be adjusted independently. Alignment routines are used to set “x” and “y” values for the paper trays. With “alignment” displayed on the lcd, pressing the “ x” button will enter the “alignment” menu and disp...

Page 171

2 - 7 chapter 2 diagnostics 7. Maintenance info maintenance info indicates the current count of the selected menu, the serial number of the printer, or resets the error log. With “maintenance info” displayed on the lcd, pressing the “ x” button will enter the maintenance info menu and display the fi...

Page 172

2 - 8 chapter 2 diagnostics using the “ t “or “s“ buttons scroll through the possible choices that can be entered in each digit loca- tion. The choices are: ! " # $ % & ' ( ) * + , -. / 0 1 2 3 4 5 6 7 8 9 : ; ? @ a b c d e f g h i j k l m n o p q r s t u v w x y z [ \ ] ^ _ ` a b c d e f g h i j k ...

Page 173

2 - 9 chapter 2 diagnostics 8. Operator panel operator panel menu enables the running of tests on operator panel. These tests include the leds, the lcd, and the keys (buttons). With “operator panel” displayed on the lcd, pressing the “ x” button will enter the operator panel menu and display the fir...

Page 174

2 - 10 chapter 2 diagnostics 8.3 key test the key test enables the testing of eight buttons on the operator panel. With key test displayed, press- ing the “ x” button will enter the key test. Opn: this indicates that a button is open. As you press each button, the corresponding location will change ...

Page 175

2 - 11 chapter 2 diagnostics 9. Test print the test print menu enables the running of five test prints, selecting the tray for the source paper, and selecting duplex or simplex. With “test print” displayed on the lcd, pressing the “ x” button will enter the test print menu and dis- play the first me...

Page 176

2 - 12 chapter 2 diagnostics 9.3 engine test page with “engine test page” displayed on the lcd, pressing the “ x” button will print the engine test page. 9.4 grid page with “grid page” displayed on the lcd, pressing the “ x” button will print the grid page..

Page 177

2 - 13 chapter 2 diagnostics 9.5 blank page with “blank page” displayed on the lcd, pressing the “ x” button will print a blank page. 9.6 black page with “black page” displayed on the lcd, pressing the “ x” button will print a page with a large black square..

Page 178

2 - 14 chapter 2 diagnostics 9.7 test page with “test page” displayed on the lcd, pressing the “ x” button will print the test page..

Page 179

2 - 15 chapter 2 diagnostics 10. Flash summary with ”flash summary” displayed on the lcd, pressing the “ x” button will print the flash summary (shown below). When the print completes, the display will remain at the flash summary menu. This is an example of the flash summary report.

Page 180

2 - 16 chapter 2 diagnostics 11. Print summary with “print summary” displayed on the lcd, pressing the “ x” button will print the print summary (shown below). When the print completes, the display will remain at the print summary menu. This is an example of the print summary report.

Page 181

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents rrp1. Covers..............................................................................................................3 - 4 rrp1.1 cover rear (pl 1.1) ...................................

Page 182

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents rrp5.5 clutch assembly ph (pl 5.1.20)..................................................................................... 3 - 82 rrp5.6 sensor no paper (pl 5.1.38)..........................

Page 183

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents rrp9. Electrical ..........................................................................................................3 - 147 rrp9.1 shield plate lvps (pl 9.1) .........................

Page 184

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents rrp12.3 cover left plate (pl12.1)........................................................................................... 3 - 216 rrp12.4 opt assy size (pl12.1)...........................

Page 185

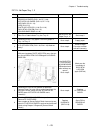

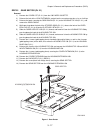

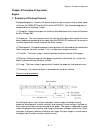

3 - 1 chapter 3 removal and replacement procedures (rrps) removal and replacement procedures 1. Removal and replacement procedures (rrps) removal and replacement procedures are described for the 9 major sections of the parts listings, plus the 3 optional components. Rrp 1 covers rrp 2 150 paper cass...

Page 186

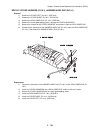

3 - 2 chapter 3 removal and replacement procedures (rrps) 1.2 prohibited matter do not remove the frame components shown in the figure below. Removing any of these components will make the laser printer go out of alignment. If the frame components are removed or their screws loosened by mistake, be ...

Page 187

3 - 3 chapter 3 removal and replacement procedures (rrps) 1.4 description of procedures "rrp x,y "aaaaa" at the top of procedures represent the part name aaaaa are to be removed and replaced. "(pl x.Y.Z)" following the parts name in procedures represent that the parts are those of the plate (pl) "...

Page 188

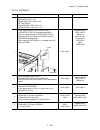

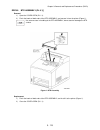

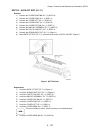

3 - 4 chapter 3 removal and replacement procedures (rrps) rrp1. Covers rrp1.1 cover rear (pl 1.1) removal 1) remove the 500 cover rear (pl 7.1) (rrp7.9) 2) remove the 5 screws (silver with flange, 8mm x 2, gold tapping, 8mm x 3) securing the cover rear to the printer (figure 1). 3) open the cover re...

Page 189

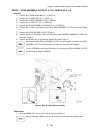

3 - 5 chapter 3 removal and replacement procedures (rrps) rrp1.2 cover right (pl 1.1) removal 1) loosen the screw securing the cover right to the rear side of the printer (figure 1). 2) shift the cover right in the direction of the arrow to release the 4 hooks, two below, one in front and one on rea...

Page 190

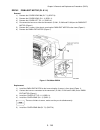

3 - 6 chapter 3 removal and replacement procedures (rrps) rrp1.3 cover left (pl 1.1) removal 1) remove the 500 cover rear (pl 7.1.21) (rrp7.9). 2) remove the cover rear (pl 1.1) (rrp1.1). 3) shift the cover left in the direction of the arrow to release the 4 hooks, two below and two on rear, securin...

Page 191

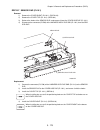

3 - 7 chapter 3 removal and replacement procedures (rrps) rrp1.4 cover top (pl 1.1), operation panel (pl 1.1) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9). 2) remove the cover rear (pl 1.1) (rrp1.1). 3) remove the cover right (pl 1.1) (rrp1.2). 4) remove the cover left (pl 1.1) (rrp1.3). 5...

Page 192

3 - 8 chapter 3 removal and replacement procedures (rrps) replacement 1) install the operation panel to the cover top, and secure it using the 2 hooks. 2) connect p/j1 of the operation panel. 3) secure the harnesses with the 2 clamps on the operation panel. 4) install the cover top to the printer, a...

Page 193

3 - 9 chapter 3 removal and replacement procedures (rrps) rrp1.5 cover front (pl 1.1) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9) 2) remove the cover rear (pl 1.1) (rrp1.1) 3) remove the cover left (pl 1.1) (rrp1.3) 4) remove the cover right (pl 1.1) (rrp1.2) 5) remove the cover exit 500 ...

Page 194

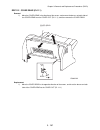

3 - 10 chapter 3 removal and replacement procedures (rrps) rrp2. 150 paper cassette.

Page 195

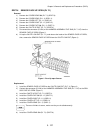

3 - 11 chapter 3 removal and replacement procedures (rrps) rrp2.1 roll assembly retard (pl 2.1.2) removal 1) pull out the 150 paper cassette from the printer. 2) release the hooks securing the holder retard (pl 2.1) to the 150 paper cassette using a screwdriver (figure 1). 3) lift up the holder reta...

Page 196

3 - 12 chapter 3 removal and replacement procedures (rrps) replacement 1) install the roll assembly retard to the shaft retard (pl 2.1), and secure the roll assembly retard with the hook. When installing, do not touch the roller surface of the roll assembly retard. Be sure to install the hook of the...

Page 197

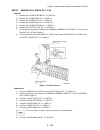

3 - 13 chapter 3 removal and replacement procedures (rrps) rrp2.2 rack size (pl 2.1) removal 1) remove the cover cst (pl 2.1) from the 150 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing the gear pinio...

Page 198

3 - 14 chapter 3 removal and replacement procedures (rrps) 7) remove the 2 screws (gold tapping, 8mm) from both right and left side, as well as the 6 screws (gold tapping, 8mm) on the back, that secure the housing top 150 (pl 2.1) to the housing base 150 (pl 2.1) (figure 2). 8) release the 4 hooks o...

Page 199

3 - 15 chapter 3 removal and replacement procedures (rrps) figure 3. Size rack replacement 1) put the hook of the tip of the rack size (pl 2.1) into the groove of the housing extension 150, and turn it in the opposite direction of the arrow. 2) align the end of the rack size with the triangle mark p...

Page 200

3 - 16 chapter 3 removal and replacement procedures (rrps) after tightening the screws, move the guide assembly end 150 back and forth, and make sure that the link sw sizes operate smoothly. 6) while pressing down the hook of the housing top 150, install the guide assembly sd r150 (pl 2.1) to the ho...

Page 201

3 - 17 chapter 3 removal and replacement procedures (rrps) rrp2.3 gear sector (pl 2.1) removal 1) remove the cover cst (pl 2.1) from the 150 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing the gear pin...

Page 202

3 - 18 chapter 3 removal and replacement procedures (rrps) replacement 1) install the gear sector to the housing extension 150 (pl 2.1) (figure 1). 2) secure the gear sector using the screw (black with flange, 8mm). 3) install the rack size 150 (pl 2.1) (rrp2.2). 4) install the cover extension (pl 2...

Page 203

3 - 19 chapter 3 removal and replacement procedures (rrps) 10) with completely opened guide assembly sd l150 (pl 2.1) and guide assembly sd r150 (pl 2.1), install the gear pinion (pl 2.1) to the housing top 150. When installing the gear pinion, make sure the guide assembly sd r150 and guide assembly...

Page 204

3 - 20 chapter 3 removal and replacement procedures (rrps) rrp2.4 guide assembly end 150 (pl 2.1) removal 1) remove the cover cst (pl 2.1) from the 150 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing t...

Page 205

3 - 21 chapter 3 removal and replacement procedures (rrps) 11) remove the rack size (pl 2.1) (rrp2.2). 12) remove the gear sector (pl 2.1) (rrp2.3). 13) release the hooks securing the guide assy end 150 to the housing extension 150. Be careful handling the hooks of the guide assy end150. They are fr...

Page 206

3 - 22 chapter 3 removal and replacement procedures (rrps) when installing the gear pinion, make sure the guide assembly sd r150 and guide assembly sd l150 are completely opened. If not, the side register may be mis- aligned. 11) install the cover cst (pl 2.1) to the 150 paper cassette..

Page 207

3 - 23 chapter 3 removal and replacement procedures (rrps) rrp2.5 plate assembly btm (pl 2.1) removal 1) remove the cover cst (pl 2.1) from the 150 paper cassette (figure 1). 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go (figure 1). 3) release th...

Page 208

3 - 24 chapter 3 removal and replacement procedures (rrps) in the following steps, the gear pb l (pl 2.1), gear btm dmp oneway (pl 2.1) and gear btm lock oneway (pl 2.1) will be detached. Be careful not to lose these gears (figure 2). 7) release the hook of the gear pb r (pl 2.1), and remove it from...

Page 209

3 - 25 chapter 3 removal and replacement procedures (rrps) when installing the plate assembly btm, be sure to put 2 spring btm up 150s (pl 2.1) into the bosses on the back of the plate assembly btm (note 1) (figure 2). Be sure to put 2 claws on the top of the plate assembly btm under the hooks on th...

Page 210

3 - 26 chapter 3 removal and replacement procedures (rrps) rrp2.6 gear lever lock (pl 2.1.25), lever btm lock (pl 2.1) removal 1) remove the cover cst (pl 2.1) from the 150 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) while p...

Page 211

3 - 27 chapter 3 removal and replacement procedures (rrps) replacement when installing, be sure to lift up the plate assembly btm. If the plate assembly btm is inclined, a paper skew or jam may occur. Check after the installation is completed. 1) put the spring stopper gear (pl 2.1) into the stopper...

Page 212

3 - 28 chapter 3 removal and replacement procedures (rrps) rrp2.7 handle extension 150 (pl 2.1) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) remove the 2 screws on the back side of the handle extension 150 (pl 2.1) (figure 1). 3) release the 5 hooks at the upper side and...

Page 213

3 - 29 chapter 3 removal and replacement procedures (rrps) rrp3. 550 paper cassette.

Page 214

3 - 30 chapter 3 removal and replacement procedures (rrps) rrp3.1 roll assembly retard (pl 3.1) removal 1) pull out the 550 paper cassette from the printer. 2) release the hooks securing the holder retard (pl 3.1) to the 550 paper cassette using a screwdriver (figure 1). 3) lift up the holder retard...

Page 215

3 - 31 chapter 3 removal and replacement procedures (rrps) it is also possible to remove the roll assembly retard by pushing the holder retard down (figure 2). Figure 2. Holder retard replacement 1) install the roll assembly retard to the shaft retard (pl 12.3), and secure the roll assembly retard w...

Page 216

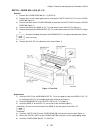

3 - 32 chapter 3 removal and replacement procedures (rrps) rrp3.2 rack size (pl 4.1.40) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing the gear p...

Page 217

3 - 33 chapter 3 removal and replacement procedures (rrps) 7) remove the 2 screws (gold tapping, 8mm) from both right and left sides, as well as the 6 screws (gold tapping, 8mm) on the back (figure 2), that secure the housing top 550 to the housing base 550 (pl 3.1). 8) release the 4 hooks of the ho...

Page 218

3 - 34 chapter 3 removal and replacement procedures (rrps) figure 3. Size rack replacement 1) put the hook on top of the rack size into the groove of the housing extension 550 (pl 3.1), and turn it in the opposite direction of the arrow. 2) align the end of the rack size with the triangle mark print...

Page 219

3 - 35 chapter 3 removal and replacement procedures (rrps) figure 4. Link size switches after tightening the screws, move the guide assembly end 550 back and forth, and make sure that the link sw sizes operate smoothly. 6) insert the link lever of the guide indicator 1 (pl 3.1) into the hole of the ...

Page 220

3 - 36 chapter 3 removal and replacement procedures (rrps) rrp3.3 gear sector (pl 3.1) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing the gear pi...

Page 221

3 - 37 chapter 3 removal and replacement procedures (rrps) replacement 1) install the gear sector to the housing extension 550 (pl 3.1). 2) secure the gear sector using the screw (black with flange, 8mm). 3) install the rack size (pl 3.1) (rrp3.2). 4) install the cover extension (pl 3.1) to the hous...

Page 222

3 - 38 chapter 3 removal and replacement procedures (rrps) 8) while pressing down the hook of the housing top 550, install the guide assembly sd r550 (pl 12.3) to the housing top 550. After installing, make sure that the 3 claws of the guide assembly sd r550 sit cor- rectly in the grooves of the hou...

Page 223

3 - 39 chapter 3 removal and replacement procedures (rrps) rrp3.4 guide assembly end 550 (pl 3.1) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing ...

Page 224

3 - 40 chapter 3 removal and replacement procedures (rrps) 8) release the 4 hooks of the housing top 550, and remove the housing top 550 together with the housing extension 550 (pl 3.1) from the housing base 550. 9) remove the 4 screws (gold tapping, 6mm) securing the cover extension (pl 3.1) to the...

Page 225

3 - 41 chapter 3 removal and replacement procedures (rrps) 5) install the housing extension 550 and housing top 550 (pl 12.3) to the housing base 550 while pushing the link sw size1-550 (pl 3.1), link sw size2-550 (pl 3.1) and link sw size3-550 (pl 3.1) of the housing base 550 outward (rrp3.2). Be s...

Page 226

3 - 42 chapter 3 removal and replacement procedures (rrps) rrp3.5 plate assembly btm removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing the gear pini...

Page 227

3 - 43 chapter 3 removal and replacement procedures (rrps) 7) release the hook of the gear pb r (pl 3.1), and remove the gear pb r from the shaft pb (pl 3.1) (figure 2). It is hard to remove gear pb r. When removing it, be careful not to break it (figure 2). 8) disengage the gear pb l from the plate...

Page 228

3 - 44 chapter 3 removal and replacement procedures (rrps) replacement 1) insert the shaft pb (pl 3.1) into the plate assembly btm, and insert the gear btm dmp oneway, gear pb l and gear btm lock oneway to the shaft pb. 2) while disengaging the gear pb l, install the assembled plate assembly btm to ...

Page 229

3 - 45 chapter 3 removal and replacement procedures (rrps) after installing, make sure that the 3 claws of the guide assembly sd r550 sit cor- rectly in the grooves of the housing top 550 (note 3) (figure 1). 6) while pressing down the hook of the housing top 550, install the guide assembly sd l550 ...

Page 230

3 - 46 chapter 3 removal and replacement procedures (rrps) rrp3.6 gear lever lock (pl 3.1.26), lever btm lock (pl 3.1) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) while ...

Page 231

3 - 47 chapter 3 removal and replacement procedures (rrps) when removing the stopper gear, be careful not to lose the spring stopper gear. Replacement when installing, be sure to lift up the plate assembly btm. If the plate assembly btm is inclined, a paper skew or jam may occur. Check after the ins...

Page 232

3 - 48 chapter 3 removal and replacement procedures (rrps) be sure to install the hook of the gear pb r into the groove of the shaft pb. 8) install the plate gear lock 550 (pl 3.1) to the housing base 550, and secure it with the hook. 9) secure the plate gear lock 550 using the screw (gold tapping, ...

Page 233

3 - 49 chapter 3 removal and replacement procedures (rrps) rrp3.7 handle extension 550 (pl 3.1) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) remove the 2 screws on the back side of the handle extension 550. 3) release the 5 hooks at the upper side and 2 hooks at the lowe...

Page 234

3 - 50 chapter 3 removal and replacement procedures (rrps) rrp3.8 guide indicator 3 (pl 3.1.36) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) remove the handle extension 550 (pl 3.1) (rrp3.7). When removing the handle extension 550, the low indicator (pl 3.1) and low ind ...

Page 235

3 - 51 chapter 3 removal and replacement procedures (rrps) rrp3.9 guide indicator 2 (pl 3.1.35) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) release the lock of the lock extension, and pull out the cassette extension as far as it will go. 3) release the hooks securing th...

Page 236

3 - 52 chapter 3 removal and replacement procedures (rrps) figure 2. Lever btm lock 11) remove the guide indicator 1 (pl 3.1) from the hooks of the housing top 550, and remove the support guide ind together with the guide indicator 1 and guide indica- tor 2 from the housing top 550. 12) release the ...

Page 237

3 - 53 chapter 3 removal and replacement procedures (rrps) 3) install the support guide ind together with the guide indicator 1 and guide indica- tor 2 to the housing top 550 (pl 12.3), and secure the guide indicator 1 using the 2 hooks of the housing top 550. 4) slide the support guide ind (pl 3.1)...

Page 238

3 - 54 chapter 3 removal and replacement procedures (rrps) when installing the gear pinion, make sure the guide assembly sd r550 and guide assembly sd l550 are completely opened. If not, the side register may be mis- aligned. 12) install the cover cst (pl 12.3) to the 550 paper cassette. After assem...

Page 239

3 - 55 chapter 3 removal and replacement procedures (rrps) rrp3.10 low ind front (pl 3.1) removal 1) remove the cover cst (pl 12.3) from the 550 paper cassette. 2) remove the handle extension 550 (pl 3.1) (rrp3.7). 3) turn the low indicator (pl 3.1) by 90 degrees, and remove it together with the low...

Page 240

3 - 56 chapter 3 removal and replacement procedures (rrps) rrp4. 150 paper feeder.

Page 241

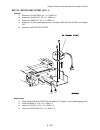

3 - 57 chapter 3 removal and replacement procedures (rrps) rrp4.1 150 feeder assembly (pl 4.1) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9). 2) remove the fuser assembly (pl 6.1) (rrp6.8). 3) remove the cover rear (pl 1.1) (rrp1.1). 4) remove the chute transfer (pl 6.1) together with the b...

Page 242

3 - 58 chapter 3 removal and replacement procedures (rrps) replacement 1) while lifting up the 150 feeder assembly in the direction of the arrow (a), and install it to the printer. Then, put the bosses at right and left of the 150 feeder assembly into the holes of the printer. 2) secure the 150 feed...

Page 243

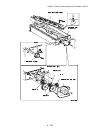

3 - 59 chapter 3 removal and replacement procedures (rrps) rrp4.2 roll assembly nudger (pl 4.1), roll assembly feed (pl 4.1) removal 1) open the cover open (pl 1.1). 2) release the hook securing the roll assembly nudger, and pull the roll assembly nudger out from the shaft nudger (pl 4.1) (figure 1)...

Page 244

3 - 60 chapter 3 removal and replacement procedures (rrps) rrp4.3 clutch oneway nudger (pl 4.1) removal 1) open the cover open (pl 1.1). 2) remove the roll assembly feed (pl 4.1) (rrp4.2). When removing, do not touch the roller surface of the roll assembly feed. 3) pull out the clutch oneway feed (p...

Page 245

3 - 61 chapter 3 removal and replacement procedures (rrps) rrp4.4 gear nudger (pl 4.1) removal 1) open the cover open (pl 1.1). 2) while pressing down the boss of the holder left (pl 4.1) at the back of the 150 feeder assembly, shift the holder left in the direction of the arrow to remove the 3 hook...

Page 246

3 - 62 chapter 3 removal and replacement procedures (rrps) replacement 1) install the gear nudger to the shaft nudger (pl 4.1), and secure the gear nudger with the hook. When installing, do not touch the roller surface of the roll assembly nudger and gear nudger. Be sure to install the hook of the g...

Page 247

3 - 63 chapter 3 removal and replacement procedures (rrps) rrp4.5 roll regi rubber (pl 4.1.12) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9). 2) remove the fuser assembly (pl 6.1) (rrp6.8). 3) remove the cover rear (pl 1.1) (rrp1.1) 4) remove the chute transfer (pl 6.1) together with the bt...

Page 248

3 - 64 chapter 3 removal and replacement procedures (rrps) replacement 1) shift the roll regi rubber in the opposite direction of the arrow, and install it to the 150 feeder assembly. When installing, do not touch the roller surface of the roll regi rubber. Install the roll regi rubber so that its d...

Page 249

3 - 65 chapter 3 removal and replacement procedures (rrps) rrp4.6 clutch assembly ph (pl 4.1.21), clutch regi (pl 4.1) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9). 2) remove the fuser assembly (pl 6.1) (rrp6.8). 3) remove the cover rear (pl 1.1) (rrp1.1). 4) remove the chute transfer (pl ...

Page 250

3 - 66 chapter 3 removal and replacement procedures (rrps) when installing, make sure that the notch of the clutch assembly ph is combined with the boss of the chute regi. The harness of the clutch asy ph should be routed around the portion of the chute regi as shown (figure 1). 4) connect the conne...

Page 251

3 - 67 chapter 3 removal and replacement procedures (rrps) rrp4.7 sensor regi (pl 4.1.30) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9). 2) remove the cover rear (pl 1.1) (rrp1.1). 3) release the hooks securing the cover sensor (pl 4.1), and remove the cover sensor from the chute assembly r...

Page 252

3 - 68 chapter 3 removal and replacement procedures (rrps) rrp4.8 sensor no paper (pl 4.1.38) removal 1) open the cover open (pl 1.1). 2) remove the cover rear 500 (pl 7.1) (rrp7.9). 3) remove the fuser assembly (pl 6.1) (rrp6.8). 4) lift up the 150 feeder assembly a little, insert a screwdriver thr...

Page 253

3 - 69 chapter 3 removal and replacement procedures (rrps) 3) put the wires of the harness assembly tray 1 into the notch of the holder no paper sensor as shown (figure 1). 4) insert a screwdriver through the space left by the fuser assembly, and install the holder no paper sensor to the 150 feeder ...

Page 254

3 - 70 chapter 3 removal and replacement procedures (rrps) rrp4.9 sensor toner (pl 4.1.46) removal 1) open the cover open (pl 1.1). 2) disconnect the connector (p/j220) of the sensor toner from the harness assembly toner 1 (pl 4.1) (figure 1). 3) release the holdings of the harness of the sensor ton...

Page 255

3 - 71 chapter 3 removal and replacement procedures (rrps) rrp4.10 actuator no paper (pl 4.1) removal 1) remove the cover rear 500 (pl 7.1) (rrp7.9). 2) remove the fuser assembly (pl 6.1) (rrp6.8). 3) place the printer down on its left side. Be careful not to scratch the cover, and do not drop the p...

Page 256