- DL manuals

- Oki

- Printer Accessories

- B6500 Series

- Troubleshooting Manual

Oki B6500 Series Troubleshooting Manual

Summary of B6500 Series

Page 1

B6500 troubleshooting manual 032107a.

Page 2

Chapter 1 troubleshooting chapter 1 troubleshooting contents chapter 1 troubleshooting............................................................................................ 1 - 1 1. Progressing with the troubleshooting ........................................................................ 1 ...

Page 3

Chapter 1 troubleshooting chapter 1 troubleshooting contents fip1.37 motor assy exit ............................................................................................................. 1 - 58 fip1.38 clutch regi .................................................................................

Page 4

Chapter 1 troubleshooting chapter 1 troubleshooting contents fip4.3 low paper in tray/tray 3, 4 .................................................................................................. 1 - 100 fip4.4 no recognition of option 550 paper feeder ...................................................

Page 5: Chapter 1 Troubleshooting

1 – 1 chapter 1 troubleshooting the fip makes the assumption that the printer controller (pwba ess) is functioning normally. If the problem cannot be corrected by using the fip, replace the printer controller with a new one and check for proper operation. Any oem with unique specifications, or the d...

Page 6

1 – 2 chapter 1 troubleshooting 1.2 preparatory requirements be sure to check the following items before beginning the troubleshooting procedures: 1) voltage of the power supply is within specifications (measure the voltage at the electric outlet). 2) power cord is free from breakage, short-circuit,...

Page 7

1 – 3 chapter 1 troubleshooting 1.3 cautions for service operations 1) when servicing the printer, be sure to remove the power cord from the power outlet except when absolutely necessary. Unless specifically indicated, whenever the printer power is on, never touch any of the electrical components. T...

Page 8

1 – 4 chapter 1 troubleshooting 1.4 cautions for fip use 1) the fip makes the assumption that the printer controller (pwba ess) is functioning normally. If the problem cannot be corrected by using the fip, replace the printer controller with a new one and check for proper operation. If the trouble i...

Page 9

1 – 5 chapter 1 troubleshooting 14) "replacement" in the fip indicates replacement of parts which are considered to be the source of trouble. These parts are sometimes components of assemblies containing them, or of a higher- level assembly. In such an instant, the higher-level assembly must be repl...

Page 10: 2. Level 1 Fip

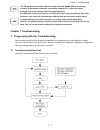

1 – 6 chapter 1 troubleshooting 2. Level 1 fip 2.1 level 1 fip the level 1 fip is the first step for problem resolution. The level 1 fip isolates the presence of various troubles including error codes. The level 2 fip provides a guide for proceeding with the troubleshooting. 2.2 flow of level 1 fip.

Page 11

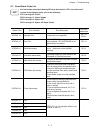

1 – 7 chapter 1 troubleshooting 2.3 error/status code list for information about the following fip items described in “fip to be referenced” column in the following table, refer to the following: fip1.1 through 45: printer fip2.1 through 11: option duplex fip3.1 through 15: option oct fip4.1 through...

Page 12

1 – 8 chapter 1 troubleshooting status 3-6 paper size mismatch - paper size detected by the paper size switch or set in the nvram does not match the paper length obtained from on time of regi sensor at feeding. Fip1.12 status 15-1 xero warning - remaining toner in ep cartridge became low. Fip1.16 st...

Page 13

1 – 9 chapter 1 troubleshooting js4 js3 js2 js1 js0 contents of jam error description fip to be referred 1 0 0 0 1 exit jam 1 paper jam/exit -when the paper was not fed to exit sensor within the specified time. - when exit sensor turned on in warming up. Fip1.8 1 1 0 0 1 exit jam 2 paper jam/exit - ...

Page 14: 3. Level 2 Fip

1 – 10 chapter 1 troubleshooting 3. Level 2 fip 3.1 level 2 fip the level 2 fip is the diagnostic procedure to sort various troubles in addition to the error codes. When troubleshooting, executing the steps given in the fip or checkout procedure allows you to quickly find the cause of a problem..

Page 15: 4. Error Code Fip

1 – 11 chapter 1 troubleshooting 4. Error code fip 4.1 level 1 fip fip1.1 nvm error *1: though some kind of foreign noise would be possible cause, go to [fip1.42 electrical noise] and check, to make sure. Step check yes no possible causes: hvps/mcu (pl12.1.19) 1 does error occur when the power is tu...

Page 16

1 – 12 chapter 1 troubleshooting fip1.2 ros error step check yes no possible causes: ros assy (pl8.1.1) hvps/mcu (pl12.1.19) ep cartridge harness assy ros (pl8.1.2) lvps (pl12.1.5) 1 checking nvram for data setup value. Are the values of nv03 (resolution) and the value of nv04 (laser diode output) s...

Page 17

1 – 13 chapter 1 troubleshooting fip1.3 fuser error step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy fuser (pl8.1.17) harness assy lvps (pl12.1.1) 1 checking the thermistor for operation. Does error occur soon after the power is turned on? Er...

Page 18

1 – 14 chapter 1 troubleshooting fip1.4 fan error step check yes no possible causes: fan main (pl1.1.14) fan sub (pl8.1.5) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking fan main for rotation (1). Does fan main rotate, when the power is turned on? Go to step 2. Go to step 5. 2 checking fan sub for ...

Page 19

1 – 15 chapter 1 troubleshooting fip1.5 main motor error step check yes no possible causes: main motor (pl11.1.2) gear assy housing (pl11.1.3) gear assy plate (pl11.1.10) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking main motor installation are main motor, gear assy housing and gear assy plate ins...

Page 20

1 – 16 chapter 1 troubleshooting fip1.6 cover error step check yes no possible causes: interlock s/w 24v (pl8.1.11) interlock s/w 5v (pl8.1.12) interlock s/w rear (pl12.1.7) switch i/l assy (pl1.1.11) cover open (pl1.1.2) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking cover open and cover rear are ...

Page 21

1 – 17 chapter 1 troubleshooting fip1.7 fip paper jam/regi to fuser step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) clutch regi (pl5.1.23) btr assy (pl8.1.21) ep cartridge gear assy housing (pl11.1.3) harness assy fuser (pl8.1.17) lvps (pl12.1.5) 150 feeder assy (pl5.1....

Page 22

1 – 18 chapter 1 troubleshooting 10 checking harness assy fuser for continuity warning; start the operation after the fuser assy have cooled down. Disconnect p/j46 from lvps. Remove fuser assy. (rrp8.8) is there continuity between p/j46 and p/j4647? Go to step 11. Replace har- ness assy fuser. 11 ch...

Page 23

1 – 19 chapter 1 troubleshooting 20 checking glutch regi for function does clutch regi function appropriately? Check using chapter 2 diagnostic [regi. Roll clutch test]. Go to step 21. Go to fip1.38 clutch regi. 21 checking gear assy housing operation (1) remove ep cartridge. Install cover assy and ...

Page 24

1 – 20 chapter 1 troubleshooting fip1.8 paper jam/exit step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) harness assy fuser (pl8.1.17) motor assy exit (pl10.1.15) lvps (pl12.1.5) roll pinch exit (pl10.1.23) 500 exit assy (pl10.1.2) 150 paper cassette (pl2.1.50) 550 paper ...

Page 25

1 – 21 chapter 1 troubleshooting 11 checking exit sensor for operation (2). Remove ep cartridge. Is the voltage across p/j46-5(+) and p/j46-4(-) on lvps, 0vdc when actuator exit is pushed, and 3.3vdc when released? Go to step 14. Go to step 12. 12 checking the power to exit sensor. Is the voltage ac...

Page 26

1 – 22 chapter 1 troubleshooting fip1.9 paper jam/tray to regi step check yes no possible causes: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) chute assy fdr1 (pl5.1.3) hvps/mcu (pl12.1.19) lvps (pl12.1.5) chute assy fdr2 (pl7.1.21, pl20.2.2) c...

Page 27

1 – 23 chapter 1 troubleshooting 10 checking chute assy fdr1/2 (pl5.1.3, pl7.1.21) for operation does each gear and roller of chute assy fdr1/2 rotate smoothly? Turn each gear and roller with a finger to check. Go to step 11. Replace chute assy fdr1/2. 11 checking a paper feeding tray when running a...

Page 28

1 – 24 chapter 1 troubleshooting fip1.10 paper jam/misfeed step check yes no possible causes: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) lvps (pl12.1.5) hvps/mcu (pl12.1.19) clutch regi (pl5.1.23) chute assy fdr1 (pl5.1.3) gear assy housing (...

Page 29

1 – 25 chapter 1 troubleshooting 7 checking paper position remove ep cartridge. Does the front end of paper touch actuator b of sensor regi? Go to step 8. Go to fip1.28 sensor regi. 8 checking roll assy retard is roll assy retard clean and installed correctly? Check roll assy retard installed to eac...

Page 30

1 – 26 chapter 1 troubleshooting fip1.11 ep cartridge step check yes no possible causes: hvps/mcu (pl12.1.19) ep cartridge guide assy cru r (pl8.1.25) 1 checking ep cartridge (1) is the ep cartridge appropriate model? Remove the ep cartridge to check the model. Go to step 2. Replace ep car- tridge. ...

Page 31

1 – 27 chapter 1 troubleshooting fip1.12 paper size error step check yes no possible causes: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) 550 feeder assy (pl7.1.10) 550 paper cassette (pl4.1.50) 1 ...

Page 32

1 – 28 chapter 1 troubleshooting fip1.13 no tray/tray 1, 2 step check yes no possible causes: guide tray left (pl7.1.7) 150 paper cassette (pl2.1.50) hvps/mcu (pl12.1.19) 550 paper cassette (pl4.1.50) 1 does error occur with tray 3 or tray 4? Go to fip4.1 "no tray/tray 3.4". Go to step 2. 2 does err...

Page 33

1 – 29 chapter 1 troubleshooting fip1.14 no paper/tray 1, 2 step check yes no possible causes: sensor no paper (pl5.1.38, pl7.1.38) actuator no paper (pl5.1.6, pl7.1.14) hvps/mcu (pl12.1.19) lvps (pl12.1.5) plate assy btm (pl2.1.10, pl4.1.10) rack btm lock 550 (pl4.1.21) housing base 550(pl4.1.44) 1...

Page 34

1 – 30 chapter 1 troubleshooting fip1.15 low paper in tray/tray 2 step check yes no possible causes: sensor low paper (pl7.1.4) actuator low paper (pl7.1.5) plate assy btm (pl4.1.10) hvps/mcu (pl12.1.19) 550 paper cassette (pl4.1.50) 550 feeder assy (pl7.1.10) 1 checking the sensor for operation doe...

Page 35

1 – 31 chapter 1 troubleshooting fip1.16 drum life step check yes no possible causes: ep cartridge guide assy cru r (pl8.1.25) hvps/mcu (pl12.1.19) 1 checking ep cartridge does error still occur, after installing a new ep car- tridge? Go to step 2. End of work 2 checking guide assy cru r for continu...

Page 36

1 – 32 chapter 1 troubleshooting fip1.17 fuser life step check yes no possible causes: fuser assy (pl8.1.20) harness assy fuser (pl8.1.17) hvps/mcu (pl12.1.19) 1 checking fuser assy does error still occur, after installing a new fuser assy and sending reset fuser life warning command? Checks by send...

Page 37

1 – 33 chapter 1 troubleshooting fip1.18 no power step check yes no possible causes: power cord (pl12.1.23) lvps (pl12.1.5) hvps/mcu (pl12.1.19) operation panel (pl1.1.1) harness assy panel (pl1.1.10) interlock s/w 24v (pl8.1.11) interlock s/w 5v (pl8.1.12) interlock s/w rear (pl12.1.7) fan main (pl...

Page 38

1 – 34 chapter 1 troubleshooting 7 checking clutch regi (pl5.1.23) remove shield plate hvps (pl12.1.18). Disconnect p/j243. Remove ep cartridge. Does fan main rotate, when the power is turned on? Go to fip1.38 clutch regi. Go to step 8. 8 checking operation panel disconnect harness assy panel from p...

Page 39

1 – 35 chapter 1 troubleshooting 17 checking fan sub replace fan sub. (rrp8.2) remove ep cartridge. Does the fan sub rotate, when the power is turned on? End of work replace hvps/ mcu. (rrp12.10) step check yes no.

Page 40

1 – 36 chapter 1 troubleshooting fip1.19 lcd/led display error step check yes no possible causes: operation panel (pl1.1.1) harness assy panel (pl1.1.10) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking 3.3vdc power line is the voltage across the harness of operation panel, 3.3 vdc? Go to step 2. Go ...

Page 41

1 – 37 chapter 1 troubleshooting fip1.20 inoperative keypad step check yes no possible causes: operation panel (pl1.1.1) harness assy panel (pl1.1.10) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking 3.3 vdc power line is the voltage across the harness of operation panel, 3.3 vdc? Go to step 2. Go to...

Page 42

1 – 38 chapter 1 troubleshooting fip1.21 other printer error step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 run a test print. Is the printer able to test print? Check using chapter 2 diagnostic [test pattern mode menu]. Go to step 4. Go to step 2. 2 checking lvps (1) remov...

Page 43

1 – 39 chapter 1 troubleshooting fip1.22 face up tray error step check yes no possible causes: hvps/mcu (pl12.1.19) sensor face up open (pl10.1.25) gate fu (pl10.2.6) lever gate fu (pl10.2.17) 1 checking actuator for operation does actuator full stack in gate fu move smoothly, when moving lever gate...

Page 44

1 – 40 chapter 1 troubleshooting fip1.23 full stack error/500 paper exit step check yes no possible causes: sensor full stack (pl10.1.26) actuator full stack (pl10.1.10) hvps/mcu (pl12.1.19) 1 checking actuator full stack for operation does actuator full stack in paper feed out sec- tion move smooth...

Page 45

1 – 41 chapter 1 troubleshooting 4.2 level 2 fip fip1.24 lvps step check yes no possible causes: lvps (pl12.1.5) hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) 1 checking lvps (pl12.1.5) control power remove shield plate lvps. (rrp12.1) disconnect p/j41 from lvps. Turn the power on. Check the vol...

Page 46

1 – 42 chapter 1 troubleshooting fip1.25 main motor step check yes no possible causes: main motor (pl11.1.2) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking main motor remove ep cartridge. Close cover open (pl1.1.2). Does main motor rotate, when the power is turned on? C...

Page 47

1 – 43 chapter 1 troubleshooting fip1.26 ros assy step check yes no possible causes: ros assy (pl8.1.1) harness assy ros (pl8.1.2) interlock s/w 5v (pl8.1.12) harness assy lvps (pl12.1.1) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking the power to laser diode of ros assy remove cover top assy (pl1....

Page 48

1 – 44 chapter 1 troubleshooting 9 checking /rosmot on signal of scanner motor install ep cartridge. Close cover open (pl1.1.2). Is p/j13-3(+) and p/j13-2(-) on hvps/mcu, 0 v just after when the power is turned on, and 5vdc 10 sec- onds after stopping main motor? Go to step 11. Go to step 10. 10 che...

Page 49

1 – 45 chapter 1 troubleshooting fip1.27 fuser assy step check yes no possible causes: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) interlock s/w 24v (pl8.1.11) harness assy fuser 100v/200v (pl8.1.17) harness assy ac100v/200v (pl12.1.8) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1 checking heater ci...

Page 50

1 – 46 chapter 1 troubleshooting 7 checking the resistance of thermistor of temperature sensor disconnect p/j46 from lvps. Is the resistance between p/j46-6 and p/j46-7 and p/ j46-1 and p/j46-2 about 480 k-ohm in the normal tem- perature (about 20 °c)? Go to step 8. Replace fuser assy. (rrp8.8) 8 ch...

Page 51

1 – 47 chapter 1 troubleshooting fip1.28 sensor regi step check yes no possible causes: sensor regi (pl5.1.30) actuator b (pl5.1.17) 150 feeder assy (pl5.1.1) harness assy tray1 (pl5.1.37) harness assy chute (pl12.1.17) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking actuator b for operation and sha...

Page 52

1 – 48 chapter 1 troubleshooting 6 checking harness assy tray1 for continuity remove sensor regi. (rrp5.7) disconnect p/j245. Is there continuity between p/j245-4 and p/j241-3? P/j245-5 and p/j241-2? P/j245-6 and p/j241-1? Go to step 8. Replace har- ness assy tray1. 7 checking hvps/mcu for continuit...

Page 53

1 – 49 chapter 1 troubleshooting fip1.29 sensor no paper step check yes no possible causes: sensor no paper (pl5.1.38, pl7.1.38) actuator no paper (pl5.1.6, pl7.1.14) 150 feeder assy (pl5.1.1) harness assy tray1 (pl5.1.37) harness assy tray2 (pl7.1.36) harness assy chute (pl12.1.17) hvps/mcu (pl12.1...

Page 54

1 – 50 chapter 1 troubleshooting 6 checking harness assy chute for continuity disconnect p/j24 from hvps/mcu. Disconnect p/j245 and p/j248. Is there continuity between j24-6 and j245-13? J24-7 and j245-12? J24-8 and j245-11? J24-1 and j248-5? J24-2 and j248-4? J24-3 and j248-3? Go to step 7. Replace...

Page 55

1 – 51 chapter 1 troubleshooting fip1.30 sensor low paper step check yes no possible causes: sensor low paper (pl7.1.4) actuator low paper (pl7.1.5) plate assy btm (pl4.1.10) harness assy low1 (pl7.1.2) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking actuator low paper for operation install paper ca...

Page 56

1 – 52 chapter 1 troubleshooting fip1.31 sensor toner step check yes no possible causes: sensor toner (pl5.1.46) sensor toner assy (pl5.1.45) harness assy toner1 (pl5.1.50) harness assy toner2 (pl12.1.28) ep cartridge hvps/mcu (pl12.1.19) 1 checking ep cartridge (1) does sufficient toner in ep cartr...

Page 57

1 – 53 chapter 1 troubleshooting fip1.32 interlock s/w 24v step check yes no possible causes: interlock s/w 24v (pl8.1.11) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w 24v disconnect p/j45 from lvps. Is p/j45-1 and p/j45-3 continuous, when interlock s/w 24v is pushed, and not when r...

Page 58

1 – 54 chapter 1 troubleshooting fip1.33 interlock s/w 5v, switch i/l assy step check yes no possible causes: interlock s/w 5v (pl8.1.12) switch i/l assy (pl1.1.11) harness assy ros (pl8.1.2) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w 5vl remove interl...

Page 59

1 – 55 chapter 1 troubleshooting fip1.34 interlock s/w rear step check yes no possible causes: interlock s/w rear (pl12.1.7) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w rear for continuity disconnect p/j44 from lvps. Is p/j44-1 and p/j44-3 continuous, when interlock s/w rear is pus...

Page 60

1 – 56 chapter 1 troubleshooting fip1.35 switch i/l assy (interlock s/w front r) step check yes no possible causes: switch i/l assy (pl1.1.11) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking switch i/l assy for continuity disconnect p/j411. Is p/j411-1 and p/j411-2 continuous, when switch i/ l assy ...

Page 61

1 – 57 chapter 1 troubleshooting fip1.36 pwba exit motor step check yes no possible causes: pwba exit motor (pl12.1.4) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking harness assy lvps for continuity disconnect p/j27, p/j10, p/j102 and p/j101 from harness assy lvps. Is t...

Page 62

1 – 58 chapter 1 troubleshooting fip1.37 motor assy exit step check yes no possible causes: motor assy exit (pl10.1.15) pwba exit motor (pl12.1.4) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking motor assy exit for operation. Not using diag tool- replace motor assy exit....

Page 63

1 – 59 chapter 1 troubleshooting fip1.38 clutch regi step check yes no possible causes: clutch regi (pl5.1.23) harness assy chute (pl12.1.17) harness assy tray1 (pl5.1.37) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy chute for continuity disconnect p/j24 from hvps/mcu. Is there conti...

Page 64

1 – 60 chapter 1 troubleshooting fip1.39 clutch assy ph step check yes no possible causes: clutch assy ph (pl5.1.21, pl7.1.20) harness assy tray1 (pl5.1.37) harness assy tray2 (pl7.1.36) harness assy chute (pl12.1.17) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy chute for continuity ...

Page 65

1 – 61 chapter 1 troubleshooting fip1.40 guide tray left step check yes no possible causes: guide tray left (pl7.1.7) harness assy lvps (pl12.1.1) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy lvps for continuity disconnect p/j18 from hvps/mcu. Disconnect p/j1821. Is each cable betwee...

Page 66

1 – 62 chapter 1 troubleshooting fip1.41 hvps/mcu step check yes no possible causes: hvps/mcu (pl12.1.19) guide assy cru r (pl8.1.25) ep cartridge harness assy ant (pl8.1.24) harness assy lvps (pl12.1.1) 1 checking the power by guide assy cru r is guide assy cru r installed appropriately? Does the c...

Page 67

1 – 63 chapter 1 troubleshooting fip1.42 electrical noise step check yes no possible causes: hvps/mcu (pl12.1.19) guide assy cru r (pl8.1.25) fuser assy (pl8.1.20) ep cartridge harness assy ant (pl8.1.24) harness assy ac100v/200v (pl12.1.8) harness assy lvps (pl12.1.1) option 550 paper feeder pwba f...

Page 68

1 – 64 chapter 1 troubleshooting 8 checking pwb ground remove shield plate lvps (pl12.1.3) and shield plate hvps (pl12.1.8). (rrp12.1, 12.9) is the ground normal? Are screws for ground of the following pwbs firmly tightened? All screws of hvps/mcu (pl12.1.19) all screws of lvps (pl12.1.5) when optio...

Page 69

1 – 65 chapter 1 troubleshooting fip1.43 motor assy exit step check yes no possible causes: motor assy exit (pl10.1.15) harness assy lvps (pl12.1.1) pwba exit motor (pl12.1.4) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking motor assy exit. Not using diag tool: replace motor assy exit (rrp10.5) is t...

Page 70

1 – 66 chapter 1 troubleshooting fip1.44 sensor face up open step check yes no possible causes: sensor face up open (pl10.1.25) gate fu (pl10.2.6) lever gate fu (pl10.2.17) harness assy exit snr (pl10.1.27) hvps/mcu (pl12.1.19) 1 checking gate fu for operation open cover assy rear 500. Move lever ga...

Page 71

1 – 67 chapter 1 troubleshooting fip1.45 sensor full stack step check yes no possible causes: sensor full stack (pl10.1.26) actuator full stack (pl10.1.10) harness assy exit snr (pl10.1.27) hvps/mcu (pl12.1.19) 1 checking actuator full stack open cover assy rear 500. Move actuator full stack with a ...

Page 72

1 – 68 chapter 1 troubleshooting blank page.

Page 73: Duplex Option

1 – 69 chapter 1 troubleshooting duplex option 4.3 error/status code list 4.4 table 1 status code error contents error description fip to be referred status 3-1 js0 status 3-1 to 3-5 indicates jam by combination of table 1-1. Status 3-2 js1 status 3-3 js2 status 3-4 js3 status 3-5 js4 status 17-3 du...

Page 74

1 – 70 chapter 1 troubleshooting 4.5 level 1 fip fip2.1 option duplex cover error step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) hsg lower dup (pl21.1.6) cover hsg dup (pl21.1.18) switch duplex (pl21.1.27) pwba duplex (pl21.1.32) 1 checking cover hsg dup open cover hsg dup. ...

Page 75

1 – 71 chapter 1 troubleshooting fip2.2 option duplex error step check yes no possible causes: hvps/mcu (pl12.1.19) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) 1 checking option duplex installation does error still occur, after removing option duplex once, reinstalling, and then turning the ...

Page 76

1 – 72 chapter 1 troubleshooting fip2.3 paper jam/exit to dup step check yes no possible causes: hvps/mcu (pl12.1.19) sensor dup (pl21.1.34) actuator dup (pl21.1.37) roll dup (pl21.1.17) roll pinch (pl21.1.4) motor duplex (pl21.1.29) 1 does error occur, when the power is turned on? Go to step 2. Go ...

Page 77

1 – 73 chapter 1 troubleshooting fip2.4 paper jam/dup to regi step check yes no possible causes: hvps/mcu (pl12.1.19) fdr1 as sub 150 a4 (pl5.1.2) sensor dup (pl21.1.34) actuator dup (pl21.1.37) roll dup (pl21.1.17) roll pinch (pl21.1.4) motor duplex (pl21.1.29) 1 checking option duplex installation...

Page 78

1 – 74 chapter 1 troubleshooting fip2.5 paper jam/duplex misfeed step check yes no possible causes: fdr1 as sub 150 a4 (pl5.1.2) hvps/mcu (pl12.1.19) roll dup (pl21.1.17) roll pinch (pl21.1.4) motor duplex (pl21.1.29) 1 checking option duplex installation remove option duplex, and then reinstall. Do...

Page 79

1 – 75 chapter 1 troubleshooting fip2.6 paper size error/duplex step check yes no 1 possible causes: hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) pwba feeder 550 (pl20.1.34) checking paper size is the paper size capable for duplex printing? Go to step 2. Replace the paper. 2 checking the paper siz...

Page 80

1 – 76 chapter 1 troubleshooting fip2.7 no recognition of option duplex step check yes no possible causes: hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) 1 checking option duplex detection signal (1) remove pwba duplex. (rrp21.5) remove harness ...

Page 81

1 – 77 chapter 1 troubleshooting 4.6 level 2 fip fip2.8 pwba duplex step check yes no possible causes: pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) 1 checking harness assy dup for continuity remove option duplex. Disconnect p/j50 from pwba dup...

Page 82

1 – 78 chapter 1 troubleshooting fip2.9 motor duplex step check yes no possible causes: motor duplex (pl21.1.29) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1 checking harness assy dup for continuity remove option duplex. Disc...

Page 83

1 – 79 chapter 1 troubleshooting fip2.10 sensor dup step check yes no possible causes: sensor dup (pl21.1.34) actuator dup (pl21.1.37) harness assy dup snr (pl21.1.35) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1 checking act...

Page 84

1 – 80 chapter 1 troubleshooting fip2.11 switch duplex step check yes no possible causes: switch duplex (pl21.1.27) harness assy lvps (pl12.1.1) harness assy dup cover (pl21.1.31) pwba duplex (pl21.1.32) harness assy dup (pl21.1.7) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking switch duplex for co...

Page 85: Oct Option

1 – 81 chapter 1 troubleshooting oct option 4.7 error/status code list table 1-1 status code error contents error description fip to be referred status 3-1 js0 status 3-1 to 3-5 indicates jam by combina- tion of table 1-1. Status 3-2 js1 status 3-3 js2 status 3-4 js3 status 3-5 js4 status 16-5 full ...

Page 86

1 – 82 chapter 1 troubleshooting 4.8 level 1 fip fip3.1 option oct cover error step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) pwba oct (pl23.1.22) cover rear (pl23.1.4) cover oct (pl23.1.1) s/w rear cover (pl23.1.18) harness assy rear cover (pl23.1.29) 1 checking cover rear ...

Page 87

1 – 83 chapter 1 troubleshooting fip3.2 option oct error step check yes no possible causes: harness assy oct1 (pl12.1.26) hvps/mcu (pl12.1.19) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) 1 checking option oct installation remove option oct, reinstall and turn the power on. Does error still oc...

Page 88

1 – 84 chapter 1 troubleshooting fip3.3 paper jam/exit to oct step check yes no possible causes: hvps/mcu (pl12.1.19) sensor oct (pl23.1.30) actuator oct (pl23.1.31) roll oct lower (pl23.1.16) roll oct upper (pl23.1.36) roll pinch (pl23.1.34) motor assy oct (pl23.1.6) 1 does error occur, when the po...

Page 89

1 – 85 chapter 1 troubleshooting fip3.4 paper jam/oct step check yes no possible causes: hvps/mcu (pl12.1.19) sensor oct (pl23.1.30) actuator oct (pl23.1.31) roll oct lower (pl23.1.16) roll oct upper (pl23.1.36) roll pinch (pl23.1.34) motor assy oct (pl23.1.6) 1 does error occur, when the power is t...

Page 90

1 – 86 chapter 1 troubleshooting fip3.5 paper size error/oct step check yes no possible causes: hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) pwba feeder 550 (pl20.1.34) 1 checking the paper size setup does the size of paper in use match the size set by guide assy end? Go to step 2. Change the pape...

Page 91

1 – 87 chapter 1 troubleshooting fip3.6 full stack error/oct step check yes no possible causes: sensor full stack (0n pwba oct) hvps/mcu (pl12.1.19) pwba oct (pl23.1.22) actuator full stack (pl23.1.15) 1 checking actuator full stack for operation does actuator full stack move smoothly, when you move...

Page 92

1 – 88 chapter 1 troubleshooting fip3.7 no recognition of option oct step check yes no possible causes: hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) 1 checking option oct detection signal (1) disconnect p/j70 on pwba oct. Is the voltage across...

Page 93

1 – 89 chapter 1 troubleshooting 4.9 level 2 fip fip3.8 pwba oct step check yes no possible causes: pwba oct (pl23.1.22) harness assy oct1 (pl12.1.26) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy oct2 for continuity remove option oct. (rrp23.1) disconnec...

Page 94

1 – 90 chapter 1 troubleshooting fip3.9 motor assy oct step check yes no possible causes: motor assy oct (pl23.1.6) pwba oct (pl23.1.22) harness assy oct mot (pl23.1.46) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking harness assy oct mot for continuity re...

Page 95

1 – 91 chapter 1 troubleshooting fip3.10 motor assy offset step check yes no possible causes: motor assy offset (pl23.1.20) motor assy oct (pl23.1.6) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking motor assy offset not using diag tool...

Page 96

1 – 92 chapter 1 troubleshooting fip3.11 solenoid assy gate step check yes no possible causes: solenoid assy gate (pl23.1.27) p wba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking solenoid assy gate not using diag tool: replace solenoid ass...

Page 97

1 – 93 chapter 1 troubleshooting fip3.12 s/w rear cover step check yes no possible causes: s/w rear cover (pl23.1.18) harness assy rear cover (pl23.1.29) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy oct1 (pl12.1.26) 1 checking s/w rear cover fo...

Page 98

1 – 94 chapter 1 troubleshooting fip3.13 sensor oct step check yes no possible causes: sensor oct (pl23.1.30) actuator oct (pl23.1.31) harness assy oct snr (pl23.1.26) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking actuator oct for op...

Page 99

1 – 95 chapter 1 troubleshooting fip3.14 sensor full stack (on pwba oct) step check yes no possible causes: sensor full stack (mounted on pwba oct) actuator full stack (pl23.1.15) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking actuato...

Page 100

1 – 96 chapter 1 troubleshooting fip3.15 sensor offset (on pwba oct) step check yes no possible causes: sensor offset (mounted on pwba oct) chute offset assy (pl23.1.35) pwba oct (pl23.1.22) harness assy oct2 (pl23.1.25) hvps/mcu (pl12.1.19) harness assy oct1 (pl12.1.26) 1 checking the actuator of c...

Page 101: 550 Paper Feeder Option

1 – 97 chapter 1 troubleshooting 550 paper feeder option 4.10 error/status code list status code error contents error description fip to be referred status 1-5 cassette fail - paper size is not specified. Fip4.1 status 15-3 near end of paper in tray 4 - remaining paper in tray 4 became low. Fip4.3 s...

Page 102

1 – 98 chapter 1 troubleshooting 4.11 level 1 fip fip4.1 no tray/tray 3, 4 step check yes no possible causes: hvps/mcu (pl12.1.19) opt assy size (pl20.1.8) option 550 paper feeder 550 paper cassette (pl20.3.50) 1 does error still occur, after removing and reinstalling the 550 paper cassette of optio...

Page 103

1 – 99 chapter 1 troubleshooting fip4.2 no paper/tray 3, 4 step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) sensor no paper (pl20.2.33) actuator no paper (pl20.2.6) option 550 paper feeder 550 paper cassette (pl20.3.50) plate assy btm (pl20.3.10) rack btm lock 550 (pl20.3.21) ...

Page 104

1 – 100 chapter 1 troubleshooting fip4.3 low paper in tray/tray 3, 4 step check yes no possible causes: hvps/mcu (pl12.1.19) lvps (pl12.1.5) sensor low paper (pl20.1.30) actuator low paper (pl20.1.31) plate assy btm (pl20.3.10) option 550 paper feeder 550 paper cassette (pl20.3.50) 1 checking the se...

Page 105

1 – 101 chapter 1 troubleshooting fip4.4 no recognition of option 550 paper feeder the description below is on the assumption that option 550 paper feeder's are installed to tray 3 and tray 4. Step check yes no possible causes: lvps (pl12.1.5) hvps/mcu (pl12.1.19) pwba feeder 550 (pl20.1.34) harness...

Page 106

1 – 102 chapter 1 troubleshooting fip4.5 inappropriate option 550 paper feeder step check yes no possible causes: pwba feeder 550 (pl20.1.34) 1 checking option 550 paper feeder is option 550 paper feeder for correct jigen2 installed? Go to fip4.6, 4.7 pwba feeder 550. Replace option 550 paper feeder...

Page 107

1 – 103 chapter 1 troubleshooting 4.12 level 2 fip fip4.6 pwba feeder 550 it is stated here as option 550 paper feeder is set as tray 3. When it is set as tray 4, refer to the statement in fip2.21 pwba feeder 550 for the circuit usage condition. Step check yes no possible causes: harness assy fdr1 (...

Page 108

1 – 104 chapter 1 troubleshooting fip4.7 pwba feeder 550 it is stated here as option 550 paper feeder is set as tray 4. When it is set as tray 3, refer to the statement in fip2.20 pwba feeder 550 for the circuit usage condition. Step check yes no possible causes: pwba feeder 550 (pl20.1.34) harness ...

Page 109

1 – 105 chapter 1 troubleshooting fip4.8 sensor no paper step check yes no possible causes: sensor no paper (pl20.2.33) actuator no paper (pl20.2.6) harness assy clsnr1 (pl20.2.31) harness assy clsnr2 (pl20.1.36) 550 paper cassette (pl20.3.50) option 550 paper feeder pwba feeder 550 (pl20.1.34) hvps...

Page 110

1 – 106 chapter 1 troubleshooting 6 checking hvps/mcu for continuity disconnect p/j11 and p/j20 from hvps/mcu. Is there continuity between p11-16 and p20-5? Go to step 7. Replace hvps/ mcu. (rrp12.10) 7 checking after replacing sensor no paper (3) replace sensor no paper. (rrp20.16) does the problem...

Page 111

1 – 107 chapter 1 troubleshooting fip4.9 sensor low paper step check yes no possible causes: sensor low paper (pl20.1.30) actuator low paper (pl20.1.31) harness low paper (pl20.1.33) harness assy fdr2 (pl20.1.5) option 550 paper feeder 550 paper cassette pwba feeder 550 (pl20.1.34) plate assy btm (p...

Page 112

1 – 108 chapter 1 troubleshooting fip4.10 opt assy size step check yes no possible causes: opt assy size (pl20.1.18) harness assy size fdr1 (pl20.1.19) harness assy size fdr2 (pl20.1.35) option 550 paper feeder 550 paper cassette pwba feeder 550 (pl20.1.34) hvps/mcu (pl12.1.19) 1 checking harness as...

Page 113

1 – 109 chapter 1 troubleshooting fip4.11 clutch assy ph step check yes no possible causes: clutch assy ph (pl20.2.21) option 550 paper feeder 550 paper cassette (pl20.3.50) pwba feeder 550 (pl20.1.34) harness assy clsnr1 (pl20.2.31) harness assy clsnr2 (pl20.1.36) harness assy fdr2 (pl20.1.5) hvps/...

Page 114

1 – 110 chapter 1 troubleshooting fip4.12 clutch pr-regi step check yes no possible causes: clutch pr-regi (pl20.2.22) option 550 paper feeder 550 paper cassette (pl20.3.50) pwba feeder 550 (pl20.1.34) harness assy clsnr1 (pl20.2.31) harness assy clsnr2 (pl20.1.36) harness assy fdr2 (pl20.1.5) hvps/...

Page 115: 5. Image Quality Defects

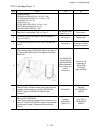

1 – 111 chapter 1 troubleshooting 5. Image quality defects 5.1 entry chart for image quality troubleshooting it is assumed that the printer controller is functioning normally. By running a test print with the engine only, if the trouble is on the printer controller side or the engine side, diagnosis...

Page 116

1 – 112 chapter 1 troubleshooting when an image quality problem occurs, run a test print to clearly define the defect. Next, troubleshoot using the image quality fip table accordingly. If the problem cannot be resolved using the image quality fip, check again with the image quality fip. Next, replac...

Page 117

1 – 113 chapter 1 troubleshooting 5.2 image quality fip fip- 1.P1 faint print before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the density of the im...

Page 118

1 – 114 chapter 1 troubleshooting 7 checking the image development process operate test print, and turn off the power of the printer while printing. Remove the ep cartridge with care, and check the toner image formed on the drum, right before the tran- scribe part (btr). Is the image on the drum com...

Page 119

1 – 115 chapter 1 troubleshooting fip- 1.P2 blank print (no print) before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the entire paper is printed pure...

Page 120

1 – 116 chapter 1 troubleshooting 5 checking btr assy remove btr assy. (rrp8.10) check if any stains and/or wear on btr assy. Are there any stains and/or wear on btr? Go to step 6. Replace btr assy. (rrp8.10) 6 checking the image development process operate test print, and turn off the power of the ...

Page 121

1 – 117 chapter 1 troubleshooting fip- 1.P3 solid black before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the entire paper is printed jet-black. Ess ...

Page 122

1 – 118 chapter 1 troubleshooting fip- 1.P4 vertical blank lines (white stripes in paper transport direction) before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on pri...

Page 123

1 – 119 chapter 1 troubleshooting 6 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? ...

Page 124

1 – 120 chapter 1 troubleshooting fip- 1.P5 horizontal band cross out before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are some extremely fain...

Page 125

1 – 121 chapter 1 troubleshooting 6 checking the image transcribe process check the toner image formed on the drum, right after the transcribe part (btr). Is the toner image on the drum completely transcribed on the paper? Go to step 7. Go to fip1.41 hvps/mcu. 7 checking drive assy and gear assy hou...

Page 126

1 – 122 chapter 1 troubleshooting fip- 1.P6 vertical stripes before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are vertical black stripes along...

Page 127

1 – 123 chapter 1 troubleshooting fip- 1.P7 horizontal stripes before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are horizontal black stripes a...

Page 128

1 – 124 chapter 1 troubleshooting 6 checking drum ground check the plate earth of guide assy cru r. Are there any stains or deformation on the plate earth? Go to step 7. Restore or clean the plate earth, or replace guide assy cru r. (rrp8.13) 7 checking btr assy remove btr assy. (rrp8.10) check if a...

Page 129

1 – 125 chapter 1 troubleshooting fip- 1.P8 partial deletion before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are some extremely faint or comp...

Page 130

1 – 126 chapter 1 troubleshooting fip- 1.P9 spots before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there are toner spots all over the paper disorder...

Page 131

1 – 127 chapter 1 troubleshooting fip- 1.P10 ghosting before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the ghost appears on the paper. The ghost may...

Page 132

1 – 128 chapter 1 troubleshooting 6 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? ...

Page 133

1 – 129 chapter 1 troubleshooting fip- 1.P11 background (fog) before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect there is toner stain all over or a pa...

Page 134

1 – 130 chapter 1 troubleshooting fip- 1.P12 skew before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the printed image is not paralleled with both sid...

Page 135

1 – 131 chapter 1 troubleshooting fip- 1.P13 paper damage before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the paper comes out from the printer crum...

Page 136

1 – 132 chapter 1 troubleshooting 6 checking ep cartridge install a new ep cartridge. Carry out a test printing. Is the paper still damaged? Go to step [ess and possible causes]. End of work step check yes no.

Page 137

1 – 133 chapter 1 troubleshooting fip- 1.P14 unfused image before commencing troubleshooting, check the paper transfer course. Make sure there is no foreign articles on the transfer course, such as staples, paper clips, scraps of paper and so on. Print defect the printed image is not fixed on the pa...

Page 138

1 – 134 chapter 1 troubleshooting 4 checking fuser assy turn the gear of the heater roller with a finger. Check the contact condition of heat roll and pressure roll when rotating. Do heat roll and pressure roll contact evenly? Go to step [ess and possible causes]. Replace fuser assy. (rrp8.8) step c...

Page 139

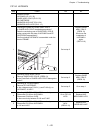

1 – 135 chapter 1 troubleshooting 6. Judgment of print consistency it is stated here how to judge simply the main print consistency printing with the standard paper (letter size). Keep the paper packaged in the operating environment for 12 hours, and then use the paper just after it has been unpacke...

Page 140

1 – 136 chapter 1 troubleshooting 6.2 side edge registration measure the amount of shift from the ideal point 108.0 mm away from the left end at center of front and- back of the paper. Reference: less than +/-2.5 mm.

Page 141

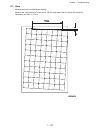

1 – 137 chapter 1 troubleshooting 6.3 skew measurement of the inclined paper feeding measure the vertical distance of two points 190 mm away each other on the top horizontal line. Reference: less than +/-1.2 mm.

Page 142

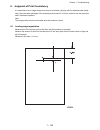

1 – 138 chapter 1 troubleshooting 6.4 perpendicularity measurement of the perpendicularity for suppressing inclines of ros and opc. Check the perpendicular line to the horizontal line to measure the horizontal distance at the point 114.5 mm away vertically from center of top horizontal line. Referen...

Page 143

1 – 139 chapter 1 troubleshooting 6.5 parallelism the parallelism is difference of feeding speed between left and right sides of the paper. Measure the difference of length between two 234 mm long vertical lines 190 mm away each other. Reference: less than +/-1.2 mm.

Page 144: 7. Preventive Maintenance

1 – 141 chapter 1 troubleshooting 7. Preventive maintenance when visiting the customer for a service call, perform the maintenance work to prevent any additional problems. Procedure for preventive maintenance 1) check how the customer is using the machine. 2) write down the cumulative print count. U...

Page 145

Chapter 2 printer diagnostics chapter 2 diagnostics contents chapter 2 diagnostics ....................................................................................................2 - 1 1. Diagnostics....................................................................................................

Page 146

Chapter 2 printer diagnostics chapter 2 diagnostics contents 11. Print summary.........................................................................................................2 - 16.

Page 147

2 - 1 chapter 2 diagnostics chapter 2 diagnostics 1. Diagnostics 1.1 overview diagnostics enable you to run various test on printer components. You can run motors forward and reverse and at different speeds, the actuation and de-actuation of sensors or switches, energize and de-energize solenoids, e...

Page 148

2 - 2 chapter 2 diagnostics 2. Entering diagnostics to enter diagnostics, perform the following: 1. Switch the printer power off. 2. Press and hold both the “menu” and “x” buttons on the operator panel 3. Switch the printer power on. 4. Continue to hold the “menu” and “x” buttons until “initializing...

Page 149

2 - 3 chapter 2 diagnostics 3. Main menu 3.1 navigating through the diagnostic menus four buttons are used to navigate through the diagnostic menus and sub-menus, (w, x, s, t). From the initial menu selection “output tests” (see 3.2), pressing the “t” button moves down the menu to “input tests” then...

Page 150

2 - 4 chapter 2 diagnostics 4. Output tests with “output tests” displayed on the lcd, pressing the “x” button will enter the “output tests” menu and display the first menu selection. The complete output tests menu is displayed in the figure below. None of the menu selections in the output tests have...

Page 151

2 - 5 chapter 2 diagnostics 5. Input tests input tests are used to test cover interlocks, paper path sensors, paper size switches, etc., fuser tem- perature and rom checksum. With “input tests” displayed on the lcd, pressing the “x” button will enter the “input tests” menu and display the first menu...

Page 152

2 - 6 chapter 2 diagnostics 6. Alignment the image registration alignment allows each tray to be adjusted independently. Alignment routines are used to set “x” and “y” values for the paper trays. With “alignment” displayed on the lcd, pressing the “x” button will enter the “alignment” menu and displ...

Page 153

2 - 7 chapter 2 diagnostics 7. Maintenance info maintenance info indicates the current count of the selected menu, the serial number of the printer, or resets the error log. With “maintenance info” displayed on the lcd, pressing the “x” button will enter the maintenance info menu and display the fir...

Page 154

2 - 8 chapter 2 diagnostics using the “t “or “s“ buttons scroll through the possible choices that can be entered in each digit loca- tion. The choices are: ! " # $ % & ' ( ) * + , -. / 0 1 2 3 4 5 6 7 8 9 : ; ? @ a b c d e f g h i j k l m n o p q r s t u v w x y z [ \ ] ^ _ ` a b c d e f g h i j k l...

Page 155

2 - 9 chapter 2 diagnostics 8. Operator panel operator panel menu enables the running of tests on operator panel. These tests include the leds, the lcd, and the keys (buttons). With “operator panel” displayed on the lcd, pressing the “x” button will enter the operator panel menu and display the firs...

Page 156

2 - 10 chapter 2 diagnostics 8.3 key test the key test enables the testing of eight buttons on the operator panel. With key test displayed, press- ing the “x” button will enter the key test. Opn: this indicates that a button is open. As you press each button, the corresponding location will change t...

Page 157

2 - 11 chapter 2 diagnostics 9. Test print the test print menu enables the running of five test prints, selecting the tray for the source paper, and selecting duplex or simplex. With “test print” displayed on the lcd, pressing the “x” button will enter the test print menu and dis- play the first men...

Page 158

2 - 12 chapter 2 diagnostics 9.3 engine test page with “engine test page” displayed on the lcd, pressing the “x” button will print the engine test page. 9.4 grid page with “grid page” displayed on the lcd, pressing the “x” button will print the grid page..

Page 159

2 - 13 chapter 2 diagnostics 9.5 blank page with “blank page” displayed on the lcd, pressing the “x” button will print a blank page. 9.6 black page with “black page” displayed on the lcd, pressing the “x” button will print a page with a large black square..

Page 160

2 - 14 chapter 2 diagnostics 9.7 test page with “test page” displayed on the lcd, pressing the “x” button will print the test page..

Page 161

2 - 15 chapter 2 diagnostics 10. Flash summary with ”flash summary” displayed on the lcd, pressing the “x” button will print the flash summary (shown below). When the print completes, the display will remain at the flash summary menu. This is an example of the flash summary report.

Page 162

2 - 16 chapter 2 diagnostics 11. Print summary with “print summary” displayed on the lcd, pressing the “x” button will print the print summary (shown below). When the print completes, the display will remain at the print summary menu. This is an example of the print summary report.