- DL manuals

- Vacon

- Controller

- 100X series

- Applications Manual

Vacon 100X series Applications Manual

Summary of 100X series

Page 1

Vacon ® 100 x ac drives solar pump application manual.

Page 3

Vacon • 0 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com index document: dpd01602a version release date: 25.6.14 corresponds to software package amit1181_v102.Vcx 1. Vacon 100x solar pump application ................................................................ 2 1.1 specific functi...

Page 4

Vacon • 1 tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.1 application parameter lists............................................................................................. 66 6.1.1 column explanations ..........................................................................................

Page 5

Vacon 100x solar pump application vacon • 2 service support: find your nearest vacon service center at www.Vacon.Com 1 1. V acon 100x s olar p ump a pplication the vacon ac drive contains a preloaded vacon 100x solar pump application for instant use. 1.1 specific functions of vacon solar pump applic...

Page 6

Vacon • 3 vacon 100x solar pump application 1.

Page 7

Safety vacon • 4 service support: find your nearest vacon service center at www.Vacon.Com 2 2. S afety this manual contains clearly marked warning information which is intended for your personal safety and to avoid any unintentional damage to the product or connected appliances. Before installing, c...

Page 8

2 vacon • 5 safety.

Page 9

Startup vacon • 6 service support: find your nearest vacon service center at www.Vacon.Com 3 3. S tartup 3.1 first start-up in the startup wizard , you will be prompted for essential information needed by the drive so that it can start controlling your process. In the wizard, you will need the follo...

Page 10

3 vacon • 7 startup push the ok button unless you want to set all parameter values manually. If you set motor type to induction motor, you see the next question. If your selection is pm mo- tor, the value of parameter p3.1.1.5 motor cos phi is set to 1.00 and the wizard goes directly to question 18....

Page 11

Startup vacon • 8 service support: find your nearest vacon service center at www.Vacon.Com 3 to continue to the application wizard, set the selection to yes and push the ok button. After these selections, the start-up wizard is completed. To start the start-up wizard again, you have 2 alternatives. ...

Page 12

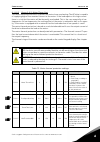

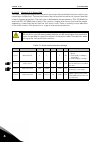

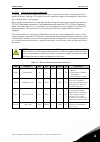

3 vacon • 9 startup 3.2 description of the applications use the parameter p1.2 (application) to make a selection of an application for the drive. Imme- diately when the parameter p1.2 changes, a group of parameters get their preset values. 3.2.0.1 m1 quick setup parameter group in the quick setup pa...

Page 13

Startup vacon • 10 service support: find your nearest vacon service center at www.Vacon.Com 3 p1.14 energy optimization 0 1 0 666 the drive searches for the minimum motor current in order to save energy and to lower the motor noise. This function can be used e.G. In fan and pump applications 0 = dis...

Page 14

3 vacon • 11 startup p1.22 i/o a ref sel 1 9 5 117 selection of ref source when control place is i/o a 1 = preset frequency 0 2 = keypad reference 3 = fieldbus 4 = ai1 5 = ai2 6 = ai1+ai2 7 = pid reference 8 = motor potentiometer 9 = max power p1.23 keypad ref sel 1 9 2 121 selection of ref source w...

Page 15

Startup vacon • 12 service support: find your nearest vacon service center at www.Vacon.Com 3 p1.27 ro1 function 0 51 2 1100 1 function selection for basic r01: 0 = none 1 = ready 2 = run 3 = general fault 4 = general fault inverted 5 = general alarm 6 = reversed 7 = at speed 8 = thermistor fault 9 ...

Page 16

3 vacon • 13 startup p1.28 basic r02 function 0 46 3 1100 4 see p1.27 p1.30 ao1 function 0 19 2 1005 0 0=test 0% (not used) 1=test 100% 2=output freq (0 -fmax) 3=freq reference (0-fmax) 4=motor speed (0 - motor nominal speed) 5=output current (0-i nmo- tor ) 6=motor torque (0-t nmotor ) 7=motor powe...

Page 17

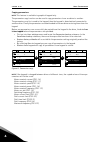

Startup vacon • 14 service support: find your nearest vacon service center at www.Vacon.Com 3 3.2.1 standard application you can use the standard application in speed-controlled processes where no special func- tions are necessary, for example pumps, fans, or conveyors. It is possible to control the...

Page 18

3 vacon • 15 startup 3.2.2 local/remote application use the local/remote application when, for example, it is necessary to switch between 2 dif- ferent control places. To change between the local and the remote control place, use di6. When remote control is active, you can give the start/stop comman...

Page 19

Startup vacon • 16 service support: find your nearest vacon service center at www.Vacon.Com 3 3.2.3 multi-step application you can use the multi-step speed application with processes where more than 1 fixed frequen- cy reference is necessary (for example test benches). It is possible to use 1 + 7 fr...

Page 20

3 vacon • 17 startup 3.2.4 pid control application you can use the pid control application with processes where you control the process variable (for example pressure) through control of the speed of the motor. In this application, the internal pid controller of the drive is configured for 1 setpoin...

Page 21

Startup vacon • 18 service support: find your nearest vacon service center at www.Vacon.Com 3 p1.34.4 fb 1 source 0 20 2 334 0 = not used 1 = ai1 2 = ai2 3 = ai3 4 = ai4 5 = ai5 6 = ai6 7 = processdatain1 8 = processdatain2 9 = processdatain3 10 = processdatain4 11 = processdatain5 12 = processdatai...

Page 22

3 vacon • 19 startup p1.34.7 sp 1 sleep freq 0.00 320.00 hz 0.00 1016 drive goes to sleep mode when the output frequency stays below this limit for a time greater than that defined by parameter sleep delay. P1.34.8 sp 1 sleep delay 0 3000 s 0 1017 the minimum amount of time the frequency has to rema...

Page 23

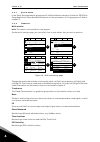

Startup vacon • 20 service support: find your nearest vacon service center at www.Vacon.Com 3 3.2.5 multi-purpose application you can use the multi-purpose application for different processes (for example conveyors) where a wide range of motor control functions is necessary. It is possible to contro...

Page 24

3 vacon • 21 startup p1.35.10 u/f mid voltg 0.0 100.0 % 100.0 605 provided that the program- mable u/f curve has been selected (par. P3.1.4.1), this parameter defines the mid- dle point voltage of the curve. P1.35.11 zero freq voltg 0.00 40.00 % varies 606 this parameter defines the zero frequency v...

Page 25

Startup vacon • 22 service support: find your nearest vacon service center at www.Vacon.Com 3 3.2.6 motor potentiometer application use the motor potentiometer application for the processes where the frequency reference of the motor is controlled (that is, increased and decreased) through digital in...

Page 26

4 vacon • 23 user interfaces 4. U ser i nterfaces 4.1 keypad of the drive the control keypad is the interface between the vacon 100 ac drive and the user. With the con- trol keypad it is possible to control the speed of a motor, to supervise the state of the equip- ment and to set the ac drive's par...

Page 27

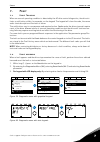

User interfaces vacon • 24 service support: find your nearest vacon service center at www.Vacon.Com 4 4.1.4 vacon graphical keypad figure 2. Main menu 4.1.4.1 using the graphical keypad editing values the selectable values can be accessed and edited in two different ways on the graphical key- pad. P...

Page 28: Or:

4 vacon • 25 user interfaces figure 3. Typical editing of values on graphical keypad (text value) figure 4. Typical editing of values on graphical keypad (numerical value) parameters with checkbox selection some parameters allow selecting several values. Make a checkbox selection at each value you w...

Page 29

User interfaces vacon • 26 service support: find your nearest vacon service center at www.Vacon.Com 4 resetting fault instructions for how to reset a fault can be found in chapter 7 . Function button the funct button is used for four functions: 1. To quickly access the control page, 2. To easily cha...

Page 30

4 vacon • 27 user interfaces figure 6. Changing control places accessing the control page the control page is meant for easy operation and monitoring of the most essential values. 1. Anywhere in the menu structure, push the funct button. 2. Push the arrow up or the arrow down button to select contro...

Page 31

User interfaces vacon • 28 service support: find your nearest vacon service center at www.Vacon.Com 4 changing direction rotation direction of the motor can quickly be changed by applying the funct button. Note! Changing direction command is not visible in the menu unless the selected control place ...

Page 32

4 vacon • 29 user interfaces copying parameters note: this feature is available in graphical keypad only. The parameter copy function can be used to copy parameters from one drive to another. The parameters are first saved to the keypad, then the keypad is detached and connected to another drive. Fi...

Page 33

User interfaces vacon • 30 service support: find your nearest vacon service center at www.Vacon.Com 4 help texts the graphical keypad features instant help and information displays for various items. All parameters offer an instant help display. Select help and press the ok button. Text information ...

Page 34

4 vacon • 31 user interfaces 4.1.5 vacon text keypad you can also choose a so-called text keypad for your user interface. It has mainly the same functionalities as the graphical keypad although some of these are somewhat limited. 4.1.5.1 keypad display the keypad display indicates the status of the ...

Page 35

User interfaces vacon • 32 service support: find your nearest vacon service center at www.Vacon.Com 4 4.1.5.2 using the text keypad editing values change value of a parameter following the procedure below: 1. Locate the parameter. 2. Enter the edit mode by pressing ok. 3. Set new value with the arro...

Page 36

4 vacon • 33 user interfaces changing control places change of control place from remote to local (keypad). 1. Anywhere in the menu structure, push the funct button. 2. Using the arrow buttons, select local/remote and confirm with the ok button. 3. On the next display, select local or remote and aga...

Page 37

User interfaces vacon • 34 service support: find your nearest vacon service center at www.Vacon.Com 4 changing direction rotation direction of the motor can quickly be changed by applying the funct button. Note! Changing direction command is not visible in the menu unless the selected control place ...

Page 38

4 vacon • 35 user interfaces 4.2 vacon live vacon live is a pc tool for commissioning and maintenance of the vacon® 10, vacon® 20, and vacon® 100 ac drives). You can download vacon live from www.Vacon.Com. The vacon live pc tool includes these functions. • parametrisation, monitoring, drive info, da...

Page 39

User interfaces vacon • 36 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3 menu structure click on and select the item you wish to receive more information about (electronic manual). Table 8. Keypad menus quick setup see chapter 3. Monitor multi-monitor* trend curve* b...

Page 40

4 vacon • 37 user interfaces 4.3.1 quick setup in the quick setup parameter group you will find the different wizards of the vacon 100 x solar pump application. More detailed information on the parameters of this group you will find in chapter 3. 4.3.2 monitor multi-monitor note: this menu is not av...

Page 41

User interfaces vacon • 38 service support: find your nearest vacon service center at www.Vacon.Com 4 external pid controller monitoring of external pid controller values. Maintenance counters monitoring of values related to maintenance counters. Fieldbus data fieldbus data shown as monitor values f...

Page 42

4 vacon • 39 user interfaces 4.3.3 parameters through this submenu, you can reach the application parameter groups and parameters. More information on parameters in chapter 6. 4.3.4 diagnostics under this menu, you can find active faults , reset faults , fault history , counters and software info. 4...

Page 43

User interfaces vacon • 40 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3.4.4 total counters table 12. Diagnostics menu, total counters parameters code parameter min max unit default id description v4.4.1 energy counter varies 2291 amount of energy taken from supply n...

Page 44

4 vacon • 41 user interfaces 4.3.4.5 trip counters 4.3.4.6 software info table 13. Diagnostics menu, trip counters parameters code parameter min max unit default id description p4.5.1 energy trip counter varies 2296 resettable energy counter. Note: the highest energy unit shown on the standard keypa...

Page 45

User interfaces vacon • 42 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3.5 i/o and hardware various options-related settings are located in this menu. Note that the values in this menu are raw values i.E. Not scaled by the application. 4.3.5.1 basic i/o monitor here ...

Page 46

4 vacon • 43 user interfaces 4.3.5.2 option board slots the parameters of this group depend on the option board installed. If no option board is placed in slots d or e, no parameters are visible. As an option board is removed, info text 39 device removed will appear on the display. 4.3.5.3 programmi...

Page 47

User interfaces vacon • 44 service support: find your nearest vacon service center at www.Vacon.Com 4 given the standard i/o board compilation on the vacon 100 ac drive, there are 6 digital inputs available (slot a terminals 8, 9, 10, 14, 15 and 16). In the programming view, these inputs are referre...

Page 48

4 vacon • 45 user interfaces figure 17. Programming digital inputs with text keypad now, the function external fault close is controlled with a digital signal to digital input di6 (ter- minal 16). Table 18. Programming digital inputs programming instructions graphical keypad text keypad 1. Select th...

Page 49

User interfaces vacon • 46 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3.5.5 analogue inputs the target input for the analogue frequency reference signal can also be chosen from the avail- able analogue inputs. Figure 18. Given the standard i/o terminals on the vacon...

Page 50

4 vacon • 47 user interfaces a.1 (text keypad). This means that the target input for the analogue frequency reference signal ai1 is now the analogue input in terminals 2/3. Whether the signal is voltage or current, must be determined with the dip switches . See the installation manual for more infor...

Page 51

User interfaces vacon • 48 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3.5.6 descriptions of signal sources 4.3.5.7 default assignments of digital and analogue inputs in vacon 100 application digital and analogue inputs are assigned certain functions by the factory. ...

Page 52

4 vacon • 49 user interfaces 4.3.5.8 real time clock 4.3.5.9 power unit settings fan control the fan operates in speed-controlled mode. The speed is controlled according to the drive’s internal logic that receives data from temperature measurements. Brake chopper sine filter table 22. I/o and hardwa...

Page 53

User interfaces vacon • 50 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3.5.10 keypad table 26. I/o and hardware menu, keypad parameters code parameter min max unit default id description p5.7.1 timeout time 0 60 min 0 time after which the display returns to page defi...

Page 54

4 vacon • 51 user interfaces 4.3.5.11 fieldbus parameters related to different fieldbus boards can also be found in the i/o and hardware menu. These parameters are explained in more detail in the respective fieldbus manual. Table 27. Submenu level 1 submenu level 2 submenu level 3 submenu level 4 rs...

Page 55

User interfaces vacon • 52 service support: find your nearest vacon service center at www.Vacon.Com 4 4.3.6 user settings 4.3.6.1 parameter backup table 28. User settings menu, general settings code parameter min max unit default id description p6.1 language selections varies varies varies 802 depen...

Page 56

4 vacon • 53 user interfaces 4.3.7 favorites note: this menu is not available in text keypad. Favorites are typically used to collect a set of parameters or monitoring signals from any of the keypad menus. You can add items or parameters to the favorites folder, see chapter . To remove an item or a ...

Page 57

User interfaces vacon • 54 service support: find your nearest vacon service center at www.Vacon.Com 4 4.4 example of control connections the terminals of the standard i/os and the relays are described below. The terminals shown on shadowed background are assigned for signals with optional functions ...

Page 58

4 vacon • 55 user interfaces 4.4.1 relay and thermistor input terminals 4.4.2 safe torque off (sto) terminals for more information on the functionalities of the safe torque off (sto), see vacon 100x in- stallation manual. Table 32. I/o terminal signals for relay and thermistor terminals and connecti...

Page 59

User interfaces vacon • 56 service support: find your nearest vacon service center at www.Vacon.Com 4.

Page 60

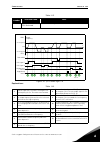

5 vacon • 57 monitoring menu 5. M onitoring m enu 5.1 monitor group vacon 100 x ac drive provides you with a possibility to monitor the actual values of parameters and signals as well as statuses and measurements. Some of the values to be monitored are customizable. 5.1.1 multimonitor on the multi-m...

Page 61

Monitoring menu vacon • 58 service support: find your nearest vacon service center at www.Vacon.Com 5 table 34. Trend curve parameters code parameter min max unit default id description m2.2.1 view trend curve enter this menu to select and monitor values for viewing in curve form. P2.2.2 sampling in...

Page 62

5 vacon • 59 monitoring menu 5.1.3 basic see table 35 in which the basic monitoring values are presented. Note! Only standard i/o board statuses are available in the monitor menu. Statuses for all i/o board signals can be found as raw data in the i/o and hardware system menu. Check expander i/o boar...

Page 63

Monitoring menu vacon • 60 service support: find your nearest vacon service center at www.Vacon.Com 5 5.1.4 i/o table 36. I/o signal monitoring code monitoring value unit scale id description v2.4.1 slot a din 1, 2, 3 1 15 shows the status of digital inputs 1-3 in slot a (standard i/o) v2.4.2 slot a...

Page 64

5 vacon • 61 monitoring menu 5.1.5 extras & advanced table 37. Advanced values monitoring code monitoring value unit scale id description v2.6.1 drivestatusword 1 43 bit coded word b1=ready b2=run b3=fault b6=runenable b7=alarmactive b10=dc current in stop b11=dc brake active b12=runrequest b13=moto...

Page 65

Monitoring menu vacon • 62 service support: find your nearest vacon service center at www.Vacon.Com 5 v2.6.5 din statusword1 1 56 16-bit word where each bit represents the status of one digital input. 6 digital inputs from every slot are read. Word 1 starts from input 1 in slot a (bit0) and goes all...

Page 66

5 vacon • 63 monitoring menu 5.1.6 timer functions here you can monitor values of timer functions and the real time clock. 5.1.7 pid controller table 38. Monitoring of timer functions code monitoring value unit scale id description v2.7.1 tc 1, tc 2, tc 3 1 1441 possible to monitor the statuses of t...

Page 67

Monitoring menu vacon • 64 service support: find your nearest vacon service center at www.Vacon.Com 5 5.1.8 extpid controller 5.1.9 mainten. Counters 5.1.10 fieldbus data table 40. External pid controller value monitoring code monitoring value unit scale id description v2.9.1 extpid setpoint varies ...

Page 68

5 vacon • 65 monitoring menu 5.1.11 solar v2.12.7 fb data in 5 1 880 raw value of process data in 32-bit signed format v2.12.8 fb data in 6 1 881 raw value of process data in 32-bit signed format v2.12.9 fb data in 7 1 882 raw value of process data in 32-bit signed format v2.12.10 fb data in 8 1 883...

Page 69

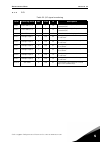

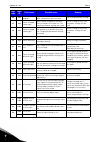

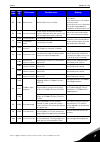

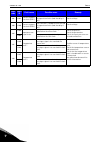

Parameters vacon • 66 service support: find your nearest vacon service center at www.Vacon.Com 6 6. P arameters the vacon ac drive contains a preloaded vacon 100x solar pump application for instant use. The parameters of this application are listed in this chapter. 6.1 application parameter lists fi...

Page 70

Vacon • 67 parameters 6 6.1.1 column explanations code = location indication on the keypad; shows the operator the parameter num- ber. Parameter= name of parameter min = minimum value of parameter max = maximum value of parameter unit = unit of parameter value; given if available default = value pre...

Page 71

Parameters vacon • 68 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.1.2.3 switching freq 1.5 varies khz varies 601 increasing the switching frequency reduces the capacity of the ac drive. It is recommended to use a lower frequency when the motor cable is long in order...

Page 72

Vacon • 69 parameters 6 6.1.2.3 group 3.1.3: limits 6.1.2.4 group 3.1.4: open loop p3.1.2.11 under volt. Control 0 1 1 608 0 = disabled 1 = enabled p3.1.2.12 energy optimization 0 1 0 666 the drive searches for the minimum motor current in order to save energy and to lower the motor noise. This func...

Page 73

Parameters vacon • 70 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.2.5 group 3.1.4.12: i/f start the i/f start function is typically used with permanent magnet synchronous motors (pmsm) to start the motor with constant current control. This is useful with high power...

Page 74

Vacon • 71 parameters 6 figure 21. I/f start table 49. I/f start parameters 6.1.2.6 group 3.1.4.13: stabilators code parameter min max unit default id description p3.1.4.12.1 i/f start 0 1 0 534 0 = disabled 1 = enabled p3.1.4.12.2 i/f start frequency 0.0 p3.1.1.2 % 15.0 535 output frequency limit b...

Page 75

Parameters vacon • 72 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.3 group 3.2: start/stop setup start/stop commands are given differently depending on the control place. Remote control place (i/o a): start, stop and reverse commands are controlled by 2 digital in- ...

Page 76

Vacon • 73 parameters 6 p3.2.10 rem to loc funct 0 2 2 181 choose whether to copy the run state and reference when changing from remote to local (keypad) control: 0 = keep run 1 = keep run & reference 2 = stop p3.2.11 start analogue signal 0 1 0 1810 0= ai1 1= ai2 p3.2.12 start analogue level 0.00 1...

Page 77

Parameters vacon • 74 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.4 group 3.3: references 6.1.4.1 frequency reference the requency reference source is programmable for all control places except pc , which al- ways takes the reference from the pc tool. Remote contro...

Page 78

Vacon • 75 parameters 6 p3.3.1.7 keypad ref sel 1 9 2 121 selection of ref source when control place is keypad: 1 = preset frequency 0 2 = keypad reference 3 = fieldbus 4 = ai1 5 = ai2 6 = ai1+ai2 7 = pid reference 8 = motor potentiometer 9 = max power p3.3.1.8 keypad reference 0.00 p3.3.1.2 hz 0.00...

Page 79

Parameters vacon • 76 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.4.2 group 3.3.3: preset freqs table 52. Preset frequencies parameters code parameter min max unit default id description p3.3.3.1 presetfreqmode 0 1 0 182 0 = binary coded 1 = number of inputs. Prese...

Page 80

Vacon • 77 parameters 6 6.1.4.3 group 3.3.4: motor potentiom with a motor potentiometer function, the user can increase and decrease the output frequen- cy. By connecting a digital input to parameter p3.3.4.1 ( motpot up ) and having the digital input signal active, the output frequency will rise as...

Page 81

Parameters vacon • 78 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.5 group 3.4: ramps and brakes 6.1.5.1 group 3.4.1: ramp 1 6.1.5.2 group 3.4.3: start magnetizat 6.1.5.3 group 3.4.3: dc brake 6.1.5.4 group 3.4.5: flux braking table 54. Ramp 1 setup code parameter m...

Page 82

Vacon • 79 parameters 6 6.1.6 group 3.5: i/o config 6.1.6.1 default assignments of programmable inputs table 58 below presents the default assignments of programmable digital and analogue inputs in vacon 100 x solar pump application. 6.1.6.2 group 3.5.1: digital inputs digital inputs are very flexib...

Page 83

Parameters vacon • 80 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.5.1.15 run enable digin slot0.2 407 must be on to set drive in ready state p3.5.1.16 run interlock 1 digin slot0.2 1041 drive may be ready but start is blocked as long as interlock is on (damper inter...

Page 84

Vacon • 81 parameters 6 6.1.6.3 group 3.5.2: analog inputs note! The number of usable analogue inputs depends on your (option) board setup. The stan- dard i/o board embodies 2 analogue inputs. Group 3.5.2.1: analog input 1 group 3.5.2.2: analog input 2 group 3.5.2.3: analog input 3 table 60. Analogu...

Page 85

Parameters vacon • 82 service support: find your nearest vacon service center at www.Vacon.Com 6 group 3.5.2.4: analog input 4 group 3.5.2.5: analog input 5 group 3.5.2.6: analog input 6 table 63. Analogue input 4 settings code parameter min max unit default id description p3.5.2.4.1 ai4 signal sele...

Page 86

Vacon • 83 parameters 6 6.1.6.4 group 3.5.3: digital outputs group 3.5.3.2: slot b basic table 66. Digital output settings on standard i/o board code parameter min max unit default id description p3.5.3.2.1 ro1 function 0 59 2 1100 1 function selection for basic r01: 0 = none 1 = ready 2 = run 3 = g...

Page 87

Parameters vacon • 84 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.6.5 expander slots d and e digital outputs shows only parameters for existing outputs on option boards placed in slots d and e. Selec- tions as in standard ro1 (p3.5.3.2.1). This group or these param...

Page 88

Vacon • 85 parameters 6 6.1.6.7 expander slots d to e analogue outputs shows only parameters for existing outputs on option boards placed in slots d and e. Selec- tions as in standard ao1 (p3.5.4.1.1). This group or these parameters are not visible if no digital outputs exist in slots d or e. 6.1.7 ...

Page 89

Parameters vacon • 86 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.8 group 3.7: prohibit freq in some systems it may be necessary to avoid certain frequencies due to mechanical reso- nance problems. By setting up prohibit frequencies it is possible to skip these ran...

Page 90

Vacon • 87 parameters 6 6.1.10 group 3.9: protections 6.1.10.1 group 3.9.1: general p3.8.6 superv2 mode 0 2 0 1436 see p3.8.2 p3.8.7 superv2 limit -50.00 50.00 varies 40.00 1437 see p3.8.3 p3.8.8 superv2 hyst 0.00 50.00 varies 5.00 1438 see p3.8.4 table 72. General protections settings code paramete...

Page 91

Parameters vacon • 88 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.10.2 group 3.9.2: motor therm prot the motor thermal protection is to protect the motor from overheating. The ac drive is capable of supplying higher than nominal current to the motor. If the load re...

Page 92

Vacon • 89 parameters 6 6.1.10.3 group 3.9.3: motor stall the motor stall protection protects the motor from short time overload situations such as one caused by a stalled shaft. The reaction time of the stall protection can be set shorter than that of motor thermal protection. The stall state is de...

Page 93

Parameters vacon • 90 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.10.4 group 3.9.4: motor underload the purpose of the motor underload protection is to ensure that there is load on the motor when the drive is running. If the motor loses its load there might be a pr...

Page 94

Vacon • 91 parameters 6 6.1.10.5 group 3.9.6: temperature input fault 1 note! This parameter group is visible only with an option board for temperature measure- ment (opt-bh) installed. Table 76. Temperature input fault 1 settings code parameter min max unit default id description p3.9.6.1 temperatu...

Page 95

Parameters vacon • 92 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.10.6 group 3.9.6: temperature input fault 2 note! This parameter group is visible only with an option board for temperature measure- ment (opt-bh) installed. Table 77. Temperature input fault 2 setti...

Page 96

Vacon • 93 parameters 6 6.1.10.7 group 3.9.8: ai low protection 6.1.10.8 group 3.9.9: user defined fault 1 6.1.10.9 group 3.9.10: user defined fault 2 table 78. Ai low protection settings code parameter min max unit default id description p3.9.8.1 ai low protection 0 2 2 767 this parameter defines i...

Page 97

Parameters vacon • 94 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.11 group 3.10: automatic reset 6.1.12 group 3.11: appl. Settings table 81. Autoreset settings code parameter min max unit default id description p3.10.1 automatic reset 0 1 0 731 0 = disabled 1 = ena...

Page 98

Vacon • 95 parameters 6 6.1.13 group 3.12: timer functions the time functions (time channels) in the vacon 100 x give you the possibility to program func- tions to be controlled by the internal rtc (real time clock). Practically every function that can be controlled by a digital input can also be co...

Page 99

Parameters vacon • 96 service support: find your nearest vacon service center at www.Vacon.Com 6 timers timers can be used to set a time channel active during a certain time by a command from a digital input (or a time channel). Figure 23. Activation signal comes from a digital input or " a virtual ...

Page 100

Vacon • 97 parameters 6 interval 2: p3.12.2.1: on time: 09:00:00 p3.12.2.2: off time: 13:00:00 p3.12.2.3: days: saturday, sunday p3.12.2.4: assigntochannel: time channel 1 timer 1 the manual bypassing can be handled by a digital input 1 on slot a (by a different switch or con- nection to lighting). ...

Page 101

Parameters vacon • 98 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.13.1 group 3.12.1: interval 1 6.1.13.2 group 3.12.2: interval 2 6.1.13.3 group 3.12.3: interval 3 6.1.13.4 group 3.12.4: interval 4 table 83. Timer functions, interval 1 code parameter min max unit d...

Page 102

Vacon • 99 parameters 6 6.1.13.5 group 3.12.5: interval 5 6.1.13.6 group 3.12.6: timer 1 6.1.13.7 group 3.12.7: timer 2 6.1.13.8 group 3.12.8: timer 3 table 87. Timer functions, interval 5 code parameter min max unit default id description p3.12.5.1 on time 00:00:00 23:59:59 hh:mm:ss 00:00:00 1484 s...

Page 103

Parameters vacon • 100 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.14 group 3.13: pid controller 6.1.14.1 group 3.13.1: basic settings table 91. Pid controller 1 basic settings code parameter min max unit default id description p3.13.1.1 gain 0.00 1000.00 % 100.00 ...

Page 104

Vacon • 101 parameters 6 6.1.14.2 group 3.13.2: setpoints table 92. Setpoints settings code parameter min max unit default id description p3.13.2.1 keypad sp 1 varies varies varies 0 167 p3.13.2.2 keypad sp 2 varies varies varies 0 168 p3.13.2.3 ramp time 0.00 300.0 s 0.00 1068 defines the rising an...

Page 105

Parameters vacon • 102 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.14.3 group 3.13.3: feedbacks table 93. Feedback settings code parameter min max unit default id description p3.13.3.1 function 1 9 1 333 1=only source1 in use 2=sqrt(source1);(flow=con stant x sqrt(...

Page 106

Vacon • 103 parameters 6 6.1.14.4 group 3.13.4: feedforward feedforward usually needs accurate process models, but in some simple cases a gain + offset type of feedforward is enough. The feedforward part does not use any feedback measurements of the actual controlled process value (water level in th...

Page 107

Parameters vacon • 104 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.14.6 group 3.13.6: feedback superv. Process supervision is used to control that the pid feedback value (process actual value) stays within predefined limits. With this function you can e.G. Detect a...

Page 108

Vacon • 105 parameters 6 6.1.14.8 group 3.13.8: soft fill the process is brought to a certain level (p3.13.8.3) at slow frequency (p3.13.8.2) before the pid controller starts to control. In addition, you can also set a timeout for the soft fill function. If the set level is not reached within the ti...

Page 109

Parameters vacon • 106 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.14.9 group 3.13.9: input press.Superv. The input pressure supervision function is used to supervise that there is enough water in the inlet of the pump, to prevent the pump from sucking air or causi...

Page 110

Vacon • 107 parameters 6 table 99. Input pressure supervision parameters code parameter min max unit default id description p3.13.9.1 superv. Enable 0 1 0 1685 0 = disabled 1 = enabled enables the input pressure supervision. P3.13.9.2 superv. Signal 0 13 hz 0 1686 the source of input pres- sure meas...

Page 111

Parameters vacon • 108 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.15 group 3.14: extpid controller 6.1.15.1 group 3.14.1: basic settings for more detailed information, see chapter 6.1.14. P3.13.9.10 pid setpoint reduct. 0.0 100.0 % 10.0 1694 defines the rate of th...

Page 112

Vacon • 109 parameters 6 6.1.15.2 group 3.14.2: setpoints table 101. External pid-controller, setpoints code parameter min max unit default id description p3.14.2.1 keypad sp 1 0.00 100.00 varies 0.00 1640 p3.14.2.2 keypad sp 2 0.00 100.00 varies 0.00 1641 p3.14.2.3 ramp time 0.00 300.00 s 0.00 1642...

Page 113

Parameters vacon • 110 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.15.3 group 3.14.3: feedbacks for more detailed information, see chapter 6.1.14. 6.1.15.4 group 3.14.4: feedback superv. For more detailed information, see chapter 6.1.14. Table 102. External pid-con...

Page 114

Vacon • 111 parameters 6 6.1.16 group 3.16: mainten. Counters the maintenance counter is a way of indicating the operator that maintenance needs to be car- ried out. For example, a belt needs to be replaced or oil in a gearbox should be changed. There are two different modes for the maintenance coun...

Page 115

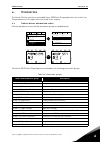

Parameters vacon • 112 service support: find your nearest vacon service center at www.Vacon.Com 6 6.1.17 group 3.21: pump control 6.1.17.1 group 3.21.1: auto-cleaning the auto-cleaning function is used to remove any dirt or other material that may have attached to the pump impeller. Auto-cleaning is...

Page 116

Vacon • 113 parameters 6 6.1.18 group 3.22: solar 6.1.18.1 group 3.22.1: start settings 6.1.18.2 group 3.22.2: mppt table 106. Start settings parameters code parameter min max unit defau lt id description p3.22.1.1 start dc voltage 400 800 v 650 1916 dv voltage threshold level to activate run enable...

Page 117

Parameters vacon • 114 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2 additional parameter information due to its user-friendliness and simplicity of use, the most parameters of the vacon 100x solar pump application only require a basic description which is given in t...

Page 118

Vacon • 115 parameters 6 p3.1.2.4 i dentification the automatic motor identification calculates or measures the motor parameters that are needed for optimum motor and speed control. Identification run is a part of tuning the motor and the drive specific parameters. It is a tool for commissioning and...

Page 119

Parameters vacon • 116 service support: find your nearest vacon service center at www.Vacon.Com 6 figure 27. Motor switch p3.1.2.7 l oad drooping the drooping function enables speed drop as a function of load. This parameter sets that amount corresponding to the nominal torque of the motor. This fun...

Page 120

Vacon • 117 parameters 6 p3.1.2.11 u nder v olt . C ontrol this parameter allow the undervoltage controller to be switched out of operation. This may be useful, for example, if the mains supply voltage varies more than -15% and the application will not tolerate this undervoltage. In this case, the r...

Page 121

Parameters vacon • 118 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.1.3.1 c urrent limit this parameter determines the maximum motor current from the ac drive. The parameter value range differs from size to size. When the current limit is active the drive output freq...

Page 122

Vacon • 119 parameters 6 figure 31.Programmable u/f curve p3.1.4.3 v oltage at fwp above the frequency at the field weakening point, the output voltage remains at the set maxi- mum value. Below the frequency at the field weakening point, the output voltage depends on the setting of the u/f curve par...

Page 123

Parameters vacon • 120 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.1.4.12.2 i/ f start freq i/f start function is used when the drive’s output frequency is below this frequency limit. When the output frequency exceeds this limit, the drive operation mode is changed ...

Page 124

Vacon • 121 parameters 6 p3.2.6 i/o a start logic values 0...4 offer possibilities to control the starting and stopping of the ac drive with digital signal connected to digital inputs. Cs = control signal. The selections including the text 'edge' shall be used to exclude the possibility of an uninte...

Page 125

Parameters vacon • 122 service support: find your nearest vacon service center at www.Vacon.Com 6 figure 32. I/o a start logic = 0 explanations: table 115. Selection number selection name note 0 cs1: forward cs2: backward the functions take place when the contacts are closed. Table 116. 1 control si...

Page 126

Vacon • 123 parameters 6 figure 33. I/o a start logic = 1 table 117. Selection number selection name note 1 cs1: start cs2: reverse the function takes place when the contacts are closed. Table 118. 1 control signal (cs) 1 activates causing the out- put frequency to rise. The motor runs forward. 7 ru...

Page 127

Parameters vacon • 124 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.4 references p3.3.1.1 m in f req r eference minimum frequency reference. Note: when drive is fed by solar power, if available power is not sufficient to maintain dc volt- age above the minimum and f...

Page 128

Vacon • 125 parameters 6 6.2.5 preset freqs p3.3.3.1 p reset f req m ode you can use the preset frequency parameters to define certain frequency references in ad- vance. These references are then applied by activating/inactivating digital inputs connected to parameters p3.3.3.10, p3.3.3.11 and p3.3....

Page 129

Parameters vacon • 126 service support: find your nearest vacon service center at www.Vacon.Com 6 value ‘1’ selected for parameter p3.3.3.1: according to how many of the inputs assigned for preset frequency selections are active, you can apply the preset frequencies 1 to 3. P3.3.3.10 p reset f req s...

Page 130

Vacon • 127 parameters 6 6.2.6 motor potentiom. P3.3.4.1 m ot p ot up p3.3.4.2 m ot p ot down with a motor potentiometer, the user can increase and decrease the output frequency. By con- necting a digital input to parameter p3.3.4.1 ( motpot up ) and having the digital input signal ac- tive, the out...

Page 131

Parameters vacon • 128 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.7 ramps and brakes p3.4.1.2 a ccel t ime 1 ramp time, referred to variation from zero frequency to max frequency. A specific acceleration time from zero to minimum frequency is available (p2.9). Nor...

Page 132

Vacon • 129 parameters 6 6.2.8 flux braking p3.4.5.1 f lux b raking instead of dc braking, flux braking is a useful way to raise the braking capacity in cases where additional brake resistors are not needed. When braking is needed, the frequency is reduced and the flux in the motor is increased, whi...

Page 133

Parameters vacon • 130 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.10 analog inputs p3.5.2.1.2 ai1 f ilter t ime when this parameter is given a value greater than 0 the function that filters out disturbances from the incoming analogue signal is activated. Note: lon...

Page 134

Vacon • 131 parameters 6 figure 36. Analogue input signal range, selection ‘0’ figure 37. Analogue input signal range, selection ‘1’ p3.5.2.1.4 ai1 c ustom m in p3.5.2.1.5 ai1 c ustom m ax these parameters allow you to freely adjust the analogue input signal range between -160…160%. Example: if the ...

Page 135

Parameters vacon • 132 service support: find your nearest vacon service center at www.Vacon.Com 6 figure 38. Ai signal custom min/max p3.5.2.1.6 ai1 s ignal i nv invert the analogue signal with this parameter. In the following examples, the analogue input signal is used as frequency reference. The f...

Page 136

Vacon • 133 parameters 6 figure 40. Ai signal inversion, selection ‘1’ 6.2.11 digital outputs p3.5.3.2.1 ro1 function selection number selection name description 1 inverted signal inverted. The analogue input signal value 0% corresponds to the maxfreqreference and the analogue input signal value 100...

Page 137

Parameters vacon • 134 service support: find your nearest vacon service center at www.Vacon.Com 6 13 limit supervision 1 activates if the signal value falls below or exceeds the set supervision limit (p3.8.3 or p3.8.7) depending on the selected function. 14 limit supervision 2 15 no function 16 no f...

Page 138

Vacon • 135 parameters 6 6.2.12 analog outputs p3.5.4.1.1 ao1 function this parameter defines the content of the analogue output signal 1. The scaling of the analogue output signal depends on the selected signal. See table 124. 54 no function 55 no function 56 auto-cleaning active pump auto-cleaning...

Page 139

Parameters vacon • 136 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.5.4.1.4 ao1 m in s cale p3.5.4.1.5 ao1 m ax s cale these parameters can be used to freely adjust the analogue output signal scaling. The scale is defined in process units and it depends on the select...

Page 140

Vacon • 137 parameters 6 6.2.13 prohibit freq p3.7.1 r ange 1 l ow l im p3.7.2 r ange 1 h igh l im p3.7.3 r ange 2 l ow l im p3.7.4 r ange 2 h igh l im p3.7.5 r ange 3 l ow l im p3.7.6 r ange 3 h igh l im figure 42. Prohibited frequencies p3.7.7 r amp t ime f actor the ramp time factor defines the a...

Page 141

Parameters vacon • 138 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.14 protections p3.9.1.2 e xternal f ault an alarm message or a fault action and message is generated by an external fault external fault signal in one of the programmable digital inputs (di3 by defa...

Page 142

Vacon • 139 parameters 6 figure 45. Motor thermal time constant p3.9.2.5 m ot t herm l oadbil setting value to 130% means that the nominal temperature will be reached with 130% of motor nominal current. Figure 46. Motor temperature calculation i/i t 100% 63% t t t 907 7. Em f t = motor thermal time ...

Page 143

Parameters vacon • 140 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.9.3.2 s tall c urrent the current can be set to 0.0…2*i l . For a stall stage to occur, the current must have exceeded this limit. See figure 47. If parameter p3.1.3.1 current limit is changed, this ...

Page 144

Vacon • 141 parameters 6 figure 48. Setting of minimum load p3.9.4.4 t ime l imit this time can be set between 2.0 and 600.0 s. This is the maximum time allowed for an underload state to exist. An internal up/down counter counts the accumulated underload time. If the underload counter value goes abo...

Page 145

Parameters vacon • 142 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.15 automatic reset p3.10.1 automatic fault reset 0: disabled 1: enabled the automatic reset function deletes fault state when the fault cause has been eliminated and the wait time p10.2 has elapsed....

Page 146

Vacon • 143 parameters 6 6.2.16 feedbacks p3.13.1.9 d ead b and p3.13.1.10 d ead b and d elay the pid controller output is locked if the actual value stays within the deadband area around the reference for a predefined time. This function will prevent unnecessary movement and wear on actuators, e.G....

Page 147

Parameters vacon • 144 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.17 feedforward p3.13.4.1 f eedforward function feedforward usually needs accurate process models, but in some simple cases a gain + offset type of feedforward is enough. The feedforward part does no...

Page 148

Vacon • 145 parameters 6 6.2.18 sleep function p3.13.5.1 s leep frequency limit 1 p3.13.5.2 sp 1 s leep d elay p3.13.5.3 sp 1 w ake u p l evel this function will put the drive into sleep mode if the frequency stays below the sleep limit for a longer time than that set with the sleep delay (p3.13.5.2...

Page 149

Parameters vacon • 146 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.19 feedback superv. P3.13.6.1 e nable s uperv these parameters define the range within which the pid feedback signal value is supposed to stay in a normal situation. If the pid feedback signal goes ...

Page 150

Vacon • 147 parameters 6 6.2.20 press.Loss.Comp figure 54. Position of pressure sensor if pressurizing a long pipe with many outlets, the best place for the sensor would probably be halfway down the pipe (position 2). However, sensors might, for example, be placed directly af- ter the pump. This wil...

Page 151

Parameters vacon • 148 service support: find your nearest vacon service center at www.Vacon.Com 6 p3.13.7.1 e nable sp 1 p3.13.7.2 s etpoint 1 max compensation the sensor is placed in position 1. The pressure in the pipe will remain constant when we have no flow. However, with flow, the pressure wil...

Page 152

Vacon • 149 parameters 6 6.2.21 soft fill p3.13.8.1 e nable p3.13.8.2 s oft f ill f req p3.13.8.3 s oft f ill l evel p3.13.8.4 t imeout ti me the drive runs at the soft fill frequency (par. P3.13.8.2) until the feedback value reaches the soft fill level set parameter p3.13.8.3. After this the drive ...

Page 153

Parameters vacon • 150 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.22 auto-cleaning p3.21.1.1 c leaning function if auto-cleaning function is enabled by parameter p3.21.1.1 the auto-cleaning sequence will start by activating the digital input signal selected by par...

Page 154

Vacon • 151 parameters 6 figure 57. Auto-cleaning functionality zero frequency output frequency cleaning forward frequency cleaning reverse frequency cleaning forward time cleaning activation cleaning reverse time cleaning function cycle 1 cycle 2 cleaning cycles 9139.Emf.

Page 155

Parameters vacon • 152 service support: find your nearest vacon service center at www.Vacon.Com 6 6.2.23 solar 6.2.23.1 start settings p3.22.1.1 s tart dc v oltage start enable from solar condition needs that the dc voltage is above the threshold in p3.22.1.1 (at least for 5s). P3.22.1.2 s hort rest...

Page 156

Vacon • 153 parameters 6 mppt feed-forward parameters mpp feed-forward controller continuously changes the reference from vmp@10% to vmp@100%, according to actual motor power. The main purpose of this term is to follow vari- ation of irradiation. P3.22.2.1 v mp at 100% power p3.22.2.2 v mp at 10% po...

Page 157

Parameters vacon • 154 service support: find your nearest vacon service center at www.Vacon.Com 6 mppt correction parameters this algorithm changes the dc voltage reference, to compensate temperature variations (usu- ally slow) and to correct the error in feed-forward curve. Correction can be up to ...

Page 158

Vacon • 155 parameters 6 p&o in local max points a panel with partial irradiation, or somehow defective, could cause a discontinuity on the pow- er/voltage curve of the array. In this situation the basic p&o logic (perturb and observe) could lead to a local maximum point, that is not corresponding t...

Page 159

Parameters vacon • 156 service support: find your nearest vacon service center at www.Vacon.Com 6 mppt oscillation damping if the power regulation enters the “current source” branch of the panel current/voltage char- acteristic, the typical result is a oscillation in dc voltage and output frequency....

Page 160

Vacon • 157 parameters 6.

Page 161

Fault vacon • 158 service support: find your nearest vacon service center at www.Vacon.Com 7 7. F ault 7.1 fault tracing when an unusual operating condition is detected by the ac drive control diagnostics, the drive ini- tiates a notification visible, for example, on the keypad. The keypad will show...

Page 162

7 vacon • 159 fault 7.3 fault history in menu m4.3 fault history you find the maximum number of 40 occurred faults. On each fault in the memory you will also find additional information, see below. Figure 61. Fault history menu with graphical keypad. Figure 62. Fault history menu with text keypad. D...

Page 163

Fault vacon • 160 service support: find your nearest vacon service center at www.Vacon.Com 7 7.4 fault codes fault code fault id fault name possible cause remedy 1 1 overcurrent (hardware fault) ac drive has detected too high a cur- rent (>4*i h ) in the motor cable: • sudden heavy load increase • s...

Page 164

7 vacon • 161 fault 8 600 system fault communication between control board and power unit has failed. Reset the fault and restart. Should the fault re-occur, con- tact the distributor near to you. 601 communication between control board and power unit has interference, but it is still working. 602 w...

Page 165

Fault vacon • 162 service support: find your nearest vacon service center at www.Vacon.Com 7 11 100 output phase supervision current measurement has detected that there is no current in one motor phase. Check motor cable and motor. 12 110 brake chopper supervision (hardware fault) no brake resistor ...

Page 166

7 vacon • 163 fault 33 320 fire mode enabled fire mode of the drive is enabled. The drive's protections are not in use. Check the parameter settings 37 360 device changed (same type) option board changed for one previ- ously inserted in the same slot. The board’s parameter settings are saved. Device...

Page 167

Fault vacon • 164 service support: find your nearest vacon service center at www.Vacon.Com 7 57 1057 identification identification run has failed. Check that motor is connected to the drive. Ensure that there is no load on the motor shaft. Ensure that the start command will not be removed before com...

Page 168

7 vacon • 165 fault 101 1101 process supervi- sion fault (pid1) pid controller: feedback value outside of supervision limits (and the delay if set). Check settings. 105 1105 process supervi- sion fault (pid2) pid controller: feedback value outside of supervision limits (and the delay if set). Check ...

Page 169

Fault vacon • 166 service support: find your nearest vacon service center at www.Vacon.Com 7.

Page 170

7 vacon • 167 fault.

Page 172

Document id: rev. A manual authoring: documentation@vacon.Com vacon plc. Runsorintie 7 65380 vaasa finland subject to change without prior notice © 2014 vacon plc. Find your nearest vacon office on the internet at: www.Vacon.Com.