- DL manuals

- Vacon

- Controller

- 100X series

- Installation, Technical And Maintenance Manual

Vacon 100X series Installation, Technical And Maintenance Manual

Summary of 100X series

Page 1

Vacon ® 100 x ac drives installation, technical and maintenance manual.

Page 3

Vacon • 1 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ i ndex document code (original instructions): dpd00534j order code: doc-ins03985+dluk rev. J revision release date: 13.2.17 1. Safety.......................................................................................

Page 4

Vacon • 2 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.1.4 safe torque off (sto) terminals .......................................................................................48 5.1.5 selection of terminal functions with dip switches ....................................

Page 5

Vacon • 3 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9.6 commissioning ...............................................................................................................121 9.6.1 general wiring instructions .....................................................

Page 6

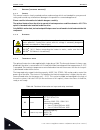

1 vacon • 4 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1. S afety this manual contains clearly marked warning information which is intended for your personal safe- ty and to avoid any unintentional damage to the product or connected appliances. Please read the wa...

Page 7

Safety vacon • 5 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 1.3 danger 1.4 warnings the components of the power unit of vacon ® 100 x drives are live when the drive is con- nected to mains potential. Coming into contact with this voltage is extremely dangerous and may...

Page 8

1 vacon • 6 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ only spare parts delivered by vacon ® can be used. At power-up or fault reset, the motor will start immediately if the start signal is active, (unless the pulse control for start/stop logic has been selected)...

Page 9

Safety vacon • 7 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 1.5 grounding and earth fault protection the vacon ® 100 x ac drive must always be earthed with a grounding conductor connected to the grounding terminal marked with . See table 16 and table 17 for the requir...

Page 10

1 vacon • 8 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 1. Earth connections and metal aglet in mm4. Figure 2. Earth connections and metal aglet in mm5. Earth connection metal aglet earth connection earth connection earth connections metal aglet earth conne...

Page 11

Safety vacon • 9 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 figure 3. Earth connections and metal aglet in mm6. However, always follow the local regulations for the minimum size of the protective grounding conductor. Note: due to the high capacitive currents present i...

Page 12

1 vacon • 10 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1.6 insulation system a distinction has to be made for the following three groups of terminals, according the insulation system of vacon ® 100 x: • mains and motor connections (l1, l2, l3, u, v, w) • relays ...

Page 13

Safety vacon • 11 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 1.7 compatibility with rcds 1.8 extended temperature range vacon ® 100 x has an integrated cooling system , independent from the motor fan. Under maxi- mum operating conditions, the ambient temperature canno...

Page 14: Eu Declaration of Conformity

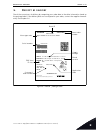

1 vacon • 12 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1.10 declaration of conformity figure 6. Declaration of conformity. Date issued by date approved by 15-04-2016 signature name: antti vuola title: head of standard drives 15-04-2016 signature name: timo kasi ...

Page 15

Safety vacon • 13 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 figure 7. Sto certificate..

Page 16

1 vacon • 14 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1.11 marine environment for installation, safety and emc requirements in a marine environment download and read the ma- rine installation guide. Note! You can download the english and french product manuals ...

Page 17

Receipt of delivery vacon • 15 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2 2. R eceipt of delivery check the correctness of delivery by comparing your order data to the drive information found on the package label. If the delivery does not correspond to your order, con...

Page 18

2 vacon • 16 receipt of delivery local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2.1 type designation code vacon ® type designation code is formed of a nine-segment code and optional +codes. Each seg- ment of the type designation code uniquely corresponds to the product and ...

Page 19

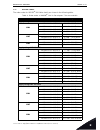

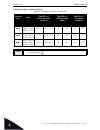

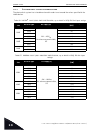

Receipt of delivery vacon • 17 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2 2.2 order codes the order codes for vacon ® 100 x drive family are shown in the following table: table 3. Order codes of vacon ® 100 x. See chapter 7 for more details. Enclosure size order code ...

Page 20

2 vacon • 18 receipt of delivery local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2.3 unpacking and lifting the ac drive the weights of the ac drives vary according to enclosure size. You may need to use a piece of special lifting equipment to move the drive from its package....

Page 21

Receipt of delivery vacon • 19 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2 2.4.2 frame mm5 2.4.3 frame mm6 table 6. Content of accessory bag, mm5. Item quantity purpose sto terminal connector 1 six pin black connector (see figure 9) to use sto function m4 x 12 din6900-...

Page 22

2 vacon • 20 receipt of delivery local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2.4.4 sto terminal connector figure 9. Sto connector. 2.4.5 ‘product modified’ sticker in the small plastic bag included in the delivery you will find a silver product modified sticker. The purp...

Page 23

Mounting vacon • 21 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 3. M ounting vacon ® 100 x is the ideal solution for a decentralised installation. It is conceived to be mounted on a wall or directly on the motor, saving space and reducing the cabling complexity. In bot...

Page 24

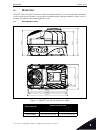

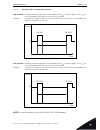

3 vacon • 22 mounting local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3.2 dimensions mm5 figure 12. Vacon ® 100 x drive dimensions, mm5. Enclosure size dimensions w x h x d [mm] [in] mm5 232.6 x 367.4 x 213.5 9.16 x 14.46 x 8.41 mm5 +hmgr 232.6 x 367.4 x 230.8 9.16 x 14.46 x...

Page 25

Mounting vacon • 23 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 3.3 dimensions mm6 figure 13. Vacon ® 100 x drive dimensions, mm6. Enclosure size dimensions w x h x d [mm] [in] mm6 349.5 x 499.8 x 235.4 13.76 x 19.68 x 9.27 mm6 +hmgr 349.5 x 499.8 x 254.2 13.76 x 19.68...

Page 26

3 vacon • 24 mounting local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3.4 introduction of modules the mechanical concept of vacon ® 100 x drive is based on two segregated parts, power and con- trol, connected to each other by pluggable terminals. The power unit, called power...

Page 27

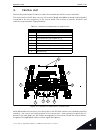

Mounting vacon • 25 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 3.5 mounting the drive consists of two main elements: 1. The terminal box that includes the power terminals and control board with the control terminals and 2. The powerhead containing all the power electr...

Page 28

3 vacon • 26 mounting local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3.5.1 wall-mounting the drive can be mounted in vertical or horizontal position on the wall or any other relatively even mounting plane or machine frame and fixed with the screws recommended in table 8. Re...

Page 29

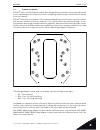

Mounting vacon • 27 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 3.6 cooling the ac drive produces heat in operation and is cooled down by air circulated by a fan. The cooling concept is independent of the motor fan. Enough free space must be left around the ac drive to...

Page 30

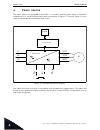

4 vacon • 28 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4. P ower cabling the mains cables are connected to terminals l1, l2 and l3 and the motor cables to terminals marked with u, v and w. See principal connection diagram in figure 17. See also table 12 f...

Page 31

Power cabling vacon • 29 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 1 = power cable intended for fixed installation and the specific mains voltage. Shielded cable not required. (mcmk or similar recommended). 2 = symmetrical power cable equipped with concentric protect...

Page 32

4 vacon • 30 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4.1 circuit breaker please disconnect the drive via an external circuit breaker. You have to provide a switching device between supply and main connection terminals. When connecting the input terminal...

Page 33

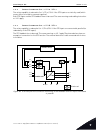

Power cabling vacon • 31 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 4.3 description of the terminals the following pictures describe the power terminals and the typical connections in vacon ® 100 x drives. Figure 19. Power connections, mm4. Table 13. Terminal descript...

Page 34

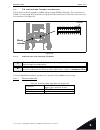

4 vacon • 32 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 20. Power connections, mm5. Table 14. Terminal description. Terminal description l1 l2 l3 these terminals are the input connections for the power supply. Dc- dc+/r+ r- dc bus terminals (dc- dc+...

Page 35

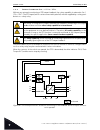

Power cabling vacon • 33 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 figure 21. Power connections, mm6. Table 15. Terminal description. Terminal description l1 l2 l3 these terminals are the input connections for the power supply. Dc- dc+/r+ r- dc bus terminals (dc- dc+...

Page 36

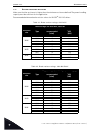

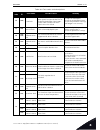

4 vacon • 34 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4.4 cable dimensioning and selection table 16 and table 17 show the minimum dimensions of the cu-cables and the corresponding fuse sizes. These instructions apply only to cases with one motor and one ...

Page 37

Power cabling vacon • 35 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 the terminal sizes are intended for 1 conductor. For mm6, the max. Diameter of the ring terminal is 14 mm. The cable dimensioning is based on the criteria of the international standard iec60364-5-52 :...

Page 38

4 vacon • 36 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4.4.2 cable and fuse sizes, frames mm4 to mm6, north america the recommended fuse type is class t (ul & csa). The fuse voltage rating must be selected accord- ing to the supply network. The final sele...

Page 39

Power cabling vacon • 37 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 for important information on the requirements of the grounding conductor, see standard underwriters’ lab- oratories ul508c. For the correction factors for each temperature, see the instructions of sta...

Page 40

4 vacon • 38 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4.5 cable installation • before starting, check that none of the components of the ac drive is live. Read carefully the warnings in chapter 1. • place the motor cables sufficiently far from other cabl...

Page 41

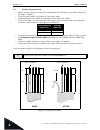

Power cabling vacon • 39 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 iec installation: figure 23. Cable entry plate, mm4. Table 18. Cables stripping lengths [mm]. Enclosure size a1 b1 c1 d1 c2 d2 e mm4 15 70 10 30 7 30 as short as possible mm5 20 70 10 40 10 40 mm6 20 ...

Page 42

4 vacon • 40 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 24.Cable entry plate, mm5. Figure 25.Cable entry plate, mm6. Figure 26.Cable gland. 4 • cable glands must be made of plastic materials. They are used for sealing cables passing through cable en...

Page 43

Power cabling vacon • 41 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 tightening torques of cable glands: ul installation: figure 27.Cable entry plate, mm4 ul installation. Table 19. Tightening torque and dimension of cable glands. Enclosure size gland screw type [metri...

Page 44

4 vacon • 42 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 28.Cable entry plate, mm5 ul installation. Figure 29.Cable entry plate, mm6 ul installation..

Page 45

Power cabling vacon • 43 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 cable installation: 7 • all the (3) terminal box openings are closed with the standard plastic plates with the metric threads. 8 • the metal cable entry plate for ul installation has to be installed i...

Page 46

4 vacon • 44 power cabling local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ tightening torques of cable terminals: table 20. Tightening torques of terminals. Enclosure size type tightening torque [nm]/[lb-in.] power and motor terminals tightening torque [nm]/[lb-in.] emc grou...

Page 47

Control unit vacon • 45 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5. C ontrol unit remove the powerhead of the drive to reveal the terminal box with the control terminals. The control unit of the ac drive consists of the control board and additional boards (option bo...

Page 48

5 vacon • 46 control unit local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ the control board can be powered externally (+24vdc, max. 1000ma, ±10%) by connecting the ex- ternal power source to terminal #30, see chapter 5.1.2. This voltage is sufficient for parameter set- ting ...

Page 49

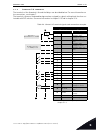

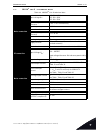

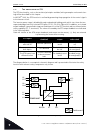

Control unit vacon • 47 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.1.2 standard i/o terminals the terminals of the standard i/os and the relays are described below. For more information on the connections, see chapter 7. The terminals shown on shadowed background ar...

Page 50

5 vacon • 48 control unit local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.1.3 relay and thermistor input terminals 5.1.4 safe torque off (sto) terminals for more information on the functionalities of the safe torque off (sto), see chapter 9. Table 24. I/o terminal signals ...

Page 51

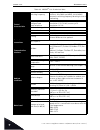

Control unit vacon • 49 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.1.5 selection of terminal functions with dip switches the vacon ® 100 x drive embodies five so-called dip switches that allow for three functional selec- tions each. The shadowed terminals in table 2...

Page 52

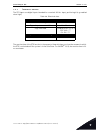

5 vacon • 50 control unit local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.1.7 bus termination of the rs485 connection this dip switch is related to the rs485 connection. It is used for bus termination. The bus termina- tion must be set to the first and to the last device o...

Page 53

Control unit vacon • 51 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.2 i/o cabling and fieldbus connection the ac drive can be connected to fieldbus either through rs485 or ethernet. The connection for rs485 is on the standard i/o terminals (a and b) and the connectio...

Page 54

5 vacon • 52 control unit local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.2.2 prepare for use through rs485 1 strip about 15 mm of the rs485 cable (see specification on page 53) and cut off the grey cable shield. Remember to do this for both bus cables (except for the last...

Page 55

Control unit vacon • 53 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.2.3 rs485 cable data table 27. Rs485 cable data. 6 the bus termination must be set for the first and the last device of the fieldbus line. See picture below and step 4. We recommend that the first de...

Page 56

5 vacon • 54 control unit local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.3 battery installation for real time clock (rtc) enabling the functions of the real time clock (rtc) requires that an optional battery is installed in the vacon ® 100 x drive. Detailed information on...

Page 57

Control unit vacon • 55 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 37. Open the cover of control box. 2 rotate and open the cover of the control box as shown in figure 37..

Page 58

5 vacon • 56 control unit local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 38. Location and connector for the battery on the control box. 3 install the battery in the correct place and connect it to the control box. See figure 38 for battery location and connector. Loc...

Page 59

Commissioning vacon • 57 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6. C ommissioning before commissioning, note the following directions and warnings: internal components and circuit boards of vacon ® 100 x drive (except for the galvan- ically isolated i/o terminals)...

Page 60

6 vacon • 58 commissioning local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.1 commissioning of the drive read carefully the safety instructions in chapter 1 and above and follow them. After the installation: check that both the ac drive and the motor are grounded. Check tha...

Page 61

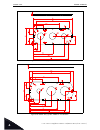

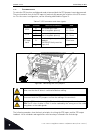

Commissioning vacon • 59 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.2 changing emc protection class if your supply network is an it (impedance-grounded) system but your ac drive is emc-protected according to class c1 or c2 you need to modify the emc protection of th...

Page 62

6 vacon • 60 commissioning local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 41. Powerhead separated from the terminal box in mm6. Figure 42.Locations of emc screws in mm6. 2 caution! Before connecting the ac drive to mains make sure that the emc protec- tion class sett...

Page 63

Commissioning vacon • 61 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.3 running the motor motor run check list 6.3.1 cable and motor insulation checks 1. Motor cable insulation checks disconnect the motor cable from terminals u, v and w of the ac drive and from the mo...

Page 64

6 vacon • 62 commissioning local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.4 maintenance in normal conditions, the ac drive is maintenance-free. However, regular maintenance is recom- mended to ensure trouble-free operation and longevity of the drive. We recommend the tabl...

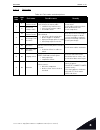

Page 65: Mm4

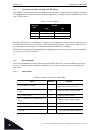

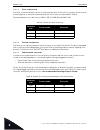

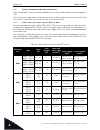

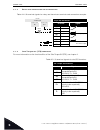

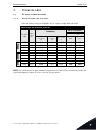

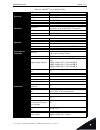

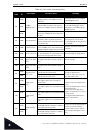

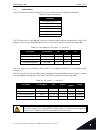

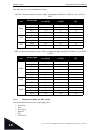

Technical data vacon • 63 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 7. T echnical data 7.1 ac drive power ratings 7.1.1 mains voltage 3ac 208-240v note: the rated currents in given ambient temperatures (in table 28) are achieved only when the switching frequency is e...

Page 66: Mm4

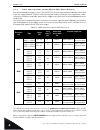

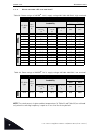

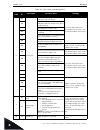

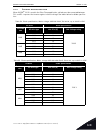

7 vacon • 64 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.1.2 mains voltage 3ac 380-480/500v note: the rated currents in given ambient temperatures (in table 29 and table 30) are achieved only when the switching frequency is equal to or less than the fact...

Page 67

Technical data vacon • 65 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 7.1.3 definitions of overloadability high overload = following continuous operation at rated output current i n , the drive supplies 150% * i n for 1 min, followed by a period of at least 9 min at i ...

Page 68

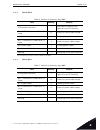

7 vacon • 66 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.2 brake resistor ratings make sure that the resistance is higher than the minimum resistance defined. The power handling capacity must be sufficient for the application. Recommended minimum brake r...

Page 69

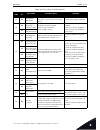

Technical data vacon • 67 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 7.3 vacon ® 100 x - technical data table 33. Vacon ® 100 x technical data. Mains connection input voltage u in 3ac 208…240v 3ac 380...480v 3ac 380...500v input voltage tolerance -15%...+10% continuou...

Page 70

7 vacon • 68 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control characteristics switching frequency programmable 1.5…16 khz; default: 6 khz (mm4 and mm5); 4 khz (mm6) automatic switching frequency derating in case of overheating frequency reference analog...

Page 71

Technical data vacon • 69 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 directives emc 2004/108/ec low voltage directive 2006/95/ec rohs 2002/95/ec weee 2012/19/ec standards immunity en61800-3 (2004), 1 st and 2 nd environment emissions en61800-3 (2004), category c2 the ...

Page 72

7 vacon • 70 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.3.1 technical information on control connections table 34. Technical information on standard i/o terminals. Standard i/o terminal signal technical information 1 reference output +10v, +3%; maximum ...

Page 73

Technical data vacon • 71 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 a rs485 differential receiver/transmitter set bus termination with dip switches (see page 49). Default: but termination disconnected. B rs485 table 35. Technical information on relay and thermistor t...

Page 74

8 vacon • 72 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8. O ptions the options available for vacon ® 100 x are described below. 8.1 mains switch the purpose of the mains switch is to disconnect the vacon ® 100 x from the mains when, for ex- ample, service actio...

Page 75

Options vacon • 73 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 47. Cable entry plate from the bottom side of the drive. Figure 48. Powerhead separated from the terminal box. 2 • remove the cable entry plate from the bottom side of the terminal box by loos- ing t...

Page 76

8 vacon • 74 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 49. Connection of the supply cable to the mains switch (right-hand-side example). 4 • connect the supply cable to the mains switch passing through the cable entry plate of the bottom side (use the ca...

Page 77

Options vacon • 75 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 50. Mains switch, cable entry and cables connected. Figure 51. Mount the powerhead on the terminal box. 8 • mount the powerhead on the terminal box with its screws: the installation pro- cess has bee...

Page 78

8 vacon • 76 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.2 control keypad the control keypad is the interface between the vacon ® 100 x ac drive and the user. With the con- trol keypad it is possible to control the speed of a motor, to supervise the state of th...

Page 79

Options vacon • 77 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.2.2 installation figure 53. Disconnection of the hmi cap from the drive. Figure 54. Installation of the keypad holder on the powerhead. 1 • remove the hmi cap from the drive as shown in the figure 53. 2 •...

Page 80

8 vacon • 78 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 55. Mounting of the keypad. Figure 56. Keypad mounted onto the drive. Tighten the fixing screws of the cable connector (to 0.5 nm or 4.5 lb-in) to the enclosure of the drive. This is to keep the high...

Page 81

Options vacon • 79 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.2.3 wall-mounting the keypad can be mounted on the wall in a convenient location by using the same keypad holder and three screws provided with the keypad option kit. Figure 57. Fix the keypad holder with...

Page 82

8 vacon • 80 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 58. Keypad connected to the drive. 2 • connect and fix the cable to the enclosure of the drive and hold the keypad to the wall..

Page 83

Options vacon • 81 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.2.4 graphical and text keypad there are two keypad types you can choose for your user interface: keypad with graphical display and keypad with text segment display (text keypad). The button section of the...

Page 84

8 vacon • 82 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.2.5 vacon ® keypad with graphical display the graphical keypad features an lcd display and 9 buttons. 8.2.5.1 keypad display the keypad display indicates the status of the motor and the drive and any irre...

Page 85: Or:

Options vacon • 83 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 61. Typical editing of values on graphical keypad (text value). Figure 62. Typical editing of values on graphical keypad (numerical value). Parameters with checkbox selection some parameters allow se...

Page 86

8 vacon • 84 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ resetting fault instructions for how to reset a fault can be found in chapter 8.2.7. Function button the funct button is used for four functions: 1. To quickly access the control page, 2. To easily change b...

Page 87

Options vacon • 85 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 64. Changing control places. Accessing the control page the control page is meant for easy operation and monitoring of the most essential values. 1. Anywhere in the menu structure, push the funct but...

Page 88

8 vacon • 86 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ changing direction rotation direction of the motor can quickly be changed by applying the funct button. Note! Chang- ing direction command is not visible in the menu unless the selected control place is loc...

Page 89

Options vacon • 87 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 copying parameters note: this feature is available with graphical keypad only. The parameter copy function can be used to copy parameters from one drive to another. The parameters are first saved to the key...

Page 90

8 vacon • 88 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ help texts the graphical keypad features instant help and information displays for various items. All parameters offer an instant help display. Select help and press the ok button. Text information is also ...

Page 91

Options vacon • 89 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.2.6 vacon ® keypad with text segment display you can also choose a keypad with text segment display (text keypad) for your user interface. It has mainly the same functionalities as the keypad with graphic...

Page 92

8 vacon • 90 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.2.6.3 using the keypad editing values change value of a parameter following the procedure below: 1. Locate the parameter. 2. Enter the edit mode by pressing ok. 3. Set new value with the arrow buttons up/...

Page 93

Options vacon • 91 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 changing control places change of control place from remote to local (keypad). 1. Anywhere in the menu structure, push the funct button. 2. Using the arrow buttons, select local/remote and confirm with the ...

Page 94

8 vacon • 92 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ changing direction rotation direction of the motor can quickly be changed by applying the funct button. Note! Chang- ing direction command is not visible in the menu unless the selected control place is loc...

Page 95

Options vacon • 93 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.2.7 fault tracing when an unusual operating condition is detected by the ac drive control diagnostics, the drive ini- tiates a notification visible, for example, on the keypad. The keypad will show the co...

Page 96

8 vacon • 94 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.2.7.1 fault history in menu m4.3 fault history you find the maximum number of 40 occurred faults. On each fault in the memory you will also find additional information, see below. Figure 75. Fault history...

Page 97

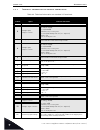

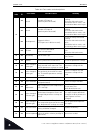

Options vacon • 95 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.2.7.2 fault codes table 36. Fault codes and descriptions. Fault code fault id fault name possible cause remedy 1 1 overcurrent (hardware fault) ac drive has detected too high a cur- rent (>4*i h ) in the ...

Page 98

8 vacon • 96 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 600 system fault communication between control board and power unit has failed. Reset the fault and restart. Should the fault re-occur, con- tact the distributor near to you. 601 communication between con...

Page 99

Options vacon • 97 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 11 100 output phase supervision current measurement has detected that there is no current in one motor phase. Check motor cable and motor. 12 110 brake chopper supervision (hardware fault) no brake resistor...

Page 100

8 vacon • 98 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 30 290 safe off unstable sto input a (spurious pulses detected). Check the safety switch and cabling. Reset the fault and restart. Should the fault re-occur, con- tact the distributor near to you. 291 safe ...

Page 101

Options vacon • 99 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 50 1050 ai low fault at least one of the available analogue input signals has gone below 50% of the defined minimum signal range. Control cable is broken or loose. Signal source has failed. Change the faile...

Page 102

8 vacon • 100 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 69 1310 fieldbus mapping error non-existing id number is used for mapping values to fieldbus process data out. Check parameters in fieldbus data mapping menu. 1311 not possible to convert one or more value...

Page 103

Options vacon • 101 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 300 700 unsupported the application is not compatible (it is unsupported). Replace the application. 701 the option board or the slot is not com- patible (it is unsupported). Remove the option board. Table ...

Page 104

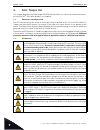

8 vacon • 102 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.3 heater (arctic option) 8.3.1 safety this manual contains clearly marked cautions and warnings which are intended for your personal safety and to avoid any unintentional damage to the product or connect...

Page 105

Options vacon • 103 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.3.4 fuses the recommended fuse types for the heater supply voltage are shown in the table below. 8.3.5 mounting instructions: mm4 example figure 77. Heater option for mm4. Table 39. Fuses ratings. Fuses ...

Page 106

8 vacon • 104 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 78. Remove the cable entry plate (right side example). Figure 79. Remove the powerhead from the terminal box..

Page 107

Options vacon • 105 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 80. Connect the supply voltage (black cable) and the output relay (red cable) to the op- tional heater through the bottom cable entry plate. Color of the cables is only an example. Figure 81. Mount ...

Page 108

8 vacon • 106 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.4 option boards vacon ® 100 x drive family embodies a wide selection of expander boards with which the available i/o of vacon ® 100 x ac drive can be increased and its versatility improved. There are two...

Page 109

Options vacon • 107 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8.5 flange adapter vacon ® 100 x is an ip66/type 4x outdoor drive, designed to be installed as close as possible to the motor, minimizing the use of electrical rooms, integrating the drive as part of the m...

Page 110

8 vacon • 108 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ table 41 shows the corresponding flange adapters for different motor sizes. See also the relations with the inverter enclosure sizes. Figure 83. Mm4 flange adapter dimensions. Table 41. Correspondences bet...

Page 111

Options vacon • 109 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 84. Mm5 flange adapter dimensions. Figure 85. Mm6 flange adapter dimensions..

Page 112

8 vacon • 110 options local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.5.1 mounting instructions: mm4 example figure 86. Flange adapter for mm4. Figure 87. Mount the flange adapter on the motor..

Page 113

Options vacon • 111 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 figure 88. Mount the drive on the flange adapter using 4 screws. Note: recommended screw type: countersunk head. Figure 89. Drive mounted onto the motor..

Page 114

9 vacon • 112 safe torque off local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9. S afe t orque o ff this chapter describes the safe torque off (sto) function which is a functional safety feature pres- ent into vacon ® 100 x drive products as standard. 9.1 general description...

Page 115

Safe torque off vacon • 113 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 9.3 standards the sto function has been designed for use in accordance with the following standards: the sto function has to be applied correctly to achieve the desired level of operational safety....

Page 116

9 vacon • 114 safe torque off local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9.4 the principle of sto the sto functionality, such as the technical principles and data (wiring examples and commission- ing) will be described in this chapter. In vacon ® 100 x, the sto function...

Page 117

Safe torque off vacon • 115 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 9.4.1 technical details the sto inputs are digital inputs intended for a nominal 24v d.C. Input, positive logic (e.G. Enabled when high). The reaction time of the sto function is the amount of time...

Page 118

9 vacon • 116 safe torque off local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9.5 connections to make the sto function available and ready to be used, both the sto jumpers have to be removed. They are located in front of the sto inputs to mechanically prevent the insertion o...

Page 119

Safe torque off vacon • 117 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 9.5.1 safety capability cat. 4 / pl e / sil 3 for this safety capability, an external safety device must be installed. This must be used to dynam- ically activate the sto inputs and to monitor the ...

Page 120

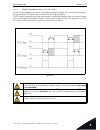

9 vacon • 118 safe torque off local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ the picture below shows an example of connection for the sto function. The external device has to be connected with 6 wires to the drive. Figure 93. Sto example with automatic monitoring of the fee...

Page 121

Safe torque off vacon • 119 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 9.5.2 safety capability cat. 3 / pl e / sil 3 the safety capability is reduced to cat. 3 / pl e / sil 3 if the sto inputs are statically used (which means they are forced to commute together). Both...

Page 122

9 vacon • 120 safe torque off local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9.5.4 safety capability cat. 1 / pl c / sil 1 without any automatic monitoring of sto output feedback, the safety capability is reduced to cat. 1 / pl c / sil 1. The sto inputs (which can be connec...

Page 123

Safe torque off vacon • 121 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 9.6 commissioning 9.6.1 general wiring instructions the wiring must be done according to the general wiring instructions for the specific product. A shielded cable is required. In addition, the vol...

Page 124

9 vacon • 122 safe torque off local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9.7 parameters and fault tracing there are no parameters for the sto function itself. To re-enable motor operation, after the sto state, it is necessary to perform the following steps: • release th...

Page 125

Solar pump application vacon • 123 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10. S olar pump application the installation instructions in this chapter are intended only for vacon ® 100 x drives with addi- tional solar pump application. 10.1 danger 10.2 warning 10.3 ...

Page 126

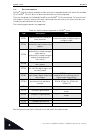

10 vacon • 124 solar pump application local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ see table below for recommended fuse sizes: 10.4 manufacturers of gpv fuses recommanded manufacturers of gpv type fuses: • littelfuse • siba • bussmann • mersen • eti • df electric table 52...

Page 127

Solar pump application vacon • 125 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10.5 parallel diode selection when vacon ® 100 x is used in the solar pump application, a diode must be connected between dc+ and dc- to protect the inverter against reverse voltage. See ta...

Page 128

10 vacon • 126 solar pump application local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.6 photovoltaic system dimensioning the photovoltaic system has to be dimensioned in order to not exceed the values specified in the tables below. Table 56. Vacon ® 100 x (208…240v 3ac 50...

Page 129

Solar pump application vacon • 127 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10.7 grounding 10.7.1 pole grounding it is prohibited to connect any pole, dc+ or dc-, of the photovoltaic system directly to pe. 10.7.2 drive grounding all non-current-carrying metal parts...

Page 130

10 vacon • 128 solar pump application local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.10 dc power connection figure 96. Example of the power connections: mm4/mm5 11742_uk 3ac pe pe pes dc switch protection diode dc fuses dc+ dc power supply dc-.

Page 131

Solar pump application vacon • 129 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 figure 97. Example of the power connections: mm6 11743_uk dc switch protection diode dc fuses 3ac pe pe dc+ dc power supply dc- pes.

Page 132

Document id: dpd00534j rev. J vacon ltd member of the danfoss group runsorintie 7 65380 vaasa finland www.Danfoss.Com.