- DL manuals

- Vega

- Radar

- VEGAPULS 68

- Operating Instructions Manual

Vega VEGAPULS 68 Operating Instructions Manual

Summary of VEGAPULS 68

Page 1

O perating i nstructions vegapuls 68 p ro fi bus pa.

Page 2: Ontents

C ontents 1 a bout this document 1 . 1 f unction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1 . 2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1 . 3 s ymbolism used . . . . . . . . . . . . . . . . . . . . . . . 5 2 f or your safety 2 . 1 a uthorised personnel ...

Page 3

6 . 4 s etup procedure . . . . . . . . . . . . . . . . . . . . . . . 39 6 . 5 m enu schematic . . . . . . . . . . . . . . . . . . . . . . . 45 6 . 6 s aving the parameter adjustment data . . . . . . . 47 7 s etup with pact ware ™ and other adjustment programs 7 . 1 c onnecting the pc . . . . . . . ....

Page 4

S upplementary operating instructions manuals i nformation : vegapuls 68 is available in many versions and is therefore supplied according to customer order . D epending on the selected version , supplementary operating instructions man - uals also come with the delivery . Y ou will fi nd the supple ...

Page 5: Bout This Document

1 a bout this document 1 . 1 f unction t his operating instructions manual has all the information you need for quick setup and safe operation . P lease read this manual before you start setup . 1 . 2 t arget group t his operating instructions manual is directed to trained , quali fi ed personnel . T...

Page 6: Or Your Safety

2 f or your safety 2 . 1 a uthorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator . F or safety and warranty reasons , any internal work on the instruments must be carried out only by per...

Page 7

- e mission en 61326 : 1997 ( class b ) - s usceptibility en 61326 : 1997 / a 1 : 1998 l r & tte directive : i - ets 300 - 440 e xpert o pinion n o . 05 - 111723 , n oti fi ed b ody n o . 0700 l lvd : en 61010 - 1 : 2001 2 . 6 f ul fi lling namur recommendations w ith regard to interference resistance...

Page 8

L t he instrument must not cause any interfering emissions l t he instrument must be insensitive to interfering emis - sions , also to such that may cause unwanted operating conditions . 2 . 8 s afety instructions for e x areas p lease note the e x - speci fi c safety information for installation and...

Page 9

L m ake sure that the cable gland is tight and strain - relieved . T he outer diameter of the connection cable must be adapted to the cable gland . T ighten the pressure screw of the cable gland carefully . L c over unused openings for cable glands tightly l m ount the instrument in such a way that ...

Page 10: Roduct Description

3 p roduct description 3 . 1 c on fi guration t he scope of delivery encompasses : l vegapuls 68 radar sensor l d ocumentation - this operating instructions manual - o perating instructions manual " i ndicating and adjust - ment module plicscom " ( optional ) - s upplementary instructions manual " h ...

Page 11

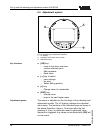

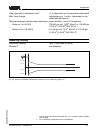

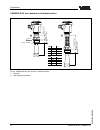

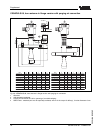

1 2 3 4 f ig . 1 : vegapuls 68 with horn antenna and swivelling holder 1 h ousing cover with integrated plicscom ( optional ) 2 h ousing with electronics 3 s wivelling holder with fl ange 4 h orn antenna 3 . 2 p rinciple of operation vegapuls 68 is a radar sensor in k - band technology for continuous...

Page 12

Proportional to the distance and hence to the level . T he determined level is converted into an appropriate output signal and outputted as measured value . P ower supply via the p ro fi bus dp / pa segment coupler or vegalog 571 ep cards . A two - wire cable according to p ro fi bus speci fi cation se...

Page 13

T he entered parameters are generally saved in vegapuls 68 , optionally also in the indicating and adjustment module or in pact ware ™ . 3 . 4 s torage and transport y our instrument was protected by packaging during transport . I ts capacity to handle normal loads during transport is assured by a t...

Page 14: Ount

4 m ount 4 . 1 g eneral instructions s elect an installation position you can easily reach for mounting and connecting as well as later retro fi tting of an indicating and adjustment module . T he housing can be rotated by 330 ° without the use of any tools . Y ou can also install the indicating and ...

Page 15

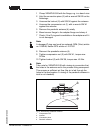

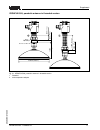

1 3 2 100% 0% 4 f ig . 3 : m easuring range ( operating range ), max . Measuring distance and reference plane 1 full 2 empty ( max . Measuring distance ) 3 m easuring range 4 r eference plane i nformation : i f the medium reaches the antenna , buildup can form on it and cause faulty measurements lat...

Page 16

N ote : t he plastic conemust not be pulled out of the antenna socket . 3 i nsert the antenna from below into the vessel socket and secure it against falling o ff 4 r etighten the antenna with hexagon screws to the antenna socket ; torque max . 10 n m ( 7 . 5 lbf ft ) n ote : vegapuls 68 with rinsing...

Page 17

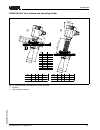

1 c lamp vegapuls 68 with the fl ange , e . G . In a bench vice 2 h old the connection piece ( 3 ) with a wrench sw 22 on the fl attenings 3 u nscrew the locknut ( 2 ) with sw 36 against the antenna 4 u nscrew the compression nut ( 1 ) with a wrench sw 41 against the antenna 5 r emove the parabolic an...

Page 18

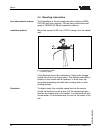

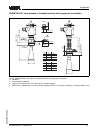

4 . 4 m ounting instructions t he illustrations in the mounting instructions show a vega - puls 68 with horn antenna . T he mounting instructions also apply to vegapuls 68 with parabolic antenna . M ount the sensor at 200 mm ( 7 . 874 in ) away from the vessel wall . 1 2 f ig . 6 : i nstallation pos...

Page 19

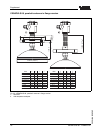

F ig . 7 : o rientation i f mounting in the center of the silo is not possible , the sensor can be directed to the vessel center by means of an optional swivelling holder . T he following description gives an overview on the determination of the necessary angle of inclination . Vegapuls 68 - p ro fi ...

Page 20

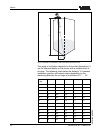

D a α f ig . 8 : p roposal for installation after orientation vegapuls 68 t he angle of inclination depends on the vessel dimensions . I t can be checked easily on the sensor with a suitable level or air - lever . T he following chart states the distance " a " between installation position and vesse...

Page 21

D istance d ( m ) 2 ° 4 ° 6 ° 8 ° 10 ° 50 1 . 7 3 . 5 5 . 3 7 . 0 8 . 8 55 1 . 9 3 . 8 5 . 8 7 . 7 9 . 7 60 2 . 1 4 . 2 6 . 3 8 . 4 10 . 6 65 2 . 3 4 . 5 6 . 8 9 . 1 11 . 5 70 2 . 4 4 . 9 7 . 4 9 . 8 12 . 3 e xample : i n a vessel with 20 m height , the installation position of the sensor is 1 . 4 m...

Page 22

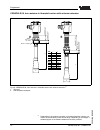

F ig . 9 : i n fl owing medium s ocket pieces should be dimensioned such that the antenna end protrudes at least 10 mm ( 0 . 4 in ) out of the socket . Ca. 10 mm f ig . 10 : r ecommended socket mounting i f the re fl ective properties of the medium are good , you can mount vegapuls 68 on sockets which...

Page 23

D h max. D 1½" 50 mm/2" 80 mm/3" 100 mm/4" 150 mm/6" 200 mm 250 mm 300 mm 500 mm 800 mm h max. F ig . 11 : d eviating socket dimensions t ip : vegapuls 68 is optionally also available with antenna extension . H ence the antenna length can be selected such that the antenna end protrudes 10 mm ( 0 . 4...

Page 24

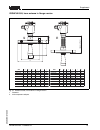

F ig . 12 : i nstallation of vegapuls 68 in multiple chamber silos f ig . 13 : o rientation of vegapuls 68 for emptying in the silo center s ilo installations such as e . G . Ladders , level switches , struts , and also structured vessel walls , can cause false echoes that get superimposed on the us...

Page 25

Cross the microwave signals . M ake sure when planning your measurement loop that the radar signals have a " clear view " to the product . I f there are existing vessel installations , a false signal storage should be carried out during setup . I f large vessel installations such as struts or suppor...

Page 26

F ig . 16 : p urging air connection with parabolic antenna i n practice it was shown that a pressure of approx . 0 . 2 … 1 bar is enough to provide a su ffi cient air fl ow ( see diaphragm in chapter " t echnical data " ). L arge material heaps are detected with several sensors , which can be mounted o...

Page 27

5 c onnecting to voltage supply 5 . 1 p reparing the connection a lways keep in mind the following safety instructions : l c onnect only in the complete absence of line voltage l i f overvoltage surges are expected , overvoltage arresters should be installed according to p ro fi bus speci fi cation i ...

Page 28

Must be connected directly to the internal ground terminal . T he ground terminal outside on the housing must be connected to the potential equalisation ( low impedance ). I n systems without potential equalisation , connect the cable screen directly to ground potential at the power supply unit and ...

Page 29

F ig . 18 : c onnection steps 6 and 7 8 p ress down the opening levers of the terminals , you will hear the terminal spring closing 9 c heck the hold of the wires in the terminals by lightly pulling on them 10 c onnect the screen to the internal ground terminal and the external ground terminal to po...

Page 30

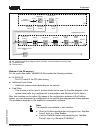

1 4 4 4 2 3 f ig . 19 : m aterial versions , single chamber housing 1 p lastic 2 a luminium 3 s tainless steel 4 f ilter element for air pressure compensation of all material versions . B lind stopper with version ip 66 / ip 68 , 1 bar for a luminium and stainless steel i2c display 1 2 5 6 7 8 3 4 1...

Page 31

I2c display 1 1 2 5 6 7 8 f ig . 21 : w iring plan , single chamber housing 1 v oltage supply / s ignal output 5 . 4 w iring plan , double chamber housing t he following illustrations apply to the non - e x as well as to the e x ia version . 1 2 3 4 5 f ig . 22 : d ouble chamber housing 1 h ousing c...

Page 32

1 3 2 display 1 2 5 6 7 8 i2c f ig . 23 : e lectronics compartment , double chamber housing 1 p lug connector for vegaconnect ( i ² c interface ) 2 i nternal connection cable to the connection compartment 3 t erminals for vegadis 61 3 1 2 display 1 2 i²c f ig . 24 : c onnection compartment , double ...

Page 33

I2c 1 1 2 f ig . 25 : w iring plan , double chamber housing 1 v oltage supply / s ignal output 5 . 5 w iring plan , double chamber housing e xd i nformation : i nstruments in e xd version with hardware revision …- 01 or higher as well as with national approvals such as e . G . According to fm or csa...

Page 34

1 3 2 display 1 2 5 6 7 8 i2c f ig . 27 : e lectronics compartment , double chamber housing 1 p lug connector for vegaconnect ( i ² c interface ) 2 i nternal connection cable to the connection compartment 3 t erminals for vegadis 61 1 2 1 2 f ig . 28 : c onnection compartment , double chamber housin...

Page 35

1 1 2 f ig . 29 : w iring plan , double chamber housing e xd 1 v oltage supply / s ignal output 5 . 6 w iring plan , version ip 66 / ip 68 , 1 bar + - 1 2 f ig . 30 : w ire assignment , connection cable 1 brown ( + ) and blue (-) to power supply or to the processing system 2 s creen 5 . 7 s witch - ...

Page 36: Adjustment Module

6 s et up with the indicating and adjustment module plicscom 6 . 1 s hort description t he indicating and adjustment module is used for measured value display , adjustment and diagnosis . I t can be mounted in the following housing versions and instruments : l a ll sensors of the plics ® instrument ...

Page 37

R emoval is carried out in reverse order . T he indicating / adjustment module is powered by the sensor , an additional connection is not necessary . F ig . 31 : i nstallation of the indicating and adjustment module n ote : i f you intend to retro fi t vegapuls 68 with an indicating and adjustment mo...

Page 38

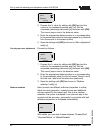

6 . 3 a djustment system 1.1 2 3 1 f ig . 32 : i ndicating and adjustment elements 1 lc display 2 i ndication of the menu item number 3 a djustment keys l [ ok ] key : - move to the menu overview - con fi rm selected menu - e dit parameter - s ave value l [- > ] key to select : - menu change - list e...

Page 39

6 . 4 s etup procedure b efore starting the actual parameter adjustment of a p ro fi bus pa sensor , the address setting must fi rst be carried out . Y ou will fi nd a detailed description in the operating instructions manual of the indicating and adjustment module or in the online help of pact ware ™ ...

Page 40

M in . Adjustment 0 . 00 % = 5 , 000 m ( d ) 4 , 000 m ( d ) 3 p repare the % value for editing with [ ok ] and set the cursor to the requested position with [- > ] . S et the requested percentage value with [ + ] and save with [ ok ] . T he cursor jumps now to the distance value . 4 e nter the appr...

Page 41

I n liquids , fl uctuating surfaces and foam generation are further interfering factors . T o adapt the sensor to the di ff erent conditions , a general selection is made in this menu item , i . E . " s olid " or " l iquid " . E nter the requested parameter via the appropriate keys , save your setting...

Page 42

Measurement . T o detect these over the complete measuring range , the gating our of false signals should be carried out with empty vessel . I nformation : h owever , the measuring signals are not damped by the product in completely empty , closed metal vessels . D ue to this , considerable multiple...

Page 43

N ote : s ince with the function " q uick level change > 1 m / min . " the generation of an averafy value of the signal processing is considerably reduced , false re fl ections by agitators or vessel installations can cause measured value fl uctuations . A false echo memory is thus recommended . T his...

Page 44

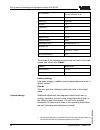

M in . Adjustment 15 m ( d ) ( vegapuls 67 ) 70 m ( d ) ( vegapuls 68 ) m edium s olid v essel form not known d amping 0 s l inearization linear c hannel pv lin . % s ensor - tag s ensor d isplayed value pa - o ut e xtended settings k eine a dditional pa value s econdary v alue 1 % o ut - s cale - u...

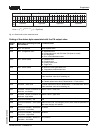

Page 45

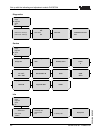

6 . 5 m enu schematic i nformation : d epending on the version and application , the highlighted menu windows are not always available . B asic adjustment 1 ▶ b asic adjustment d isplay d iagnostics s ervice i nfo 1 . 1 s ensor address 000 1 . 2 m in . Adjustment 000 . 0 % = 10 . 000 m ( d ) 1 . 245...

Page 46

D iagnostics 3 b asic adjustment d isplay ▶ d iagnostics s ervice i nfo 3 . 1 p ointer d istance min .: 0 . 234 m ( d ) d istance max .: 5 . 385 m ( d ) 3 . 2 m eas . Reliability 8 db s ensor status ok 3 . 3 c urve selection e cho curve 3 . 4 e cho curve p resentation of the echo curve s ervice 4 b ...

Page 47

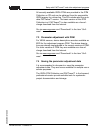

6 . 6 s aving the parameter adjustment data i t is recommended noting the adjusted data , e . G . In this operating instructions manual and archive them afterwards . T hey are hence available for multiple use or service purposes . I f vegapuls 68 is equipped with an indicating and adjust - ment modu...

Page 48: Etup With

7 s etup with pact ware ™ and other adjustment programs 7 . 1 c onnecting the pc ~ = power supply vegaconnect 3 pactware / tm >pa 2 3 1 f ig . 33 : c onnection directly to the sensor 1 rs 232 connection 2 vegapuls 68 3 i ² c adapter cable for vegaconnect 3 n ecessary components : l vegapuls 68 l pc ...

Page 49

A ll currently available vega dtm s are provided in the dtm c ollection on cd and can be obtained from the responsible vega agency for a token fee . T his cd includes also the up - to - date pact ware ™ version . T he basic version of this dtm c ollection incl . Pact ware ™ is also available as a fr...

Page 50: fi

8 m aintenance and fault recti fi cation 8 . 1 m aintenance w hen used as directed in normal operation , vegapuls 68 is completely maintenance free . I n some applications , builup on the antenna system can in fl uence the measuring result . D epending on the sensor and application , make arrangements...

Page 51

? W rong presentation of the measured value in s imatic s 5 l s imatic s 5 cannot interpret the number format ieee of the measured value à i nsert converting component from s iemens ? I n s imatic s 7 the measured value is always presented as 0 l o nly four bytes are consistently loaded in the plc à...

Page 52

à sensor does not fi nd an echo , e . G . Because of faulty installation or incorrect parameter adjustment ? E 017 l a djustment span too small à c arry out a fresh adjustment and increase the distance between min . And max . Adjustment ? E 036 l no operable sensor software à c arry out a software up...

Page 53

I nformation : w hen loading on site , the order data must be downloaded from the i nternet ( see o perating i nstructions manual " o scillator " ). T he oscillators are adapted to the respective sensor and di ff er in their signal output or in their power supply . Y ou can fi nd a suitable oscillator...

Page 54: Ismounting

9 d ismounting 9 . 1 d ismounting steps w arning : b efore dismounting , be aware of dangerous process con - ditions such as e . G . Pressure in the vessel , high temperatures , corrosive or toxic products etc . T ake note of chapters " m ounting " and " c onnecting to power supply " and carry out t...

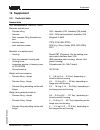

Page 55: Upplement

10 s upplement 10 . 1 t echnical data g eneral data 316 l corresponds to 1 . 4404 or 1 . 4435 m aterials , wetted parts - p rocess fi tting 316 l , h astelloy c 22 , h astelloy c 22 plated - a ntenna 316 l , 316 l electropolished , h astelloy c 22 - s eal , process fi tting threaded ver - sion k linge...

Page 56

O utput variable o utput signal digital output signal , format according to ieee - 754 s ensor address 126 ( default setting ) c urrent value 10 m a , ± 0 . 5 m a i ntegration time ( 63 % of the input variable ) 0 … 999 s , adjustable s tep response or adjustment time ≤ 250 ms ( ti : 0 s , 10 … 90 %...

Page 57

S tep response or adjustment time 7 ) > 1 s ( dependent on the parameter adjustment ) m ax . Level change adjustable up to 1 m / min . ( dependent on the parameter adjustment ) r eceived average emitted power reaching an object directly in front of the antenna - d istance 1 m ( 3 . 28 ft ) 108 n w p...

Page 58

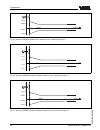

3.280 ft 229.7 ft 1.180 in 0.590 in - 0.590 in - 1.180 in f ig . 35 : a ccuracy vegapuls 68 with horn antenna in i nch , measuring range in ft 2,0 m 70 m 40 mm 15 mm -15 mm -40 mm f ig . 36 : a ccuracy vegapuls 68 with parabolic antenna in mm , measuring range in m 6.562 ft 229.7 ft 1.574 in 0.590 i...

Page 59

I n fl uence of the ambient temperature to the sensor electronics 9 ) a verage temperature coe ffi cient of the zero signal ( temperature error ) 0 . 03 % / 10 k a mbient conditions a mbient , storage and transport tem - perature - 40 … + 80 ° c (- 40 … + 176 ° f ) p rocess conditions p rocess temperat...

Page 60

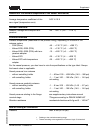

A ir quantity see diagram 0,1 0,0 1,0 2,0 3,0 4,0 5,0 6,0 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 1,9 2,0 (bar) (m 3 /h) f ig . 38 : a ir quantity diagram t hread g ⅛ a c atch - with non - e x d ust protection cover of pe - with e x t hreaded plug of 316 t i r e fl ux valv...

Page 61

E lectromechanical data - version ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar c able entry / plug 11 ) - s ingle chamber housing l 1 x cable entry m 20 x 1 . 5 ( cable - ø 5 … 9 mm ), 1 x blind stopper m 20 x 1 . 5 or : l 1 x cloasing cap m 20 x 1 . 5 , 1 x blind stopper m 20 x 1 . 5 or : l 1 x clos...

Page 62

- m ax . Length 1000 m ( 3280 ft ) - m in . Bending radius 25 mm ( 1 in ) at 25 ° c ( 77 ° f ) - d iameter approx . 8 mm ( 0 . 315 in ) - c olour - standard pe b lack - c olour - standard pur b lue - c olour - e x - version b lue i ndicating and adjustment module p ower supply and data transmission ...

Page 63

E lectrical protective measures p rotection - p lastic housing ip 66 / ip 67 - a lu and stainless steel standard ip 66 / ip 68 ( 0 . 2 bar ) 12 ) - a lu and stainless housing ( optionally available ) ip 66 / ip 68 ( 1 bar ) o vervoltage category iii p rotection class ii a pprovals 13 ) 14 ) atex ia ...

Page 64

10 . 2 p ro fi bus pa i nstrument master fi le t he instrument master fi le ( gsd ) contains the characteristic data of the p ro fi bus pa instrument . T hese data are , e . G . The permissible transmission rates as well as information on diagnostics values and the format of the measured value outputted...

Page 65

M(d) % lin% min-max adjustment linearization profibus pa-output primary value secondary value 2 secondary value 1 target mode failure mode alarms scaling source for scaling t i integration sensor characteristics pa-out tb fb select additional cyclic value f ig . 39 : vegapuls 68 : b lock diagram wit...

Page 66

E xamples of telegram con fi guration i n the following you will see how the modules can be combined and how the appendant data telegram is structured . E xample 1 ( standard setting ) with distance value and additional cyclical value : l ai ( pa - out ) l a dditional c yclic v alue byte-no. 1 2 3 4 ...

Page 67

Byte n byte n+1 bit 7 vz exponent bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bit 0 2 bit 7 2 bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bit 0 2 sign bit significant 7 6 5 4 3 2 1 0 -1 -2 -3 -4 -5 -6 -7 byte n+2 byte n+3 bit 7 2 significant bit 6 2 bit 5 2 bit 4 2 bit 3 2 bit 2 2 bit 1 2 bi...

Page 68

S tatus code d escription according to p ro fi - bus standard p ossible cause 0 x 8 e good ( non - cascade ) - active crit - ical alarm - high limited h i - h i - a larm s upplement 68 vegapuls 68 - p ro fi bus pa 29263 - en - 070305.

Page 69

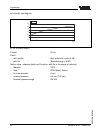

10 . 3 d imensions h ousing in protection ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar 112mm (4 13 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") 120mm (4 23 / 32 ") ~ 69mm (2 23 / 32 ") ø 77mm (3 1 / 32 ") ~ 69mm (2 23 / 32 ") ~ 116mm (4 9 / 16 ") ~ 87mm (3 27 / 64 ") ø 77mm (3 1 / 32 ") ø 84mm (3 5...

Page 70

Vegapuls 68 , horn antenna in threaded version mm inch 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ") 118mm (4 41 / 64 ") 46mm (1 13 / 16 ") 3 15 / 16 " ø1 37 / 64 " ø1 57 / 64 " ø2 61 / 64 " ø3 47 / 64 " 4 23 / 32 " 8 1 / 2 " 16 59 / 64 " x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1...

Page 71

Vegapuls 68 , horn antenna in threaded version with purging air connection mm inch 3 15 / 16 " 4 23 / 32 " 8 1 / 2 " 16 59 / 64 " ø1 37 / 64 " ø1 57 / 64 " ø2 61 / 64 " ø3 47 / 64 " x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1½" 2" 3" 4" 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ")...

Page 72

Vegapuls 68 , horn antenna in threaded version with antenna extension mm inch 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ") 118mm (4 41 / 64 ") 7 7 / 8 " ø1 37 / 64 " ø1 57 / 64 " ø2 61 / 64 " ø3 47 / 64 " 8 21 / 32 " 12 7 / 16 " 20 55 / 64 " 46mm (1 13 / 16 ") x y g1½a / 1½ npt x y > 200 ø40...

Page 73

Vegapuls 68 , horn antenna in fl ange version 60mm (2 23 / 64 ") 140mm (5 33 / 64 ") 4xø 3 / 4 " 4xø 3 / 4 " 8xø 55 / 64 " 8xø 3 / 4 " 8xø 7 / 8 " 4xø 45 / 64 " 8xø 45 / 64 " 8xø 45 / 64 " 4 3 / 4 " 4 59 / 64 " 6 19 / 64 " 2 61 / 64 " 3 47 / 64 " 3 47 / 64 " 16 59 / 64 " 16 59 / 64 " 1 57 / 64 " 4 23...

Page 74

Vegapuls 68 , horn antenna in fl ange version with purging air connection d k x d b y 1 2 140mm (5 33 / 64 ") 4xø 3 / 4 " 4xø 3 / 4 " 8xø 55 / 64 " 8xø 3 / 4 " 8xø 7 / 8 " 4xø 45 / 64 " 8xø 45 / 64 " 8xø 45 / 64 " 4 3 / 4 " 4 59 / 64 " 6 19 / 64 " 2 61 / 64 " 3 47 / 64 " 3 47 / 64 " 16 59 / 64 " 16 5...

Page 75

Vegapuls 68 , horn antenna and swivelling holder mm inch d mm b k d dn 50 / 2" 165 11,5 122,8 4xø19 dn 80 / 3" 200 11,5 156,2 4xø21 dn 100 / 4" 220 11,5 182,5 4xø22 d inch b k d dn 50 / 2" dn 80 / 3" dn 100 / 4" 120mm (4 2 3 / 3 2 ") 20 mm ( 2 5 / 3 2 ") 20mm ( 2 5 / 3 2 ") 6 1 / 2 " 4 53 / 64 " 4xø...

Page 76

Vegapuls 68 , horn antenna , swivelling holder and rinsing air connection d mm b k d dn 50 / 2" 165 11,5 122,8 4xø19 dn 80 / 3" 200 11,5 156,2 4xø21 dn 100 / 4" 220 11,5 182,5 4xø22 d inch b k d dn 50 / 2" dn 80 / 3" dn 100 / 4" mm inch 8 1 / 2 " 16 59 / 64 " 3 15 / 16 " ø1 37 / 64 " ø1 57 / 64 " ø2...

Page 77

Vegapuls 68 , parabolic antenna in threaded version 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ") 118mm (4 41 / 64 ") 138mm (5 7 / 16 ") ø 244mm (9 39 / 64 ") 46mm (1 13 / 16 ") g1½a / 1½ npt 2 1 f ig . 51 : vegapuls 68 , parabolic antenna in threaded version 1 s tandard 2 with temperature ad...

Page 78

Vegapuls 68 , parabolic antenna in fl ange version d mm b k d dn 50 pn 40 165 20 125 4xø18 dn 80 pn 40 200 24 160 8xø18 dn 100 pn 16 220 20 180 8xø18 dn 150 pn 16 285 22 240 8xø22 2" 150 lb 152,4 19,1 120,7 4xø19,1 3" 150 lb 190,5 23,9 152,4 4xø19,1 4" 150 lb 228,6 23,9 190,5 8xø19,1 6" 150 lb 279,4 ...

Page 79

Vegapuls 68 , parabolic antenna and swivelling holder d d mm b k d dn 50 / 2" 165 11,5 122,8 4xø19 dn 80 / 3" 200 11,5 156,2 4xø21 dn 100 / 4" 220 11,5 182,5 4xø22 d inch b k d dn 50 / 2" dn 80 / 3" dn 100 / 4" 6 1 / 2 " 4 53 / 64 " 4xø 3 / 4 " 4xø 53 / 64 " 8xø 55 / 64 " 6 5 / 32 " 7 3 / 16 " 29 / ...

Page 80

Vegapuls 68 , parabolic antenna and swivelling holder with purging air connection d d mm b k d dn 50 / 2" 165 11,5 122,8 4xø19 dn 80 / 3" 200 11,5 156,2 4xø21 dn 100 / 4" 220 11,5 182,5 4xø22 d inch b k d dn 50 / 2" dn 80 / 3" dn 100 / 4" 6 1 / 2 " 4 53 / 64 " 4xø 3 / 4 " 4xø 53 / 64 " 8xø 55 / 64 "...

Page 81

10 . 4 i ndustrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit gesch ü tzt durch gewerbliche schutzr...

Page 82

S upplement 82 vegapuls 68 - p ro fi bus pa 29263 - en - 070305.

Page 83

S upplement vegapuls 68 - p ro fi bus pa 83 29263 - en - 070305.

Page 84

Vega g rieshaber kg a m h ohenstein 113 77761 s chiltach g ermany p hone + 49 7836 50 - 0 f ax + 49 7836 50 - 201 e - mail : info @ de . Vega . Com www . Vega . Com iso 9001 a ll statements concerning scope of delivery , application , practical use and operating conditions of the sensors and process...