- DL manuals

- Vega

- Switch

- VEGASWING 61

- Operating Instructions Manual

Vega VEGASWING 61 Operating Instructions Manual

Summary of VEGASWING 61

Page 1

Operating instructions vegaswing 61, 63 with oscillator sw e60n (ex).

Page 2

2 vegaswing 61, 63 - n 25470-en-030707 contents contents safety information ........................................................................ 2 note ex area ................................................................................ 2 1 product description ..................................

Page 3: 1 Product Description

Vegaswing 61, 63 - n 3 25470-en-030707 product description 1 product description vegaswing 61 and 63 vegaswing 61/63 vibrating level switches are used for level detection of liquids. Typical applications are overfill and dry run protection. Using a tuning fork with a length of only 40 mm, vegaswing ...

Page 4: 2 Function and Application

4 vegaswing 61, 63 - n 25470-en-030707 function and application 2 function and application 2.1 principle of operation vegaswing vibrating level switches detect levels in almost all liquids. Viscosity: 0.1 ... 10.000 mpa s density: 0.5 ... 2.5 g/cm 3 vegaswing measuring principle the tuning fork is p...

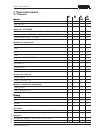

Page 5: 3 Types and Versions

Vegaswing 61, 63 - n 5 25470-en-030707 3 types and versions 3.1 overview 61 61 61 61 61 63 63 63 63 63 61 61 61 61 61 63 63 63 63 63 v v v v version ersion ersion ersion ersion exd exd exd exd exd exd exd exd exd exd standard (fixed installation length) • • tube version • • approvals (sw e60n) ex-zo...

Page 6

6 vegaswing 61, 63 - n 25470-en-030707 3.2 technical data vegaswing 61 and 63 housing housing material pbt (polyester), aluminium (plastic coated) protection ip 66 and ip 67 (meets both requirements) cable entry 2 x m20 x 1.5 or 2 x ½ npt terminals max. 1 x 1.5 mm 2 adapters gastight leadthrough (op...

Page 7

Vegaswing 61, 63 - n 7 25470-en-030707 types and versions tuning fork material 1.4435 (316 l), 2.4610 (hastelloy c4), 2.4610 hastelloy c4 enamelled, 1.4435 (316 l) with ectfe or pfa coating coating thicknesses - ectfe approx. 0.5 … 0.8 mm - pfa approx. 0.3 … 0.5 mm - enamel approx. 0.8 mm high volta...

Page 8

8 vegaswing 61, 63 - n 25470-en-030707 types and versions function modes min. Rising characteristics (high current with submersion) max. Falling characteristics (low current with submersion) namur output switchable to falling or rising characteristics integration time approx. 500 ms frequency approx...

Page 9

Vegaswing 61, 63 - n 9 25470-en-030707 approvals vegaswing 61 and 63 water resources law (whg) approval as part of an overfill protection system acc. To the water resources law (whg) ambient temperature on the housing -40°c … 70°c process temperature -50°c … 150°c - test report vegaswing 61 ex and 6...

Page 10

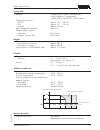

10 vegaswing 61, 63 - n 25470-en-030707 3.3 dimensions vegaswing 61 types and versions ø 34 156 55 58 53 50 5 3 3 7 26 sw32 21,3 40 66 16 53 36 13 ø 77 ~ 69 112 (*123 ) () 20x1,5 ø 84 ~ 116 112 (*123 ) () ~ 69 112 (*123) () ø 77 ½ npt ½ m20x1,5 ½ npt conus dn 25 bolting dn 40 flange dn 25 pn 40 thre...

Page 11

Vegaswing 61, 63 - n 11 25470-en-030707 types and versions vegaswing 63 sw32 ø 21,3 40 16 36 l ( min. 150, max. 3000 ) 58 50 3 7 ø 77 ~ 69 112 (*1 2 ( 20x1,5 ø 84 ~ 116 112 (*123 ) () ~ 69 112 (*123 ) () ø 77 ø 34 156 13 26 ½ ½ npt m20x1 ½ npt temperature adapter of 1.4435 (316 l) (option) in conjun...

Page 12: 4 Mounting

12 vegaswing 61, 63 - n 25470-en-030707 mounting 4 mounting 4.1 vegaswing in principle, vegaswing can be mounted in any position. The instrument must be mounted such that the tuning fork is at the height of the required switching point. Note the following installation instructions. Transport do not ...

Page 13

Vegaswing 61, 63 - n 13 25470-en-030707 mounting fig. 2.3 adhesive products in case of horizontal mounting in adhesive and viscous products, the surfaces of the tuning fork should be vertical in order to reduce buildup on the tuning fork (see fig. 2.2). The orientation of the tuning fork is marked b...

Page 14

14 vegaswing 61, 63 - n 25470-en-030707 mounting fig. 2.5 fig. 2.4 moisture turn the cable entries of horizontally mounted instruments downwards to avoid moisture in- gress. For this purpose the plastic housing can be rotated by approx. 330°. For vertically installed instruments, loop the cable con-...

Page 15

Vegaswing 61, 63 - n 15 25470-en-030707 fig. 2.6 marking mounting mounting boss vegaswing’s thread starting point is de- fined. This means that every vegaswing is in the same position after being screwed in. Remove therefore the supplied seal from the thread of vegaswing. This seal is not re- quired...

Page 16: 5 Electrical Connection

16 vegaswing 61, 63 - n 25470-en-030707 5 electrical connection 5.1 vegaswing 61 and 63 note switch off the power supply before starting connection work. Connect supply voltage according to the following wiring diagrams. As a rule, connect vegaswing to vessel ground (pa) or, in plastic vessels, to t...

Page 17: 6 Set-Up

Vegaswing 61, 63 - n 17 25470-en-030707 6 set-up 6.1 vegaswing 61 and 63 the numbers in brackets relate to the follow- ing illustration. Display and adjustment elements the switching status of the electronics can be checked when the housing is closed (led display). In basic adjustment, products with...

Page 18

18 vegaswing 61, 63 - n 25470-en-030707 set-up 1 2 s im ul. 1 2 3 4 sw e60n ex n a m u r ( i e c 6 0 9 4 7 - 5 - 6 ) + 1 2 0,5 g / cm3 min. Simul. 0,7 g / cm3 max. Simulation key (4) the simulation key is lowered in the upper side of the oscillator. Press the simulation key with a suitable object (s...

Page 19

Vegaswing 61, 63 - n 19 25470-en-030707 set-up 6.2 function chart the following chart provides an overview of the switching conditions depending on the ad- justed mode and level. Level signal control current lamp vega- (red) swing falling character- istics max. ≥ 2.2 ma ≤ 1.0 ma rising character- is...

Page 20

Iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing sys- tems correspond to the latest information at the time of printing. Technical data subject to alterations vega grieshaber kg am hohenstein 113 d-77761 schiltach...