- DL manuals

- Xerox

- Printer

- DocuColor 1632

- Service Manual

Xerox DocuColor 1632 Service Manual

Summary of DocuColor 1632

Page 1

701p39969 february, 2003 docucolor 3535/2240/1632 service manual t he d ocument c ompany xerox caution certain components in the docucolor 3535/2240/ 1632 are susceptible to damage from electrostatic discharge. Observe all esd procedures to avoid component damage..

Page 2

Warning this equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with the instructions documentation, may cause inter- ference to radio communications. It has been tested and found to comply with the limits for a class a computing device purs...

Page 3: Introduction

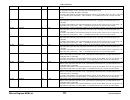

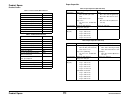

02/03 i dc 3535/2240/1632 introduction initial issue introduction about this manual ........................................................................................................... Iii organization ..............................................................................................

Page 4

02/03 ii dc 3535/2240/1632 initial issue introduction.

Page 5

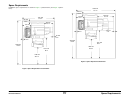

02/03 iii dc 3535/2240/1632 introduction initial issue about this manual this service manual is part of the multinational documentation system for docucolor 3535/ 2240/1632 copier/printers. The service documentation is used in order to diagnose machine malfunctions, adjust components and has informa...

Page 6

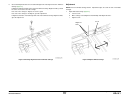

02/03 iv dc 3535/2240/1632 initial issue introduction warnings, cautions, and notes warnings, cautions, and notes will be found throughout the service documentation. The words warning or caution may be listed on an illustration when the specific component associated with the potential hazard is poin...

Page 7

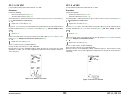

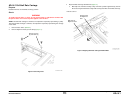

02/03 v dc 3535/2240/1632 introduction initial issue electrostatic discharge (esd) field service kit the purpose of the esd protection program is to preserve the inherent reliability and quality of electronic components that are handled by the field service personnel. This program is being implement...

Page 8

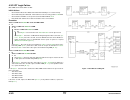

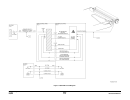

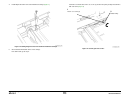

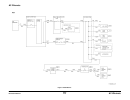

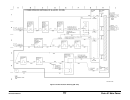

02/03 vi dc 3535/2240/1632 initial issue introduction signal nomenclature refer to figure 7 for an example of signal nomenclature used in circuit diagrams and bsds. Figure 7 signal nomenclature voltage measurement and specifications measurements of dc voltage must be made with reference to the speci...

Page 9

02/03 vii dc 3535/2240/1632 introduction initial issue translated warnings.

Page 10

02/03 viii dc 3535/2240/1632 initial issue introduction introduction symbology and nomenclature warning a warning is used whenever an operating or maintenance procedure, a practice, condi- tion, or statement, if not strictly observed, could result in personal injury. Danger: une note danger est util...

Page 11

02/03 ix dc 3535/2240/1632 introduction initial issue danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des activités de maintenance ou de réglage avec l'équipement sur marche ou avec le cordon d'alimentation branché. Rep 1.7 dev/btr2/dts hvps; bcr hvps warning to avoid ...

Page 12

02/03 x dc 3535/2240/1632 initial issue introduction rep 4.2 ibt motor assembly warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs électriques,...

Page 13

02/03 xi dc 3535/2240/1632 introduction initial issue danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des activités de maintenance ou de réglage avec l'équipement sur marche ou avec le cordon d'alimentation branché. Rep 5.10 set gate solenoid assembly warning to avoid ...

Page 14

02/03 xii dc 3535/2240/1632 initial issue introduction warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des act...

Page 15

02/03 xiii dc 3535/2240/1632 introduction initial issue rep 7.4 tray 1 feed/lift motor warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs élect...

Page 16

02/03 xiv dc 3535/2240/1632 initial issue introduction activités de maintenance ou de réglage avec l'équipement sur marche ou avec le cordon d'alimentation branché. Rep 7.16 tray 2 feeder (3tm) warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power s...

Page 17

02/03 xv dc 3535/2240/1632 introduction initial issue warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des acti...

Page 18

02/03 xvi dc 3535/2240/1632 initial issue introduction warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des act...

Page 19

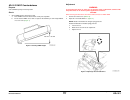

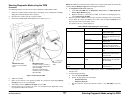

02/03 xvii dc 3535/2240/1632 introduction initial issue warning personal injury may result from grasping hot areas of fuser module. If a hot fuser mod- ule must be removed, grasp fuser module by grip rings (figure 1). Danger: des blessures peuvent résulter si les zones chaudes du module de four sont...

Page 20

02/03 xviii dc 3535/2240/1632 initial issue introduction d'alimentation branché. Rep 12.10 rail warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des ch...

Page 21

02/03 xix dc 3535/2240/1632 introduction initial issue the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des activités de maintenance ou de réglage avec l'équipement sur marche ou avec le cordon d'alimentati...

Page 22

02/03 xx dc 3535/2240/1632 initial issue introduction warning to avoid personal injury or shock, do not perform repair or adjustment activities with the power switch on or electrical power applied to the machine. Danger: afin d'éviter des blessures ou des chocs électriques, ne pas effectuer des acti...

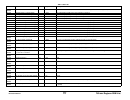

Page 23: 1 Service Call Procedures

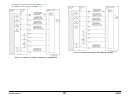

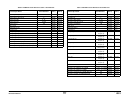

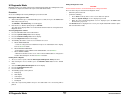

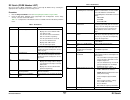

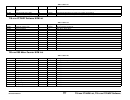

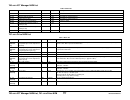

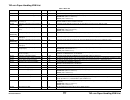

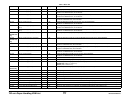

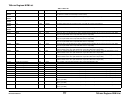

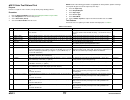

02/03 1-1 dc 3535/2240/1632 service call procedures initial issue 1 service call procedures service call procedures.................................................................................................. 1-3 initial actions .....................................................................

Page 24

02/03 1-2 dc 3535/2240/1632 initial issue service call procedures.

Page 25

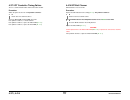

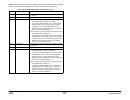

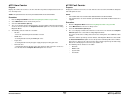

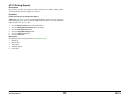

02/03 1-3 dc 3535/2240/1632 service call procedures service call procedures initial issue service call procedures service strategy the service strategy for the docucolor 3535/2240/1632 copier/printer is to perform any high frequency service item (hfsi) actions before attempting to repair any problem...

Page 26

02/03 1-4 dc 3535/2240/1632 initial actions initial issue service call procedures initial actions purpose the purpose of the initial action section of the service call procedures is to determine the rea- son for the service call and to identify and organize the actions which must be performed. Proce...

Page 27

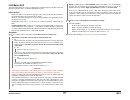

02/03 1-5 dc 3535/2240/1632 call flow service call procedures initial issue call flow this procedure should be performed at every service call. Initial actions ask the operator about the problem. If the problem appears to be related to operator error, or an attempt to perform a job outside of the ma...

Page 28

02/03 1-6 dc 3535/2240/1632 call flow initial issue service call procedures the problem is image quality (print mode) y n verify that the ac power, scan, and ddi cables are connected correctly. If the cables are ok, refer to the network controller service documentation to verify the correct operatio...

Page 29

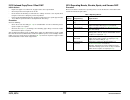

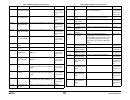

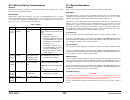

02/03 1-7 dc 3535/2240/1632 detailed maintenance activities service call procedures initial issue detailed maintenance activities (hfsi) procedure 1. Clean the adc sensor on every call. 2. Enter diagnostics and select dc135 . 3. Perform the service actions in table 1 for any high frequency service i...

Page 30

02/03 1-8 dc 3535/2240/1632 cleaning procedures, final actions initial issue service call procedures cleaning procedures purpose the purpose is to provide cleaning procedures to be performed at every call. Procedure caution do not use any solvents unless directed to do so by the service manual. Gene...

Page 31: 2 Status Indicator Raps

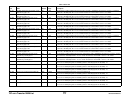

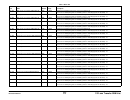

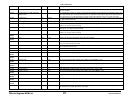

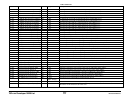

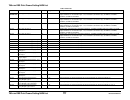

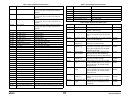

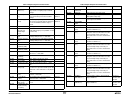

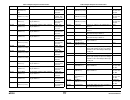

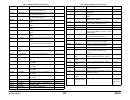

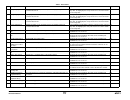

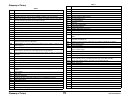

02/03 2-1 dc 3535/2240/1632 status indicator raps initial issue 2 status indicator raps chain 1 1-300 rap....................................................................................................................... 2-9 1-301 rap.................................................................

Page 32

02/03 2-2 dc 3535/2240/1632 initial issue status indicator raps 4-361 drum motor ........................................................................................................... 2-63 4-362 iot nvm read write ....................................................................................

Page 33

02/03 2-3 dc 3535/2240/1632 status indicator raps initial issue 8-184 registration sensor off......................................................................................... 2-165 8-620 regicon temp sensor ........................................................................................

Page 34

02/03 2-4 dc 3535/2240/1632 initial issue status indicator raps 12-262 eject clamp home sensor off............................................................................ 2-267 12-267 decurler ..........................................................................................................

Page 35

02/03 2-5 dc 3535/2240/1632 status indicator raps initial issue 16-729 tiff data ............................................................................................................ 2-349 16-730 art command ........................................................................................

Page 36

02/03 2-6 dc 3535/2240/1632 initial issue status indicator raps 102-313 as uses wrong api.......................................................................................... 2-401 102-314 wait event time out .........................................................................................

Page 37

02/03 2-7 dc 3535/2240/1632 status indicator raps initial issue 103-372 iot sc soft failure ........................................................................................... 2-453 103-701 changed output bin: side to center ............................................................... 2-4...

Page 38

02/03 2-8 dc 3535/2240/1632 initial issue status indicator raps 121-335 foreign interface wake up answer fail ........................................................... 2-504 121-336 unknown foreign device .................................................................................. 2-505 121-...

Page 39

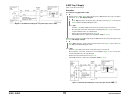

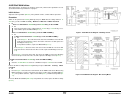

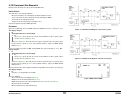

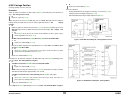

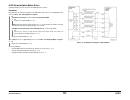

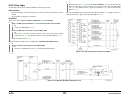

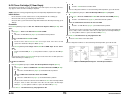

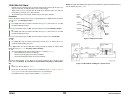

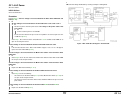

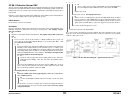

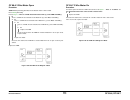

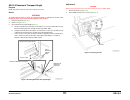

02/03 2-9 dc 3535/2240/1632 1-300 status indicator raps initial issue 1-300 rap the left cover is open. Procedure enter dc330 [001-301] and press the start button. Open and close the left cover ( pl 2.7 ). The display changes state. Y n +24 vdc is measured between +24 lvps p/j502-1 and gnd(-). Y n r...

Page 40

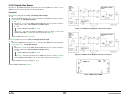

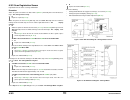

02/03 2-10 dc 3535/2240/1632 1-301 initial issue status indicator raps 1-301 rap the left lower cover is open procedure enter dc330 [001-302] and press the start button. Open the left lower cover. Actuate the lh lower cover interlock switch ( pl 2.3 ) with a screwdriver. The display changes state. Y...

Page 41

02/03 2-11 dc 3535/2240/1632 1-302 status indicator raps initial issue 1-302 rap the front cover or the right side cover is open. Initial actions check the operation of the actuator and the switch. Procedure open the front cover. Cheat the front interlock switch. The fault code 001-302 is cleared. Y...

Page 42

02/03 2-12 dc 3535/2240/1632 1-303 initial issue status indicator raps 1-303 rap the tray module left door is open. Procedure enter dc330 [001-304] and press the start button. Actuate the tray module lh cover interlock switch ( pl 16.13 ) with a screwdriver. The display changes state. Y n +24 vdc is...

Page 43

02/03 2-13 dc 3535/2240/1632 1-306 status indicator raps initial issue 1-306 rap the duplex cover is open. Procedure enter dc330 [008-300] and press the start button. Open the duplex transport. Actuate the duplex cover interlock switch ( pl 12.2 ) with a screwdriver. The display changes state. Y n d...

Page 44

02/03 2-14 dc 3535/2240/1632 1-306 initial issue status indicator raps.

Page 45

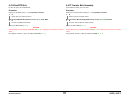

02/03 2-15 dc 3535/2240/1632 3-205, 3-206 status indicator raps initial issue 3-205 billing meter mismatch the billing meters on the three serialized pwbs do not match. Procedure switch the power off then on. If the fault remains, perform gp 10 . 3-206 billing restoration failure one of the billing ...

Page 46

02/03 2-16 dc 3535/2240/1632 3-317 , 3-318 initial issue status indicator raps 3-317 iit software failure configuration mismatch procedure change the position of the document sensor. The problem continues. Y n return to service call procedures. Rewrite the nvm values. 3-318 iit software failure proc...

Page 47

02/03 2-17 dc 3535/2240/1632 3-319 , 3-320 status indicator raps initial issue 3-319 iit video driver failure video driver declared a dma or compression error. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the software. If the problem...

Page 48

02/03 2-18 dc 3535/2240/1632 3-321, 3-322 initial issue status indicator raps 3-321 iit-ess communication failure 2 controller received check code error (wrong sequence number in sent message packet). Procedure switch the power off then on. The problem continues. Y n return to service call procedure...

Page 49

02/03 2-19 dc 3535/2240/1632 3-323, 3-324 status indicator raps initial issue 3-323 iit-ess communication failure 4 controller received check code error (wrong message packet length in sent packet). Procedure switch the power off then on. The problem continues. Y n return to service call procedures....

Page 50

02/03 2-20 dc 3535/2240/1632 3-325, 3-326 initial issue status indicator raps 3-325 iit-ess communication failure 6 controller received check code error (parity error in iiss). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the softwar...

Page 51

02/03 2-21 dc 3535/2240/1632 3-327, 3-328 status indicator raps initial issue 3-327 iit-ess communication failure 8 controller received check code error (over-run error in iiss). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the softw...

Page 52

02/03 2-22 dc 3535/2240/1632 3-329, 3-330 initial issue status indicator raps 3-329 iit-ess communication failure 10 controller received check code error (wrong sequence number in received message packet). Procedure switch the power off then on. The problem continues. Y n return to service call proc...

Page 53

02/03 2-23 dc 3535/2240/1632 3-331, 3-332 status indicator raps initial issue 3-331 iit-ess communication failure 12 controller received check code error (wrong message packet length in received packet). Procedure switch the power off then on. The problem continues. Y n return to service call proced...

Page 54

02/03 2-24 dc 3535/2240/1632 3-333, 3-334 initial issue status indicator raps 3-333 iit-ess communication failure 14 controller received check code error (parity error in uart) procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the softwar...

Page 55

02/03 2-25 dc 3535/2240/1632 3-335, 3-336 status indicator raps initial issue 3-335 iit-ess communication failure 16 controller received check code error (uart over-run error). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the softwar...

Page 56

02/03 2-26 dc 3535/2240/1632 3-337, 3-340 initial issue status indicator raps 3-337 iit-ess communication failure 18 controller received check code error (reception aborted after header received). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. R...

Page 57

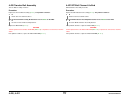

02/03 2-27 dc 3535/2240/1632 3-341, 3-342 status indicator raps initial issue 3-341 iot-ess communication failure 2 controller received check code error (wrong sequence number in sent message packet). Procedure switch the power off then on. The problem continues. Y n return to service call procedure...

Page 58

02/03 2-28 dc 3535/2240/1632 3-343, 3-345 initial issue status indicator raps 3-343 iot-ess communication failure 4 controller received check code error (wrong message packet length in sent packet). Procedure switch the power off then on. The problem continues. Y n return to service call procedures....

Page 59

02/03 2-29 dc 3535/2240/1632 3-346, 3-347 status indicator raps initial issue 3-346 iot-ess communication failure 6 controller received check code error (parity error in iot). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the software...

Page 60

02/03 2-30 dc 3535/2240/1632 3-348, 3-349 initial issue status indicator raps 3-348 iot-ess communication failure 8 controller received check code error (iot over-run error). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the software....

Page 61

02/03 2-31 dc 3535/2240/1632 3-350, 3-351 status indicator raps initial issue 3-350 iot-ess communication failure 10 controller received check code error (wrong sequence number in received message packet). Procedure switch the power off then on. The problem continues. Y n return to service call proc...

Page 62

02/03 2-32 dc 3535/2240/1632 3-352, 3-353 initial issue status indicator raps 3-352 iot-ess communication failure 12 controller received check code error (wrong message packet length in received packet). Procedure switch the power off then on. The problem continues. Y n return to service call proced...

Page 63

02/03 2-33 dc 3535/2240/1632 3-354, 3-355 status indicator raps initial issue 3-354 iot-ess communication failure 14 controller received check code error (uart parity error). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the software....

Page 64

02/03 2-34 dc 3535/2240/1632 3-356, 3-357 initial issue status indicator raps 3-356 iot-ess communication failure 16 controller received check code error (uart over-run error). Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the softwar...

Page 65

02/03 2-35 dc 3535/2240/1632 3-358, 3-359 status indicator raps initial issue 3-358 iot-ess communication failure 18 controller received check code error. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the software. If the problem cont...

Page 66

02/03 2-36 dc 3535/2240/1632 3-360, 3-364 initial issue status indicator raps 3-360 iot-ess initialization failure iot driver initialization failure. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Reinstall the software. If the problem continues...

Page 67

02/03 2-37 dc 3535/2240/1632 3-365, 3-366 status indicator raps initial issue 3-365 overflow on write loop back the extended data exceeds the reserved buffer size procedure switch the power off then on. The problem continues. Y n return to service call procedures. Replace the ess pwb ( pl 13.1 ). 3-...

Page 68

02/03 2-38 dc 3535/2240/1632 3-370, 3-747 initial issue status indicator raps 3-370 marker code detect failure the end code cannot be found in the compressed data. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Replace the ram ( pl 13.1 ). Perfo...

Page 69

02/03 2-39 dc 3535/2240/1632 3-750, 3-761 status indicator raps initial issue 3-750 insufficient number of document pages insufficient number of pages programed when making a book. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Set the number of...

Page 70

02/03 2-40 dc 3535/2240/1632 3-941, 3-942 initial issue status indicator raps 3-941 insufficient page memory procedure switch the power off then on. The problem continues. Y n return to service call procedures. Perform the operation again. 3-942 document size error dadf mode: the dadf document senso...

Page 71

02/03 2-41 dc 3535/2240/1632 3-946, 3-947 status indicator raps initial issue 3-946 tray 1 not in position tray 1 not in ready position. Initial actions • check that the paper size setting is correct. • check the tray 1 paper size sensor for damage or incorrect mounting. Repair or replace as require...

Page 72

02/03 2-42 dc 3535/2240/1632 3-948, 3-949 initial issue status indicator raps 3-948 tray 3 not in position tray 3 not in ready position. Initial actions • check that the paper size setting is correct. • check the tray 3 paper size sensor for damage or incorrect mounting. Repair or replace as require...

Page 73

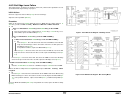

02/03 2-43 dc 3535/2240/1632 3-950, 3-951 status indicator raps initial issue 3-950 tray 1 empty paper is not detected in tray 1 procedure remove tray 1. Enter dc330 [007-120] and press start. Actuate the tray 1 no paper sensor ( pl 2.4 ). The display changes state. Y n press stop. Check the circuit...

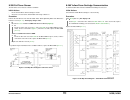

Page 74

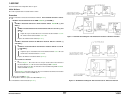

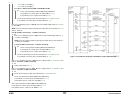

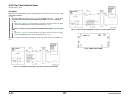

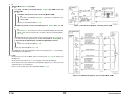

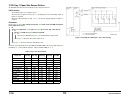

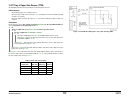

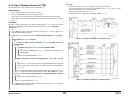

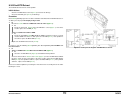

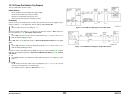

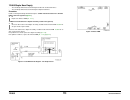

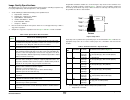

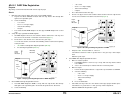

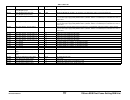

02/03 2-44 dc 3535/2240/1632 3-951, 3-952 initial issue status indicator raps figure 2 3-951 rap circuit diagram - tray 2 no paper sensor (3tm) 3-952 tray 3 empty paper is not detected in tray 3 procedure the machine is equipped with a 3tm. Y n remove tray 3. Enter dc330 [007-122] and press start. A...

Page 75

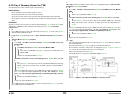

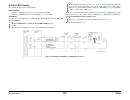

02/03 2-45 dc 3535/2240/1632 3-952, 3-953 status indicator raps initial issue figure 2 3-952 rap circuit diagram - tray 3 no paper sensor (3tm) 3-953 tray 4 empty paper is not detected in tray 4. Procedure the machine is equipped with a 3tm. Y n remove tray 4. Enter dc330 [007-123] and press start. ...

Page 76

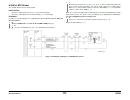

02/03 2-46 dc 3535/2240/1632 3-953, 3-954 initial issue status indicator raps figure 2 9-353 rap circuit diagram - tray 4 no paper sensor (3tm) 3-954 tray 5 empty paper is not detected in tray 5. Procedure enter dc330 [007-125] and press start. Actuate the tray 5 no paper sensor. The display changes...

Page 77

02/03 2-47 dc 3535/2240/1632 3-958, 3-959 status indicator raps initial issue 3-958 tray 5 paper size mismatch the paper in the tray 5 does not match the paper size selected. Procedure the correct size paper is loaded in tray 5. Y n load the correct size paper and return to service call procedures. ...

Page 78

02/03 2-48 dc 3535/2240/1632 3-960, 3-961 initial issue status indicator raps 3-960 tray 2 paper size mismatch the paper in tray 2 does not match the paper size selected. Procedure the correct size paper is loaded in tray 2. Y n load the correct size paper and return to service call procedures. Go t...

Page 79

02/03 2-49 dc 3535/2240/1632 3-962, 3-965 status indicator raps initial issue 3-962 tray 4 paper size mismatch the paper in tray 4 does not match the paper size selected. Procedure the machine is equipped with a 3tm. Y n the correct size paper is loaded in tray 4. Y n load the correct size paper and...

Page 80

02/03 2-50 dc 3535/2240/1632 3-971, 3-972 initial issue status indicator raps 3-971 magnification incompatible magnification selected procedure switch the power off then on. The problem continues. Y n return to service call procedures. Change parameters and rerun job. 3-972 over number of document p...

Page 81

02/03 2-51 dc 3535/2240/1632 3-974, 3-975 status indicator raps initial issue 3-974 next document specified manual placement of next document specified procedure manually change documents on platen glass. The problem continues. Y n return to service call procedures. Switch the power off then on. 3-9...

Page 82

02/03 2-52 dc 3535/2240/1632 3-980, 3-985 initial issue status indicator raps 3-980 stapler position error the stapler is not available at the specified position. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Re-set the parameters. 3-985 tray 5...

Page 83

02/03 2-53 dc 3535/2240/1632 3-986 status indicator raps initial issue 3-986 print completion error the number of spooled pages does not match the output. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Count the number of prints to ensure job in...

Page 84

02/03 2-54 dc 3535/2240/1632 3-986 initial issue status indicator raps.

Page 85

02/03 2-55 dc 3535/2240/1632 4-340 status indicator raps initial issue 4-340 iot ram failure mcu pwb ram test failed. Procedure switch the power off, then on. The problem continues. Y n return to service call procedures. Check the connection between the mcu pwb and the mcu nvm pwb. If the check is o...

Page 86

02/03 2-56 dc 3535/2240/1632 4-341 initial issue status indicator raps 4-341 iot logic failure mcu pwb cannot detect intlk +5 vdc. Initial actions • check that the waste toner bottle and all four drum cartridges are seated correctly. • check fault history for 9-925 faults. If this fault has occurred...

Page 87

02/03 2-57 dc 3535/2240/1632 4-342, 4-343 status indicator raps initial issue 4-342 flash rom limit failure limit failure of flash rom procedure switch the power off, then on. The problem continues. Y n return to service call procedures. Replace the mcu pwb ( pl 13.1 ). 4-343 iot flash rom read writ...

Page 88

02/03 2-58 dc 3535/2240/1632 4-344, 4-345 initial issue status indicator raps 4-344 iot micro pitch the micro pitch did not occur within the specified time. Procedure switch the power off, then on. The problem continues. Y n return to service call procedures. Replace the mcu pwb ( pl 13.1 ). 4-345 m...

Page 89

02/03 2-59 dc 3535/2240/1632 4-346 status indicator raps initial issue 4-346 transfer belt home fault the ibt home sensor does not detect the belt home signal. Note: if this fault is declared 3 times in succession, print mode will be disabled. In order to clear this condition, reset nvm location 741...

Page 90

02/03 2-60 dc 3535/2240/1632 4-347 initial issue status indicator raps 4-347 transfer belt out of position the ibt edge sensor does not sense the transfer belt edge in the correct position. Initial actions check the following: • check that the ibt belt cleaner is not damaged, binding, or incorrectly...

Page 91

02/03 2-61 dc 3535/2240/1632 4-348 status indicator raps initial issue 4-348 transfer belt edge not detected the ibt edge sensor cannot sense the transfer belt edge. Initial actions check the following: • check that the ibt belt cleaner is not damaged, binding, or incorrectly assembled. • ensure tha...

Page 92

02/03 2-62 dc 3535/2240/1632 4-349, 4-358 initial issue status indicator raps 4-349 marking software logic control logic detected a fatal failure in the marking software. Procedure switch the power off, then on. The problem continues. Y n return to service call procedures. Again, switch the power of...

Page 93

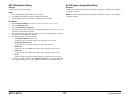

02/03 2-63 dc 3535/2240/1632 4-361 status indicator raps initial issue 4-361 drum motor drum motor failure. Initial actions • remove all drum cartridges. • perform rep 1.6 . Procedure the machine is a dc3535. Y n enter dc330 [004-003] and press start. The drum motor energizes and the drives rotate. ...

Page 94

02/03 2-64 dc 3535/2240/1632 4-361 initial issue status indicator raps • p/j535 -b4 (+) and gnd (-) • p/j535 -b5 (+) and gnd (-) less than +1 vdc is measured on p/j535-b3,b4 and b5. Y n • check connection between mcu pwb and i/f pwb (p410). • if no problems are found, replace the mcu pwb ( pl 13.1 )...

Page 95

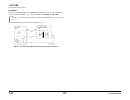

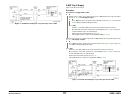

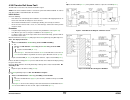

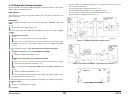

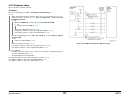

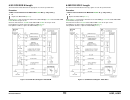

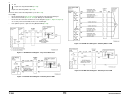

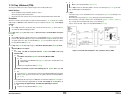

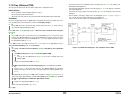

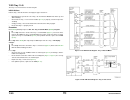

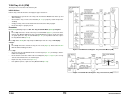

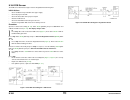

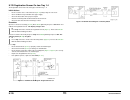

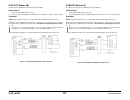

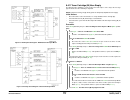

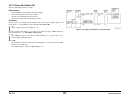

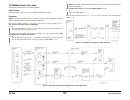

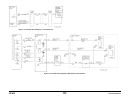

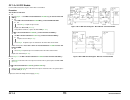

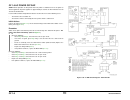

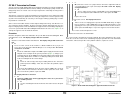

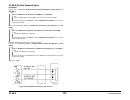

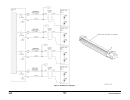

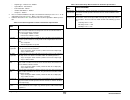

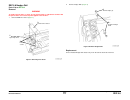

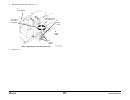

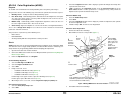

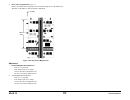

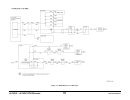

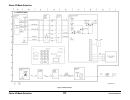

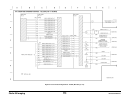

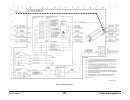

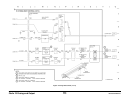

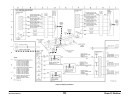

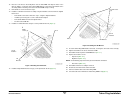

02/03 2-65 dc 3535/2240/1632 4-361, 4-362 status indicator raps initial issue figure 2 4-361 rap circuit diagram - drum motor (y,m,c) (dc3535) 4-362 iot nvm read write read write at the mcu pwb nvm r/w. Procedure switch the power off, then on. The problem continues. Y n return to service call proced...

Page 96

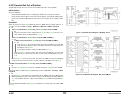

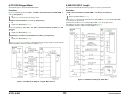

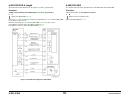

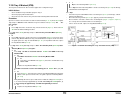

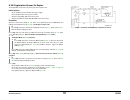

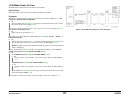

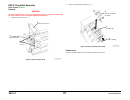

02/03 2-66 dc 3535/2240/1632 4-363 initial issue status indicator raps 4-363 k drum motor drum motor k failure. Initial actions • remove all drum cartridges. • perform rep 1.6 . Procedure the machine is a dc3535. Y n enter dc330 [004-006] and press start. Drum motor k energizes. Y n go to figure 1 o...

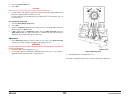

Page 97

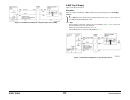

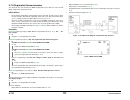

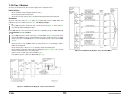

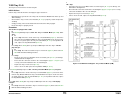

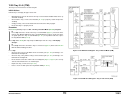

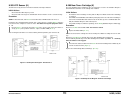

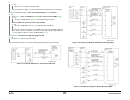

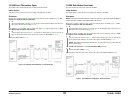

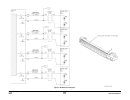

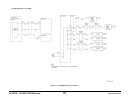

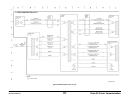

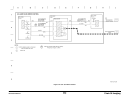

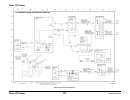

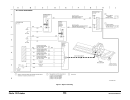

02/03 2-67 dc 3535/2240/1632 4-363 status indicator raps initial issue • if no problems are found, replace the mcu pwb ( pl 13.1 ). • if the problem persists, replace the i/f pwb ( pl 9.1 ). Figure 1 4-363 rap circuit diagram - drum motor (k) (dc2240/1632) figure 2 4-363 rap circuit diagram - drum m...

Page 98

02/03 2-68 dc 3535/2240/1632 4-371, 4-414 initial issue status indicator raps 4-371 iot controller timing failure there is a communication failure between the ess and iot. Procedure switch the power off, then on. The problem continues. Y n return to service call procedures. Check the mcu pwb and ess...

Page 99

02/03 2-69 dc 3535/2240/1632 4-415, 4-417 status indicator raps initial issue 4-415 2nd btr unit it is time to replace the 2nd btr unit. Procedure replace the 2nd btr unit ( pl 2.8 ). The problem continues. Y n return to service call procedures. Was the 2nd btr unit hfsi counter reset in dc135 on th...

Page 100

02/03 2-70 dc 3535/2240/1632 4-420, 4-421 initial issue status indicator raps 4-420 transfer belt assembly transfer belt assembly end of life. Procedure replace the transfer belt assembly ( pl 5.3 ). The problem continues. Y n return to service call procedures. Was the transfer belt assembly hfsi co...

Page 101

02/03 2-71 dc 3535/2240/1632 4-605 status indicator raps initial issue 4-605 iot nvm corrupt the system detected that the nvm of the iot is empty. Procedure switch the power off, then on. The problem continues. Y n return to service call procedures. Replace the mcu pwb ( pl 13.1 ). Caution careful r...

Page 102

02/03 2-72 dc 3535/2240/1632 4-640 initial issue status indicator raps 4-640 belt walk failure this hidden fault is declared if the dynamic (short term) color-to-color registration exceeds specification while image formation is in progress. Initial actions adjust the color registration ( adj 9.6 ). ...

Page 103

02/03 2-73 dc 3535/2240/1632 4-641 status indicator raps initial issue 4-641 belt edge learn failure this hidden fault is declared if the dynamic (short term) color-to-color registration exceeds specification while edge learning is in progress. Initial actions check the edge of the transfer belt ( p...

Page 104

02/03 2-74 dc 3535/2240/1632 4-642, 4-650 initial issue status indicator raps 4-642 belt edge check failure this hidden fault is declared if the dynamic (short term) color-to-color registration exceeds specification while edge checking is in progress after power on or interlock actuation. Procedure ...

Page 105

02/03 2-75 dc 3535/2240/1632 4-908 status indicator raps initial issue 4-908 2nd btr life end 2nd btr end of life. Procedure replace the 2nd btr ( pl 2.8 ) ( rep 9.24 ). The problem continues. Y n return to service call procedures. Was the 2nd btr unit hfsi counter reset in dc135 on the pws. Y n res...

Page 106

02/03 2-76 dc 3535/2240/1632 4-908 initial issue status indicator raps.

Page 107

02/03 2-77 dc 3535/2240/1632 5-110 status indicator raps initial issue 5-110 registration sensor on the registration sensor did not detect a document within 800 msec. After the feed motor energized. Initial actions • this fault can be caused by the following operator errors: – pulling the document o...

Page 108

02/03 2-78 dc 3535/2240/1632 5-111 initial issue status indicator raps 5-111 registration sensor off the document did not deactuate the registration sensor within 1000 msec after the dadf belt motor energized. Initial actions this fault can be caused by an operator loading a large quantity of docume...

Page 109

02/03 2-79 dc 3535/2240/1632 5-112 status indicator raps initial issue 5-112 registration sensor inversion the document does not actuate the dadf registration sensor within 1000 msec after the belt motor energized for document inversion. Initial actions this fault can be caused by using documents wi...

Page 110

02/03 2-80 dc 3535/2240/1632 5-113 initial issue status indicator raps 5-113 registration sensor inversion the document does not deactuate the dadf registration sensor 1500 msec after the belt motor energized for document inversion. Initial actions • ensure that the platen belt is properly aligned o...

Page 111

02/03 2-81 dc 3535/2240/1632 5-115 status indicator raps initial issue 5-115 exit sensor on the dadf exit sensor does not detect a document 1500 msec after the dadf exit motor energized at document replacement/output. Initial actions • check the customer’s documents to ensure they meet the specifica...

Page 112

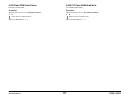

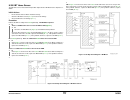

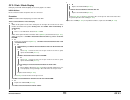

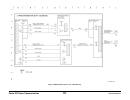

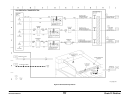

02/03 2-82 dc 3535/2240/1632 5-115 initial issue status indicator raps figure 3 dadf control pwb.

Page 113

02/03 2-83 dc 3535/2240/1632 5-116 status indicator raps initial issue 5-116 exit sensor off the document does not deactuate the dadf exit sensor after the dadf exit sensor actuated. Initial actions check the customer’s documents to ensure they meet the specification for the dadf. Ensure the exit ro...

Page 114

02/03 2-84 dc 3535/2240/1632 5-116 initial issue status indicator raps figure 3 dadf control pwb.

Page 115

02/03 2-85 dc 3535/2240/1632 5-195 status indicator raps initial issue 5-195 document size mismatch different sized documents are detected in the no mix mode. Initial actions this fault can be caused by the following: • mixed size documents are fed without selecting that option on the ui. • there is...

Page 116

02/03 2-86 dc 3535/2240/1632 5-274 initial issue status indicator raps 5-274 original size sensor at power on, the dadf registration sensor turns off, and the dadf size sensor 1 or the dadf size sensor 2 turns on (size sensor detection failure) procedure enter dc330 [5-150] and select start. The dis...

Page 117

02/03 2-87 dc 3535/2240/1632 5-275 status indicator raps initial issue 5-275 dadf ram failure ram failure of the dadf pwb. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Replace the dadf control pwb ( pl 20.3 )..

Page 118

02/03 2-88 dc 3535/2240/1632 5-301 initial issue status indicator raps 5-301 top cover interlock open the top cover is open. Procedure manually actuate both dadf top cover interlock switches (front/rear) at the same time. The 5-301 fault is cleared. Y n remove the dadf rear cover ( rep 5.18 ). Close...

Page 119

02/03 2-89 dc 3535/2240/1632 5-700 status indicator raps initial issue 5-700 set gate solenoid rap use this rap when directed to troubleshoot problems with the dadf set gate solenoid. Initial actions remove the following: • front cover ( pl 20.1 ) • entrance tray ( pl 20.1 ) • lower chute assembly (...

Page 120

02/03 2-90 dc 3535/2240/1632 5-701 initial issue status indicator raps 5-701 feed motor rap use this rap when directed to troubleshoot problems with the feed motor. Initial actions remove the following: • front cover ( pl 20.1 ) • entrance tray ( pl 20.1 ) • lower chute assembly ( rep 5.8 ) • rear c...

Page 121

02/03 2-91 dc 3535/2240/1632 5-702 status indicator raps initial issue 5-702 registration sensor rap use this rap when directed to troubleshoot problems with the registration sensor. Initial actions remove the following: • front cover ( pl 20.1 ) • entrance tray ( pl 20.1 ) • lower chute assembly ( ...

Page 122

02/03 2-92 dc 3535/2240/1632 5-703 initial issue status indicator raps 5-703 dadf belt motor rap use this rap when directed to troubleshoot problems with the dadf belt motor. Initial actions remove the following: • front cover ( pl 20.1 ) • entrance tray ( pl 20.1 ) • lower chute assembly ( rep 5.8 ...

Page 123

02/03 2-93 dc 3535/2240/1632 5-900, 5-901 status indicator raps initial issue 5-900 document sensor timing one of the following dadf interlocks was opened during dadf operation: • dadf interlock switch ( pl 20.3 ) • top cover interlock switch (front) ( pl 20.2 ) • top cover interlock switch (rear) (...

Page 124

02/03 2-94 dc 3535/2240/1632 5-902, 5-903 initial issue status indicator raps 5-902 power on registration sensor the registration sensor detected a document when the top cover/platen interlock was closed or power was switched on. Initial actions clean the registration sensor. Ensure there are no pie...

Page 125

02/03 2-95 dc 3535/2240/1632 5-904, 5-940 status indicator raps initial issue 5-904 power on duplex sensor the dadf duplex sensor detected a document when the top cover/platen interlock was closed or power was switched on initial actions clean the duplex sensor. Ensure there are no pieces of paper o...

Page 126

02/03 2-96 dc 3535/2240/1632 5-941 initial issue status indicator raps 5-941 document miscount the software detected a document miscount. Procedure rerun the job. 5-941 continues. Y n return to service call procedures. Replace the dadf control pwb ( pl 20.3 )..

Page 127

02/03 2-97 dc 3535/2240/1632 6-277 status indicator raps initial issue 6-277 iit/dadf communication communication cannot be established between the iit/ips and the dadf control pwb. Procedure switch on the power. Cr4 on the dadf control pwb illuminates. Y n +5vdc is measured between the dadf control...

Page 128

02/03 2-98 dc 3535/2240/1632 6-300, 6-312 initial issue status indicator raps 6-300 dadf open the dadf was opened during the dadf job. Procedure enter dc330 [006-300] and place a magnet over the platen open switch ( pl 18.4 ). The dis- play changes. Y n remove the platen glass ( rep 6.2 ). Remove ii...

Page 129

02/03 2-99 dc 3535/2240/1632 6-340, 6-345 status indicator raps initial issue 6-340 ess ram test error at power on, the system detected a iit/ips pwb ram test error. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. Replace the iit/ips pwb ( pl 18....

Page 130

02/03 2-100 dc 3535/2240/1632 6-355 initial issue status indicator raps 6-355 ips fan the control logic detects an ips fan failure. Procedure enter dc330 [006-014] and select start. The ips fan ( pl 18.4 ) energizes. Y n switch off the power. Remove the platen glass ( rep 6.2 ) and the ips cover ( p...

Page 131

02/03 2-101 dc 3535/2240/1632 6-360 status indicator raps initial issue 6-360 carriage position a carriage position error was detected. Procedure switch the power off. Remove the platen glass ( rep 6.2 ). Manually move the full rate car- riage. The carriage moves easily. Y n repair as required ( pl ...

Page 132

02/03 2-102 dc 3535/2240/1632 6-361 initial issue status indicator raps 6-361 scan registration sensor registration sensor failure at carriage initialization. Procedure switch the power off. Remove the platen glass ( rep 6.2 ). Manually move the full rate car- riage. The carriage moves easily. Y n r...

Page 133

02/03 2-103 dc 3535/2240/1632 6-371 status indicator raps initial issue 6-371 exposure lamp open circuit of the lamp was detected. Procedure enter dc330 [006-002]. Press start. The exposure lamp illuminates. Y n switch off the power. Remove the platen glass ( rep 6.2 ) and the ips cover ( pl 18.3 )....

Page 134

02/03 2-104 dc 3535/2240/1632 6-372, 6-380 initial issue status indicator raps 6-372 ros polygon motor the control logic has detected a ros motor failure. Procedure enter dc330 [006-031] and select start. +3.3vdc is measured between the mcu pwb p/ j402 (+) and ground (-) y n go to flag 1 . Check the...

Page 135

02/03 2-105 dc 3535/2240/1632 6-381, 6-382 status indicator raps initial issue 6-381 ros sos m length the interval of the ros start-of-scan (m) signals exceeds the specified value. Procedure +5vdc is measured between the mcu pwb p/j401 -b19 (+) and ground (-). Y n replace the mcu pwb ( pl 13.1 ). Re...

Page 136

02/03 2-106 dc 3535/2240/1632 6-383, 6-385 initial issue status indicator raps 6-383 ros sos k length the interval of the ros start-of-scan (k) signals exceeds the specified value. Procedure +5vdc is measured between the mcu pwb p/j401 -a2 (+) and ground (-). Y n replace the mcu pwb ( pl 13.1 ). Ref...

Page 137

02/03 2-107 dc 3535/2240/1632 6-389 status indicator raps initial issue 6-389 carriage over run right the carriage has overrun at the scan end. Procedure switch the power off. Remove the platen glass ( rep 6.2 ). Manually move the full rate car- riage. The carriage moves easily. Y n repair as requir...

Page 138

02/03 2-108 dc 3535/2240/1632 6-390 initial issue status indicator raps 6-390 carriage over run left the carriage has overrun at the home end. Procedure switch the power off. Remove the platen glass ( rep 6.2 ). Manually move the full rate car- riage. The carriage moves easily. Y n repair as require...

Page 139

02/03 2-109 dc 3535/2240/1632 6-391 status indicator raps initial issue 6-391 scan initialize motor driver a carriage motor error was detected after initialization was started. Procedure manually move the full rate carriage to the left until it stops. Enter dc330 [006-005] (scan) and select start. T...

Page 140

02/03 2-110 dc 3535/2240/1632 6-391 initial issue status indicator raps.

Page 141

02/03 2-111 dc 3535/2240/1632 7-104 status indicator raps initial issue 7-104 tray 1 feed out sensor the tray 1 feed out sensor does not detect paper fed from tray 2, 3, or 4 within the specified time after the takeaway sensor was actuated. Initial actions • check condition and specification of pape...

Page 142

02/03 2-112 dc 3535/2240/1632 7-104 initial issue status indicator raps y n replace the tray module pwb ( pl 15.9 ). Replace the takeaway motor 1 ( pl 15.9 ). Check the drives of the takeaway motor 1 (refer to pl 15.9 ) press stop. • ensure that the chutes ( pl 2.3 , pl 15.10 ) are properly seated a...

Page 143

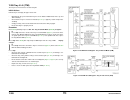

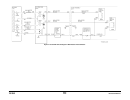

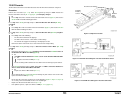

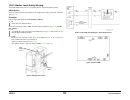

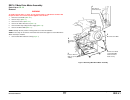

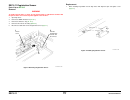

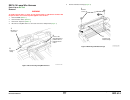

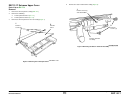

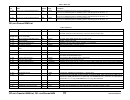

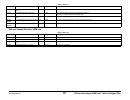

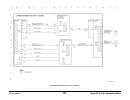

02/03 2-113 dc 3535/2240/1632 7-104 status indicator raps initial issue figure 5 7-104 circuit diagram - takeaway motor 1 3tm.

Page 144

02/03 2-114 dc 3535/2240/1632 7-105 initial issue status indicator raps 7-105 tray 1 misfeed the tray 1 feed out sensor does not detect paper after feeding from tray 1. Initial actions • check condition and specification of paper in tray 1. • check the paper path for obstructions. • check for wear a...

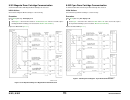

Page 145

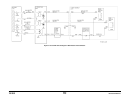

02/03 2-115 dc 3535/2240/1632 7-110 status indicator raps initial issue 7-110 tray 2 misfeed the takeaway sensor does not detect paper after feeding from tray 2. Initial actions • check condition and specification of paper in tray 2. • check the paper path for obstructions. • check for wear and clea...

Page 146

02/03 2-116 dc 3535/2240/1632 7-110 initial issue status indicator raps y n takeaway motor 1 ( pl 15.9 ) energizes. Y n press stop. +24 vdc is measured between p/j552 -3 and gnd on the tray module pwb. Y n +24 vdc is measured at p/j 555-3 on the tray module pwb. Y n refer to the +24 vdc wirenets ( f...

Page 147

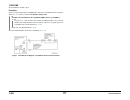

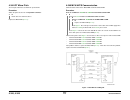

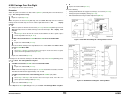

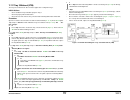

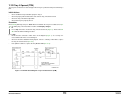

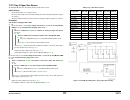

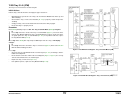

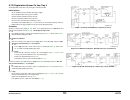

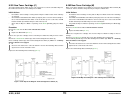

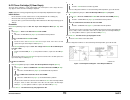

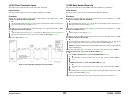

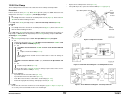

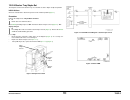

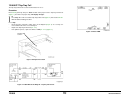

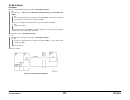

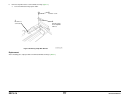

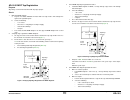

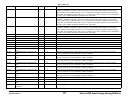

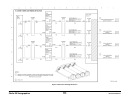

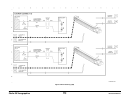

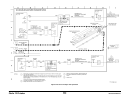

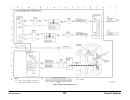

02/03 2-117 dc 3535/2240/1632 7-110 status indicator raps initial issue figure 3 7-110 rap circuit diagram - takeaway motor 1 (ttm) figure 4 7-110 rap circuit diagram - takeaway sensor (3tm) figure 5 7-110 rap circuit diagram - tray 2 feed/lift motor (3tm).

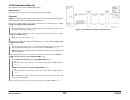

Page 148

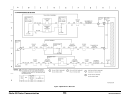

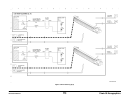

02/03 2-118 dc 3535/2240/1632 7-110 initial issue status indicator raps figure 6 7-110 rap circuit diagram - takeaway motor 1 (3tm).

Page 149

02/03 2-119 dc 3535/2240/1632 7-115 status indicator raps initial issue 7-115 tray 3 misfeed (ttm) the tray 3 feedout sensor does not detect paper after feeding from tray 3. Initial actions • check condition and specification of paper in tray 3. • check the paper path for obstructions. • check for w...

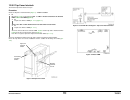

Page 150

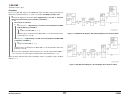

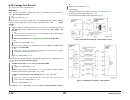

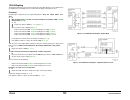

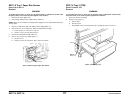

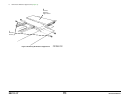

02/03 2-120 dc 3535/2240/1632 7-115 initial issue status indicator raps figure 2 7-115 rap circuit diagram - tray 3 feed/lift motor (ttm) figure 3 7-115 rap circuit diagram - takeaway motor 1 (ttm).

Page 151

02/03 2-121 dc 3535/2240/1632 7-117 status indicator raps initial issue 7-117 tray 3 misfeed (3tm) the tray 3 feed out sensor does not detect paper after feeding from tray 3. Initial actions • check condition and specification of paper in tray 3. • check the paper path for obstructions. • check for ...

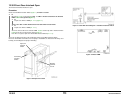

Page 152

02/03 2-122 dc 3535/2240/1632 7-117 initial issue status indicator raps figure 2 7-117 rap circuit diagram - tray 3 feed/lift motor (3tm) figure 3 7-117 rap circuit diagram - takeaway motor 1 (3tm).

Page 153

02/03 2-123 dc 3535/2240/1632 7-119 status indicator raps initial issue 7-119 tray 4 misfeed (ttm) the tray 4 feed out sensor does not detect paper after feeding from tray 4. Initial actions • check condition and specification of paper in tray 4. • check the paper path for obstructions. • check for ...

Page 154

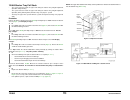

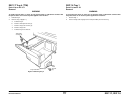

02/03 2-124 dc 3535/2240/1632 7-119 initial issue status indicator raps figure 2 7-119 rap circuit diagram - tray 4 feed/lift motor (ttm) figure 3 7-119 rap circuit diagram - takeaway motor 2 (ttm).

Page 155

02/03 2-125 dc 3535/2240/1632 7-120 status indicator raps initial issue 7-120 tray 4 misfeed (3tm) the tray 4 feed out sensor does not detect paper after feeding from tray 4. Initial actions • check condition and specification of paper in tray 4. • check the paper path for obstructions. • check for ...

Page 156

02/03 2-126 dc 3535/2240/1632 7-120 initial issue status indicator raps figure 2 7-120 rap circuit diagram - tray 4 feed/lift motor (3tm) figure 3 7-120 rap circuit diagram - takeaway motor 1 (3tm).

Page 157

02/03 2-127 dc 3535/2240/1632 7-122 status indicator raps initial issue 7-122 tray 4 opened (ttm) the tray 4 feed out sensor detected paper when tray 4 is pulled out and pushed in during a print. Initial actions • check condition and specification of paper in tray 4. • check the paper path for obstr...

Page 158

02/03 2-128 dc 3535/2240/1632 7-250 initial issue status indicator raps 7-250 tray communication communication fault between tray module pwb and mcu pwb. Procedure +5 vdc is measured at p/j541 -9 on the tray module pwb. Y n 2.5 vdc is measured at p/j541-9 on the tray module pwb. Y n go to figure 1 ....

Page 159

02/03 2-129 dc 3535/2240/1632 7-252 status indicator raps initial issue 7-252 out module logic incorrect software data was detected. Procedure switch the power off then on. The problem continues. Y n return to service call procedures. If the problem continues, replace the mcu pwb ( pl 13.1 ). Reinst...

Page 160

02/03 2-130 dc 3535/2240/1632 7-270 initial issue status indicator raps 7-270 tray 1 paper size sensor failure an abnormal a/d value was detected by the tray 1 paper size sensor. Initial actions • check that the paper size setting is correct. • check the tray 1 paper size sensor ( pl 2.1 ) for damag...

Page 161

02/03 2-131 dc 3535/2240/1632 7-271 status indicator raps initial issue 7-271 tray 2 paper size sensor an abnormal ad value was detected by the tray 2 paper size sensor. Initial actions • check that the paper size setting is correct. • check the tray 2 paper size sensor for damage or incorrect mount...

Page 162

02/03 2-132 dc 3535/2240/1632 7-271 initial issue status indicator raps figure 2 7-271 rap circuit diagram - tray 2 paper size sensing.

Page 163

02/03 2-133 dc 3535/2240/1632 7-272 status indicator raps initial issue 7-272 tray 3 paper size sensor (3tm) an abnormal ad value was detected by the tray 3 paper size sensor. Initial actions • check that the paper size setting is correct. • check the tray 3 paper size sensor ( pl 15.1 ) for damage,...

Page 164

02/03 2-134 dc 3535/2240/1632 7-273 initial issue status indicator raps 7-273 tray 4 paper size sensor (3tm) an abnormal ad value was detected by the tray 4 paper size sensor. Initial actions • check that the paper size setting is correct. • check the tray 4 paper size sensor ( pl 15.1 ) for damage,...

Page 165

02/03 2-135 dc 3535/2240/1632 7-274 status indicator raps initial issue 7-274 tray 5 paper size sensor failure an abnormal a/d value was detected by the tray 5 paper size sensor. Initial actions check the connectors between the tray 5 paper size sensor and the i/f pwb procedure enter dc140 [007-100]...

Page 166

02/03 2-136 dc 3535/2240/1632 7-276 initial issue status indicator raps 7-276 tray 3 paper size sensor (ttm) an abnormal a/d value was detected by the tray 3 paper size sensor. Initial actions • check that the paper size setting is correct. • check the tray 3 paper size sensor ( pl 16.1 ) for damage...

Page 167

02/03 2-137 dc 3535/2240/1632 7-277 status indicator raps initial issue 7-277 tray 4 paper size sensor (ttm) an abnormal a/d value was detected by the tray 4 paper size sensor. Initial actions • check that the paper size setting is correct. • check the tray 4 paper size sensor ( pl 16.1 ) for damage...

Page 168

02/03 2-138 dc 3535/2240/1632 7-281 initial issue status indicator raps 7-281 tray 1 lift the tray 1 level sensor does not detect tray lift. Initial actions remove tray 1 from the machine and empty the paper stock, then: • manually turn the gear at the rear of tray 1 to check that the bottom plate m...

Page 169

02/03 2-139 dc 3535/2240/1632 7-282 status indicator raps initial issue 7-282 tray 2 lift the tray 2 level sensor does not detect tray lift. Initial actions remove tray 2 from the machine and empty the paper stock, then: • manually turn the gear at the rear of tray 2 to check that the bottom plate m...

Page 170

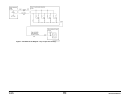

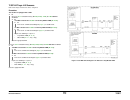

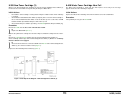

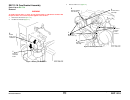

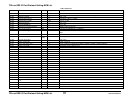

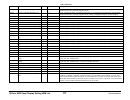

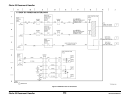

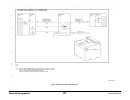

02/03 2-140 dc 3535/2240/1632 7-282 initial issue status indicator raps figure 2 7-282 rap circuit diagram - tray 2 level sensor (ttm) figure 3 7-282 rap circuit diagram - tray 2 feed lift motor (3tm) figure 4 7-282 rap circuit diagram - tray 2 level sensor (3tm).

Page 171

02/03 2-141 dc 3535/2240/1632 7-283 status indicator raps initial issue 7-283 tray 3 lift (3tm) the tray 3 level sensor does not detect tray lift. Initial actions remove tray 3 from the machine and empty the paper stock, then: • manually turn the gear at the rear of tray 3 to check that the bottom p...

Page 172

02/03 2-142 dc 3535/2240/1632 7-284 initial issue status indicator raps 7-284 tray 4 lift (3tm) the tray 4 level sensor does not detect tray lift. Initial actions remove tray 4 from the machine and empty the paper stock, then: • manually turn the gear at the rear of tray 4 to check that the bottom p...

Page 173

02/03 2-143 dc 3535/2240/1632 7-291 status indicator raps initial issue 7-291 tray 3 lift (ttm) the tray 3 level sensor does not detect tray lift. Initial actions pull out tray 3 and empty the paper stock, then: • manually turn the gear on the left side of tray 3 to check that the bottom plate moves...

Page 174

02/03 2-144 dc 3535/2240/1632 7-293 initial issue status indicator raps 7-293 tray 4 lift (ttm) the tray 4 level sensor does not detect tray lift. Initial actions pull out tray 4 and empty the paper stock, then: • manually turn the gear underneath tray 4 to check that the bottom plate moves up and d...

Page 175

02/03 2-145 dc 3535/2240/1632 7-397 status indicator raps initial issue 7-397 all trays lift sensors none of the tray level sensors can be energized. Procedure the machine is equipped with a 3tm. Y n check the dc122 shutdown history. A 7-281 , 7-282 , 7-291 , or 7-293 fault has occurred. Y n +24 vdc...

Page 176

02/03 2-146 dc 3535/2240/1632 7-397 initial issue status indicator raps figure 2 7-397 rap circuit diagram +5 vdc to the tray module pwb.

Page 177

02/03 2-147 dc 3535/2240/1632 7-930 status indicator raps initial issue 7-930 tray 1 paper size mismatch the paper in tray 1 does not match the paper size selected. Procedure the correct size paper is loaded in tray 1 and the paper guides are set correctly. Y n load the correct size paper. Go to the...

Page 178

02/03 2-148 dc 3535/2240/1632 7-931, 7-932 initial issue status indicator raps 7-931 tray 2 paper size mismatch the paper in tray 2 does not match the paper size selected. Procedure the correct size paper is loaded in tray 2 and the paper guides are set correctly. Y n ensure paper guides are correct...

Page 179

02/03 2-149 dc 3535/2240/1632 7-933, 7-935 status indicator raps initial issue 7-933 tray 4 paper size mismatch the paper in tray 4 does not match the paper size selected. Procedure the machine is equipped with a 3tm. Y n the correct size paper is loaded in tray 4 and the paper guides are set correc...

Page 180

02/03 2-150 dc 3535/2240/1632 7-954, 7-959 initial issue status indicator raps 7-954 tray 5 size mismatch (slow scan direction) the paper in the slow scan direction is shorter than the specified paper size. Procedure the correct size paper is loaded in the tray 5. Y n load the correct size paper. Re...

Page 181

02/03 2-151 dc 3535/2240/1632 7-960, 7-969 status indicator raps initial issue 7-960 tray 5 paper mismatch 2 a different paper type or transparency was detected when plain/heavyweight paper was speci- fied. Initial actions • check that the loaded paper type matches the ui selection. • check the ohp ...

Page 182

02/03 2-152 dc 3535/2240/1632 7-960, 7-969 initial issue status indicator raps.

Page 183

02/03 2-153 dc 3535/2240/1632 8-149 status indicator raps initial issue 8-149 tray 3 takeaway sensor on (3tm) the takeaway sensor does not detect paper fed from tray 3. Initial actions • check condition and specification of paper in tray 3. • check the paper path and sensor area for obstructions. • ...

Page 184

02/03 2-154 dc 3535/2240/1632 8-150 initial issue status indicator raps 8-150 tray 4 takeaway sensor on (3tm) the takeaway sensor does not detect paper fed from tray 4. Initial actions • check condition and specification of paper in tray 4. • check the paper path and sensor area for obstructions. • ...

Page 185

02/03 2-155 dc 3535/2240/1632 8-151 status indicator raps initial issue 8-151 tray 3 takeaway sensor on (ttm) the takeaway sensor does not detect paper fed from tray 3. Initial actions • check condition and specification of paper in tray 3. • check the paper path and sensor area for obstructions. • ...

Page 186

02/03 2-156 dc 3535/2240/1632 8-152 initial issue status indicator raps 8-152 tray 4 takeaway sensor on (ttm) the takeaway sensor does not detect paper fed from tray 4. Initial actions • check condition and specification of paper in tray 4. • check the paper path and sensor area for obstructions. • ...

Page 187

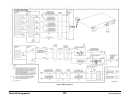

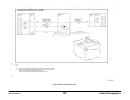

02/03 2-157 dc 3535/2240/1632 8-152 status indicator raps initial issue figure 2 8-152 rap circuit diagram - takeaway motor 1 figure 3 8-152 rap circuit diagram - takeaway motor 2.

Page 188

02/03 2-158 dc 3535/2240/1632 8-164 initial issue status indicator raps 8-164 pob sensor the pob sensor did not detect paper after the registration clutch energized. Initial actions • check condition and specification of the paper supply. • check for paper on the ibt. • check for obstructions in the...

Page 189

02/03 2-159 dc 3535/2240/1632 8-175 status indicator raps initial issue 8-175 registration sensor on jam tray 5 the registration sensor does not detect paper fed from the msi. Initial actions • check condition and specification of the paper supply. • check for obstructions in the paper feed path. • ...

Page 190

02/03 2-160 dc 3535/2240/1632 8-176 initial issue status indicator raps 8-176 registration sensor on jam tray 1-4 the registration sensor does not detect paper fed from tray 1 - 4. Initial actions • ensure customer closes left lower cover ( pl 2.3 ) firmly if dog ears also occur. • check condition a...

Page 191

02/03 2-161 dc 3535/2240/1632 8-180 status indicator raps initial issue 8-180 registration sensor on duplex the registration sensor does not detect paper after a duplex feed. Initial actions • check condition and specification of the paper supply. • check for obstructions in the paper feed path. • c...

Page 192

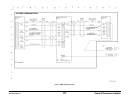

02/03 2-162 dc 3535/2240/1632 8-180 initial issue status indicator raps figure 2 8-180 rap circuit diagram - duplex motor figure 3 8-180 rap circuit diagram - inverter reverse clutch.

Page 193

02/03 2-163 dc 3535/2240/1632 8-181 status indicator raps initial issue 8-181 registration sensor on wait sensor the registration sensor does not detect paper after the duplex wait sensor was energized. Initial actions • check condition and specification of the paper supply. • check for obstructions...

Page 194

02/03 2-164 dc 3535/2240/1632 8-181 initial issue status indicator raps figure 2 8-181 rap circuit diagram - duplex wait sensor figure 3 8-181 rap circuit diagram - duplex motor.

Page 195

02/03 2-165 dc 3535/2240/1632 8-184 status indicator raps initial issue 8-184 registration sensor off the fuser exit switch did not detect paper after the registration clutch was energized. Initial actions • check condition and specification of the paper supply. • check for obstructions in the paper...

Page 196

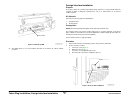

02/03 2-166 dc 3535/2240/1632 8-620, 8-622 initial issue status indicator raps 8-620 regicon temp sensor environment sensor not in range. Procedure note: machine operation continues. Status code not displayed on ui. Status code logged in history. Turn the power off. Disconnect the environment sensor...

Page 197

02/03 2-167 dc 3535/2240/1632 8-623, 8-624 status indicator raps initial issue 8-623 regicon data overflow (a2 patch y) at a2 patch detection, the yso correction setting value of either y, m, c, or k exceeds the set- ting range (nvm value 0 to 474). Note: status code not displayed on ui. Machine ope...

Page 198

02/03 2-168 dc 3535/2240/1632 8-625, 8-626 initial issue status indicator raps 8-625 regicon sample block (a1 patch-rear) at a1 (in) patch detection, the number of the sample blocks does not reach the specified num- ber. Note: status code not displayed on ui. Machine operation continues. Procedure c...

Page 199

02/03 2-169 dc 3535/2240/1632 8-627, 8-628 status indicator raps initial issue 8-627 regicon sample lateral (a1 patch-rear) at a1 (in) patch detection, the fast scan scan position of cyan color that is the standard for the rest is incorrect. (against the mob sensor, the center position of the cyan p...

Page 200

02/03 2-170 dc 3535/2240/1632 8-629, 8-630 initial issue status indicator raps 8-629 regicon skew (patch y) during a1 patch detection, skew deviation for y exceeded tolerance. Note: machine operation continues. Status code not displayed on ui. Status code logged in history. Initial actions clean mob...

Page 201

02/03 2-171 dc 3535/2240/1632 8-631, 8-900 status indicator raps initial issue 8-631 regicon skew (patch k) during a1 patch detection, skew deviation for k exceeded tolerance. Note: machine operation continues. Status code not displayed on ui. Status code logged in history. Initial actions clean mob...

Page 202

02/03 2-172 dc 3535/2240/1632 8-631, 8-900 initial issue status indicator raps.

Page 203

02/03 2-173 dc 3535/2240/1632 9-342 status indicator raps initial issue 9-342 2nd btr contact the 2nd btr did not reach the contact position. Initial actions • clean the 2nd btr retract sensor ( pl 2.9 ) and check for damage. • check the 2nd btr gears ( pl 2.8 ) for breakage. Procedure enter dc330 [...

Page 204

02/03 2-174 dc 3535/2240/1632 9-342 initial issue status indicator raps figure 2 9-342 rap circuit diagram - 2nd btr retract motor.

Page 205

02/03 2-175 dc 3535/2240/1632 9-343 status indicator raps initial issue 9-343 2nd btr retract the 2nd btr did not reach the retract position. Initial actions • clean the 2nd btr retract sensor ( pl 2.9 ) and check for damage. • check the 2nd btr gears ( pl 2.8 ) for breakage. Procedure enter dc330 [...

Page 206

02/03 2-176 dc 3535/2240/1632 9-343 initial issue status indicator raps figure 2 9-343 rap circuit diagram - 2nd btr retract motor.

Page 207

02/03 2-177 dc 3535/2240/1632 9-348 status indicator raps initial issue 9-348 1st btr contact the 1st btr did not reach the contact position. Initial actions • clean the 1st btr retract sensor ( pl 5.4 ) and check for damage • check the 1st btr worm gear and retract shaft ( pl 5.4 ) for breakage pro...

Page 208

02/03 2-178 dc 3535/2240/1632 9-348 initial issue status indicator raps figure 2 9-348 rap circuit diagram - 1st btr retract motor.

Page 209

02/03 2-179 dc 3535/2240/1632 9-349 status indicator raps initial issue 9-349 1st btr retract the 1st btr did not reach the retract position. Initial actions • clean the 1st btr retract sensor ( pl 5.4 ) and check for damage. • check the 1st btr worm gear and retract shaft ( pl 5.4 ) for breakage. P...

Page 210

02/03 2-180 dc 3535/2240/1632 9-349 initial issue status indicator raps figure 2 9-349 rap circuit diagram - 1st btr retract motor.

Page 211

02/03 2-181 dc 3535/2240/1632 9-350 status indicator raps initial issue 9-350 ibt home sensor the ibt home sensor detected the ibt position strip before the ibt belt made a complete rev- olution. Initial actions • ensure that the transfer belt is installed correctly. • clean the ibt home sensor ( pl...

Page 212

02/03 2-182 dc 3535/2240/1632 9-351 initial issue status indicator raps 9-351 drive logic the ibt edge sensor detected that the ibt belt is not tracking correctly. Initial actions • check the ibt edge sensor for damage. Ensure that the actuator is touching the edge of the belt. • check the ibt steer...

Page 213

02/03 2-183 dc 3535/2240/1632 9-358, 9-360 status indicator raps initial issue 9-358 full toner sensor the full toner sensor detects a full toner condition. Initial actions • ensure that the waste toner cartridge is not full. • check the sensor for toner contamination and foreign substances. Procedu...

Page 214

02/03 2-184 dc 3535/2240/1632 9-361, 9-362 initial issue status indicator raps 9-361 magenta drum cartridge communication a communication failure with magenta drum cartridge was detected. Initial actions check that the magenta drum cartridge is seated correctly. Procedure enter dc330 [009-152]. The ...

Page 215

02/03 2-185 dc 3535/2240/1632 9-363, 9-380 status indicator raps initial issue 9-363 black drum cartridge communication a communication failure with the black drum cartridge was detected. Initial actions check that the black drum cartridge is seated correctly. Procedure enter dc330 [009-154]. The di...

Page 216

02/03 2-186 dc 3535/2240/1632 9-381, 9-382 initial issue status indicator raps 9-381 atc sensor (m) the atc sensor (m) detects a low tc (toner concentration) initial actions • check that toner/developer is present. • check the atc sensor (m) for contamination. Ensure that the sensor is seated correc...

Page 217

02/03 2-187 dc 3535/2240/1632 9-383, 9-390 status indicator raps initial issue 9-383 atc sensor (k) the atc sensor (k) detects an insufficient amount of developer material initial actions • check that toner/developer is present. • check the atc sensor (k) for contamination. Ensure that the sensor is...

Page 218

02/03 2-188 dc 3535/2240/1632 9-391, 9-392 initial issue status indicator raps 9-391 new toner cartridge (c) the new cartridge detect switch (c) was not engaged to reset the accumulative dispense time nvm value to 0 when a new cartridge was installed. Initial actions • re-install the toner cartridge...

Page 219

02/03 2-189 dc 3535/2240/1632 9-393, 9-408 status indicator raps initial issue 9-393 new toner cartridge (y) when a new toner cartridge was installed, the level of the new cartridge detect switch (y) remained l when it should be changed to h by the dispense motor drive. Initial actions • re-install ...

Page 220

02/03 2-190 dc 3535/2240/1632 9-410 initial issue status indicator raps 9-410 toner cartridge (y) near empty the yellow toner cartridge is nearly empty/empty. This fault requires service only if the mes- sage appears before the toner cartridge is depleted. Note: continuous running of high density pr...

Page 221

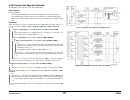

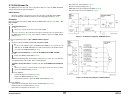

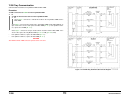

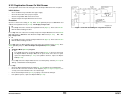

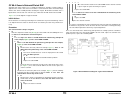

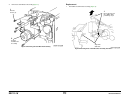

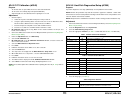

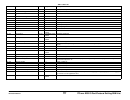

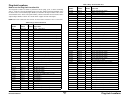

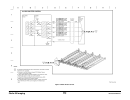

02/03 2-191 dc 3535/2240/1632 9-410, 9-411 status indicator raps initial issue figure 2 9-410 rap circuit diagram - dc2240/1632 developer motor figure 3 9-410 rap circuit diagram - dc3535 developer motor 9-411 toner cartridge (m) near empty the magenta toner cartridge is nearly empty. This fault req...

Page 222

02/03 2-192 dc 3535/2240/1632 9-411 initial issue status indicator raps y n go to the 9-381 , atc sensor failure rap. After checking that no failures are detected during normal operation, go to call closeout. Enter dc330 [009-014] and press start. The developer motor ( pl 1.1 ) energizes. Y n go to ...

Page 223

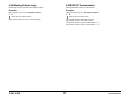

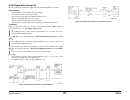

02/03 2-193 dc 3535/2240/1632 9-412 status indicator raps initial issue 9-412 toner cartridge (c) near empty the cyan toner cartridge is nearly empty/empty. This fault requires service only if the mes- sage appears before the toner cartridge is depleted. Note: continuous running of high density prin...

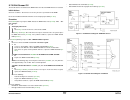

Page 224

02/03 2-194 dc 3535/2240/1632 9-412 initial issue status indicator raps figure 2 9-412 rap circuit diagram - dc2240/1632 developer motor figure 3 9-412 rap circuit diagram - dc3535 developer motor.

Page 225

02/03 2-195 dc 3535/2240/1632 9-413 status indicator raps initial issue 9-413 toner cartridge (k) near empty the black toner cartridge is nearly empty. This fault requires service only if the message appears before the toner cartridge is depleted. Note: continuous running of high density prints can ...

Page 226

02/03 2-196 dc 3535/2240/1632 9-428, 9-429 initial issue status indicator raps 9-428 change drum cartridge (k) soon the drum cartridge (k) needs to be replaced soon/reached end of life. Procedure replace the black drum cartridge (refer to section 6, machine consumables ). The problem is corrected. Y...

Page 227

02/03 2-197 dc 3535/2240/1632 9-430, 9-431 status indicator raps initial issue 9-430 change drum cartridge (m) soon the drum cartridge (m) needs to be replaced soon. Procedure replace the magenta drum cartridge (refer to section 6, machine consumables ). The prob- lem is corrected. Y n replace the m...

Page 228

02/03 2-198 dc 3535/2240/1632 9-654 initial issue status indicator raps 9-654 adc sensor the machine logic detected an adc sensor operation failure. Procedure the machine is a dc3535. Y n check adj 9.4 . The fail judgement of the adc sensor is ok. Y n there is +5vdc from p/j536 -a13 on the i/f pwb (...

Page 229

02/03 2-199 dc 3535/2240/1632 9-654 status indicator raps initial issue figure 1 9-654 rap circuit diagram - dc2240/1632 adc sensor figure 2 9-654 rap circuit diagram - dc3535 adc sensor.

Page 230

02/03 2-200 dc 3535/2240/1632 9-660, 9-661 initial issue status indicator raps 9-660 environment sensor temperature an incorrect value was detected by the environment sensor (temperature). Procedure disconnect p/j255 . There is 1 ohm or less measured between p255-3 and p255-4 on the environment sens...

Page 231

02/03 2-201 dc 3535/2240/1632 9-670, 9-671 status indicator raps initial issue 9-670 new toner cartridge (k) detected the machine logic detected that the toner cartridge has been replaced. This is a message fault only. Procedure switch the power off, then on. The message fault clears. Y n go to the ...

Page 232

02/03 2-202 dc 3535/2240/1632 9-672, 9-673 initial issue status indicator raps 9-672 new toner cartridge (m) detected the machine logic detected that the toner cartridge has been replaced. This is a message fault only. Procedure switch the power off, then on. The message fault clears. Y n go to the ...

Page 233

02/03 2-203 dc 3535/2240/1632 9-684 status indicator raps initial issue 9-684 adc shutter the machine logic detected an adc shutter operation failure. Procedure the machine is a dc3535. Y n enter dc330 [009-078] and press start. The adc shutter solenoid energized. Y n there is +24vdc from p/j536 -a7...

Page 234

02/03 2-204 dc 3535/2240/1632 9-684 initial issue status indicator raps figure 1 9-684 rap circuit diagram - dc2240/1632 adc sensor figure 2 9-684 rap circuit diagram - dc3535 adc sensor.

Page 235

02/03 2-205 dc 3535/2240/1632 9-910, 9-911 status indicator raps initial issue 9-910 drum (y) type mismatch drum type mismatch initial actions ensure that the correct drum type is installed. Procedure enter dc330 [009-151], (drum (y) data). The display is h. Y n go to figure 1 . Check the wires and ...

Page 236

02/03 2-206 dc 3535/2240/1632 9-912, 9-913 initial issue status indicator raps 9-912 drum (c) type mismatch drum type mismatch initial actions ensure that the correct drum type is installed. Procedure enter dc330 [009-153] (drum (c) data). The display is h. Y n check the wires and connectors. If the...

Page 237

02/03 2-207 dc 3535/2240/1632 9-920, 9-921 status indicator raps initial issue 9-920 toner cartridge (y) empty the yellow toner cartridge is empty. This fault requires service only if the message appears before the toner cartridge is depleted. Note: continuous running of high density prints can temp...

Page 238

02/03 2-208 dc 3535/2240/1632 9-922, 9-923 initial issue status indicator raps 9-922 toner cartridge (c) empty the cyan toner cartridge is empty. This fault requires service only if the message appears before the toner cartridge is depleted. Note: continuous running of high density prints can tempor...

Page 239

02/03 2-209 dc 3535/2240/1632 9-924, 9-925 status indicator raps initial issue 9-924 waste toner cartridge full the waste toner cartridge is full. Initial actions replace the waste toner cartridge. Check the full toner sensor for contaminants. Procedure if the problem persists, go to the 9-358 rap. ...

Page 240

02/03 2-210 dc 3535/2240/1632 9-926, 9-927 initial issue status indicator raps 9-926 drum cartridge (k) end of life the drum cartridge (k) needs to be replaced. Procedure replace the black drum cartridge (refer to section 6, machine consumables ). The problem is corrected. Y n replace the mcu pwb. (...

Page 241

02/03 2-211 dc 3535/2240/1632 9-928, 9-929 status indicator raps initial issue 9-928 drum cartridge (m) end of life the drum cartridge (m) needs to be replaced. Procedure replace the magenta drum cartridge (refer to section 6, machine consumables ). The prob- lem is corrected. Y n replace the mcu pw...

Page 242

02/03 2-212 dc 3535/2240/1632 9-930, 9-931 initial issue status indicator raps 9-930 black drum cartridge not detected the machine logic detected that black drum cartridge is not installed. Initial actions • ensure black drum cartridge is installed correctly. • switch the power off, then on. Procedu...

Page 243

02/03 2-213 dc 3535/2240/1632 9-932, 9-933 status indicator raps initial issue 9-932 magenta drum cartridge not detected the machine logic detected that magenta drum cartridge is not installed. Initial actions • ensure magenta drum cartridge is installed correctly. • switch the power off, then on. P...

Page 244

02/03 2-214 dc 3535/2240/1632 9-932, 9-933 initial issue status indicator raps.

Page 245

02/03 2-215 dc 3535/2240/1632 10-110 status indicator raps initial issue 10-110 fuser exit switch on (duplex) the fuser exit switch did not energize. Initial actions • check condition and specification of the paper supply. • check for obstructions in the paper feed path. • clean the fuser exit roll ...

Page 246

02/03 2-216 dc 3535/2240/1632 10-111 initial issue status indicator raps 10-111 fuser exit switch off the fuser exit switch did not de-energize. Initial actions • check condition and specification of the paper supply. • check for obstructions in the paper feed path. • clean the fuser exit roll and c...

Page 247

02/03 2-217 dc 3535/2240/1632 10-125 status indicator raps initial issue 10-125 duplex wait sensor on paper did not arrive at the duplex wait sensor within the specified period of time. Initial actions • check condition and specification of the paper supply. • check the paper path for obstructions. ...

Page 248

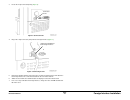

02/03 2-218 dc 3535/2240/1632 10-125 initial issue status indicator raps figure 2 10-125 rap circuit diagram - duplex wait sensor figure 3 10-125 rap circuit diagram - duplex motor.

Page 249

02/03 2-219 dc 3535/2240/1632 10-125 status indicator raps initial issue figure 4 10-125 rap circuit diagram - inverter forward clutch figure 5 10-125 rap circuit diagram - inverter reverse clutch.

Page 250

02/03 2-220 dc 3535/2240/1632 10-348 initial issue status indicator raps 10-348 main heater over heat the front thermistor detected an overheat condition. Initial actions turn off the power, remove the fuser assembly, and allow it to cool down. Procedure note: if this fault is declared 3 times in su...

Page 251

02/03 2-221 dc 3535/2240/1632 10-349, 10-350 status indicator raps initial issue 10-349 front thermistor open the machine logic detected an open circuit in the front thermistor. Initial actions turn off the power, remove the fuser assembly, and allow it to cool down. Procedure measure the resistance...

Page 252

02/03 2-222 dc 3535/2240/1632 10-350 initial issue status indicator raps figure 2 10-350 rap circuit diagram - main heater and sub heater.

Page 253

02/03 2-223 dc 3535/2240/1632 10-351, 10-352 status indicator raps initial issue 10-351 rear thermistor open the machine logic detected an open circuit in the rear thermistor. Initial actions turn off the power, remove the fuser assembly and allow it to cool down. Procedure measure the resistance be...

Page 254

02/03 2-224 dc 3535/2240/1632 10-352 initial issue status indicator raps figure 1 10-352 rap circuit diagram - front thermistor figure 2 10-352 rap circuit diagram - main heater and sub heater.

Page 255

02/03 2-225 dc 3535/2240/1632 10-353 status indicator raps initial issue 10-353 main heater on time the main heater remained on for more than the specified time. Initial actions turn off the power, remove the fuser assembly, and allow it to cool down. Procedure measure the resistance between p600 -4...

Page 256

02/03 2-226 dc 3535/2240/1632 10-353 initial issue status indicator raps figure 2 10-353 rap circuit diagram - main heater and sub heater.

Page 257

02/03 2-227 dc 3535/2240/1632 10-354 status indicator raps initial issue 10-354 sub heater warm up the temperature did not reach the ready temperature. Initial actions turn off the power, remove the fuser assembly, and allow it to cool down. Procedure note: if this fault is declared 3 times in succe...

Page 258

02/03 2-228 dc 3535/2240/1632 10-354 initial issue status indicator raps figure 2 10-354 rap circuit diagram - main heater and sub heater.

Page 259

02/03 2-229 dc 3535/2240/1632 10-356 status indicator raps initial issue 10-356 sub heater on time the sub heater remained on for more than the specified time. Initial actions turn off the power, remove the fuser assembly, and allow it to cool down. Procedure measure the resistance between p600 -7 a...

Page 260

02/03 2-230 dc 3535/2240/1632 10-356 initial issue status indicator raps figure 2 10-356 rap circuit diagram - main heater and sub heater.

Page 261

02/03 2-231 dc 3535/2240/1632 10-398 status indicator raps initial issue 10-398 fan lock the machine logic detected a failure of the fuser fan, lvps fan or the rear fan. Procedure enter dc330 [004-050]. Press start. The fuser fan ( pl 8.1 ) revolves at high speed. Y n there is +24 vdc from p/j222 pi...

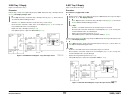

Page 262

02/03 2-232 dc 3535/2240/1632 10-398 initial issue status indicator raps figure 1 10-398 rap circuit diagram - fuser fan figure 2 10-398 rap circuit diagram - dc 2240/1632 rear fan figure 3 10-398 rap circuit diagram - dc 3535 rear fan figure 4 10-398 rap circuit diagram - dc 2240/1632 lvps fan.

Page 263

02/03 2-233 dc 3535/2240/1632 10-398, 10-420 status indicator raps initial issue figure 5 10-398 rap circuit diagram - dc 3535 lvps fan 10-420 fuser near end of life replace the fuser assembly in x copies. Procedure the fuser assembly was replaced. Y n replace the fuser assembly ( pl 7.2 ) run the d...

Page 264

02/03 2-234 dc 3535/2240/1632 10-421 initial issue status indicator raps 10-421 fuser end of life fuser at end of life. Procedure the fuser assembly was replaced. Y n replace the fuser assembly ( pl 7.2 ). Run the dc135 [954-804]. The initial value is 0. Y n replace the mcu pwb ( pl 13.1 ). Ensure t...

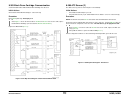

Page 265

02/03 2-235 dc 3535/2240/1632 12-100 status indicator raps initial issue 12-100 h transport entrance sensor on the h transport entrance sensor does not detect paper after the registration clutch (in iot) energized. Initial actions • check condition and specification of the paper supply. • check for ...

Page 266

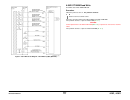

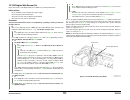

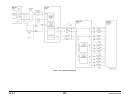

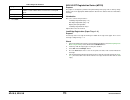

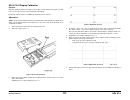

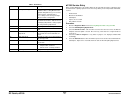

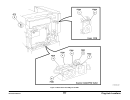

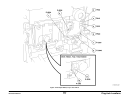

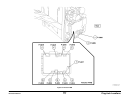

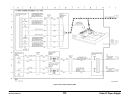

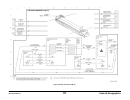

02/03 2-236 dc 3535/2240/1632 12-100 initial issue status indicator raps figure 4 12-100 rap circuit diagram - finisher drive motor figure 5 finisher pwb.

Page 267