- DL manuals

- Panasonic

- Copier

- Workio DP-C265

- Service Manual

Panasonic Workio DP-C265 Service Manual

Order Number: MGCS071206C0

H21

Digital Color Imaging Systems

DP-C405 / C305 / C265

[

Version 1.1

]

This service information is designed for experienced repair technicians only and is not intended for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt within this service information by anyone else could result in serious injury or death.

WARNING

© 2008 Panasonic Communications Co., Ltd.

All rights reserved. Unauthorized copying and distribution is

a violation of law.

Summary of Workio DP-C265

Page 1

Order number: mgcs071206c0 h21 digital color imaging systems dp-c405 / c305 / c265 [ version 1.1 ] this service information is designed for experienced repair technicians only and is not intended for use by the general public. It does not contain warnings or cautions to advise non-technical individu...

Page 2

2.

Page 3

3.

Page 4: Important Notice

4 important notice this service information is designed for experienced repair technicians only and is not intended for use by the general public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by...

Page 5

5.

Page 6

6 for pb and other destinations, not for pu (usa/canada).

Page 7: Unpacking Caution

7 unpacking caution do not lift the paper transport unit by the pc board, as damage to the pc board will occur. Make sure to lift the paper transport unit as shown in the illustrations below . Note: refer to the installation instructions when installing the unit..

Page 8

8 precautions power and ground connection cautions ensure that the plug connection is free of dust. In a damp environment, a contaminated connector can draw a significant amount of current that can generate heat and eventually cause fire if left unattended over an extended period of time. Always use...

Page 9

9 once a month, unplug the machine and check the power cord for the following. If you notice any unusual condition, contact your authorized panasonic dealer . The power cord is plugged firmly into the receptacle. The plug is not excessively heated, rusted, or bent. The plug and receptacle are free o...

Page 10

10 operating safeguards do not place a magnet near the safety switch of the machine. A magnet can activate the machine accidentally, resulting in injuries. Do not use a highly flammable spray, or solvent near the machine. It can cause fire. When copying a thick document, do not use excessive force t...

Page 11

11.

Page 12

12.

Page 13

13.

Page 14

14 memo.

Page 15

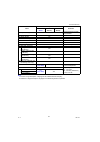

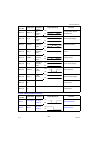

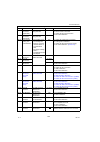

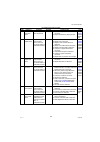

Table of contents 15 specifications table .............................. 17 1.1. Copy function.........................................17 1.2. Fax, printer and internet fax functions ................................................28 1.3. System combination for dp-c405 series...........................

Page 16

Table of contents 16 7.5. Adjustment............................................623 7.6. Service notes .......................................625 installation (for pb and other destinations)......... 627 8.1. Precautions during set up ...................627 8.2. Unpacking...............................

Page 17

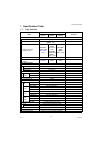

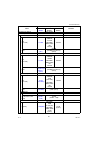

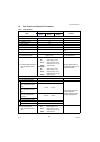

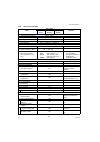

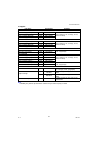

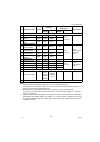

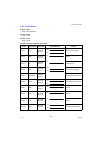

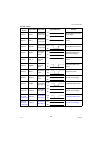

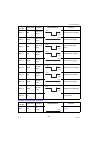

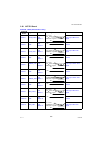

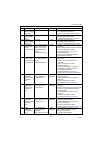

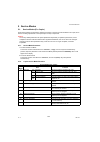

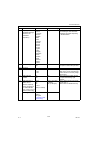

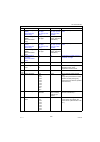

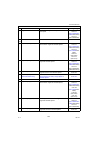

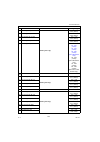

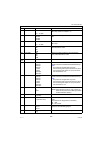

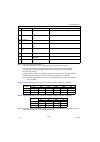

17 dp-c405/c305/c265 feb 2008 ver. 1.1 1 specifications table 1.1. Copy function items description remarks dp-c405 series (dp-c354 series) (dp-c322 series) multi function 1 copy function yes 2 printer function std : pcl6 option : ps3 3 scanner function (network only) dp-c405 / c305 / c265 std : mono...

Page 18

18 dp-c405/c305/c265 feb 2008 ver. 1.1 10 adf paper capacity (original) 100 sheets (ltr) 100 sheets (a4) 85 sheets (ltr) 70 sheets (a4) 70 sheets (ltr/a4) usa/canada etc. Ltr : 20 lb (75 g/m 2 ) other destinations a4 : 80 g/m 2 original exchange speed mono up to 45 cpm up to 35 cpm up to 32 cpm ltr ...

Page 19

19 dp-c405/c305/c265 feb 2008 ver. 1.1 mono lt / a4, from paper tray exit to inner tray up to 40 cpm dp-c405 - - up to 35 cpm - dp-c354 - up to 32 cpm - dp-c323 dp-c322 up to 30 cpm dp-c305 - - up to 26 cpm dp-c265 dp-c264 / c263 dp-c262 up to 21 cpm - dp-c213 - 15 tone scale color 256 steps (each c...

Page 20

20 dp-c405/c305/c265 feb 2008 ver. 1.1 25 multi copy range 999 sheets 26 memory main memory std. (sc pcb) 512 mb dp-c354 / c264-pu 512 mb dp-c323 / c263 / c213- pu 256 mb 256 mb max. 512 mb (std.) 512 mb (256 mb page memory: option) page memory std. (sc pcb) 512 mb dp-c354 / c264-pu 384mb dp-c323 / ...

Page 21

21 dp-c405/c305/c265 feb 2008 ver. 1.1 27 paper stack capacity inner tray ltr : 24 lb / a4 : 90 g/m 2 these numbers may vary with the kind of paper used and/or ambient conditions by detecting paper full sensor. Std. 250 sheets with paper transport (opt.) 150 sheets outer tray 250 sheets ltr : 24 lb ...

Page 22

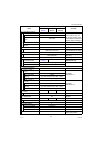

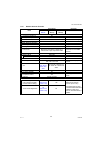

22 dp-c405/c305/c265 feb 2008 ver. 1.1 7 counter key counter capability no mechanical total counter yes supplied as a service part for usa/canada etc. 8 memory page memory 256 mb 128 mb x 2 sd memory card (w/ sd/sdhc memory card on sc pcb) 96 mb (64 mb - 4 gb) 96 mb (64 mb - 1 gb) for fax/internet f...

Page 23

23 dp-c405/c305/c265 feb 2008 ver. 1.1 image overlay yes (12 images) (hdd: std.) yes (1 image) max 12 images with hdd option image repeat yes others (inverting adf & adu) 2-page copy mode yes ldr → ltr x 2 (a3 → a4 x 2, b4 → b5 x 2) 2 in 1 yes 4 in 1 yes 6 in 1 yes for usa/canada, etc. 8 in 1 yes fo...

Page 24

24 dp-c405/c305/c265 feb 2008 ver. 1.1 job completion notice yes proof copy mode yes function mode yes interrupt yes electronic counter yes digital sky shot mode yes manual skyshot mode yes 3 control panel display color vga touch panel lcd status lamp yes green: data & active red/yellow: caution & w...

Page 25

25 dp-c405/c305/c265 feb 2008 ver. 1.1 error code yes finishing yes warning indicators yes add toner yes (each color) drum yes (each color) toner waste container full yes paper indicator yes 0% and less than 10%, 50%, 100% add paper (under 50 sheets) no paper jam indication yes paper jam location ye...

Page 26

26 dp-c405/c305/c265 feb 2008 ver. 1.1 toner waste container 28 k ratio: color vs. Black = 2 : 8, image coverage 5%, lt/a4, 4 pages/job. Developer life 480 k change as developer unit efficiency 1 productivity adf productivity (ltr / a4) i-adf 100% adu copy productivity (ltr / a4) throughput when exi...

Page 27

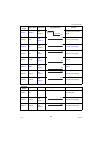

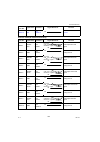

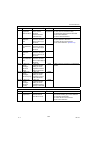

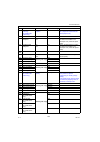

27 dp-c405/c305/c265 feb 2008 ver. 1.1 2 packing weight scanner/ i-adf pre-installed model 407.9 lb (185 k g) - usa/canada only scanner & i-adf unit 127.9 lb (58 k g) 123.2 lb (56 k g) printer unit 313.1 lb (142 k g) 321.2 lb (146 k g) 3 accessories process unit yes developer yes toner no toner wast...

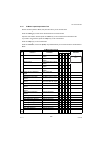

Page 28

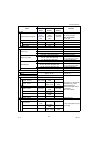

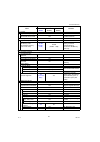

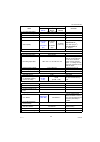

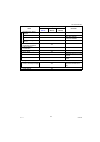

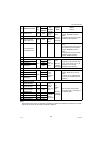

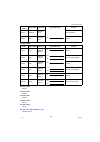

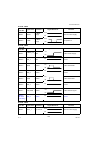

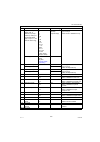

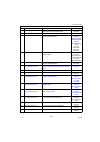

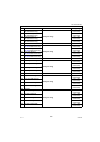

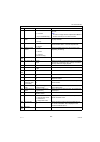

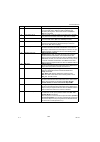

28 dp-c405/c305/c265 feb 2008 ver. 1.1 1.2. Fax, printer and internet fax functions 1.2.1. Fax function items description remarks dp-c405 series (dp-c354 series) (dp-c322 series) main specifications 1 compatibility g3 itu-t std. & non-std. 2 pstn line port yes 1-line only 3 leased line port no 4 v.2...

Page 29

29 dp-c405/c305/c265 feb 2008 ver. 1.1 5 document size (max.) adf: ldr / a3 6 effective scanning width ldr :10.8 in (274 mm) / a3 : (292 mm) 7 a3 size tx/rx yes conforms to itu-t a3 8 reduction xmt yes a3 to b4 / a3 to a4 / b4 to a4 9 adf capacity 100 sheets (ltr) 100 sheets (a4) 85 sheets (ltr) 70 ...

Page 30

30 dp-c405/c305/c265 feb 2008 ver. 1.1 6 max. Station name characters 15 7 full number dialing (buffered dialing) yes max. 70 stations 8 direct dialing (monitor dialing) yes voice mode 9 automatic redialing yes default setting is up to 5 times at 3 min. Intervals, however, if a busy line is not dete...

Page 31

31 dp-c405/c305/c265 feb 2008 ver. 1.1 16 duplex scanning yes 17 multi-station selection prohibition yes no 18 confirmation of selected station yes no 19 direct dial prohibition yes no 20 direct dial re-entering yes no reception features 1 substitute reception yes 2 fixed reduction yes ltr/a4/lgl: 7...

Page 32

32 dp-c405/c305/c265 feb 2008 ver. 1.1 4 comm. Journal yes with image data 5 last ind. Xmt journal yes list printouts 1 one-touch list - 2 abbr. No. List - 3 program list yes 4 address book search list yes auto dialer list 5 fax parameter list yes 6 file list yes with view mode 7 ind. Xmt journal ye...

Page 33

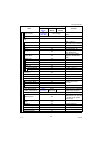

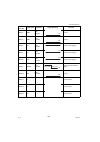

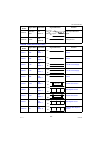

33 dp-c405/c305/c265 feb 2008 ver. 1.1 1.2.2. Printer function items description remarks dp-c405 series (dp-c354 series) (dp-c322 series) interface 1 centronics parallel i/f no 2 lan (network) ethernet 10base-t / 100base-tx 3 usb port yes usb 2.0 high/full speed support 4 ieee-1394 no firewire print...

Page 34

34 dp-c405/c305/c265 feb 2008 ver. 1.1 note: 1. Pcl6 is a page description language of the hewlett-packard company. 2. Ps/ps3 is a page description language of the adobe systems incorporated. 11 duplex printing yes custom size/postcard size is not available. 12 collation stack yes 13 status monitor ...

Page 35

35 dp-c405/c305/c265 feb 2008 ver. 1.1 1.2.3. Network scanner function items description remarks dp-c405 series (dp-c354 series) (dp-c322 series) interface 1 centronics parallel i/f no 2 lan (network) ethernet 10base-t/ 100base-tx 3 usb port no port is used for printing only. 4 ieee-1394 no firewire...

Page 36

36 dp-c405/c305/c265 feb 2008 ver. 1.1 1.2.4. Internet fax function items description remarks dp-c405 series (dp-c354 series) (dp-c322 series) main specifications 1 communication protocols smtp / pop3 2 max. Modem speed n/a 3 coding scheme jbig/mmr/mr/mh 4 file format tiff 5 lan (network) ethernet 1...

Page 37

37 dp-c405/c305/c265 feb 2008 ver. 1.1 received fax / email forward yes local print available pc to fax transmission no inbound routing yes using sub-address local print available phone book registration from pc yes via email 4 internet fax parameters registration via email yes 5 internet delivery c...

Page 38

38 dp-c405/c305/c265 feb 2008 ver. 1.1 1.2.5. Sd memory card on the sc pcb (not the front slot) sd memory card formatting structure and partitioning by function note: 1. This function is available only when an sd memory card is installed on the pcb (not in the front slot), and is used for g3 fax / i...

Page 39

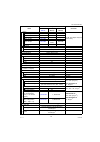

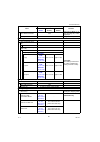

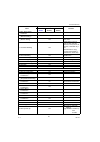

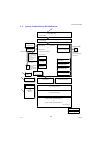

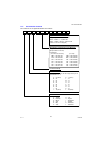

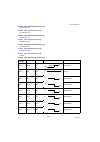

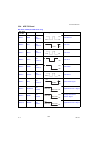

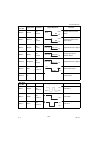

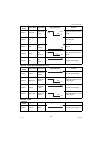

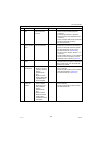

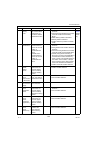

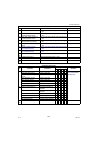

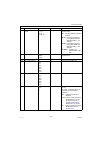

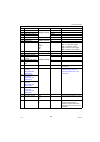

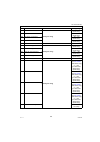

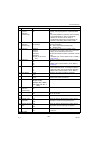

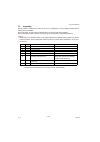

39 dp-c405/c305/c265 feb 2008 ver. 1.1 1.3. System combination for dp-c405 series scanner unit main pc board (sc pc board) - usb interface - 10/100 ethernet interface tray 2 (550 sheet paper) inverting adf (i-adf) adf pc board option standard configuration color panel (pnl pc board) main memory 256 ...

Page 40

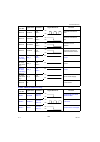

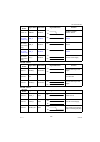

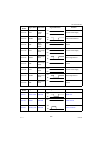

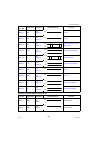

40 dp-c405/c305/c265 feb 2008 ver. 1.1 1.4. Options and supplies for dp-c405 series 1. Options note: 1. Pcl6 is a page description language of the hewlett-packard company. 2. Ps3 is a page description language of the adobe systems incorporated. 3. Availability may differ as per destination. Please a...

Page 41

41 dp-c405/c305/c265 feb 2008 ver. 1.1 2. Supplies note: 1. Availability may differ as per destination. Please ask your sales company for detail. 2. The yield of a toner cartridge varies depending on the coverage, temperature, humidity, media, etc. Therefore, the average yield cannot be guaranteed (...

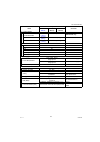

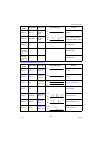

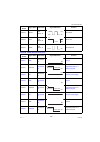

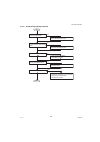

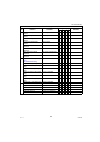

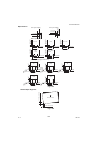

Page 42: Tion

42 dp-c405/c305/c265 feb 2008 ver. 1.1 3. Option configuration a d u pr inter sc anner i- adf da-fs405 da-fs402 d a -x t320 d a -sp41 1- b in fin isher ex it tr ay ( o uter ) 1-b in s a ddle-s titch fin isher pu nch unit pa per transpo rt un it 550 x 2 550 + c ab in e t d a -d s 320 d a -d s 321 sy ...

Page 43

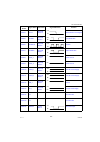

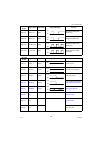

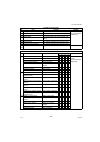

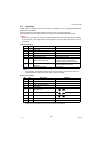

43 dp-c405/c305/c265 feb 2008 ver. 1.1 1.5. Options and supplies for dp-c354/c322 series 1. Options note: 1. Pcl6 is a page description language of the hewlett-packard company. 2. Ps3 is a page description language of the adobe systems incorporated. 3. Availability may differ as per destination. Ple...

Page 44

44 dp-c405/c305/c265 feb 2008 ver. 1.1 2. Supplies note: availability may differ as per destination. Please ask your sales company for detail. Part name part number remarks dp-c354/c323/c264/c263 toner cartridge (black) 28k dq-tus28k (yield is based on 5% coverage, lt/a4, continuous print) toner car...

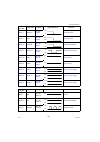

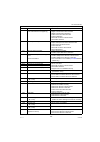

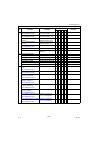

Page 45: Tion

45 dp-c405/c305/c265 feb 2008 ver. 1.1 3. Option configuration a d u pr inter sc anner i- adf da-fs356 da-fs350 d a -x t320 d a -sp41 1- b in fin isher ex it tr ay ( o uter ) 1-b in s a ddle-s titch fin isher pu nch unit pa per transpo rt un it 550 x 2 550 + c ab in e t d a -d s 320 d a -d s 321 sy ...

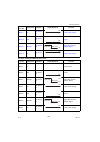

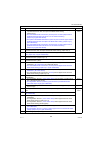

Page 46: Tion

46 dp-c405/c305/c265 feb 2008 ver. 1.1 a d u pr inter sc anner i- adf d a -x t320 d a -sp41 1- b in fin isher ex it tr ay ( o uter ) 1-b in s a ddle-s titch fin isher pu nch unit pa per transpo rt un it 550 x 2 550 + c ab in e t d a -d s 320 d a -d s 321 sy stem c onso le sy stem c onso le 2 pa ge m...

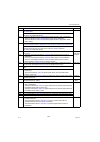

Page 47: Tion

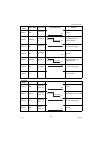

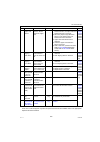

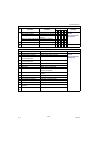

47 dp-c405/c305/c265 feb 2008 ver. 1.1 a d u pr inter sc anner i- adf d a -fs325 d a -fs320 d a -x t320 d a -sp4 1 1- b in fin isher ex it tr ay ( o uter ) 1-b in s a ddle-s titch fin isher pu nch u n it pa per transpo rt un it fax c omm unicat ion b oar d d a -f g320 550 x 2 550 + c ab in e t d a -...

Page 48

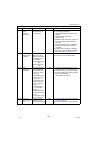

48 dp-c405/c305/c265 feb 2008 ver. 1.1 1.6. External view 1. Standard configuration 32.5 in (826mm) 36.7 in (933 mm) 26.1 in (664 mm) manufacturer's name and address factory id complies with fda radiation performance standards, 21 cfr subchapter j (for usa only) front view right view left view rear ...

Page 49

49 dp-c405/c305/c265 feb 2008 ver. 1.1 2. With optional system console and finisher configuration 1-bin finisher (da-fs402 / fs350 / fs320) 1-bin saddle-stitch finisher (da-fs405 / fs356 / fs325) 46.73 in (1187 mm) 10.51 in (267 mm) 14.84 in (377 mm) front view right view left view top view rear vie...

Page 50

50 dp-c405/c305/c265 feb 2008 ver. 1.1 3. Space requirements with options main unit + exit tray (outer) main unit main unit + 1 bin finisher 55.48 in (1410 mm) 45.87 in (1165mm) 3.94 in (100 mm) 11.85 in (301 mm) 3.94 in (100 mm) 3.94 in (100 mm) 3.94 in (100 mm) 15.11 in (384 mm) main unit + 1 bin ...

Page 51

51 dp-c405/c305/c265 feb 2008 ver. 1.1 1.6.1. Serial number contents the contents of the 11-digit serial number is as follows: 2 3 4 5 6 1 sequential production number 5-digit sequential production number 00001 ~ 99999 = 1 ~ 99,999 units a0001 ~ y9999 = 100,000 ~ 329,976 units (letters "i" and "o" a...

Page 52

52 dp-c405/c305/c265 feb 2008 ver. 1.1 1.7. Control panel note 1: model availability may differ as per destination. Please ask your sales company for details. Note 2: lcd display brightness adjustment to adjust the brightness of the lcd display, press and while holding down the “clear” key, keep pre...

Page 53

53 dp-c405/c305/c265 feb 2008 ver. 1.1 1.8. Fans 1.9. Motors pressure roller fan right cover fan ih fan lsu fan lvps fan ih driver fan toner bottle fan lift motor (tray 1) lift motor (tray 2) lift motor (tray 3) lift motor (tray 4) adf paper feed motor adf feed motor drum motor 1 paper transport uni...

Page 54

54 dp-c405/c305/c265 feb 2008 ver. 1.1 1.10. Sensors paper size sensor (1722, 1723) platen cover (adf) open sensor (401-12) platen cover (adf) angle sensor (401-11) adf original length sensor 2 (401-03) adf original length sensor 1 (401-04) adf original width sensor 1 (401-02) adf original width sen...

Page 55

55 dp-c405/c305/c265 feb 2008 ver. 1.1 thermistor (hr1) thermistor (hr2) fuser roller rotating encoder 1 (1819-19) fuser roller rotating encoder 2 (1819-18) thermistor (pr) (5031) fuser pressure release sensor 1 (1819-17) fuser pressure release sensor 2 (1819-16) fuser entrance sensor (1819-43) ih c...

Page 56

56 dp-c405/c305/c265 feb 2008 ver. 1.1 1.11. Clutches and switches 1.12. Pc board pickup roller solenoid (tray 1) paper feed roller clutch (tray 1) pickup roller solenoid (tray 2) paper feed roller clutch (tray2) pickup roller solenoid (tray 3) paper feed roller clutch (tray 3) pickup roller solenoi...

Page 57

57 dp-c405/c305/c265 feb 2008 ver. 1.1 2 disassembly instructions 2.1. General disassembly pertinent disassembly instruction sections are shown below. I-adf str unit and intermediate transfer (it) unit 2.2.1. Scanner unit 2.2.10. 2.2.2. Process unit control panel unit 2.2.11. 2.2.3. Lsu fuser unit 2...

Page 58

58 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2. Disassembly instructions 2.2.1. Inverting-automatic document feeder (i-adf) unit (1) lift the original tray assembly. (2) clean the exit roller (814). (3) open the adf cover. (4) clean the pickup roller (511), paper feed roller (508), separation roller (61...

Page 59

59 dp-c405/c305/c265 feb 2008 ver. 1.1 (7) remove the paper feed roller shaft assembly by pulling in the arrow direction. (8) remove the paper feed roller (508). (9) move the pickup bracket. (10) remove 2 snap rings (h7). (11) remove the pickup roller shaft (510). (12) remove the pickup roller (511)...

Page 60

60 dp-c405/c305/c265 feb 2008 ver. 1.1 (13) remove 3 screws (x8). (14) remove the lower opening and shutting guide 1 (601). (15) remove the separation roller assembly. (16) remove the snap ring (h6). Note: when reinstalling, make sure that the snap ring is installed properly as illustrated..

Page 61

61 dp-c405/c305/c265 feb 2008 ver. 1.1 (17) remove the separation roller shaft (607). (18) remove the separation roller (610). Note: when reassembling the separation roller, make sure that the yellow tooler's die on the side of the roller is positioned as illustrated (facing the front frame). (19) l...

Page 62

62 dp-c405/c305/c265 feb 2008 ver. 1.1 (25) remove 1 screw (j2). (26) loosen 3 screws (s6). (27) lift up the original tray assembly. (28) remove the adf rear cover (627). (29) remove 3 screws (5m). (30) remove the front adf gear bracket assembly. (31) remove the 16t gear (825). (32) remove 1 screw (...

Page 63

63 dp-c405/c305/c265 feb 2008 ver. 1.1 (34) release the adf cover arm (624). (35) remove the adf cover assembly. Note: when reinstalling the adf cover assembly, make sure that the vibration guide sheet 1 and 2 are reinstalled properly as illustrated. Note: when reinstalling the adf cover assembly, m...

Page 64

64 dp-c405/c305/c265 feb 2008 ver. 1.1 (38) clean the registration roller 2 (818). (39) remove the snap ring (g6). (40) remove 1 screw (x5). (41) loosen 1 screw. (42) remove the registration limiter bracket (829) as illustrated. (43) remove the limiter joint (828). (44) remove the registration rolle...

Page 65

65 dp-c405/c305/c265 feb 2008 ver. 1.1 (46) remove 2 snap rings (g6). (47) remove the clutch 1 (801). (48) remove 2 d8 bearings (822). (49) remove the registration roller 2 (818). (50) remove 2 registration guide sheets 1 (1119), and 2 registration guide sheets 2 (1120). Caution: do not remove the i...

Page 66

66 dp-c405/c305/c265 feb 2008 ver. 1.1 note: when reinstalling the registration guide sheet 1 and 2, make sure that the sheets are placed on the marks as illustrated. (51) open the lower opening and shutting guide assembly. (52) lift the original tray assembly. (53) lower the inverting guide assembl...

Page 67

67 dp-c405/c305/c265 feb 2008 ver. 1.1 (56) remove 4 screws (x5). (57) remove the lower exit guide (716). (58) clean the transport roller (816)..

Page 68

68 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.2. Scanner unit (1) open the adf. (2) clean the white reference sheet, and scanning pad with a soft cloth, saturated with isopropyl alcohol. (3) clean the scanning (s) glass, and platen (l) glass with a soft cloth, saturated with isopropyl alcohol. (4) remo...

Page 69

69 dp-c405/c305/c265 feb 2008 ver. 1.1 (6) remove the glass assembly. (7) remove 1 screw (x5). (8) remove 2 screws (x3). (9) remove the heat sink plate (1608). (10) move the scanning lamp to a position where it can be easily replaced. (11) remove 3 screws (x5). (12) release the harness from the clam...

Page 70

70 dp-c405/c305/c265 feb 2008 ver. 1.1 (14) turn the inverter pc board case upside down. (15) disconnect the flat harness on the inverter pc board. (16) remove the inverter pc board assembly. (17) disconnect the lamp harness. (18) remove the scanning lamp (1615). (19) remove 2 screws (x8). (20) remo...

Page 71

71 dp-c405/c305/c265 feb 2008 ver. 1.1 (21) remove 8 screws (x5). (22) remove the ccd cover (1627). (23) disconnect 2 harnesses on the ccd pc board. (24) remove 2 screws (y23). (25) remove the ccd unit (1631). Important: before proceeding, make a note of the position of the alignment pointer. If the...

Page 72

72 dp-c405/c305/c265 feb 2008 ver. 1.1 (26) remove 2 screws (y31). Dp-c405 series : pb and other destinations (except pu / pt) (27) remove 2 metal clamps on the afe pc board. (28) disconnect all the harnesses on the afe pc board. (29) remove 4 screws (y31). (30) remove the afe pc board (1630)..

Page 73

73 dp-c405/c305/c265 feb 2008 ver. 1.1 (31) remove 2 screws (x5). (32) disconnect 2 harnesses from the sensor. (33) remove 2 multi beam sensor 1 (1722). Note: 1. Do not touch the surface of the sensors with your hands. 2. Clean any dirt or fingerprints with a dry cotton swab. 3. Do not use isopropyl...

Page 74

74 dp-c405/c305/c265 feb 2008 ver. 1.1 (41) clean the mirror 1 (1602) with a soft cloth. Note: 1. Do not touch the surface of the mirrors with your hands. 2. Clean any dirt or fingerprints with a dry cotton swab. 3. Do not use isopropyl alcohol or any other alcohol. (42) remove 2 screws (s6). (43) r...

Page 75

75 dp-c405/c305/c265 feb 2008 ver. 1.1 (47) remove 2 screws (x5). (48) remove the adf harness holder (1517). (49) disconnect the adf harness. Note: when reinstalling the adf, take note of the connector position, and its keys. Insert it gently, and do not force the connector if it is facing the wrong...

Page 76

76 dp-c405/c305/c265 feb 2008 ver. 1.1 (56) unhook, and remove the motor spring (1708). (57) disconnect the harness. (58) remove 2 screws (y21). (59) remove the motor bracket assembly. (60) remove the e-ring (j7). (61) remove the reduction gear (1711). (62) remove 2 screws (y16). (63) remove the sca...

Page 77

77 dp-c405/c305/c265 feb 2008 ver. 1.1 (64) disconnect the harness. (65) remove the photo sensor ( 401-13 ). (adf) open sensor> (66) disconnect the 2 harnesses. (67) remove 2 photo sensors ( 401-11, 401-12 ). Note: ensure that the sensor harnesses are reinstalled properly as illustrated..

Page 78

78 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.3. Control panel unit * notice: california only: this product contains a cr coin cell lithium battery which contains perchlorate material - special handling may apply. See www.Dtsc.Ca.Gov/hazardouswaste/perchlorate (1) remove 1 screw (x5). (2) remove the ba...

Page 79

79 dp-c405/c305/c265 feb 2008 ver. 1.1 (5) remove 4 black screws (1218). Note: this allows the removal of the control panel unit in the following steps. (6) adjust the control panel to the 4th position. (7) loosen 1 screw (y47). (8) loosen 1 screw (y47). (9) remove the back panel cover (1206). Avert...

Page 80

80 dp-c405/c305/c265 feb 2008 ver. 1.1 for pb and other destinations (10) remove 2 screws (x5). (11) adjust the control panel to the 2nd position. (12) unhook, and remove the damper spring (1208). (13) remove the control panel unit by pulling the release lever as illustrated. (14) disconnect the har...

Page 81

81 dp-c405/c305/c265 feb 2008 ver. 1.1 (15) turn the control panel unit upside down. (16) remove 1 screw (x8). (17) remove the battery holder (1306). (18) remove 1 screw (x5). (19) remove the release lever (1305). (20) remove 2 screws (x1). (21) remove the lower panel cover (1304). (22) release the ...

Page 82

82 dp-c405/c305/c265 feb 2008 ver. 1.1 (30) remove 1 screw (x8). (31) remove the pnl 4 pc board (1333). (32) remove 2 screws (x8). (33) remove the pnl 3 pc board (1332). (34) remove 4 screws (x8). (35) remove the pnl 2 pc board (1331). (36) remove 4 screws (x8). (37) remove the lcd module (1326). (3...

Page 83

83 dp-c405/c305/c265 feb 2008 ver. 1.1 (40) disconnect the harness on the sdi pc board. (41) remove 4 screws (x5). (42) remove the sdi cover (1203), and sdi pc board (1217)..

Page 84

84 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.4. Fuser unit (1) open the right side upper cover. (2) remove 1 screw (x5). (3) remove the harness cover 2 (4813). (4) disconnect the harness. (5) loosen 2 screws. (6) remove the fuser unit (4815)..

Page 85

85 dp-c405/c305/c265 feb 2008 ver. 1.1 (7) unhook 2 pressure springs (5006). Caution: don't use a plier for unlocking the springs, not to damage the spring. Ensure the pressure springs are unlock position when replace the fuser belt unit. Caution: to unlock the pressure springs: press the energy sav...

Page 86

86 dp-c405/c305/c265 feb 2008 ver. 1.1 (11) remove 3 black screws (y41). (12) remove the shaft plate (4916). (13) remove the worn-out fuser belt unit (4926). (16) remove 1 black screw (y41). (17) remove the harness cover 3 (4921). (18) disconnect 3 harnesses..

Page 87

87 dp-c405/c305/c265 feb 2008 ver. 1.1 (19) remove 3 black screws (y41). (20) remove the shaft plate (4916). (21) remove 3 black screws (y41). (22) remove the shaft plate (4916). (23) disconnect 2 harnesses. (24) remove the worn-out fuser belt unit (4926)..

Page 88

88 dp-c405/c305/c265 feb 2008 ver. 1.1 (25) remove all the tapes, and shipping material from the new belt unit. (26) remove the 2 bands. (27) remove the protective paper, and shipping materials. (28) remove 2 pins. (29) install the new fuser belt unit on the fuser main unit. (30) hook 2 pressure spr...

Page 89

89 dp-c405/c305/c265 feb 2008 ver. 1.1 for dp-c405 / c354 series> follow the steps below skip to step (39) (31) reinstall 2 black screws. (32) reinstall the shaft plate. (33) reinstall 1 black screw. (34) reinstall 2 black screws. (35) reinstall the shaft plate. (36) reinstall 1 black screw. (37) re...

Page 90

90 dp-c405/c305/c265 feb 2008 ver. 1.1 note: when connecting, exercise care not to touch the fuser belt. Note: ensure that the harnesses are reinstalled properly as illustrated. (39) reinstall 2 black screws. (40) reinstall the shaft plate. (41) reinstall 1 black screw. (42) reinstall 2 black screws...

Page 91

91 dp-c405/c305/c265 feb 2008 ver. 1.1 (45) connect 2 harnesses. Note: ensure that the sensor harnesses are reinstalled properly as illustrated. Red harness : “r” carved sensor black harness : “bk” carved sensor (46) remove the shipping cover. (47) connect the 3 harnesses. Note: when connecting, exe...

Page 92

92 dp-c405/c305/c265 feb 2008 ver. 1.1 note: ensure that the harnesses are reinstalled properly as illustrated. (48) reinstall the harness cover 3 (4921). (49) reinstall 1 black screw. (50) install the fuser unit. (51) secure 2 screws. (52) connect the harness. (53) reinstall the harness cover 2 (48...

Page 93

93 dp-c405/c305/c265 feb 2008 ver. 1.1 (58) remove the protective paper, and shipping materials. See the installation steps in this section. Note: when reinstalling the complete fuser unit, reset the pm counter. Perform “f8-26” fuser belt counter reset, and “f8-27” fuser main counter reset. (f7-02-6...

Page 94

94 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.5. Ih unit (1) remove 11 screws (s6). (2) remove the rear cover assembly. (3) remove 1 screw (y31). (4) remove the cone pc board (3922). For dp-c405 series pu / for dp-c354/c322 series follow steps (5) - (8) (5) disconnect all the harnesses on the sc pc boa...

Page 95

95 dp-c405/c305/c265 feb 2008 ver. 1.1 (10) remove 1 screw (x5), and harness with the metal clamp. (11) disconnect all the harnesses on the sc pc board (6401). (12) remove the harnesses from 4 clamps. (13) remove 13 screws (x5). (14) remove the sc pc board assembly by lifting, and turning to the lef...

Page 96

96 dp-c405/c305/c265 feb 2008 ver. 1.1 (18) disconnect all the harnesses on the motdrv pc board (6504). (19) remove the fan harness from 2 clamps. (20) remove 2 screws (x5). (21) remove the ih fan assembly. (22) remove 5 screws (x5). (23) remove the ih pcb bracket (4004). (24) remove 2 screws (x5). ...

Page 97

97 dp-c405/c305/c265 feb 2008 ver. 1.1 (27) remove the harness from 3 mini clamps, and 6 clamps. (28) remove 2 screws. (29) remove the right side rear cover (205). (see sect. 2.2.6.) (30) open the right side upper cover. (see sect. 2.2.4.) (31) remove the fuser unit. (see sect. 2.2.4.) (32) remove 2...

Page 98

98 dp-c405/c305/c265 feb 2008 ver. 1.1 (35) remove the harness from 6 clamps. 1. Remove 5 screws (x5, x9, y46). 2. Remove the bracket assembly by lifting up the paper transport unit. 3. Remove 1 screw (x5) by pushing the flap downward as illustrated. 4. Remove the front cover (7112). 5. Disconnect t...

Page 99

99 dp-c405/c305/c265 feb 2008 ver. 1.1 6. Remove the paper transport unit by pulling the lock lever as illustrated. (36) remove 4 screws (x5). (37) remove the paper exit unit. (38) pull tray 1, and tray 2 half way out. (39) open the front cover. (see sect. 2.2.11.) (40) remove 2 screws (y13). (41) r...

Page 100

100 dp-c405/c305/c265 feb 2008 ver. 1.1 (42) remove 2 screws (s6). (43) release the lever arm. (44) unlock 2 front cover attachment pins (220) by turning them in the upward direction, and sliding to the right. (45) remove the front cover. (46) remove 2 screws (s6). (47) remove the inner rear cover (...

Page 101

101 dp-c405/c305/c265 feb 2008 ver. 1.1 (50) remove 4 screws (s6). (51) remove the front right cover (209) by releasing the latch on the exit cover (202). (52) loosen 1 thumb screw. (53) remove 1 screw (s6). (54) lift the scanner unit slightly, and remove the exit cover (202). (55) remove the bracke...

Page 102

102 dp-c405/c305/c265 feb 2008 ver. 1.1 (56) remove 2 screws (x5). (57) remove the ih unit. Caution: when removing the ih unit, pull it out gently. To prevent damaging the harness, carefully guide it throughout the side of the frame..

Page 103

103 dp-c405/c305/c265 feb 2008 ver. 1.1 remove 2 screws from both sides. Caution: when reinstalling the ih unit, make sure that the ih fan duct is positioned inside of the ih sheet..

Page 104

104 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.6. Auto duplex unit (adu) (1) open the jam cover. (2) open the sheet bypass tray. (3) remove 2 screws (s6). (4) remove the right side front cover (206). (5) remove 3 screws (s6). (6) remove the right side rear cover (205). (7) open the upper right side cov...

Page 105

105 dp-c405/c305/c265 feb 2008 ver. 1.1 (8) disconnect 3 harnesses on the adu pc board (cn403, cn404, cn405) (9) release 3 harnesses from the edge saddle. (10) remove the lower dumper bracket (2114). (11) remove the dumper (2116). (12) open the lower right side cover. (13) remove 1 snap ring (g6). (...

Page 106

106 dp-c405/c305/c265 feb 2008 ver. 1.1 (15) remove the adu. Note: when reinstalling the adu, make sure that the harnesses are reinstalled properly as illustrated. (16) remove 1 screw (x5). (17) remove the exit guide bracket (2308)..

Page 107

107 dp-c405/c305/c265 feb 2008 ver. 1.1 (18) remove 1 screw (x5). (19) remove the exit guide bracket (2308). (20) remove 3 screws (x8). (21) remove the guide cover (2307). (22) disconnect the harness. (23) remove the photo sensor ( 1819-38 ) assembly. (24) remove 3 screws (x8). (25) remove the adu u...

Page 108

108 dp-c405/c305/c265 feb 2008 ver. 1.1 clean the adu 1st roller with a soft cloth, saturated with water. (26) remove 1 screw (x3). (27) remove the cover knob (2202). (28) remove 9 screws (x8). (29) remove the coating clip (2219)..

Page 109

109 dp-c405/c305/c265 feb 2008 ver. 1.1 (30) remove the harness clamp (2218). Note: make sure to reinstall the harness clamp properly as illustrated. (31) remove the adu cover (2201). (32) remove 5 screws (x8). (33) remove the cover plate (2203). (34) remove the spring ground (2208)..

Page 110

110 dp-c405/c305/c265 feb 2008 ver. 1.1 (35) remove 1 e-ring (j7). (36) remove the latch (2210). (37) remove the left latch spring (2211). (38) remove the bushing (2213). (39) remove the latch lever shaft (2209) assembly. (40) release the harness from the clamps. (41) remove 2 screws (x4). (42) remo...

Page 111

111 dp-c405/c305/c265 feb 2008 ver. 1.1 note: when reinstalling the cover, make sure that the harness band is reinstalled properly as illustrated..

Page 112

112 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.7. Paper exit transportation (1) open the right side upper cover. (see sect. 2.2.4.) (2) remove the fuser unit. (see sect. 2.2.4.) (3) remove 2 screws (s6). (4) remove the top cover (207). (5) disconnect 2 harnesses on the adu pc board (cn401, and cn402), ...

Page 113

113 dp-c405/c305/c265 feb 2008 ver. 1.1 (10) move the paper transport unit slightly to the left by pulling the lock lever as illustrated. (11) remove the paper exit unit (see the previous step). (12) remove 1 screw (x5). (13) disconnect the harness. (14) remove the photo sensor ( 1918-02 ). (15) rem...

Page 114

114 dp-c405/c305/c265 feb 2008 ver. 1.1 (20) remove the arm spring (3227). (21) remove 2 screws (x5). (22) remove 2 screws (y16). (23) remove the clutch bracket (3226). (24) remove the d z27m1 gear (3224). (25) remove the clutch shaft (3225). (26) remove 2 screws (x5). (27) remove the sensor cover a...

Page 115

115 dp-c405/c305/c265 feb 2008 ver. 1.1 (30) remove 1 screw (y1). (31) remove the exit guide (227). (32) clean the exit roller (3302), and upper pinch roller (3208), lower pinch roller (3301)with a soft cloth, saturated with water..

Page 116

116 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.8. Lower right side cover unit (1) remove the right front cover . (see sect. 2.2.6.) (2) remove the right rear cover . (see sect. 2.2.6.) (3) remove the sheet bypass tray cover. (see sect. 2.2.9.) (4) open the lower right side cover. (see sect. 2.2.10.) (5...

Page 117

117 dp-c405/c305/c265 feb 2008 ver. 1.1 clean the ohp detection reflector with a soft cloth, saturated with isopropyl alcohol. Note: when reinstalling the lower right side cover unit, pull the lock lever to the locked position in the direction illustrated by the arrow. (10) remove 3 screws (x5). (11...

Page 118

118 dp-c405/c305/c265 feb 2008 ver. 1.1 (13) disconnect the harness. (14) remove 1 screw (y24). (15) remove the sensor bracket (2825) assembly. (16) remove the photo sensor ( 1819-06 ). (17) remove 2 screws (y16). (18) remove guide bracket assembly. (19) remove the str unit (2535) as illustrated..

Page 119

119 dp-c405/c305/c265 feb 2008 ver. 1.1 (20) remove 1 screw (x8). (21) remove the plate cover bracket (2734). (22) turn the lower right side cover unit upside down. Note: before turning the unit upside down, make sure to remove the str unit, or the str may get damaged. (23) open the lower adu door. ...

Page 120

120 dp-c405/c305/c265 feb 2008 ver. 1.1 (27) remove 2 screws (x8). (28) remove the adu guide 2 (2824). (29) disconnect the harness. (30) release the harness from 2 latches. (31) remove 2 screws (x8). (32) remove the adu sensor base (2821) assembly. (33) remove the photo sensor ( 1819-07 )..

Page 121

121 dp-c405/c305/c265 feb 2008 ver. 1.1 (34) disconnect the harness on the adu pc board (cn407). (35) remove 4 screws (x5). (36) remove the registration unit. Intermediate roller sensor (dp-c405 / c305 only)> clean the registration sensor 2 ( 1918-01 )and intermediate roller sensor (2130)with a dry ...

Page 122

122 dp-c405/c305/c265 feb 2008 ver. 1.1 (39) disconnect the harness on the rohp pc board. (40) remove 2 screws (f10). (41) remove the rohp pc board (2110). (42) disconnect 2 harnesses. (43) remove the harness from 2 clamps. (44) remove 2 screws (f10). (45) remove the ri sensor plate (2131). For dp-c...

Page 123

123 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.9. Sheet bypass unit (1) open the jam cover. (see sect. 2.2.6.) (2) open the sheet bypass tray. (see sect. 2.2.6.) (3) remove the right front cover. (see sect. 2.2.6.) (4) remove the right rear cover. (see sect. 2.2.6.) (5) remove the sheet bypass tray cov...

Page 124

124 dp-c405/c305/c265 feb 2008 ver. 1.1 (10) lift the sheet bypass tray as illustrated. (11) remove the tray spring (2916). (12) remove 1 screw (x8). (13) remove the tray plate shaft (2917). (14) remove the tray assembly. Note: when removing the tray assembly, carefully separate as illustrated. (15)...

Page 125

125 dp-c405/c305/c265 feb 2008 ver. 1.1 (19) remove 2 screws (x8). (20) remove the arm bracket assembly. (21) remove the dfp roller (3111). Clean the dfp roller with a soft cloth, saturated with water. (22) remove 3 screws (x5). (23) remove the upper plate (3008). (24) remove 1 screws (x5). (25) rem...

Page 126

126 dp-c405/c305/c265 feb 2008 ver. 1.1 (26) remove 2 snap rings (h6). (27) remove 2 stoppers (3007). (28) remove 2 spacers (3006). (29) remove the front pickup roller (3005). (30) remove the rear pickup roller (3012). Clean the pickup roller with a soft cloth, saturated with water. Caution: when re...

Page 127

127 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.10. Str unit and intermediate transfer (it) unit (1) open the sheet bypass tray. (2) open the lower right side cover. (3) remove 2 screws (y16). (4) remove the guide bracket assembly. (5) remove the str unit (2535). (6) remove the snap ring (2714). (7) rem...

Page 128

128 dp-c405/c305/c265 feb 2008 ver. 1.1 (8) push on the str guide to lock it in the down position. (9) remove 2 screws (y45). (10) push down the white latches on both sides, and pull on them to release the it unit from the locked position. (11) while holding the it unit by the center as illustrated,...

Page 129

129 dp-c405/c305/c265 feb 2008 ver. 1.1 (12) while holding the it unit on both sides, release the lock by pushing the lever to the right. (13) carefully pull the it unit (3420) out of the machine while holding it by both sides. Caution: pull the it unit out straight and leveled (horizontal), or the ...

Page 130

130 dp-c405/c305/c265 feb 2008 ver. 1.1 and the toner registration sensor (right/left)> (15) slide the sensor cover toward the front as illustrated. (16) while holding it in the open position, wipe the surface of the toner registration, and toner density sensors through the frame holes. Note: when c...

Page 131

131 dp-c405/c305/c265 feb 2008 ver. 1.1 (24) unhook 4 link arm springs (3408). (25) set 4 link arms to the locked position as illustrated. (26) remove 4 black screws (y29) from the right side..

Page 132

132 dp-c405/c305/c265 feb 2008 ver. 1.1 (27) remove 4 black screws (y29) from the left side. (28) remove the handle plate bracket assembly. Caution: when removing and installing the handle plate bracket assembly, hold both side of the bracket as illustrated, and don’t touch the it belt. (29) remove ...

Page 133

133 dp-c405/c305/c265 feb 2008 ver. 1.1 (33) place the it unit on its side with the side that has the belt position mark facing upward. (34) bend the it unit at the bending point up to maximum bending position. Caution: confirm that the it unit is at the maximum bending position for removing the it ...

Page 134

134 dp-c405/c305/c265 feb 2008 ver. 1.1 (37) remove 4 snap rings (3545) securing the ftr by turning over the protect sheet as illustrated. Note: when removing snap rings, exercise care not to remove the snap ring holding the backup roller. (38) remove 4 ftr (3546) by turning over the protective shee...

Page 135

135 dp-c405/c305/c265 feb 2008 ver. 1.1 (41) remove 2 black screws (y29). (42) remove the drive roller brush assembly (3635). Roller, adjustment roller, and drive roller> (43) clean the bias roller, initial point sensor roller, adjustment roller, and drive roller with a soft cloth, saturated with is...

Page 136

136 dp-c405/c305/c265 feb 2008 ver. 1.1 (46) remove 2 adjust bushings (3419). Note: use the adjustment bushings enclosed with the new it belt to accommodate for the belt length variations. (47) install 1 (new) adjustment bushing (3419) to the right side. (48) install 1 (new) adjustment bushing (3419...

Page 137

137 dp-c405/c305/c265 feb 2008 ver. 1.1 note: when reinstalling the snap ring, use a pair of pliers as illustrated. (50) reinstall the 4 ftr. Note: reinstall the ftr by turning over the protective sheet. Note: when reinstalling the ftr, the direction is not critical, and it can be installed in eithe...

Page 138

138 dp-c405/c305/c265 feb 2008 ver. 1.1 caution: when removing and installing the it belt, hold the side band of the it belt as illustrated. Don’t touch the center of the belt, or the printing quality will be affected. Caution: when installing the it belt, align the position of roller steps, and bel...

Page 139

139 dp-c405/c305/c265 feb 2008 ver. 1.1 (53) straighten the it unit to its original shape as illustrated. Note: take your time during the installation, and proceed cautiously. (54) reinstall the left position plate. (55) reinstall the handle plate bracket assembly. (56) hook 4 springs. (57) reinstal...

Page 140

140 dp-c405/c305/c265 feb 2008 ver. 1.1 (62) using a pair of pliers as illustrated, reinstall the left position plate (3416). (63) reinstall 1 black screw (y29). (64) reinstall the handle plate bracket assembly. (65) reinstall 4 black screws (y29) from the left side. Caution: when removing and insta...

Page 141

141 dp-c405/c305/c265 feb 2008 ver. 1.1 (67) release 4 link arms from the locked position as illustrated. (68) hook 4 link arm springs (3408). (69) reinstall the upper paper guide (3411). (70) reinstall 2 black screws (y29). (71) reinstall the lower paper guide (3412). (72) reinstall 2 black screws ...

Page 142

142 dp-c405/c305/c265 feb 2008 ver. 1.1 (73) reinstall the cleaning unit (3418). (74) reinstall 2 black screws (y29). (75) maintain the it unit leveled by holding it on both sides while installing it into the machine. Note: when installing, ensure that the str bracket locks in place. Note: slide the...

Page 143

143 dp-c405/c305/c265 feb 2008 ver. 1.1 (77) unlock the str guide. Caution: when unlocking, exercise care not to pinch your fingers with the str guide. (78) install the str unit. Note: during the installation ensure that the hook is properly attached. (79) reinstall the guide bracket. Note: when rei...

Page 144

144 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.11. Process unit note: the procedure below describes how to replace the developer unit for the cyan color. (1) open the front cover. Caution: when the windows shown by the arrow are yellow, close all of the doors, and turn the main power switch off, and on...

Page 145

145 dp-c405/c305/c265 feb 2008 ver. 1.1 (5) unlock the drum units (cyan and magenta) by turning the drum release knob counterclockwise. Note: to remove the hopper unit in step 16, the drum unit(s) relevant to the developer unit being replaced must be unlocked, and removed first. (see the table below...

Page 146

146 dp-c405/c305/c265 feb 2008 ver. 1.1 (8) remove 2 screws (y13). (9) remove the inner stack cover (203). (10) clean the toner supply cylinder with a vacuum cleaner. (11) remove 6 screws (y33). (12) remove the pipe cover (4421). (13) place a clean sheet of paper (i.E. Ledger or a3) on top of the fr...

Page 147

147 dp-c405/c305/c265 feb 2008 ver. 1.1 (14) lock the drum unit by turning the drum release knob clockwise. Note: this step eases the removal of the hopper unit in the next step. (15) remove 1 screw (y13). (16) remove the hopper unit as illustrated. Note: pull the bottom portion out by clasping with...

Page 148

148 dp-c405/c305/c265 feb 2008 ver. 1.1 (18) clean the toner entrance with a vacuum cleaner. (19) release the lever arm. (20) remove 2 screws (y1). (21) remove the wtc lower cover (4401). (22) release 2 harness clamps. (23) disconnect the developer harness..

Page 149

149 dp-c405/c305/c265 feb 2008 ver. 1.1 (24) remove 3 screws (x5). (25) remove the developer front bracket (4422). (26) clean the developer front bracket (4422) with a vacuum cleaner. (27) pull the developer unit (cyan) (5443) out. Note: do not open the shutter, or toner will spill out. Note: ensure...

Page 150

150 dp-c405/c305/c265 feb 2008 ver. 1.1 (30) gently peel the tape off in the direction of the arrow. (31) remove 2 screws (x8). (32) remove the developer cover (5401) by releasing 4 latches. Note: only if a problem occurs, perform the step below. If there is no problem, skip to the step (34). (33) t...

Page 151

151 dp-c405/c305/c265 feb 2008 ver. 1.1 (34) shake the developer bottle a few times to loosen its contents. (35) carefully pour the developer evenly into the developer unit while turning the gear as illustrated. Make sure to empty the bottle. (36) reinstall the developer cover. (37) install the new ...

Page 152

152 dp-c405/c305/c265 feb 2008 ver. 1.1 (41) reinstall the hopper unit. Note: 1. When reinstalling, make sure that the 2 projections on the hopper unit are seated in the 2 holes firmly, and at the same time, the supply cylinder is properly positioned as illustrated. 2. If the hopper unit are not sea...

Page 153

153 dp-c405/c305/c265 feb 2008 ver. 1.1 (50) turn the toner cartridge upside down as illustrated, then reinstall the toner cartridge. (51) reinstall the toner waste container. Note: do not close the front cover. (52) plug the ac power cord. (53) turn the main power switch on the back, and the power ...

Page 154

154 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.12. Lsu (1) open the front cover. (2) pull the 2nd paper tray out. (3) remove 5 screws (s6). (4) remove the left cover. For dp-c405 series : pb and other destinations (5) loosen 4 screws. (6) remove the bracket. Caution: when reinstalling the bracket, make...

Page 155

155 dp-c405/c305/c265 feb 2008 ver. 1.1 (7) remove 1 screw (y45). (8) remove the ground harness. (9) remove 1 screw (y33). (10) remove the lsu fan (4302). (11) disconnect 3 harnesses on the lsu pc board. Important: before proceeding, make a note of the alignment pointer position. If the lsu is not r...

Page 156

156 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.13. Paper feed module (1) remove the sheet bypass tray. (see sect. 2.2.9.) (2) remove the lower right side cover unit. (see sect. 2.2.8.) (3) disconnect the harness on the adu pc board (cn408, cn409). (4) release the harness from 2 clamps. (5) pull the 1st...

Page 157

157 dp-c405/c305/c265 feb 2008 ver. 1.1 (8) remove the snap ring (h7), and pickup roller (1926) while pushing the solenoid as illustrated to lift the shaft of the pickup roller, for easy removal. Clean the pickup roller surface with a soft cloth, saturated with water. (9) remove the snap ring (h6). ...

Page 158

158 dp-c405/c305/c265 feb 2008 ver. 1.1 (13) remove the bushing (1915). (14) remove the one way clutch (1923). (15) remove the feed roller (1922). Clean the feed roller with a soft cloth, saturated with water. (16) disconnect the harnesses. (17) remove 2 sensors ( 401-14, 401-15 ). (18) remove the j...

Page 159

159 dp-c405/c305/c265 feb 2008 ver. 1.1 (20) disconnect the harness. (21) remove 1 screw (y19). (22) remove the 2nd paper feed module. Note: follow the instructions of steps (8) - (17) for the 1st paper feed module. (23) remove the sheet bypass tray. (see sect. 2.2.9.) (24) remove the lower right si...

Page 160

160 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.14. System console (1) open the jam cover. (2) pull the 3rd paper tray out. (3) remove 2 screws (s6). (4) remove the right side rear cover (6704). (5) remove 1 screw (y19). (6) remove the cover belt (6715). (7) remove the jam cover while pushing the releas...

Page 161

161 dp-c405/c305/c265 feb 2008 ver. 1.1 (8) disconnect the harness. (9) release the harness from the clamp. (10) remove 1 screw (y19). (11) remove the 3rd paper feed module. Note: follow the instructions for steps (8) - (17) of the 1st paper feed module. (see sect. 2.2.13.) (12) pull the 4th paper t...

Page 162

162 dp-c405/c305/c265 feb 2008 ver. 1.1 (15) remove 1 screw (y19). (16) remove the 4th paper feed module. Note: follow the instructions for steps (8) - (17) for the 1st paper feed module. (see sect. 2.2.13.) (17) open the jam cover. (18) clean the 3rd/4th intermediate roller with a soft cloth, satur...

Page 163

163 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.15. Pc boards, hvps, hdd (1) remove 11 screws (s6). (2) remove the rear cover assembly. (3) remove 1 screw (y31). (4) remove the cone pc board (3922). (5) disconnect all harnesses on the sc pc board. (6) remove 10 screws (y31). (7) remove the sc pc board (...

Page 164

164 dp-c405/c305/c265 feb 2008 ver. 1.1 (11) remove 3 screws (x5). (12) remove the left ec pcb bracket (3909). For dp-c405 series : pu follow steps (13) - (15) (13) remove the harnesses from all clamps on the sc pcb bracket (3901). (14) remove 12 screws (x5). (15) remove the sc pcb bracket (3901). F...

Page 165

165 dp-c405/c305/c265 feb 2008 ver. 1.1 for dp-c354 / c322 series follow steps (20) - (24) (20) remove the harnesses from all clamps on the sc pcb bracket (3901). (21) remove 12 screws (x5). Note: for pb and other destinations remove the additional 13th screw (x5), illustrated as screw a. (22) remov...

Page 166

166 dp-c405/c305/c265 feb 2008 ver. 1.1 (29) remove 7 screws (x5). (30) remove the ec pcb bracket (3908). (31) disconnect all harnesses on the hvps2 pc board. (32) remove 8 screws (y31). (33) remove the hvps2 pc board (4015). (34) remove 3 screws (x5). (35) pull the hvps1 pc board assembly out..

Page 167

167 dp-c405/c305/c265 feb 2008 ver. 1.1 (36) remove 12 screws (x5). (37) remove 2 hvps1 pc boards (4014). (a) : for yellow / magenta (b) : for cyan / black (38) remove 4 screw (x5). (39) pull the hvps2 pcb bracket (4003) out. (40) open the front cover. (41) remove the toner waste container. (42) tur...

Page 168

168 dp-c405/c305/c265 feb 2008 ver. 1.1 (45) disconnect the harness on the motor pc board assembly. (46) remove 3 screws (x5). (47) remove the motor assembly. Note: these procedures are for motor assemblies no. 1 (5901), no. 3 (5903), no. 4 (5905), and no. 6 (6126) shown in the illustration of step ...

Page 169

169 dp-c405/c305/c265 feb 2008 ver. 1.1 (51) disconnect all the harnesses on the motdrv pc board. (52) release 3 pcb spacers (4006). (53) remove the motdrv pc board (6504). (54) release the harness from 2 clamps. (55) remove 2 screws (x5). (56) remove the fan assembly. (57) remove 5 screws (x5). (58...

Page 170

170 dp-c405/c305/c265 feb 2008 ver. 1.1 (60) remove 3 screws (x5). (61) release 2 pcb spacers (4016). (62) remove the ih pc board (4020). (dp-c405 series only)> (63) remove the dc12 harness andthe sata harness from harness clamps. (64) disconnect the hd2 harness from the hdd connector. (65) disconne...

Page 171

171 dp-c405/c305/c265 feb 2008 ver. 1.1 (71) remove the dc12 harness and the hd2 harness from harness clamps. (72) disconnect the dc12 harness on the dc12 pc board (cn141 and cn142). (73) disconnect the hd2 harness on the dc12 pc board (cn143). Caution: when reinstalling 2 harnesses, the tie wrap sh...

Page 172

172 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.16. Drive unit (1) open the front cover (2) remove the toner waste container. (3) pull all the drum units out approximately 20 mm (0.79 in). (4) remove the 2 screws (x5). (5) remove the sc support bracket (3903). (6) release the harnesses from 11 clamps, a...

Page 173

173 dp-c405/c305/c265 feb 2008 ver. 1.1 (9) remove 7 screws (x5). (10) remove 1 screw (y30). (11) remove the gear box cover (5912). (12) remove 4 snap rings (h6). (13) remove the e-ring (j6). (14) remove 6 ftr coupling gears (5906). Caution: when reinstalling, align the gear holes and frame holes as...

Page 174

174 dp-c405/c305/c265 feb 2008 ver. 1.1 (18) remove the belt (6130). (19) remove the upper gear (6131). (20) remove the upper clutch (6129). (21) remove the lower gear (6131). Dp-c405 / c305 only (22) remove the lower clutch (6128). (23) release the harness from harness clamp. (24) disconnect the mo...

Page 175

175 dp-c405/c305/c265 feb 2008 ver. 1.1 (31) disconnect the lift up motor harness on the sc pcb. (32) release the harness from 2 harness clamps. (33) remove 3 screws (x5). (34) remove the lift up motor assembly. (35) remove 2 screws (x5). (36) remove the lift up motor bracket assembly. (37) remove 2...

Page 176

176 dp-c405/c305/c265 feb 2008 ver. 1.1 2.2.17. Lvps unit (1) remove the rear cover assembly. (see sect. 2.2.15.) (2) disconnect 5 harnesses; (cn52, and cn53) on the sc pcb, (cn519, and cn520) on the ec pcb, and the intermediate connector. (3) release the harnesses from 14 harness clamps. (4) releas...

Page 177

177 dp-c405/c305/c265 feb 2008 ver. 1.1 (10) disconnect the harness. (11) remove 2 screws (x5). (12) remove the nfl pcb assembly (4116). (13) release the harnesses from the edge saddle. (14) remove 2 screws (x5). (15) remove the lvps duct cover (4106). (16) release the harnesses from harness 5 clamp...

Page 178

178 dp-c405/c305/c265 feb 2008 ver. 1.1 (17) remove 6 screws (x5). (18) remove 3 screws (y16). (19) remove the lvps bracket (4102). (20) disconnect the fan harness. (21) release the harness from harness clamp. (22) remove 2 screws (4104). (23) remove the lvps fan (4103). (24) disconnect all the harn...

Page 179

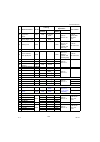

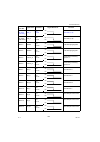

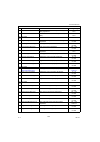

179 dp-c405/c305/c265 feb 2008 ver. 1.1 2.3. Hardware identification template part no. Figure remark ref. No. Snap ring ffpfj0033b h6 snap ring ffpfj0041b h7 shoulder screw ffpfa01632 h9 snap ring ffpfj0039b g6 screw (m3 x 4) xyn3+f4fj 5m screw (m3 x 12) xtb3+12gfj 6a silver screw xtb4+10gfn h5 silv...

Page 180

180 dp-c405/c305/c265 feb 2008 ver. 1.1 part no. Figure remark ref. No. Screw x9 xtb3+8ffj screw xtb3+8gfj x8 screw xtw3+8pfj y1 screw xtb3+6ffj-rp y2 screw xtw3+6lfj y3 screw xyn4+f6fj y10 xyn3+f6fj screw y16 xtb3+6ffj screw x5 xtb3+20gfj screw x4 screw xtw3+8lfj y13 xyn3+f8fj screw x3 xtb3+10gfj s...

Page 181

181 dp-c405/c305/c265 feb 2008 ver. 1.1 part no. Figure remark ref. No. Screw xya3+ff8fj y31 screw xsb23+10fj y32 screw xtb2+6gfj y34 screw xtw3+8pfjr y35 screw xyc3+fg10fj y38 screw xtb4+10ffj y33 screw xtw3+12qfj y36 screw xtb3+6gfj y37 screw xsb3+6fj y30 screw xsb3+8fjk y29 screw xyn4+f8fj y23 sc...

Page 182

182 dp-c405/c305/c265 feb 2008 ver. 1.1 part no. Figure remark ref. No. Screw xtb3+12gfj y42 shoulder screw dzpa000098 y43 screw xyn4+f10fj y45 screw xtb3+12ffj y46 screw xst3+4fj y47 screw xtb3+4ffj y48.

Page 183

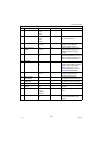

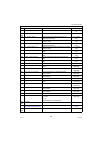

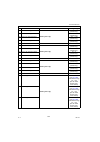

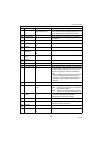

183 feb 2008 ver. 1.1 dp-c405/c305/c265 3 maintenance, adjustments and check points 3.1. Preventive maintenance preventive maintenance is performed at specific intervals, and consists of machine cleaning, and parts replacement. It is essential to perform these service activities properly, and at the...

Page 184

184 feb 2008 ver. 1.1 dp-c405/c305/c265 3.1.5. Data security precautions 1. The service mode password is essential to maintaining the security of the machine. Service technicians must change the factory default password using the service mode “f7-14: service mode password”, record the new password a...

Page 185

185 feb 2008 ver. 1.1 dp-c405/c305/c265 3.2. Required tools 3.2.1. Preventive maintenance method no. Tools no. Tools 1 personal notebook computer 10 pliers 2 cables (usb cable, crossover lan cable, etc.) 11 nipper 3 sd memory card (128 mb - 1gb) 12 cutter 4 soft cloth 13 vacuum cleaner 5 isopropyl a...

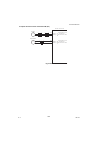

Page 186

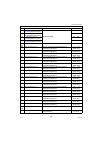

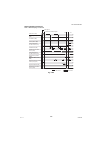

186 feb 2008 ver. 1.1 dp-c405/c305/c265 3.3. Preventive maintenance points 2 1 3 4 5 6 7 8 9 29 30 31 33 35 34 11 19 21 24 10 32 15 25 50, 52 27 28 43 51 49 46 45 48 46 45 44 16 26 42 20 22, 23 14 18 13 17 12 53 38, 39, 40, 41 47 46 45 46 45 47 47 47 48 36 37 no. 36, 37 : dp-c405 / c305 only.

Page 187

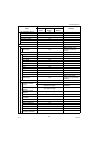

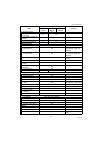

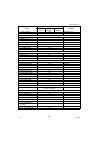

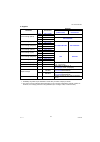

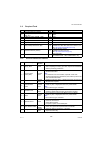

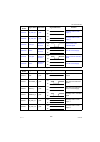

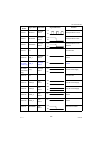

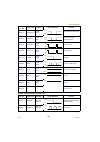

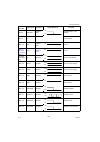

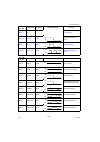

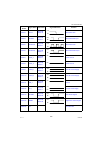

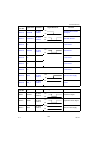

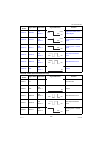

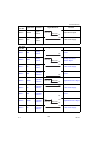

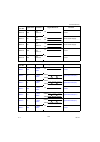

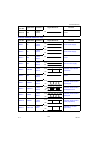

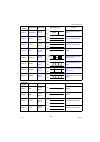

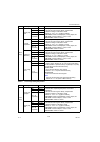

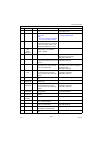

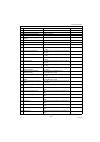

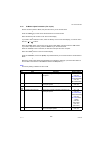

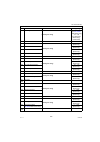

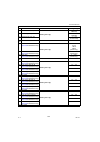

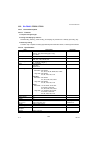

187 feb 2008 ver. 1.1 dp-c405/c305/c265 3.4. Preventive maintenance check list the chart outlined below is a general guideline for maintenance. No. Mechanical parts ref. No. Cleaning replacement/ adjustment ref. Counter cycle (sheets) method cycle (sheets) procedure i-adf unit 1 pickup roller 511 12...

Page 188

188 feb 2008 ver. 1.1 dp-c405/c305/c265 22 toner density registration sensor 3821 120k dry cotton swab - refer to sect 2.2.10. F7-02-51 transfer belt life count down 23 toner registration sensor (right / left) 3820 120k dry cotton swab - 24 cleaning unit 3418 - - 120k refer to sect 2.2.10. (replace ...

Page 189

189 feb 2008 ver. 1.1 dp-c405/c305/c265 note: 1. Clean all rollers and separation rubber with a soft cloth saturated with water. For stubborn toner accumulation, wipe with a soft cloth saturated with isopropyl alcohol first, then follow up with a soft cloth saturated with water. 2. The maintenance c...

Page 190

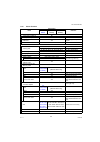

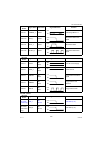

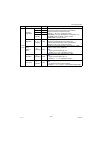

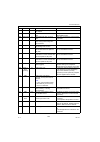

190 feb 2008 ver. 1.1 dp-c405/c305/c265 3.5. Resetting the p/m (preventive maintenance) counter when the machine reaches the preset p/m cycle, it will show “call for p/m” on the lcd display. The pm counter can be reset by following the procedures below. 1. Perform the p/m (preventive maintenance), r...

Page 191

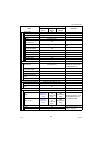

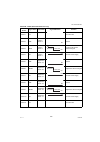

191 feb 2008 ver. 1.1 dp-c405/c305/c265 note: when replacing the it unit, the str unit and cleaning unit are also replaced at the same time, and then perform f8-29, f8-32, and f8-30 service mode operations. 24 cleaning unit 3418 120k f7-02-52 str life count 120k: alarm (machine continues operating) ...

Page 192

192 feb 2008 ver. 1.1 dp-c405/c305/c265 3.6. Lubrication point please refer to the preventive maintenance (pm) list to ensure the highest degree of reliability. The inspection interval is usually 120k copies or more, however this interval may be reduced due to environmental conditions. 3.7. Easy mai...

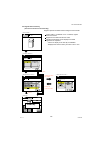

Page 193

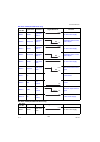

193 feb 2008 ver. 1.1 dp-c405/c305/c265 3.7.3. Procedure 1. Initial registration when the machine is installed. (registration is not completed) + + + to enter the service mode (registration is completed) category of business 00 agricultural 01 bank/finance 02 communication 03 construction 04 design ...

Page 194

194 feb 2008 ver. 1.1 dp-c405/c305/c265 2. Service history 2.1. Register service history (servicing this unit the 1st time of the day) *the service history data will start collecting the day after the customer’s information has been registered. + select service action ex: adjustment/cleaning to set ...

Page 195

195 feb 2008 ver. 1.1 dp-c405/c305/c265 2.2. Register service history (2nd visit on the unit on the same day) + + + to set to return select service action ex: call back stand by register required information before exiting the service mode. Confirm that it is a call back. If it is a call back, regis...

Page 196

196 feb 2008 ver. 1.1 dp-c405/c305/c265 2.3. Change service history select "maint. Info. Manager" select "service history" select "item from service history" to set to return select item to change check and/or change registered service history using service mode f9-23-01. Up to 200 service history r...

Page 197

197 feb 2008 ver. 1.1 dp-c405/c305/c265 3. Maintenance information list print select "print maintenance info." select a function. Select 1-sided or 2-sided + ( printing is completed ) print the list for each maintenance function using service mode f9-22. 00 simulated list: 1 month 01 simulated list:...

Page 198

198 feb 2008 ver. 1.1 dp-c405/c305/c265 select which list to print; either for the last 1 month or all (last 6 months) f9-22-00 : simulated list : 1 month f9-22-01 : simulated list : all print collective data from each month (1st -last day) black and color printing data is collected separately outpu...

Page 199

199 feb 2008 ver. 1.1 dp-c405/c305/c265 print counter value of unit using f9 service mode f9-22-02 : machine usage list. Counter increments by one for each paper feed regardless of paper size. Service mode printouts are also counted. List contents: (1) category of business, installation date, and se...

Page 200

200 feb 2008 ver. 1.1 dp-c405/c305/c265 f9-22-03 : machine diagnostic list print jam and machine error. Print pm unit usage and its estimate replacement time list contents: (1) category of business, installation date, and serial number (2) job error history top 10 (paper jam, machine error) (3) pm p...

Page 201

201 feb 2008 ver. 1.1 dp-c405/c305/c265 f9-22-04 : maintenance list print up to 200 service history items list contents: (1) category of business, installation date&time, serial number, total number of visit, total number of repair (2) service date&time, service action, counter data if the service h...

Page 202

202 feb 2008 ver. 1.1 dp-c405/c305/c265 4. Maintenance info. Clear select "ram initialize" select "maintenance info. Clear" to initialize to cancel and return ( initialization is completed ) initialize maintenance information: f9-06-08 : maintenance info. Clear items initialized : counter data, serv...

Page 203

203 feb 2008 ver. 1.1 dp-c405/c305/c265 5. Maintenance information manager 5.1. Change category of business select "maint. Info. Manager" select "category of business" to set the change to return change the category of business that was set during the initial registration using f9-23-03 : category o...

Page 204

204 feb 2008 ver. 1.1 dp-c405/c305/c265 5.2. Service history function select "maint. Info. Manager" select "service history func." + to set to return change the service history function setting. Change setting to yes/no using f9-23-04 : service history function when the service history function is s...

Page 205

205 feb 2008 ver. 1.1 dp-c405/c305/c265 6. Structure of maintenance function the items for maintenance function are located in the f9 service mode. • f9 service mode (related items) f9 unit maintenance 06 ram initialize 08 maintenance info. Clear 22 print maintenance info. 00 simulated list: 1 month...

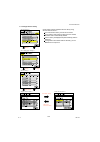

Page 206

206 feb 2008 ver. 1.1 dp-c405/c305/c265 3.8. Counter / parameter auto backup the counter information can be backed up by installing an sd memory card into the sd card slot (cn70) on the sc pc board. This prevents losing counter information due to an error in the system control (sc) pc board, or when...

Page 207

207 feb 2008 ver. 1.1 dp-c405/c305/c265 3.9. Counter / parameter backup to sd card in the front slot the counter / parameter information can also be backed up by installing an sd memory card into the front sd card slot. This prevents losing the counter / parameter information when replacing the sc/e...

Page 208

208 feb 2008 ver. 1.1 dp-c405/c305/c265 3.10. Power on display change (f9-19) to change the startup panel display (when the power switch on the left side is turned on) follow the procedure below. This feature is useful if a dealer wants to personalize the machine with its own company's logo or pictu...

Page 209

209 feb 2008 ver. 1.1 dp-c405/c305/c265 3.11. Updating the firmware (dp-c405 series) 3.11.1. Firmware configuration a. Hardware configuration this machine is controlled by a main cpu which is located on the system control (sc) pc board, and other sub cpus on the other pcbs. The firmware of sc pcb, e...

Page 210

210 feb 2008 ver. 1.1 dp-c405/c305/c265 (2)usb port the machine's firmware can be updated using your notebook pc via an usb port. This method is convenient when you brought a notebook pc into the customer's site for the purpose of updating the firmware. Refer to the firmware update operating instruc...

Page 211

211 feb 2008 ver. 1.1 dp-c405/c305/c265 1. Press the “function”, “copy”, and the “3” keys simultaneously on the control panel. 2. Input the password, and select the “ok” button to enter the service mode (default password is 00000000). 3. Press the “9” key on the control panel, and then press the “st...

Page 212

212 feb 2008 ver. 1.1 dp-c405/c305/c265 5) confirmation after the update is completed, the machine reboots itself and returns to standby. Confirm the f5 & f6 parameters according to the printed lists in step 3) above if the settings are different. Note: 1. Manual mode must be used, when updating the...

Page 213

213 feb 2008 ver. 1.1 dp-c405/c305/c265 code from the usb port. Now connect the usb cable between the unit and pc. 4) upgrading the main unit's firmware code start the local firmware update tool, and select the following parent firmware file folder in the c:\panasonic\panasonic-fup\data folder. The ...

Page 214

214 feb 2008 ver. 1.1 dp-c405/c305/c265 caution: 1. Remove the pcmcia/pc card adapter from the pcmcia/pc card slot in front of the machine. 2. Install the master firmware sd memory card into the card slot in front of the machine. Do not install it into the card slot on the sc pcb, or the machine wil...

Page 215

215 feb 2008 ver. 1.1 dp-c405/c305/c265 the sd memory card is now ready to use for firmware update. (refer to the sd memory card firmware writing tool readme file.) 3.11.6. Notice after installing the hdd option after the hard disc drive unit is installed, to prevent a disc scan function from being ...

Page 216

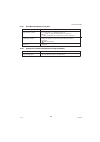

216 feb 2008 ver. 1.1 dp-c405/c305/c265 3.11.8. Firmware version sc : ec : scn : cmfp25sc a a vxxxxx pu destination code pu : usa/canada pb : uk etc. Firmware version (vxxxxx) language code a : a-english, c-french & spanish b : english, french & spanish etc. Firmware type a : standard d : ps option ...

Page 217

217 feb 2008 ver. 1.1 dp-c405/c305/c265 fcb : cmfp1fcb a a vxxxxx au destination code (fax) au : overseas firmware version (vxxxxx) firmware type a : standard model number language code a : overseas.

Page 218

218 feb 2008 ver. 1.1 dp-c405/c305/c265 3.12. Adjusting copy quality 3.12.1. Manual copy quality adjustment 1. Press the “function” key on the control panel. 2. Select “general settings” on the touch panel display. 3. Select “01 manual copy quality adj” on the touch panel display. 4. Select “on” but...

Page 219

219 feb 2008 ver. 1.1 dp-c405/c305/c265 14. Press the “reset” key twice on the control panel to exit to the initial screen of the f2 service mode. 15. Press the “function”, and the “c (clear)” keys simultaneously on the control panel to exit the service mode. 3.12.3. Color exposure (special adjustme...

Page 220

220 feb 2008 ver. 1.1 dp-c405/c305/c265 color test chart 101 (p/n pjqrc0119z : ldr, pjqrc0120z : a3).

Page 221

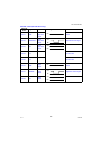

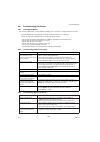

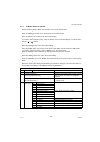

221 feb 2008 ver. 1.1 dp-c405/c305/c265 3.12.4. Copy quality adjustment procedure (order) when the following items are replaced or cleaned, perform the adjustments in the correct order. Mech. General settings image remarks part item open front cover, then power sw on tdc adj. (f8-09) close front cov...

Page 222

222 feb 2008 ver. 1.1 dp-c405/c305/c265 3.13. Adjusting the printer registration, lsu image side to side, color registration after installing the system console option, the following lsu image side to side adjustment must be performed. The printer registration is adjusted at the factory. If copy ima...

Page 223

223 feb 2008 ver. 1.1 dp-c405/c305/c265 6. Press the “reset” key on the control panel to exit to the initial screen of the f1 service mode. 7. Press the “6” key on the control panel, and then press the “start” key to enter the f6 service mode. 8. Perform the service modes f6-040 to f6-044, to adjust...

Page 224

224 feb 2008 ver. 1.1 dp-c405/c305/c265 3.14. Calibrating the lcd 1. Turn the main power switch on the back of the machine to the off position, and leave the power switch on the left side of the machine in the on ( i ) position. 2. Ensure that the sd memory card with firmware update is not installed...

Page 225

225 feb 2008 ver. 1.1 dp-c405/c305/c265 3.16. Adjusting scanner skew note: before adjusting scanner, proceed the printer registration first. Refer to sect. 3.13. 1. Remove the glass assembly, refer to section 2.2.2. 2. When the printed image is skewed to the left as illustrated. A. Turn screw (a) cl...

Page 226

226 feb 2008 ver. 1.1 dp-c405/c305/c265 3.17. Lsu replacement and color skew adjustment instructions 1. Model & part number 2. Contents • lsu : 1 • tool (jig) ; “pjzxf2170pu” : 1 • instruction (this document) : 1 3. Removing the lsu a. Remove the lsu by referring to the section 2.2.12. Important: ma...

Page 227

227 feb 2008 ver. 1.1 dp-c405/c305/c265 5. Adjustment of skew a. Open the front cover. B. Remove the toner waste container. Locate the 3 adjustment holes for the yellow, magenta, and cyan, as illustrated. C. Insert the tool (jig) into the corresponding color's adjustment hole, as illustrated. D. Tur...

Page 228

228 feb 2008 ver. 1.1 dp-c405/c305/c265 3.18. It belt replacement 1. When replacing the it belt, clean all the metal rollers, such as bias roller, and feed rollers with a soft cloth saturated with alcohol first. Toner stuck on the rollers will affect the print quality, and may reduce the life of the...

Page 229

229 feb 2008 ver. 1.1 dp-c405/c305/c265 3.19. It belt “cleaning unit” replacement (1) remove the cleaning unit. 1. Remove the it belt unit from the main unit. 2. Place a clean sheet of paper (i.E. Ledger or a3) to catch any toner spill. 3. Remove 2 black screws. 4. Remove the cleaning unit. Note: * ...

Page 230

230 feb 2008 ver. 1.1 dp-c405/c305/c265 (4) fold one cotton sheet to 1/4 as illustrated. (save the other cotton sheet as a spare) (5) lightly pat the cotton sheet on the powder. (6) generously apply the setting powder onto the surface of the it belt, by lightly and uniformly patting the belt from le...

Page 231

231 feb 2008 ver. 1.1 dp-c405/c305/c265 (7) install the new cleaning unit. (8) turn the white drive gear clockwise 5 times to make sure the it belt is turning smoothly. Note: * do not turn it counter-clockwise. * if the it belt is not turning smoothly, remove the cleaning unit, and repeat steps 5 an...

Page 232

232 feb 2008 ver. 1.1 dp-c405/c305/c265 3.20. 720k pm kit (dq-m35s72 / dq-m32n72).

Page 233

233 feb 2008 ver. 1.1 dp-c405/c305/c265 3.20.1. Replacement caution! Turn the power switch on the left side, and the main power switch on the back of the machine to the off position, and then unplug the ac power cord before beginning installation. 3.20.1.1. Fuser unit, fuser drive unit, intermediate...

Page 234

234 feb 2008 ver. 1.1 dp-c405/c305/c265 (9) open the lower right side cover. (10) remove 3 screws (s6). (11) remove the right side rear cover. (12) remove 3 screws (x5). (13) remove the interlock assy. (14) remove the interlock switch unit. Caution: when reinstalling the interlock switch unit, inser...

Page 235

235 feb 2008 ver. 1.1 dp-c405/c305/c265 (15) remove 1 screw (x5). (16) remove the exit pulley plate. (17) remove the belt. (18) loosen 2 screws. (19) pull the fuser unit out. (20) remove 3 screws (x5). (21) remove the exit roller assembly..

Page 236

236 feb 2008 ver. 1.1 dp-c405/c305/c265 (22) disconnect the harness. (23) remove 4 screws (x5). (24) lift, and remove the fuser drive unit in the direction shown by the arrow. Dp-c354/c322 series (25) release the harness from 9 clamps, and 1 edge saddle. (26) disconnect the harness from the stepping...

Page 237

237 feb 2008 ver. 1.1 dp-c405/c305/c265 (33) remove 1 screw. (34) pull out the handle. (35) lift, and remove the handle assembly in the direction shown by the arrow. (36) release the harness from the harness clamp. (37) remove the upper snap ring. (38) remove the lower snap ring. Note: for dp-c405/c...

Page 238

238 feb 2008 ver. 1.1 dp-c405/c305/c265 (42) remove the lower gear. Dp-c405/c305 only (43) remove the lower clutch. (44) remove 2 screws (s6). (45) remove the right side front cover. (46) open the sheet bypass tray. (47) remove the sheet bypass tray cover (2918) as illustrated. (48) release the harn...

Page 239

239 feb 2008 ver. 1.1 dp-c405/c305/c265 (49) disconnect 6 connectors (cn406, cn407, cn408, cn409, cn410, and cn411). (50) release the harnesses from the harness clamps. (51) open the lower right side cover. (52) remove the snap ring. (53) release the latch. (54) release the lock lever by pushing it ...

Page 240

240 feb 2008 ver. 1.1 dp-c405/c305/c265 (55) remove the lower right side cover unit by pushing the lock lever in the direction shown by the arrow. (56) remove 2 screws (x8). (57) remove the tray cover. (58) remove 4 screws (x5). (59) remove the registration guide . (60) remove the sheet bypass unit ...

Page 241

241 feb 2008 ver. 1.1 dp-c405/c305/c265 (61) pull tray 1, and tray 2 half way out. (62) remove 2 screws. (63) release 2 harness clamps. (64) disconnect the harness. (65) remove the upper unit, and lower unit by turning to the left. (66) open the front cover. (67) remove 2 screws. (68) remove the arm...

Page 242

242 feb 2008 ver. 1.1 dp-c405/c305/c265 (69) unlock 2 levers by turning in the upward direction, and sliding to the right. (70) remove the front cover. (71) remove 4 screws (s6). (72) remove the mechanical counter cover. (73) open the upper right cover, and remove 1 screw. (74) remove the front righ...

Page 243

243 feb 2008 ver. 1.1 dp-c405/c305/c265 (83) pull the handle out. (84) remove the snap ring. (85) remove the bearing. (86) remove the upper intermediate roller by sliding to the left first, and then pulling the right side out. (87) remove the gear. (88) replace the upper intermediate roller. Caution...

Page 244

244 feb 2008 ver. 1.1 dp-c405/c305/c265 (2) remove 3 screws. (3) remove 2 screws on both sides. (4) remove 2 metal parts on both sides. (5) remove the fuser exit guide..

Page 245

245 feb 2008 ver. 1.1 dp-c405/c305/c265 (6) remove the snap ring. (7) remove 2 e-rings on the front side. (8) remove 4 bushings on the both sides. (9) remove the gears. (10) remove the exit roller by sliding to the right first, and then pulling the left side out. (11) replace with the new exit rolle...

Page 246

246 feb 2008 ver. 1.1 dp-c405/c305/c265 3.20.1.2. It drive gear (removing the pc board, and the drive unit) (1) remove 11 screws (s6). (2) remove the rear cover assembly. (3) remove 1 screw (y31). (4) remove the cone pc board (3922). (5) remove 12 screws (x5). (6) remove all the harnesses from the s...

Page 247

247 feb 2008 ver. 1.1 dp-c405/c305/c265 (9) remove 6 screws (y31). (10) release the harness from 3 harness clamps. (11) remove the center bracket. (12) remove 4 screws (x5). (13) remove the left ec pcb bracket (3909). (14) remove the harnesses from the ec pc board assembly. (15) remove 7 screws (x5)...

Page 248

248 feb 2008 ver. 1.1 dp-c405/c305/c265 (17) remove all the harnesses from hvps2 pc board, and bracket. (18) remove 4 screws (x5). (19) pull the hvps2 pcb assembly out. (20) remove 3 screws (x5). (21) pull the hvps1 pc board assembly out. (1) open the front cover. (2) remove the toner waste containe...

Page 249

249 feb 2008 ver. 1.1 dp-c405/c305/c265 (7) release the harnesses from 11 clamps, and the drive unit. (8) remove the main drive unit (5811). (9) remove 12 screws (y19). (10) remove 1 e-ring. (11) replace the it drive gear (6007)..

Page 250

250 feb 2008 ver. 1.1 dp-c405/c305/c265 3.20.1.3. Voc filter (for germany / italy only with dq-m35s72-pm) : dp-c354 series only (1) loosen 11 screws (s6). (2) remove the rear cover assembly. (3) remove the ih voc filter (3927) by turning to the right. (4) install the new ih voc filter. (5) remove th...

Page 251

251 feb 2008 ver. 1.1 dp-c405/c305/c265 (8) open the right side upper cover. (9) remove 10 screws, and 1 fixing metal plate. (10) remove the adu upper guide. (11) remove 1 screw. (12) remove the release lever..

Page 252

252 feb 2008 ver. 1.1 dp-c405/c305/c265 (13) remove 2 screws. (14) remove the right side cover. (15) replace the exit voc filter (234). (16) install the right side cover by lifting the lever up..

Page 253

253 feb 2008 ver. 1.1 dp-c405/c305/c265 (17) reinstall the release lever as illustrated. Caution: if not reinstalling the lever, the cover cannot be opened. (18) secure with 1 screw. (19) reinstall the harness fastening metal plate as illustrated..

Page 254

254 feb 2008 ver. 1.1 dp-c405/c305/c265 3.20.1.4. Str unit, and intermediate transfer (it) unit (1) open the sheet bypass tray. (2) open the lower right side cover. (3) remove 2 screws (y16). (4) remove the guide bracket assembly. (5) remove the str unit (2535). (6) remove the snap ring (2714). (7) ...

Page 255

255 feb 2008 ver. 1.1 dp-c405/c305/c265 (8) push on the str guide to lock it in the down position. (9) remove 2 screws (y45). (10) push down the white latches on both sides, and pull on them to release the it unit from the locked position. (11) while holding the it unit by the center as illustrated,...

Page 256

256 feb 2008 ver. 1.1 dp-c405/c305/c265 (12) while holding the it unit on both sides, release the lock by pushing the lever to the right. (13) carefully pull the it unit (3420) out of the machine while holding it by both sides. Caution: pull the it unit out straight, and leveled (horizontal), or the...

Page 257

257 feb 2008 ver. 1.1 dp-c405/c305/c265 density sensor> (15) slide the sensor cover toward the front as illustrated. (16) while holding it in the open position, wipe the surface of the color registration, and of the toner density sensors through the frame holes. Note: when cleaning, wipe the surface...

Page 258

258 feb 2008 ver. 1.1 dp-c405/c305/c265 (19) unlock the str guide. Caution: when unlocking, exercise care not to pinch your fingers with the str guide. (20) install the str unit. Note: during the installation ensure that the hook is properly attached. (21) reinstall the guide bracket. Note: when rei...

Page 259