- DL manuals

- Vacon

- Controller

- 100 flow

- Installation Manual

Vacon 100 flow Installation Manual

Summary of 100 flow

Page 1

? vacon 100 vacon 100 flow ac drives installation manual ® phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 2

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 3

Vacon • 1 table of contents document: dpd00873d order code: doc-ins04123+dluk rev. D version release date: 7.11.12 1. Approvals ......................................................................................................... 3 1.1 ec declaration of conformity ..................................

Page 4

Vacon • 2 6.5 galvanic isolation barriers ............................................................................................... 74 7. Commissioning ............................................................................................... 75 7.1 commissioning of the drive ...............

Page 5

Approvals vacon • 3 1 1. A pprovals approvals granted to this vacon product are listed on the following pages. 1.1 ec declaration of conformity find the ec declaration of conformity on the next page. 1.2 ul approval culus approval file number e171278. 1.3 c-tick approval c-tick approval file number ...

Page 6

1 vacon • 4 approvals ec declaration of conformity we manufacturer's name: vacon oyj manufacturer's address: p.O.Box 25 7 e i t n i r o s n u r a s a a v 1 8 3 5 6 - n i f d n a l n i f hereby declare that the product product name: vacon 100 ac drive model designation: vacon 0100-3l-0003-5...0310-5 ...

Page 7

Safety vacon • 5 2 2. S afety this manual contains clearly marked cautions and warnings which are intended for your per- sonal safety and to avoid any unintentional damage to the product or connected appliances. Please read the information included in cautions and warnings carefully. The cautions an...

Page 8

2 vacon • 6 safety 2.2 warnings the ac drive is meant for fixed installations only. Do not perform any measurements when the ac drive is connected to the mains. The touch current of the ac drives exceeds 3.5 ma ac. According to standard en 61800-5-1, a reinforced protective ground connection must be...

Page 9

Safety vacon • 7 2 2.3 earthing and earth fault protection the ac drive must always be earthed with an earthing conductor connected to the earthing ter- minal marked with . The touch current of the drive exceeds 3.5 ma ac. According to en 61800-5-1, one or more of the following conditions for the as...

Page 10

2 vacon • 8 safety 2.4 electro-magnetic compatibility (emc) the ac drives comply with iec 61000-3-12 provided that the short-circuit power s sc is greater than or equal to 120 r sce at the interface point between the user’s supply and the public sys- tem. It is the responsibility of the installer or...

Page 11

Receipt of delivery vacon • 9 3 3. R eceipt of delivery check the correctness of delivery by comparing your order data to the drive information found on the package label. If the delivery does not correspond to your order, contact the supplier immediately. See chapter 3.1. Figure 1. Vacon package la...

Page 12

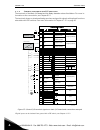

3 vacon • 10 receipt of delivery 3.1 type designation code vacon type designation code is formed of a nine-segment code and optional +codes. Each seg- ment of the type designation code uniquely corresponds to the product and options you have ordered. The code is of the following format: vacon0100-3l...

Page 13

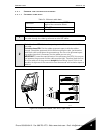

Receipt of delivery vacon • 11 3 3.2 unpacking and lifting the ac drive the weights of the ac drives vary greatly according to the size. You may need to use a piece of special lifting equipment to move the drive from its package. Note the weights of each individ- ual frame size in table below. If yo...

Page 14

3 vacon • 12 receipt of delivery vacon 100 ac drives have undergone scrupulous tests and quality checks at the factory before they are delivered to the customer. However, after unpacking the product, check that no signs of transport damages are to be found on the product and that the delivery is com...

Page 15

Receipt of delivery vacon • 13 3 3.3 accessories after having opened the transport package and lifted the drive out, check immediately that these various accessories were included in the delivery. The contents of the accessories bag differ by drive size and ip protections class: 3.3.1 frame mr4 3.3....

Page 16

3 vacon • 14 receipt of delivery 3.3.3 frame mr6 3.3.4 frame mr7 3.3.5 frame mr8 table 6. Contents of accessories bag, mr6 item quantity purpose m4x20 screw 10 screws for power cable clamps (6) and grounding clamps (4) m4x16 screw 3 screws for control cable clamps m4x8 screw 1 screw for optional gro...

Page 17

Receipt of delivery vacon • 15 3 3.3.6 frame mr9 control cable grounding lamella 3 control cable grounding cable lugs kp40 3 clamping power cables cable insulator 11 avoiding contact between cables cable grommet, hole diameter 25.3 mm 4 control cable run-through sealing ip00: touch protection shield...

Page 18

3 vacon • 16 receipt of delivery 3.4 ‘product modified’ sticker in the accessories bag included in the delivery you will find a silver product modified sticker. The purpose of the sticker is to notify the service personnel about the modifications made in the ac drive. Attach the sticker on the side ...

Page 19

Mounting vacon • 17 4 4. M ounting the ac drive must be mounted in vertical position on the wall or on the back plane of a cubicle. Ensure that the flatness variation shall not exceed 3 mm. Should the conditions of the moun- ting place require horizontal mounting, the functionalities within the give...

Page 20

4 vacon • 18 mounting figure 5. Vacon ac drive dimensions, mr5, wall mount figure 6. Vacon ac drive dimensions, mr6, wall mount *optional mounting holes (for nx replacement) 214 144 115 Ø7 Ø14 Ø7 100* 41 9 40 6 115 Ø7 100* ip21 39 130 13 4 Ø33 Ø33 Ø25 ip54 37 ,5 13 0 13 4 Ø25 9081.Emf 195 148 Ø 15,5...

Page 21

Mounting vacon • 19 4 figure 7. Vacon ac drive dimensions, mr7, wall mount 259 Ø20 660 64 5 237 190 Ø9 Ø16 Ø51 ip21 160 21 1 ip54 Ø25 Ø50 160 21 7 9083.Emf phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 22

4 vacon • 20 mounting figure 8. Vacon ac drive dimensions, mr8 ip21 and ip54 9084.Emf Ø 2 5 3 x 38 Ø 6 0 117 188 62,5 164 29 0 Ø 22 343 966 Ø 1 1 Ø 9 21 6 663 22 262 235 217 Ø 9 0 9 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 23

Mounting vacon • 21 4 figure 9. Vacon ac drive dimensions, mr8 ip00 9227.Emf 9.3 29 0 186. 5 255 217 Ø 2 2 Ø 9 Ø 9 794 683 663 18 17 1.5 343 21 5.7 10.8 15.1 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 24

4 vacon • 22 mounting figure 10. Vacon ac drive dimensions, mr9 ip21 and ip54 9085.Emf 84 3 x 42 = 12 6 318 166 77 4 x 81 ,5 = 32 6 Ø 59 1122 1150 Ø 9 14 Ø 9 48 0 Ø 2 2 400 35 5 36 5 292 284 27,5 Ø 2 5 36 0 Ø 9 Ø 9 810 36 0 m8 gn d phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - emai...

Page 25

Mounting vacon • 23 4 figure 11. Vacon ac drive dimensions, mr9 ip00 9114.Emf 130 810 840,5 16,5 65 m8 Ø 9 50 360 8 x 42 = 33 6 72 m8 g n d 318 3 x 42 = 126 84 ,5 Ø 2 5 14 Ø 9 optional main connector cover for cabinet installations phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - emai...

Page 26

4 vacon • 24 mounting 4.1.2 flange mount the ac drive can also be recessed into the cabinet wall or similar surface. A special flange mount option is available for this purpose. For an example of a flange-mounted drive, see figure 12. Note the ip classes of different sections in figure below. Figure...

Page 27

Mounting vacon • 25 4 4.1.2.1 flange mount - frames mr4 to mr9 figure 19. Presents the dimensions of the opening and drive outline with flange. Figures 13. - 18. Present dimensions of the drives with the flange mount option. Figure 13. Mr4, flange mount, dimensions 11134.Emf 152,0 15,0 122,0 Ø 7,0 2...

Page 28

4 vacon • 26 mounting figure 14. Mr5, flange mount, dimensions 11132.Emf Ø 7 ,0 Ø 7 4 36, 0 454, 1 262, 5 145,0 144,0 150,0 169,0 9 13 382 24 39 33 27, 5 100 214,0 114 11,5 72,2 145,0 10 1, 9 12,0 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 29

Mounting vacon • 27 4 figure 15. Mr6, flange mount, dimensions 11133.Emf 13,9 123,0 16 ,8 5 14,0 36,4 26,2 286,3 ± 20 229,0 106,0 Ø 7 2- Ø 4 ,0 115,5 196,0 12,0 18,0 6,0 184,0 220,0 195,0 201,0 Ø 7 101,9 566 ,0 580 232 72,2 3 55,6 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email...

Page 30

4 vacon • 28 mounting figure 16. Mr7, flange mount, dimensions 11135.Emf 230,0 51,2 35,2 720 192 ,5 1 97,5 660,0 680 192,5 10 2,1 4 41,6 20,3 237 271,0 286 7,5 72,3 8- Ø 5, 5 110,4 148,8 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 31

Mounting vacon • 29 4 figure 17. Mr8, flange mount, dimensions 11131.Emf 35 9 3 26, 0 1,9 6, 8 424,7 Ø 7 ,0 89,6 89 0, 8 233 ,0 831 ,5 Ø 7 ,0 Ø 6 ,5 3 15, 5 19,4 852,6 5 73, 5 82,5 26,0 18 2, 5 33 4, 0 72 ,2 898,0 101,8 gnd m8 29 3 109,5 Ø 7 ,0 Ø 7 ,0 phone: 800.894.0412 - fax: 888.723.4773 - web: w...

Page 32

4 vacon • 30 mounting figure 18. Mr9, flange mount, dimensions 11130.Emf 1060,0 397,5 55 0, 0 52 5, 0 10 8 25 5, 8 24 7 m8 gn d 72 ,2 101,8 73 ,0 72 ,2 17 5, 0 17 5, 0 85,0 10,5 163,0 300,0 300,0 Ø 6 ,5 1039,0 10,5 56 75,0 Ø 2 2 ,0 210 Ø 2 5 3 x 42 = 12 6, 0 12 0 44 9,0 108,5 phone: 800.894.0412 - f...

Page 33

Mounting vacon • 31 4 figure 19. Flange mount cutout dimensions for mr4 to mr9 table 10: flange mount cutout dimensions for mr4 to mr9 frame a b c d e mr4 315 137 357 152 24 mr5 408 152 454 169 23 mr6 541 203 580 220 23 mr7 655 240 680 286 13 mr8 859 298 898 359 18 mr9 975 485 1060 550 54 11136.Emf ...

Page 34

4 vacon • 32 mounting figure 20. Sealing of the cutout for mr8 and mr9 9254.Emf drive gasket tape ( ) opening outline ( ) to p phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 35

Mounting vacon • 33 4 4.2 cooling the ac drives produce heat in operation and are cooled down by air circulated by a fan. Enough free space shall therefore be left around the ac drive to ensure sufficient air circulation and cooling. Different acts of maintenance also require certain amount of free ...

Page 36

4 vacon • 34 mounting note that if several units are mounted above each other the required free space equals c + d (see figure 22.). Moreover, the outlet air used for cool- ing by the lower unit must be directed away from the air intake of the upper unit by means of e.G. A piece of metal plate fixed...

Page 37

Power cabling vacon • 35 5 5. P ower cabling the mains cables are connected to terminals l1, l2 and l3 and the motor cables to terminals marked with u, v and w. See principal connection diagram in figure 23. See also table 13 for the cable recommmendations for different emc levels. Figure 23. Princi...

Page 38

5 vacon • 36 power cabling 1 = power cable intended for fixed installation and the specific mains voltage. Shielded cable not required. (mcmk or similar recommended). 2 = symmetrical power cable equipped with concentric protection wire and intended for the specific mains voltage. (mcmk or similar re...

Page 39

Power cabling vacon • 37 5 5.1 ul standards on cabling to meet the ul (underwriters laboratories) regulations, use a ul-approved copper cable with a minium heat-resistance +60/75 °c. Use class 1 wire only. The units are suitable for use on a circuit capable of delivering not more than 100,000 rms sy...

Page 40

5 vacon • 38 power cabling 5.1.1.1 cable and fuse sizes the recommended fuse types are gg/gl (iec 60269-1) or class t (ul & csa). The fuse voltage rating should be selected according to the supply network. The final selection should be made according to local regulations, cable installation conditio...

Page 41

Power cabling vacon • 39 5 the cable dimensioning is based on the criteria of the international standard iec60364-5-52:cables must be pvc-isolated; max ambient temperature +30 °c, max temperature of cable surface +70 °c; use only cables with concentric copper shield; max number of parallel cables is...

Page 42

5 vacon • 40 power cabling 5.1.1.2 cable and fuse sizes, north america the recommended fuse types are gg/gl (iec 60269-1) or class t (ul & csa). The fuse voltage rating should be selected according to the supply network. The final selection should be made according to local regulations, cable instal...

Page 43

Power cabling vacon • 41 5 the cable dimensioning is based on the criteria of the underwriters’ laboratories ul508c:cables must be pvc-iso- lated; max ambient temperature +30 °c, max temperature of cable surface +70 °c; use only cables with concentric copper shield; max number of parallel cables is ...

Page 44

5 vacon • 42 power cabling 5.2 brake resistor cables vacon 100 ac drives are equipped with terminals for an optional external brake resistor. These terminals are marked with r+ and r- (mr4-mr6) or dc+/r+ and r- (mr7 and bigger). The re- commended sizes for the brake resistor cables are listed in tab...

Page 45

Power cabling vacon • 43 5 5.3.1 frames mr4 to mr7 figure 25. Stripping of cables 1 strip the motor, mains and brake resistor cables as advised below. Table 16. Cables stripping lengths [mm] frame a1 b1 c1 d1 c2 d2 e mr4 15 35 10 20 7 35 leave as short as pos- sible mr5 20 40 10 30 10 40 mr6 20 90 1...

Page 46

5 vacon • 44 power cabling figure 26. Opening cover figure 27. Removing screws 2 open the cover of the ac drive. 3 remove the screws of the cable protection plate. Do not open the cover of the power unit! M4x55 9174.Emf m4x8 9228.Emf phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - em...

Page 47

Power cabling vacon • 45 5 figure 28. Examples of cable entry plates with grommets, ip21 4 insert the cable grommets (included in the delivery) in the openings of the cable entry plate (included) as shown in the picture ( p icture eu version). 5 • insert the cables - supply cable, motor cable and op...

Page 48

5 vacon • 46 power cabling figure 29. Grommet cutting and sealing figure 30. Detaching cable clamps 6 detach the cable clamps and the grounding clamps (figure 30) and place the cable entry plate with the cables in the groove on the ac drive frame (figure 31). 9071.Emf m4x16 (2.2 nm) 9229.Emf phone: ...

Page 49

Power cabling vacon • 47 5 figure 31. Cable entry plate and cables figure 32. Cable connection 7 connect the stripped cables (see figure 25 and table ) as shown in figure 32. • expose the shield of all three cables in order to make a 360-degree con- nection with the cable clamp (1). • connect the (p...

Page 50

5 vacon • 48 power cabling tightening torques of cable terminals: figure 33. Additional protective earthing connector table 17. Tightening torques of terminals frame type tightening torque [nm]/[lb-in.] power and motor terminals tightening torque [nm]/[lb-in.] emc grounding clamps tightening torque,...

Page 51

Power cabling vacon • 49 5 figure 34. Re-mounting of cover components 5.3.2 frames mr8 and mr9 figure 35. Stripping of cables 9 re-mount the cable protection plate (figure 34) and the cover of the ac drive. 1 strip the motor, mains and brake resistor cables as advised below. Note! Dynamic braking an...

Page 52

5 vacon • 50 power cabling figure 36. Removing main cover (mr9) table 18. Cables stripping lengths [mm] frame a1 b1 c1 d1 c2 d2 e mr8 40 180 25 300 25 300 leave as short as possible mr9 40 180 25 300 25 300 2 mr9 only: remove the main cover of the ac drive. 9046.Emf m4 x 10 phone: 800.894.0412 - fax...

Page 53

Power cabling vacon • 51 5 figure 37. Removing cable cover and cable fitting plate (mr8). Figure 38. Removing cable cover and cable fitting plate (mr9). 3 remove the cable cover (1) and the cable fitting plate (2). 1 9029.Emf m4x8 2 9039.Emf m4 x 8 1 2 9041.Emf m4 x 8 m5 x 10 phone: 800.894.0412 - f...

Page 54: Mr9

5 vacon • 52 power cabling figure 39.Removing sealing plate (mr9) figure 40. Removing emc shield plate, left: mr8, right: mr9 4 mr9 only: loosen the screws and remove the sealing plate. 5 remove the emc shield plate. Mr9 m4x8 9048.Emf m5 m4x8 wing nut 9026.Emf phone: 800.894.0412 - fax: 888.723.4773...

Page 55

Power cabling vacon • 53 5 figure 41.Power terminals, left: mr8, right: mr9 figure 42.Cutting the cable grommets 6 locate the terminals. Observe the exceptional placement of motor cable termi- nals especially in frame mr8! 7 cut the rubber grommets open to slide the cables through. Should the grom- ...

Page 56

5 vacon • 54 power cabling figure 43. Placing the grommet figure 44. Inserting the cable insulators 8 place the grommet with the cable so that the frame end plate fits in the groove on the grommet, see figure 43. To meet the requirements of the enclosure class ip54, the connection between the gromme...

Page 57

Power cabling vacon • 55 5 figure 45. Connecting power cables, left: mr8, right: mr9 figure 46. Placing two cable lugs on top of each other 10 connect the cables stripped as shown in figure 35. • connect the (phase) conductors of the supply, brake and motor cables into their respective terminals (a)...

Page 58

5 vacon • 56 power cabling tightening torques of cable terminals: figure 47. Exposing cable shields table 19. Tightening torques of terminals frame type tightening torque [nm]/[lb-in.] power and motor terminals tightening torque [nm]/[lb-in.] emc grounding clamps tightening torque, [nm]/[lb-in.] gro...

Page 59

Power cabling vacon • 57 5 figure 48. Reattaching cable fitting plate and cover figure 49. Re-mounting the main cover (mr9) 13 re-attach then the cable fitting plate and then the cable cover. 14 mr9 only: now re-mount the main cover (unless you want to make the control connections first). M4x8 m4x8 ...

Page 60

5 vacon • 58 power cabling figure 50. Connecting the protective conductor 15 check the connection of the earth cable to the motor and the ac drive terminals marked with . Note: two protective conductors are required according to standard en61800- 5-1. See chapter earthing and earth fault protection....

Page 61

Power cabling vacon • 59 5 5.4 installation in corner-grounded network corner grounding is allowed for the drive types rating from 72 a to 310 a at 380…500 v supply and from 75 a to 310 a at 208…240 v supply. In these circumstances the emc protection class must be changed to level c4 following the i...

Page 62

6 vacon • 60 control unit 6. C ontrol unit the control unit of the ac drive consists of the standard boards and additional boards (option boards, see chapter 6.3) connected to the slot connectors of the control board. Figure 51. Location of control unit components locations of essential control unit...

Page 63

Control unit vacon • 61 6 the control board can be powered externally (+24 vdc, 1000 ma, ±10%) by connecting the ex- ternal power source to terminal #30, see page 62. This voltage is sufficient for parameter set- ting and for keeping the control unit active. Note however that the measurements of the...

Page 64

6 vacon • 62 control unit 6.1.2 control terminals and dip switches the terminals of the basic i/o board and the relay boards are described below. For more in- formation on the connections, see chapter 8.2.1. The terminals shown on shadowed background are assigned for signals with optional functions ...

Page 65

Control unit vacon • 63 6 6.1.2.1 selection of terminal functions with dip switches the shadowed terminals in figure 52 allow for three functional selections each with the so- called dip switches . The switches have two positions, up and down. See figure to locate the switches and make appropriate s...

Page 66

6 vacon • 64 control unit 6.2 fieldbus connection the ac drive can be connected to fieldbus either through rs485 or ethernet. The connection for rs485 is on the basic i/o board (terminals a and b) and the connection for ethernet is under the drive cover, left to the control keypad. See figure 55. Fi...

Page 67

Control unit vacon • 65 6 6.2.1 prepare for use through ethernet 6.2.1.1 ethernet cable data figure 56.Leading the cables, left: ip21, right: ip54 table 21. Ethernet cable data connector shielded rj45 connector; note: max length of the connector 40mm. Cable type cat5e stp cable length max .100m 1 co...

Page 68

6 vacon • 66 control unit figure 57. Distance between cables, left: ip21, right: ip54 for more detailed information, see the user’s manual of the fieldbus you are using. 6.2.2 prepare for use through rs485 6.2.2.1 rs485 cable data 3 remount the ac drive cover. Note: when planning the cable runs, rem...

Page 69

Control unit vacon • 67 6 figure 58. Connecting the rs485 cable 1 strip about 15 mm of the rs485 cable (see specification on page 66) and cut off the grey cable shield. Remember to do this for both bus cables. Leave no more than 10 mm of the cable outside the terminal block and strip the cables at a...

Page 70

6 vacon • 68 control unit 3 using the cable clamp included in the delivery of the drive, ground the shield of the rs485 cable to the frame of the ac drive. 4 if the ac drive is the last device on the bus, the bus termination must be set. Locate the dip switches to the right of the control keypad of ...

Page 71

Control unit vacon • 69 6 5 unless already done for the other control cables, cut free the opening on the ac drive cover for the rs485 cable (protection class ip21). 6 remount the ac drive cover and run the rs485 cables as shown in picture. Note: when planning the cable runs, remember to keep the di...

Page 72

6 vacon • 70 control unit 6.3 option board installation the option boards are placed in the board slots on the drive. The table below gives information about which option board can be placed in which board slot on the drive. Note! It is not allowed to add or replace option boards or fieldbus boards ...

Page 73

Control unit vacon • 71 6 figure 59.Opening the main cover 1 open the cover of the ac drive. The relay outputs and other i/o-terminals may have a dangerous control voltage present even when the drive is disconnected from mains. 2 make sure that the sticker on the connector of the board says “dv” (du...

Page 74

6 vacon • 72 control unit 3 to reveal the option board slots, open the control unit cover as shown in picture below. 4 install the option board into the appropriate slot c, d or e (see table 23 on page 70 and figure below). Close the cover of the control unit and remount the keypad. 9235.Emf d e 302...

Page 75

Control unit vacon • 73 6 6.4 battery installation for real time clock (rtc) enabling the functions of the real time clock (rtc) requires that an optional battery is in- stalled in the drive. Use ½ aa battery with voltage of 3.6 v and capacity of 1000...1200 mah (e.G. Panasonic br-1/2 aa or vitzroce...

Page 76

6 vacon • 74 control unit 6.5 galvanic isolation barriers the control connections are isolated from the mains potential and the gnd terminals are per- manently connected to ground. See figure 60. The digital inputs are galvanically isolated from the i/o ground. The relay outputs are addition- ally d...

Page 77

Commissioning vacon • 75 7 7. C ommissioning before commissioning, note the following directions and warnings: internal components and circuit boards of vacon 100 (except for the galvanically isolated i/o terminals) are live when it is connected to mains potential. Coming into contact with this volt...

Page 78

7 vacon • 76 commissioning 7.1 commissioning of the drive read carefully the safety instructions in chapter 2 and above and follow them. After the installation: check that both the ac drive and the motor are grounded. check that the mains, brake and motor cables comply with the requirements give...

Page 79

Commissioning vacon • 77 7 7.2.1 cable and motor insulation checks 1. Motor cable insulation checks disconnect the motor cable from terminals u, v and w of the ac drive and from the motor. Measure the insulation resistance of the motor cable between each phase conductor as well as between each phase...

Page 80

7 vacon • 78 commissioning 7.3 installation in it system if your supply network is an it (impedance-grounded) system but your ac drive is emc-pro- tected according to class c2 you need to modify the emc protection of the ac drive to emc- level c4. This is done by removing the built-in emc jumpers wi...

Page 81

Commissioning vacon • 79 7 7.3.2 frames mr7 and mr8 follow the procedure described below to modify the emc protection of the ac drive of frames mr7 and mr8 to emc-level c4. Figure 63.Grounding arm, mr8 figure 64. Detaching the emc jumper, mr7-8 1 remove the main cover of the ac drive and locate the ...

Page 82

7 vacon • 80 commissioning figure 65. Mr7: detaching the dc grounding busbar from frame 7.3.3 frame mr9 follow the procedure described below to modify the emc protection of the ac drive of frame mr9 to emc-level c4. Figure 66. Placing the connector 3 additionally for mr7, locate the dc grounding bus...

Page 83

Commissioning vacon • 81 7 figure 67. Removing the emc jumper 2 further remove the extension box cover, the touch shield and the i/o plate with i/ o grommet plate. Locate the emc jumper on the emc board (see magnification below) and remove it. Caution! Before connecting the ac drive to mains make su...

Page 84

7 vacon • 82 commissioning 7.4 maintenance in normal conditions, the ac drive is maintenance-free. However, regular maintenance is re- commended to ensure a trouble-free operation and a long lifetime of the drive. We recommend to follow the table below for maintenance intervals. Note: because of cap...

Page 85: Mr4

Technical data, vacon 100 vacon • 83 8 8. T echnical data , v acon 100 8.1 ac drive power ratings 8.1.1 mains voltage 208-240 v note! The rated currents in given ambient temperatures (in table 28) are achieved only when the switching frequency is equal to or less than the factory default. Note! For ...

Page 86: Mr4

8 vacon • 84 technical data, vacon 100 8.1.2 mains voltage 380-500 v note! The rated currents in given ambient temperatures (in table 28) are achieved only when the switching frequency is equal to or less than the factory default. Note! For cyclical loads such as e.G. Lifts and winches, please conta...

Page 87

Technical data, vacon 100 vacon • 85 8 8.1.3 definitions of overloadability low overload = following continuous operation at rated output current, 110% rated output current (i l ) for 1 min, followed by a period of load current less than rated current, and of such du- ration that the r.M.S output cu...

Page 88

8 vacon • 86 technical data, vacon 100 8.1.4 brake resistor ratings make sure that the resistance is higher than the minimum resistance defined. The power handling capacity must be sufficient for the application. Recommended brake resistor types and calculated resistances for vacon 100 ac drives: fi...

Page 89

Technical data, vacon 100 vacon • 87 8 figure 71. Duty cycles of ld and hd pulses table 26. Minimum resistance value and braking power with recommended resistor types, mains voltage 208-240v mains voltage 208-240 v, 50/60 hz, 3~ frame brake min. Resistance [ohm] brake power * @405 vdc [kw] * with re...

Page 90

8 vacon • 88 technical data, vacon 100 8.2 vacon 100 - technical data table 28. Vacon 100 technical data mains connection input voltage u in 208...240 v; 380…500 v; -10%…+10% input frequency 50...60 hz -5...+10% connection to mains once per minute or less starting delay 6 s (mr4 to mr6); 8 s (mr7 to...

Page 91

Technical data, vacon 100 vacon • 89 8 ambient conditions ambient operating temperature i l current: -10°c (no frost)…+40 °c i h current: -10°c (no frost)…+50 °c max. Operating temperature: +50 °c storage temperature -40 °c…+70 °c relative humidity 0...95% r h , non-condensing, non-corrosive air qua...

Page 92

8 vacon • 90 technical data, vacon 100 protections overvoltage trip limit 240-volt drives: 456 vdc 500-volt drives: 911 vdc undervoltage trip limit depends on supply voltage (0,8775*supply voltage): supply voltage 240 v: trip limit 211 vdc supply voltage 400 v: trip limit 351 vdc supply voltage 500 ...

Page 93

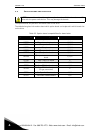

Technical data, vacon 100 vacon • 91 8 8.2.1 technical information on control connections table 29. Technical information on standard i/o board standard i/o board terminal signal technical information 1 reference output +10 v, +3%; maximum current 10 ma 2 analogue input, voltage or current analogue ...

Page 94

8 vacon • 92 technical data, vacon 100 standard relay board (+sbf3) terminal signal technical information 21 relay output 1 * * if 230 vac is used as control voltage from the output relays, the control circuitry must be powered with a separate isolation transformer to limit short circuit current and...

Page 95: Mr4

Technical data, vacon 100 flow vacon • 93 9 9. T echnical data , v acon 100 flow 9.1 ac drive power ratings 9.1.1 mains voltage 208-240 v note! The rated currents in given ambient temperatures (in table 32) are achieved only when the switching frequency is equal to or less than the factory default. ...

Page 96: Mr4

9 vacon • 94 technical data, vacon 100 flow 9.1.2 mains voltage 380-500 v note! The rated currents in given ambient temperatures (in table 32) are achieved only when the switching frequency is equal to or less than the factory default. Note! For cyclical loads, please contact vacon for dimensioning....

Page 97

Technical data, vacon 100 flow vacon • 95 9 9.1.3 definitions of overloadability low overload = following continuous operation at rated output current, 110% rated output current (i l ) for 1 min, followed by a period of load current less than rated current, and of such du- ration that the r.M.S outp...

Page 98

9 vacon • 96 technical data, vacon 100 flow 9.2 vacon 100 flow - technical data table 32. Vacon 100 flow technical data mains connection input voltage u in 208...240 v; 380…500 v; -10%…+10% input frequency 50...60 hz -5...+10% connection to mains once per minute or less starting delay 6 s (mr4 to mr...

Page 99

Technical data, vacon 100 flow vacon • 97 9 ambient conditions ambient operating temperature i l current: -10 °c (no frost)…+40 °c up to 50 °c with derating (1,5%/1°c) storage temperature -40 °c…+70 °c relative humidity 0...95% r h , non-condensing, non-corrosive air quality: • chemical vapours • me...

Page 100

9 vacon • 98 technical data, vacon 100 flow protections overvoltage trip limit 240-volt drives: 456 vdc 500-volt drives: 911 vdc undervoltage trip limit depends on supply voltage (0,8775*supply voltage): supply voltage 240 v: trip limit 211 vdc supply voltage 400 v: trip limit 351 vdc supply voltage...

Page 101

Technical data, vacon 100 flow vacon • 99 9 9.2.1 technical information on control connections table 33. Technical information on standard i/o board standard i/o board terminal signal technical information 1 reference output +10 v, +3%; maximum current 10 ma 2 analogue input, voltage or current anal...

Page 102

9 vacon • 100 technical data, vacon 100 flow standard relay board (+sbf3) terminal signal technical information 21 relay output 1 * * if 230 vac is used as control voltage from the output relays, the control circuitry must be powered with a separate isolation transformer to limit short circuit curre...

Page 103

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 104

Document id: rev. D subject to change without prior notice © 2012 vacon plc. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.