- DL manuals

- Vacon

- Controller

- 100 flow

- Installation Manual

Vacon 100 flow Installation Manual

Summary of 100 flow

Page 1

Vacon 100 vacon 100 flow vacon 100 hvac ac drives installation manual wall-mounted drives ® ® ®.

Page 3: Preface

Preface document id: dpd01711g date: 15.12.2015 about this manual this manual is copyright of vacon plc. All rights reserved. Preface vacon · 3 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com.

Page 4

Vacon · 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 5: Table of Contents

Table of contents preface about this manual 3 1 approvals 8 2 safety 10 2.1 the safety symbols used in the manual 10 2.2 warning 10 2.3 caution 11 2.4 grounding and earth fault protection 12 2.5 electro-magnetic compatibility (emc) 13 2.6 using an rcd or an rcm device 13 3 receiving the delivery 15 ...

Page 6

4.3 dimensions for wall mounting, north america 31 4.3.1 wall mounting of mr4, north america 31 4.3.2 wall mounting of mr5, north america 32 4.3.3 wall mounting of mr6, north america 33 4.3.4 wall mounting of mr7, north america 34 4.3.5 wall mounting of mr8, north america 35 4.3.6 wall mounting of m...

Page 7

6.5 installation of a battery for the real time clock (rtc) 105 6.6 galvanic isolation barriers 105 7 commissioning and additional instructions 107 7.1 commissioning safety 107 7.2 commissioning of the drive 107 7.3 operation of the motor 108 7.3.1 checks before starting the motor 108 7.4 measuring ...

Page 8: Approvals

1 approvals here are the approvals that have been granted to this vacon product. 1. Ec declaration of conformity • find the ec declaration of conformity on the next page. 2. Ul approval • culus approval file number e171278. 3. Rcm approval • rcm approval number e2204. Vacon · 8 approvals 1 tel. +358...

Page 9

Ec declaration of conformity we manufacturer’s name: vacon oyj manufacturer’s address: p.O. Box 25 runsorintie 7 fin-65381 vaasa finland hereby declare that the product product name: vacon 100 ac drive model designation: wall-mounted drives: vacon 0100 3l 0003 2...0310 2 vacon 0100 3l 0003 4...0310 ...

Page 10: Safety

2 safety 2.1 the safety symbols used in the manual this manual contains warnings and cautions, which are identified with safety symbols. The warnings and cautions give important information on how to prevent injury and damage to the equipment or your system. Read the warnings and cautions carefully ...

Page 11

Warning! Before you do electrical work, make sure that there is no voltage in the components of the drive. Warning! To do work on the terminal connections of the drive, disconnect the drive from mains and make sure that the motor has stopped. Wait 5 minutes before you open the cover of the drive. Th...

Page 12

Caution! Do not touch the components on the circuit boards. Static voltage can cause damage to these components. Caution! Make sure that the emc level of the ac drive is correct for your mains. See chapter 7.6 installation in an it system. An incorrect emc level can cause damage to the drive. Cautio...

Page 13

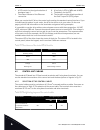

Table 2: protective grounding conductor cross-section cross-sectional area of the phase conductors (s) [mm 2 ] the minimum cross-sectional area of the protective grounding conductor in question [mm 2 ] s ≤ 16 s 16 16 35 s/2 the values of the table are valid only if the protective grounding conductor...

Page 14

Note! You can download the english and french product manuals with applicable safety, warning and caution information from www.Vacon.Com/downloads. Remarque vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'en- semble des informations de sécurité, avertisseme...

Page 15: Receiving The Delivery

3 receiving the delivery before a vacon ® ac drive is sent to the customer, the manufacturer makes many tests on the drive. However, after you remove the packaging, examine the drive for transport damages. If the drive was damaged during the shipping, speak to the cargo insurance company or the carr...

Page 16

3.2 type designation code the type designation code of vacon is made of standard codes and optional codes. Each part of the type designation code agrees to the data in your order. The code can have this format, for example: vacon0100-3l-0061-5+ip54 vacon0100-3l-0061-5-flow table 3: the description o...

Page 17

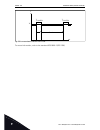

Table 4: the weights of the different frames frame weight, ip21/ip54 [kg] weight, ip00 [kg] weight, ul type 1 / type 12 [lb.] weight, ul open type [lb.] mr4 6.0 13.2 mr5 10.0 22.0 mr6 20.0 44.1 mr7 37.5 82.7 mr8 66.0 62.0 145.5 136.7 mr9 119.5 103.5 263.5 228.2 3.4.2 lifting the frames mr8 and mr9 1...

Page 18

4 the maximum lifting angle is 45 degrees. ≤45° 3.5 accessories after you open the package and lift the drive out, make sure that you received all the accessories. The content of the accessories bag is different for the different frames and protection classes. Vacon · 18 receiving the delivery 3 tel...

Page 19

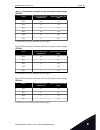

3.5.1 frame mr4 table 5: the content of the accessories bag item quantity description m4x16 screw 11 screws for the grounding clamps for cable shield (6), the grounding clamps for control cable (3), and the grounding clamps for grounding conductor (2) m4x8 screw 1 screw for the optional grounding m5...

Page 20

3.5.3 frame mr6 table 7: the content of the accessories bag item quantity description m4x20 screw 10 screws for the grounding clamps for cable shield (6), and the grounding clamps for grounding conductor (4) m4x16 screw 3 screws for the control cable clamps m4x8 screw 1 screw for the optional ground...

Page 21

3.5.4 frame mr7 table 8: the content of the accessories bag item quantity description m6x30 slotted nut 6 nuts for the grounding clamps for cable shield m4x16 screw 3 screws for the grounding clamps for control cable m6x12 screw 1 screw for the external grounding of the drive grounding clamp for con...

Page 22

3.5.6 frame mr9 table 10: the content of the accessories bag item quantity description m4x16 screw 3 screws for the grounding clamps for control cable grounding clamp for control cable 3 control cable grounding grounding clamp for cable shield kp40 5 clamping the power cables cable insulator 10 to p...

Page 23: Mounting

4 mounting 4.1 general information about mounting install the ac drive in a vertical position on the wall. If you install the drive in a horizontal position, it is possible that some functions with the nominal values that are found in chapter 8 technical data, vacon® 100 or 9 technical data, vacon® ...

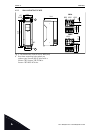

Page 24

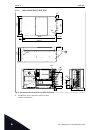

4.2.2 wall mounting of mr5 Ø7 Ø33 Ø25 Ø25 Ø33 a a 214 144 115 Ø7 Ø14 Ø7 100* 419 406 115 100* ip21 39 37.5 130 134 130 134 ip54 fig. 3: the dimensions of the ac drive, mr5 [mm] a. Use these mounting holes when you replace your vacon ® nx ac drive with a vacon ® 100, vacon ® 100 flow or vacon ® 100 h...

Page 25

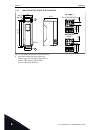

4.2.3 wall mounting of mr6 195 148 Ø15.5 Ø9 557 541 Ø9 148 229 148 151 ip21 ip54 42 43.7 148 151 Ø40 Ø33 Ø40 Ø25 fig. 4: the dimensions of the ac drive, mr6 [mm] mounting vacon · 25 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 26

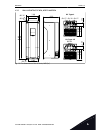

4.2.4 wall mounting of mr7 259 Ø20 660 645 237 190 ip21 ip54 160 211 160 217 Ø9 Ø16 Ø51 Ø25 Ø50 fig. 5: the dimensions of the ac drive, mr7 [mm] vacon · 26 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 27

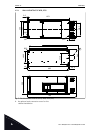

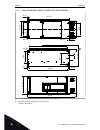

4.2.5 wall mounting of mr8, ip21 and ip54 9 3 x 38 114 117 188 62.5 164 290 343 216 663 996 22 262 235 217 Ø25 Ø60 Ø11 Ø22 Ø9 Ø9 fig. 6: the dimensions of the ac drive, mr8, ip21 and ip54 [mm] mounting vacon · 27 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 28

4.2.6 wall mounting of mr8, ip00 9.3 290 186.5 255 217 794 683 663 18 171.5 343 215.7 10.8 15.1 Ø9 Ø9 Ø22 Ø11 a fig. 7: the dimensions of the ac drive, mr8, ip00 [mm] a. An optional main connector cover for the cabinet installation vacon · 28 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 20...

Page 29

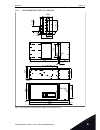

4.2.7 wall mounting of mr9, ip21 and ip54 Ø25 Ø59 Ø22 84 3 x 42 126 318 166 77 4 x 81.5 326 1122 1150 Ø9 14 480 400 355 365 292 284 27,5 360 810 360 m8 gnd Ø9 Ø9 Ø9 fig. 8: the dimensions of the ac drive, mr9, ip21 and ip54 [mm] mounting vacon · 29 24-hour support +358 (0)201 212 575 · email: vacon@...

Page 30

4.2.8 wall mounting of mr9, ip00 130 810 840.5 16.5 65 50 360 8 x 42 72 m8 gnd 318 3 x 42 84.5 14 Ø9 Ø22 400 480 355 365 Ø9 m8 a Ø25 126 336 fig. 9: the dimensions of the ac drive, mr9, ip00 [mm] a. An optional main connector cover for the cabinet installation vacon · 30 mounting 4 tel. +358 (0)201 ...

Page 31

4.3 dimensions for wall mounting, north america 4.3.1 wall mounting of mr4, north america Ø0.98 Ø0.98 Ø0.28 Ø0.51 ul type 1 ul type 12 4.41 5.79 5.04 3.94 12.32 3.94 12.91 7.48 5.94 4.41 fig. 10: the dimensions of the ac drive, mr4 [in] mounting vacon · 31 24-hour support +358 (0)201 212 575 · email...

Page 32

4.3.2 wall mounting of mr5, north america Ø0.28 Ø1.30 Ø0.98 Ø0.98 Ø1.30 a a 8.43 5.67 4.53 Ø0.28 Ø0.55 Ø0.28 3.94* 16.50 15.98 4.53 3.94* ul type 1 1.54 1.48 5.12 5.28 5.12 5.28 ul type 12 fig. 11: the dimensions of the ac drive, mr5 [in] a. Use these mounting holes when you replace your vacon ® nx ...

Page 33

4.3.3 wall mounting of mr6, north america 7.68 5.83 Ø0.61 Ø0.35 21.93 21.30 Ø0.35 5.83 9.02 5.83 5.94 ul type 1 ul type 12 1.65 1.72 5.83 5.94 Ø1.57 Ø1.30 Ø1.57 Ø0.98 fig. 12: the dimensions of the ac drive, mr6 [in] mounting vacon · 33 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 34

4.3.4 wall mounting of mr7, north america 10.20 Ø0.79 25.98 25.39 9.33 7.48 ul type 1 ul type 12 6.30 8.31 6.30 8.54 Ø0.35 Ø0.63 Ø2.01 Ø0.98 Ø1.97 fig. 13: the dimensions of the ac drive, mr7 [in] vacon · 34 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 35

4.3.5 wall mounting of mr8, north america 3 x 1.50 4.49 4.61 7.40 2.46 6.46 11.42 13.50 8.50 26.10 39.21 0.87 10.31 9.25 8.54 Ø0.98 Ø2.36 Ø0.43 Ø0.87 Ø0.35 Ø0.35 0.35 fig. 14: the dimensions of the ac drive, mr8 [in] mounting vacon · 35 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 36

4.3.6 wall mounting of mr8, ul open type, north america 0.37 11.42 7.34 10.04 8.54 31.26 26.89 26.10 0.71 6.75 13.50 8.49 0.43 0.59 Ø0.35 Ø0.35 Ø0.87 Ø0.43 a fig. 15: the dimensions of the ac drive, mr8, ul open type [in] a. An optional main connector cover for the cabinet installation vacon · 36 mo...

Page 37

4.3.7 wall mounting of mr9, north america Ø0.98 Ø2.32 Ø0.87 3.31 3 x 1.65 4.96 12.52 6.54 3.03 4 x 3.21 12.84 44.17 45.28 Ø0.35 0.55 18.90 15.75 13.98 14.37 11.50 11.18 1.08 14.17 31.89 14.17 m8 gnd Ø0.35 Ø0.35 Ø0.35 fig. 16: the dimensions of the ac drive, mr9 [in] mounting vacon · 37 24-hour suppo...

Page 38

4.3.8 wall mounting of mr9, ul open type, north america 5.12 31.89 33.09 0.65 2.56 1.97 14.17 8 x 1.65 2.83 m8 gnd 12.52 3 x 1.65 3.33 0.55 Ø0.35 Ø0.87 15.75 18.90 13.98 14.37 Ø0.35 m8 a Ø0.98 4.96 13.23 fig. 17: the dimensions of the ac drive, mr9, ul open type [in] a. An optional main connector co...

Page 39

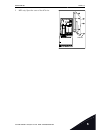

Note! The protection classes are different in different sections of the drive. A b d a c e fig. 18: example of flange mounting (frame mr9) a. The cabinet wall or other surface b. The front c. The rear d. Ip00 / ul open type e. Ip54 / ul type 12 mounting vacon · 39 24-hour support +358 (0)201 212 575...

Page 40

G f a e b d c h fig. 19: the dimensions of the opening and drive outline with flange a. The height of the opening for the flange mounting b. The width of the opening c. The height of the drive d. The width of the drive e. The distance between the bottom of the drive and the bottom of the opening f. ...

Page 41

Table 12: the dimensions of the opening for the flange mounting, frames mr4 to mr9 frame a [mm] b [mm] e [mm] a [in] b [in] e [in] mr4 315 137 24 12.4 5.4 0.9 mr5 408 152 23 16.1 6.0 0.9 mr6 541 203 23 21.3 8.0 0.9 mr7 655 240 13 25.8 9.4 0.5 mr8 859 298 18 33.8 11.7 0.7 mr9 975 485 54 38.4 19.1 2.1...

Page 42

4.4.1 flange mounting of mr4 152 15 122 285 24 113 357 341 102 72 18.5 9 32.8 39 77 190 134 128 186.9 Ø7 fig. 21: the dimensions of the ac drive, flange mounting, mr4 [mm] vacon · 42 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 43

4.4.2 flange mounting of mr5 Ø7 Ø7 436 454.1 262.5 145 144 150 169 9 13 382 24 39 33 27.5 100 214 114 11.5 72 145 102 12 fig. 22: the dimensions of the ac drive, flange mounting, mr5 [mm] mounting vacon · 43 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 44

4.4.3 flange mounting of mr6 13.9 123 16.8 514 36.4 26.2 229 106 Ø7 Ø4 115.5 196 12 18 6 184 220 195 201 Ø7 102 566 580 232 72 355.6 fig. 23: the dimensions of the ac drive, flange mounting, mr6 [mm] vacon · 44 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 45

4.4.4 flange mounting of mr7 230 51.2 35.2 720 192.5 197.5 660 680 192.5 102 441.6 20.3 237 271 286 7.5 72 Ø5.5 110.4 148.8 fig. 24: the dimensions of the ac drive, flange mounting, mr7 [mm] mounting vacon · 45 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 46

4.4.5 flange mounting of mr8 359 326 6.8 424.7 89.6 890.8 233 831.5 315.5 19.4 852.6 573.5 82.5 26 182.5 334 72 898 102 gnd m8 293 109.5 1.9 Ø7 Ø6.5 Ø7 Ø7 fig. 25: the dimensions of the ac drive, flange mounting, mr8 [mm] vacon · 46 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 47

4.4.6 flange mounting of mr9 1060 397.5 550 525 108 255.8 247 m8 gnd 72 102 73 175 175 85 10.5 163 300 300 1039 10.5 56 75 Ø22 210 Ø25 3 x 42 120 449 108.5 Ø6.5 126 fig. 26: the dimensions of the ac drive, flange mounting, mr9 [mm] mounting vacon · 47 24-hour support +358 (0)201 212 575 · email: vac...

Page 48

4.5 dimensions for flange mounting, north america 4.5.1 flange mounting of mr4, north america 5.98 0.59 4.80 11.22 0.94 4.45 14.06 13.43 4.02 2.83 0.73 0.35 1.29 1.54 3.03 7.48 5.28 5.04 7.36 Ø0.28 fig. 27: the dimensions of the ac drive, flange mounting, mr4 [in] vacon · 48 mounting 4 tel. +358 (0)...

Page 49

4.5.2 flange mounting of mr5, north america Ø0.28 Ø0.28 17.17 17.88 10.34 5.71 5.67 5.91 6.65 0.35 0.51 15.04 0.94 1.54 1.30 1.08 3.94 8.43 4.49 0.45 2.83 5.71 4.02 0.47 fig. 28: the dimensions of the ac drive, flange mounting, mr5 [in] mounting vacon · 49 24-hour support +358 (0)201 212 575 · email...

Page 50

4.5.3 flange mounting of mr6, north america 0.55 4.84 0.66 20.24 1.43 1.03 9.02 4.17 Ø0.28 Ø0.16 4.55 7.72 0.47 0.71 0.24 7.24 8.66 7.68 7.91 Ø0.28 4.02 22.28 22.84 9.13 2.83 14.00 fig. 29: the dimensions of the ac drive, flange mounting, mr6 [in] vacon · 50 mounting 4 tel. +358 (0)201 2121 · fax +3...

Page 51

4.5.4 flange mounting of mr7, north america 9.06 2.02 1.39 28.35 7.58 7.78 25.98 26.77 7.58 4.02 17.39 0.80 9.33 10.67 11.26 0.30 2.83 Ø0.22 4.35 5.86 fig. 30: the dimensions of the ac drive, flange mounting, mr7 [in] mounting vacon · 51 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 4.

Page 52

4.5.5 flange mounting of mr8, north america 14.13 12.84 0.27 16.72 3.53 35.07 9.17 32.74 12.42 0.76 33.57 22.58 3.25 1.02 7.19 13.15 2.83 35.35 4.02 gnd m8 11.54 4.31 0.07 Ø0.28 Ø0.26 Ø0.28 Ø0.28 fig. 31: the dimensions of the ac drive, flange mounting, mr8 [in] vacon · 52 mounting 4 tel. +358 (0)20...

Page 53

4.5.6 flange mounting of mr9, north america 41.73 15.65 21.65 20.67 4.25 10.07 9.72 m8 gnd 2.83 4.02 2.87 6.89 6.89 3.35 0.41 6.42 11.81 11.81 40.90 0.41 2.20 2.95 Ø0.87 8.27 Ø0.98 3 x 1.65 4.72 17.68 4.27 Ø0.26 4.96 fig. 32: the dimensions of the ac drive, flange mounting, mr9 [in] mounting vacon ·...

Page 54

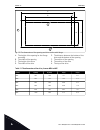

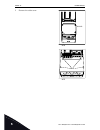

4.6 cooling the ac drive produces heat in operation. The fan circulates air and decreases the temperature of the drive. Make sure that there is sufficiently free space around the drive. Some free space is also necessary for maintenance. Make sure that the temperature of the cooling air does not beco...

Page 55

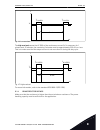

Table 13: the minimum clearances around the ac drive minimum clearance [mm] minimum clearance [in] frame a * b * c d a * b * c d mr4 20 20 100 50 0.8 0.8 3.9 2.0 mr5 20 20 120 60 0.8 0.8 4.7 2.4 mr6 20 20 160 80 0.8 0.8 6.3 3.1 mr7 20 20 250 100 0.8 0.8 9.8 3.9 mr8 20 20 300 150 0.8 0.8 11.8 5.9 mr9...

Page 56

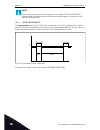

C+d fig. 34: the installation space when drives are installed on top of each other if you install many drives above each other 1. The necessary free space is c + d. 2. Make the outlet air of the lower unit go away from the air intake of the upper unit. To do this, attach a metal plate to the cabinet...

Page 57: Power Cabling

5 power cabling 5.1 cable connections the mains cables are connected to terminals l1, l2 and l3. The motor cables are connected to terminals u, v and w. A b c u/t1 v/t2 w/t3 l1 l2 l3 d c - dc+/r+ r - fig. 35: the principal connection diagram a. The control panel b. The control unit c. The power unit...

Page 58

1. A power cable for a fixed installation. A cable for the specified mains voltage. A shielded cable is not necessary. We recommend an mcmk cable. 2. A symmetrical power cable with a concentric protection wire. A cable for the specified mains voltage. We recommend an mcmk cable. See fig. 36. 3. A sy...

Page 59

Make sure that the operation time of the fuse is less than 0.4 seconds. The operation time agrees with the fuse type and the impedance of the supply circuit. For more information on faster fuses, speak to the manufacturer. The manufacturer can also recommend some ar (ul recognised, iec 60269-4) and ...

Page 60

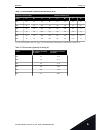

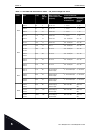

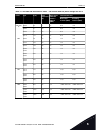

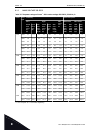

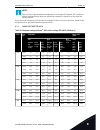

Table 16: the cable and fuse sizes for vacon ® 100, mains voltage 208-240 v and 380-500 v frame type il [a] fuse (gg/gl) [a] mains, motor and brake resistor* cable cu [mm 2 ] terminal cable size mains cable terminal [mm 2 ] grounding terminal [mm 2 ] mr4 0003 2—0004 2 0003 5—0004 5 3.7—4.8 3.4—4.8 6...

Page 61

* = if you use a multi-conductor cable, 1 of the conductors of the brake resistor cable stays unconnected. It is also possible to use a single cable if you obey the minimum cross- sectional area of the cable. Power cabling vacon · 61 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 5.

Page 62

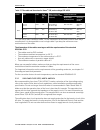

Table 17: the cable and fuse sizes for vacon ® 100, mains voltage 525-690 v frame type il [a] fuse (gg/gl) [a] mains, motor and brake resistor* cable cu [mm 2 ] terminal cable size mains cable terminal [mm 2 ] grounding terminal [mm 2 ] mr5 0004 6 3.9 6 3x1.5+1.5 1 - 10 cu 1 - 10 0006 6 6.1 10 3x1.5...

Page 63

Table 17: the cable and fuse sizes for vacon ® 100, mains voltage 525-690 v frame type il [a] fuse (gg/gl) [a] mains, motor and brake resistor* cable cu [mm 2 ] terminal cable size mains cable terminal [mm 2 ] grounding terminal [mm 2 ] mr9 0144 6 0144 7 144.0 160 3x70+35 (cu) 3x120+41 (al) bolt siz...

Page 64

Note! The vacon ® 100 flow and hvac software do not have the dynamic braking or the brake resistor functions. Vacon · 64 power cabling 5 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 65

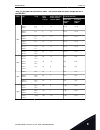

Table 18: the cable and fuse sizes for vacon ® 100 in north america, mains voltage 208-240 v and 380-500 v frame type il [a] fuse (class t/j) [a] mains, motor and brake resistor* cable cu [awg] terminal cable size mains cable terminal [awg] grounding terminal [awg] mr4 0003 2 0003 5 3.7 3.4 6 14 24-...

Page 66

Table 18: the cable and fuse sizes for vacon ® 100 in north america, mains voltage 208-240 v and 380-500 v frame type il [a] fuse (class t/j) [a] mains, motor and brake resistor* cable cu [awg] terminal cable size mains cable terminal [awg] grounding terminal [awg] mr8 0140 2 0140 5 140.0 200 3/0 1 ...

Page 67

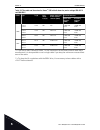

Table 19: the cable and fuse sizes for vacon ® 100 in north america, mains voltage 525-690 v frame type il [a] fuse (class t/j) [a] mains, motor and brake resistor* cable cu [awg] terminal cable size mains cable terminal [awg] grounding terminal [awg] mr5 (600 v) 0004 6 3.9 6 14 20-5 17-8 0006 6 6.1...

Page 68

Table 19: the cable and fuse sizes for vacon ® 100 in north america, mains voltage 525-690 v frame type il [a] fuse (class t/j) [a] mains, motor and brake resistor* cable cu [awg] terminal cable size mains cable terminal [awg] grounding terminal [awg] mr9 0144 6 0144 7 144.0 175 3/0 1 awg-350 kcmil ...

Page 69

Note! The frames mr7, mr8, and mr9 have the brake chopper, only if their type designation code has the code +dbin. The frames mr4, mr5, and mr6 have the brake chopper as standard. Note! The vacon ® 100 flow and hvac software do not have the dynamic braking or the brake resistor functions. 5.5 prepar...

Page 70

* = as short as possible. Table 22: the cable stripping lengths [in]. See the figure in step 1. Frame a b c d e f g mr4 0.6 1.4 0.4 0.8 0.3 1.4 * mr5 0.8 1.6 0.4 1.2 0.4 1.6 * mr6 0.8 3.6 0.6 2.4 0.6 2.4 * mr7 0.8 3.1 0.8 3.1 0.8 3.1 * * = as short as possible. 1 strip the motor cable, the mains cab...

Page 71

3 remove the screws of the cable cover. Remove the cable cover. Do not open the cover of the power unit. M4x8 4 put the grommets in the openings of the cable entry plate. These parts are included in the package. The picture shows the grommets in ip21 in the eu version. Power cabling vacon · 71 24-ho...

Page 72

5 put the cables - the mains cable, the motor cable and the optional brake cable - in the openings of the cable entry plate. A) cut the grommets open to move the cables through them. If the grommets fold in when you put the cable, pull the cable back to make the grommets straight. B) do not cut the ...

Page 73

7 put the cable entry plate with the cables into the groove on the frame of the drive. 8 connect the stripped cables. A) expose the shield of all the 3 cables to make a 360-degree connection with the grounding clamps for cable shield. B) connect the phase conductors of the mains cable and of the mot...

Page 74

9 make sure that the grounding conductor is connected to the motor and also to the terminals that are identified with . A) to obey the requirements of the standard en 61800-5-1, obey the instructions in chapter 2.4 grounding and earth fault protection. B) if a double grounding is necessary, use the ...

Page 75

Table 23: the tightening torques of the terminals frame type tightening torque: the mains cable and motor cable terminals tightening torque: the grounding clamps for cable shield tightening torque: the grounding clamps for grounding conductor nm lb-in. Nm lb-in. Nm lb-in. Mr4 0003 2 - 0012 2 0003 5 ...

Page 76

5.6.2 frames mr8 to mr9 table 24: the cable stripping lengths [mm]. See the figure in step 1. Frame a b c d e f g mr8 40 180 25 300 25 300 * mr9 40 180 25 300 25 300 * * = as short as possible. Table 25: the cable stripping lengths [in]. See the figure in step 1. Frame a b c d e f g mr8 1.6 7.1 1 11...

Page 77

2 mr9 only: open the cover of the ac drive. M4x10 power cabling vacon · 77 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 5.

Page 78

3 remove the cable cover. M4x8 mr8 m4x8 mr9 vacon · 78 power cabling 5 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 79

4 remove the cable entry plate. M4x8 mr8 m5x10 mr9 power cabling vacon · 79 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 5.

Page 80

5 mr9 only: loosen the screws and remove the sealing plate. M4x8 vacon · 80 power cabling 5 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 81

6 remove the emc shield plate. M5 m4x8 a a. The wing nut in mr8 mr9 power cabling vacon · 81 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 5.

Page 82

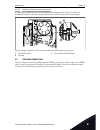

7 find the motor cable terminals. The location of the terminals is different than usually, especially in mr8. L1 u v w l2 l3 dc- dc+ r+ r- mr8 l1 u v w l2 l3 dc- dc+ r+ r- mr9 vacon · 82 power cabling 5 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 83

8 cut the grommets open to move the cables through them. A) do not cut the grommet openings wider than what is necessary for the cables that you use. B) if the grommets fold in when you put the cable, pull the cable back to make the grommets straight. 9 attach the grommet and the cable so that the f...

Page 84

10 if you use thick cables, put the cable insulators in between the terminals to prevent contact between the cables. Vacon · 84 power cabling 5 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 85

11 connect the stripped cables. A) connect the phase conductors of the mains cable and of the motor cable into the correct terminals. If you use a brake resistor cable, connect its conductors into the correct terminals. B) attach the grounding conductor of each cable to a grounding terminal with a g...

Page 86

12 if you use many cables on one connector, put the cable lugs on top of each other. A c b a. The first cable lug b. The second cable lug c. The connector 13 expose the shield of all 3 cables to make a 360- degree connection with the grounding clamp for cable shield. 14 attach again the emc shield p...

Page 87

15 attach the cable entry plate, and then the cable cover. 16 for mr9, attach the cover of the drive (unless you want to make the control connections first). M4x10 17 make sure that the grounding conductor is connected to the motor and also to the terminals that are identified with . A) to obey the ...

Page 88

Table 26: tightening torques of the terminals frame type tightening torque: the mains cable and motor cable terminals tightening torque: the grounding clamps for cable shield tightening torque: the grounding clamps for grounding conductor [nm] lb-in. [nm] lb-in. [nm] lb-in. Mr8 0140 2 - 0205 2 0140 ...

Page 89: Control Unit

6 control unit 6.1 control unit components the control unit of the ac drive contains the standard boards and the option boards. The option boards are connected to the slots of the control board (see 6.4 installation of option boards). Sto jmp l i m k h g f j e d a b c fig. 38: the components of the ...

Page 90

I. A dip switch for the signal selection of analogue input 1 j. The status indicator of the ethernet connection k. A fan (only in ip54 of mr4 and of mr5) l. The battery for the rtc m. The location and the default position of the safe torque off (sto) jumper when you receive the ac drive, the control...

Page 91

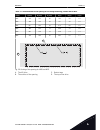

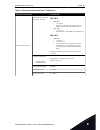

6.2.2 control terminals and dip switches here you see the basic description of the terminals of the standard i/o board and the relay board. For more information, see 11.1 technical data on control connections. Some terminals are assigned for signals that have optional functions that you can use with...

Page 92

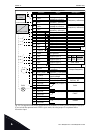

Run fault ready *) *) reference output +10 vref terminal standard i/o board signal 1 24v auxiliary voltage 24vout 6 analogue input, voltage or current reference potentiometer 1...10kΩ actual value 2-wire transmitter i = (0)4...20ma ai1+ 2 analogue input common, (current) ai1- 3 analogue input, volta...

Page 93

* = you can isolate digital inputs from ground with a dip switch. See 6.2.2.2 isolation of digital inputs from ground. There are 2 different relay boards available. Ro1 nc ro1 cm ro1 no ro2 nc ro2 cm ro2 no ro3 cm ro3 no 21 22 23 24 25 26 32 33 run run fault ready relay output 1 relay output 2 relay...

Page 94

A b a b c d e ai2 u i ai1 u i rs-485 off on ao1 u i fig. 42: the selections of the dip switches a. The voltage signal (u), 0-10 v input b. The current signal (i), 0-20 ma input c. Off d. On e. The rs-485 bus termination table 29: the default positions of the dip switches the dip switch the default p...

Page 95

6.2.2.2 isolation of digital inputs from ground it is possible to isolate from ground the digital inputs (terminals 8-10 and 14-16) on the standard i/o board. To do this, change the position of a dip switch on the control board. A b c fig. 43: change the position of this switch to isolate the digita...

Page 96

C d b a fig. 44: the ethernet and rs485 connections a. Rs485 terminal a = data - b. Rs485 terminal b = data + c. The ethernet terminal d. The control terminals 6.3.1 using fieldbus through an ethernet cable table 30: ethernet cable data item description the plug type a shielded rj45 plug, maximum le...

Page 97

2 in ip21, cut free the opening on the cover of the ac drive for the ethernet cable. In ip54, cut a hole in a grommet and move the cable through it. A) if the grommet folds in when you put the cable, pull the cable back to make the grommet straight. B) the hole in the grommet must not be wider than ...

Page 98

3 put the cover of the drive back. Keep the distance between the ethernet cable and the motor cable at a minimum of 30 cm (11.81 in). A a. The ethernet cable in ip21 a a. The ethernet cable in ip54 see more in the installation manual of the fieldbus that you have. Vacon · 98 control unit 6 tel. +358...

Page 99

6.3.2 using fieldbus through an rs485 cable table 31: rs485 cable data item description the plug type 2.5 mm 2 the cable type stp (shielded twisted pair), belden 9841 or almost the same the cable length so that it agrees with the fieldbus. See the fieldbus manual. Rs485 cabling 1 remove approximatel...

Page 100

2 connect the cable to the standard i/o board of the drive, in terminals a and b. • a = negative • b = positive 3 attach the shield of the cable to the frame of the drive with a grounding clamp for control cable to make a grounding connection. Vacon · 100 control unit 6 tel. +358 (0)201 2121 · fax +...

Page 101

4 if the drive is the last device on the fieldbus line, set the bus termination. A) find the dip switches on the left side of the control unit of the drive. B) set the dip switch of the rs485 bus termination to the on position. C) biasing is built in the bus termination resistor. The termination res...

Page 102

6 put the cover of the drive back. Pull the rs485 cables to the side. A) keep the distance of the ethernet, i/o and fieldbus cables from the motor cable at a minimum of 30 cm (11.81 in). B) move the fieldbus cables away from the motor cable. A a. The fieldbus cables 7 set the bus termination for the...

Page 103

Note! If you do power-down to the last device, there is no bus termination. 6.4 installation of option boards caution! Do not install, remove, or replace option boards on the drive when the power is on. Doing this can cause damage to the boards. Install the option boards into the option board slots ...

Page 104

The installation procedure 1 open the cover of the ac drive. Warning! Do not touch the control terminals. They can have a dangerous voltage also when the drive is disconnected from mains. M4x55 2 if you have an optb or an optc option board, make sure that the label on it says "dv" (dual voltage). Th...

Page 105

4 install the option board into the correct slot: c, d or e. See table 32. A) the option board has a slot coding, because of which it is not possible to install the option board in an incorrect slot. B a a. The slot coding b. The option board slots 5 close the cover of the control unit. Put the cove...

Page 106

A b 10vref gnd +24v gnd ai1+ ai1- ai2+ ai2- di1... Di6 cm ao1+ ao1- +24vin rs485 ro1/1 ro1/2 ro1/3 ro2/1 ro2/2 ro2/3 ti1+ ti1- l1 l2 l3 dc- dc+/r+ r- u v w fig. 45: the galvanic isolation barriers a. The control unit b. The power unit vacon · 106 control unit 6 tel. +358 (0)201 2121 · fax +358 (0)20...

Page 107: Commissioning and Additional

7 commissioning and additional instructions 7.1 commissioning safety before you start the commissioning, read these warnings. Warning! Do not touch the internal components or the circuit boards of the drive when the drive is connected to mains. These components are live. A contact with this voltage ...

Page 108

After the installation: • make sure that the motor is installed correctly. • make sure that the motor terminals are not connected to mains. • make sure that the ac drive and the motor are grounded. • make sure that you select the mains cable, the brake cable, and the motor cable correctly (see chapt...

Page 109

The insulation checks of the mains cable 1. Disconnect the mains cable from the terminals l1, l2, and l3 and from mains. 2. Measure the insulation resistance of the mains cable between phase conductors 1 and 2, between phase conductors 1 and 3, and between phase conductors 2 and 3. 3. Measure the in...

Page 110

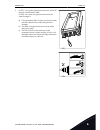

3 find the emc jumpers that connect the rfi filters to ground. Mr4 mr5 vacon · 110 commissioning and additional instructions 7 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 111

Mr6 200-500 v mr6 600/690 v 4 to disconnect the rfi filters from ground, remove the emc jumpers. Pull the emc jumper out with the tool. Commissioning and additional instructions vacon · 111 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 7.

Page 112

5 after the change, write "the emc level was changed" and the date on the "product modified" label. If the label is not attached at this time, attach it on the drive near the name plate. Product modified date: date: date: 7.6.2 the emc jumper in mr7 change the emc protection of the ac drive to level...

Page 113

4 find the dc grounding busbar between the terminals r- and u. To remove the busbar from the frame, remove the m4 screw. L1 l2 l3 dc- r- dc+ r+ u v w t1 t2 t3 5 after the change, write "the emc level was changed" and the date on the "product modified" label. If the label is not attached at this time...

Page 114

3 remove the emc jumper. 4 after the change, write "the emc level was changed" and the date on the "product modified" label. If the label is not attached at this time, attach it on the drive near the name plate. Product modified date: date: date: 7.6.3 the emc jumper in mr8 change the emc protection...

Page 115

4 find the grounding arm and push it down. A b a. The grounding arm is up b. The grounding arm is down (level c4) 5 after the change, write "the emc level was changed" and the date on the "product modified" label. If the label is not attached at this time, attach it on the drive near the name plate....

Page 116

4 find the place of the jumper behind the fan. 5 if you change the emc level, write "the emc level was changed" and the date on the "product modified" label. If the label is not attached at this time, attach it on the drive near the name plate. Product modified date: date: date: how to find the emc ...

Page 117

It is not necessary to replace the main capacitors of the drive, because they are a thin film type capacitors. Table 33: the maintenance intervals and tasks maintenance interval maintenance task regularly do a check of the tightening torques of the terminals. Do a check of the filters. 6-24 months (...

Page 118: Technical Data, Vacon

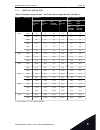

8 technical data, vacon ® 100 8.1 ac drive power ratings 8.1.1 mains voltage 208-240 v table 34: the power ratings of vacon ® 100 in mains voltage 208-240 v, 50-60 hz, 3~ frame drive type loadability motor shaft power low * high * max curre nt i s 2s 230 v mains 230 v mains contin uous curre nt il [...

Page 119

* = see chapter 8.1.5 overload capability. Note! The currents in given ambient temperatures (in chapter 8.2 vacon® 100 - technical data) are achieved only when the switching frequency is equal to or less than the factory default. If your process includes a cyclical load, for example if there are lif...

Page 120

8.1.2 mains voltage 380-500 v table 35: the power ratings of vacon ® 100 in mains voltage 380-500 v, 50-60 hz, 3~ frame drive type loadability motor shaft power low * high * max curre nt i s 2s 400 v mains 480 v mains contin uous curre nt i l [a] input curre nt i in [a] 10% over- load curre nt [a] c...

Page 121

Note! The currents in given ambient temperatures (in chapter 8.2 vacon® 100 - technical data) are achieved only when the switching frequency is equal to or less than the factory default. If your process includes a cyclical load, for example if there are lifts or winches, speak to the manufacturer to...

Page 122

8.1.4 mains voltage 525-690 v table 37: the power ratings of vacon ® 100 in mains voltage 525-690 v, 50-60 hz, 3~ frame drive type loadability motor shaft power low high max curre nt i s 2s 600 v 690 v contin uous curre nt i l [a] input curre nt i in [a] 10% over- load curre nt [a] contin uous curre...

Page 123

Il il*110% 1 min 9 min i t il*110% fig. 46: low overload the high overload means that if 150% of the continuous current (i h ) is necessary for 1 minute each 10 minutes, the remaining 9 minutes must be approximately 92% of i h or less. This is to make sure that the output current is not more than i ...

Page 124

Table 38: the recommended brake resistor types, mains voltage 208-240 v and 380-500 v frame duty cycle type of brake resistor resistance [Ω] mr4 light duty brr 0022 ld 5 63.0 heavy duty brr 0022 hd 5 63.0 mr5 light duty brr 0031 ld 5 41.0 heavy duty brr 0031 hd 5 41.0 mr6 light duty brr 0045 ld 5 21...

Page 125

Table 39: the recommended brake resistor types, mains voltage 525-690 v frame drive type duty cycle type of brake resistor resistance [Ω] mr5 0004-0011 light duty brr 0013 ld 6 100 heavy duty brr 0013 hd 6 100 mr6 0007-0013 light duty brr 0013 ld 6 100 heavy duty brr 0013 hd 6 100 0018-0034 light du...

Page 126

A b p [%] 120 100 80 60 40 20 0 0 1 2 3 4 5 6 7 8 9 t [s] 10 fig. 48: the ld and hd pulses, p = brake power a. Light duty (ld) b. Heavy duty (hd) 0 0 3 5 10 100 p [%] t [s] 120 240 123 125 130 fig. 49: the duty cycles of the ld and hd pulses table 40: the minimum resistance and the brake power, main...

Page 127

Table 41: the minimum resistance and the brake power, mains voltage 380-500 v frame the minimum brake resistance [Ω] brake power* @845 vdc [kw] mr4 63.0 11.3 mr5 41.0 17.0 mr6 21.0 34.0 mr7 14.0 51.0 mr8 6.5 109.9 mr9 3.3 216.4 * = when you use recommended resistor types. Table 42: the minimum resis...

Page 128

8.2 vacon ® 100 - technical data table 44: the technical data of the vacon ® 100 ac drive technical item or function technical data mains connection input voltage u in 208-240 v, 380-500 v, 525-600 v, 525-690 v, -10%… +10% input frequency 50-60 hz, -5...+10% connection to mains once per minute or le...

Page 129

Table 44: the technical data of the vacon ® 100 ac drive technical item or function technical data control characteristics switching frequency (see parameter p3.1.2.3) 200-500 v • mr4-mr6: • 1.5-10 khz • default: 6 khz (except for 0012 2, 0031 2, 0062 2, 0012 5, 0031 5 and 0061 5: 4 khz) • mr7-mr9: ...

Page 130

Table 44: the technical data of the vacon ® 100 ac drive technical item or function technical data ambient conditions ambient operating tem- perature i l current: -10°c (no frost)...+40 °c i h current: -10°c (no frost)...+50 °c maximum operating temperature: +50 °c storage temperature -40 °c...+70 °...

Page 131

Table 44: the technical data of the vacon ® 100 ac drive technical item or function technical data ambient conditions vibration: • en 61800-5-1 • en 60068-2-6 5-150 hz displacement amplitude 1 mm (peak) at 5-15.8 hz (mr4-mr9) maximum acceleration amplitude 1 g at 15.8-150 hz (mr4-mr9) shock: • en 60...

Page 132

Table 44: the technical data of the vacon ® 100 ac drive technical item or function technical data protections overvoltage trip limit mains voltage 240 v: 456 vdc mains voltage 500 v: 911 vdc mains voltage 600 v: 1094 vdc mains voltage 690 v: 1258 vdc undervoltage trip limit depends on mains voltage...

Page 133: Technical Data, Vacon

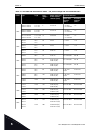

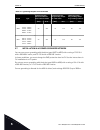

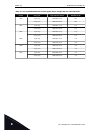

9 technical data, vacon ® 100 flow 9.1 ac drive power ratings 9.1.1 mains voltage 208-240 v table 45: the power ratings of vacon ® 100 flow in mains voltage 208-240 v, 50-60 hz, 3~ frame drive type loadability * motor shaft power continuous current i l [a] input current i in [a] 10% overload current...

Page 134

Note! The currents in given ambient temperatures (in chapter 9.2 vacon® 100 flow - technical data) are achieved only when the switching frequency is equal to or less than the factory default. If your process includes a cyclical load, for example if there are lifts or winches, speak to the manufactur...

Page 135

9.1.2 mains voltage 380-500 v table 46: the power ratings of vacon ® 100 flow in mains voltage 380-500 v, 50-60 hz, 3~ frame drive type loadability * motor shaft power continuous current i l [a] input current i in [a] 10% overload current [a] max current i s 2s 400 v mains 480 v mains 10% overload 4...

Page 136

Note! The currents in given ambient temperatures (in chapter 9.2 vacon® 100 flow - technical data) are achieved only when the switching frequency is equal to or less than the factory default. If your process includes a cyclical load, for example if there are lifts or winches, speak to the manufactur...

Page 137

9.1.4 mains voltage 525-690 v table 48: the power ratings of vacon ® 100 flow in mains voltage 525-690 v, 50-60 hz, 3~ frame drive type loadability motor shaft power continuous current i l [a] input current i in [a] 10% overload current [a] max continuous current i s 2s 600 v 690 v 10% overload 40°c...

Page 138

Il il*110% 1 min 9 min i t il*110% fig. 50: low overload in vacon ® 100 flow for more information, refer to the standard iec61800-2 (iec:1998). Vacon · 138 technical data, vacon® 100 flow 9 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 139

9.2 vacon ® 100 flow - technical data table 49: the technical data of the vacon ® 100 flow ac drive technical item or function technical data mains connection input voltage u in 208-240 v, 380-500 v, 525-600 v, 525-690 v, -10%… +10% input frequency 50-60 hz, -5...+10% connection to mains once per mi...

Page 140

Table 49: the technical data of the vacon ® 100 flow ac drive technical item or function technical data control characteristics switching frequency (see parameter p3.1.2.3) 200-500 v • mr4-mr6: • 1.5-10 khz • default: 6 khz (except for 0012 2, 0031 2, 0062 2, 0012 5, 0031 5 and 0061 5: 4 khz) • mr7-...

Page 141

Table 49: the technical data of the vacon ® 100 flow ac drive technical item or function technical data ambient conditions ambient operating tem- perature i l current: -10°c (no frost)…+40 °c up to 50 °c with derating (1.5%/1°c) storage temperature -40 °c…+70 °c relative humidity 0-95% r h , non-con...

Page 142

Table 49: the technical data of the vacon ® 100 flow ac drive technical item or function technical data ambient conditions vibration: • en 61800-5-1 • en 60068-2-6 5-150 hz displacement amplitude 1 mm (peak) at 5-15.8 hz (mr4-mr9) maximum acceleration amplitude 1 g at 15.8-150 hz (mr4-mr9) shock: • ...

Page 143

Table 49: the technical data of the vacon ® 100 flow ac drive technical item or function technical data protections overvoltage trip limit mains voltage 240 v: 456 vdc mains voltage 500 v: 911 vdc mains voltage 600 v: 1094 vdc mains voltage 690 v: 1258 vdc undervoltage trip limit depends on mains vo...

Page 144

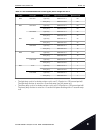

10 technical data, vacon® 100 hvac 10.1 ac drive power ratings 10.1.1 mains voltage 208-240 v table 50: the power ratings of vacon ® 100 hvac in mains voltage 208-240 v, 50-60 hz, 3~ frame drive type loadability motor shaft power low* 230 v mains 208-240 v mains continuous current i l [a] input curr...

Page 145

Note! The currents in given ambient temperatures (in chapter 10.2 vacon® 100 hvac - technical data) are achieved only when the switching frequency is equal to or less than the factory default. 10.1.2 mains voltage 380-500 v table 51: the power ratings of vacon ® 100 hvac in mains voltage 380-500 v, ...

Page 146

Note! The currents in given ambient temperatures (in chapter 10.2 vacon® 100 hvac - technical data) are achieved only when the switching frequency is equal to or less than the factory default. 10.1.3 overload capability the low overload means that if 110% of the continuous current (i l ) is required...

Page 147

10.2 vacon ® 100 hvac - technical data table 52: the technical data of the vacon ® 100 hvac ac drive technical item or function technical data mains connection input voltage u in 208-240 v, 380-500 v, 525-600 v, -10%…+10% input frequency 50-60 hz, -5...+10% connection to mains once per minute or les...

Page 148

Table 52: the technical data of the vacon ® 100 hvac ac drive technical item or function technical data control characteristics switching frequency (see parameter p3.1.2.3) 200-500 v • mr4-mr6: • 1.5-10 khz • default: 6 khz (except for 0012 2, 0031 2, 0062 2, 0012 5, 0031 5 and 0061 5: 4 khz) • mr7-...

Page 149

Table 52: the technical data of the vacon ® 100 hvac ac drive technical item or function technical data ambient conditions ambient operating tem- perature i l current: -10°c (no frost)…+40 °c up to 50 °c with derating (1.5%/1°c) storage temperature -40 °c…+70 °c relative humidity 0-95% r h , non-con...

Page 150

Table 52: the technical data of the vacon ® 100 hvac ac drive technical item or function technical data emc (at default settings) immunity fulfils en 61800-3 (2004), 1 st and 2 nd environment emissions • 200-500 v: en 61800-3 (2004), category c2. • 600 v: en 61800-3 (2004), category c3. • all: the p...

Page 151

Table 52: the technical data of the vacon ® 100 hvac ac drive technical item or function technical data protections overvoltage trip limit mains voltage 240 v: 456 vdc mains voltage 500 v: 911 vdc mains voltage 600 v: 1094 vdc undervoltage trip limit depends on mains voltage (0.8775 x mains voltage)...

Page 152

11 technical data on control connections 11.1 technical data on control connections table 53: the standard i/o board standard i/o board terminal signal technical information 1 reference output +10 v, +3%, maximum current: 10 ma 2 analogue input, voltage or cur- rent analogue input channel 1 0...+10 ...

Page 153

Table 53: the standard i/o board standard i/o board terminal signal technical information 12 24 v aux. Voltage +24 v, ±10%, max volt. Ripple max. 250 ma short-circuit protected 13 i/o ground ground for reference and controls (connected internally to frame ground through 1 mΩ) 14 digital input 4 posi...

Page 154

Table 54: the standard relay board (+sbf3) terminal signal technical information 21 relay output 1 * change-over contact (spdt) relay. 5.5 mm isolation between channels. Switching capacity • 24 vdc/8 a • 250 vac/8 a • 125 vdc/0.4 a minimum switching load • 5 v/10 ma 22 23 24 relay output 2 * change-...

Page 155

Table 55: the optional relay board (+sbf4) terminal signal technical information 21 relay output 1 * change-over contact (spdt) relay. 5.5 mm isolation between channels. Switching capacity • 24 vdc/8 a • 250 vac/8 a • 125 vdc/0.4 a minimum switching load • 5 v/10 ma 22 23 24 relay output 2 * change-...

Page 156

Document id: rev. G sales code: doc-ins100wm+dluk vacon ltd member of the danfoss group runsorintie 7 65380 vaasa finland www.Danfoss.Com.