- DL manuals

- Vacon

- Power Supply

- NX

- User Manual

Vacon NX User Manual

Summary of NX

Page 1

Vacon nx ac drives liquid-cooled drives user manual ® phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 2

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 3

Vacon • 1 table of contents document id:dpd00887d revision release date: 18.11.2013 1. Safety .......................................................................................................... 6 1.1. Danger ........................................................................................

Page 4

Vacon • 2 6.1.3. Fuse sizes...................................................................................................................... 73 6.1.4. Cable installation instructions...................................................................................... 79 6.1.5. Supply busbars f...

Page 5

Vacon • 3 10.1. Introduction ............................................................................................................... 146 10.2. Diagrams ................................................................................................................... 146 10.2.1. Active front...

Page 6

Vacon • 4 at least the following steps of the start-up quick guide must be performed during the installation and commissioning. If any problems occur, please contact your local distributor. Start-up quick guide 1. Check that the delivery corresponds to your order, see chapter 3. 2. Before taking any...

Page 7

Vacon • 5 about the vacon nx liquid-cooled frequency converters and inverters user's manual congratulations for choosing the smooth control provided by vacon nx_w liquid cooled drives! The user's manual will provide you with the necessary information about the installation, commissioning and operati...

Page 8

1 vacon • 6 safety 1. Safety only a competent electrician may carry out the electrical installation! 1.1 danger = dangerous voltage! = general warning! The components of the power unit of the frequency converter are live when vacon nx liquid-cooled drive is connected to mains potential. Coming into ...

Page 9

Safety vacon • 7 1 1.2 warnings the vacon nx liquid-cooled drive is meant for fixed installations only. Do not perform any measurements when the frequency converter is connected to the mains. Prior to measurements on the motor or the motor cable, disconnect the motor cable from the frequency convert...

Page 10

1 vacon • 8 safety 1.3 cautions 1.4 earthing and earth fault protection the vacon nx liquid-cooled frequency converter must always be earthed with an earthing conductor connected to the earthing terminal . See page 81. The earth leakage current of vacon nx_ exceeds 3.5 ma ac. According to en 61800-5...

Page 11

Safety vacon • 9 1 1.5 running the motor warning symbols for your own safety, please pay special attention to the instructions marked with the following symbols: motor run check list = dangerous voltage = general warning = hot surface – risk of burn before starting the motor, check that it is mounte...

Page 12

1 vacon • 10 safety note! You can download the english and french product manuals with applicable safety, warning and caution information from website. Remarque vous pouvez télécharger les versions anglaise et française des manuels produit contenant l’ensemble des informations de sécurité, avertisse...

Page 13

Eu directive vacon • 11 2 2. Eu directive 2.1 ce marking the ce marking on the product guarantees the free movement of the product within the eea (european economic area). Vacon nx frequency converters carry the ce label as a proof of compliance with the low voltage directive and the electro magneti...

Page 14

2 vacon • 12 eu directive 2.2.4.1 it networks the grounding of input capacitors made by default with the grounding screw at terminal x41 of the bus board in all drives is imperative in all variations of tn/tt networks. Should a drive originally purchased for tn/tt networks be used in an it network, ...

Page 15

Receipt of delivery vacon • 13 3 3. Receipt of delivery the standard delivery of vacon liquid-cooled drives includes all or part of the following components: vacon liquid-cooled frequency converters have undergone scrupulous tests and quality checks at the factory before they are delivered to the cu...

Page 16

3 vacon • 14 receipt of delivery 3.2 storage and shipping if the frequency converter is to be kept in store before use make sure that the ambient conditions are acceptable: storing temperature –40…+70 ° c (no cooling liquid inside cooling element allowed below 0 ºc relative humidity if the storage t...

Page 17

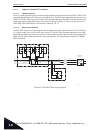

Technical data vacon • 15 4 4. Technical data 4.1 introduction the vacon nx_w liquid-cooled product range consists of active front ends, inverters, brake choppers and frequency converters. Figure 1 & figure 2 presents the block diagram of the vacon nx liquid-cooled inverter and frequency converter. ...

Page 18

4 vacon • 16 technical data figure 1. Vacon nx liquid-cooled converter principal block diagram = = l1 l2 l3 pe u/t1 v/t2 w/t3 3~ 3~ rs 232 3065_uk mains motor measure- ments gate drivers motor control asic motor and application control control keypad current sensors rectifier (frequency converters o...

Page 19

Technical data vacon • 17 4 figure 2. Vacon nx liquid-cooled inverter principal block diagram = pe u/t1 v/t2 w/t3 3~ rs 232 + - dc supply motor measure- ments gate drivers motor control asic motor and application control control keypad current sensors igbt inverter power supply control i/o control i...

Page 20

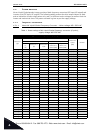

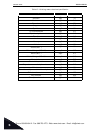

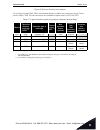

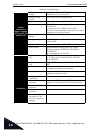

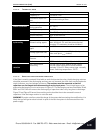

4 vacon • 18 technical data 4.2 power ratings vacon liquid-cooled product range consists of both frequency converters (ac input, ac output) and inverter units (dc input, ac output). The following tables present the drive output values for both and an indication of motor shaft power at i th and i l a...

Page 21

Technical data vacon • 19 4 i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadability or the process does not include any load variation or margin for overloadability. I l = low overloadability current. Allow...

Page 22

4 vacon • 20 technical data note! Braking power: p brake = u brake ^2 / r brake note! Braking dc current: i in_max = p brake_max / u brake 1) only 6 pulse drives the internal brake chopper can also be used in motor application where 2…4 x ch7x drives are used for a single motor, but in this case the...

Page 23

Technical data vacon • 21 4 i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadability or the process does not include any load variation. I l = low overloadability current. Allows +10% load variation. 10% exc...

Page 24

4 vacon • 22 technical data all values with cos ϕ = 0.83 and efficiency = 97%. *) c = power loss into coolant; a = power loss into air; t = total power loss; power losses of input chokes not included. All power losses obtained using max. Supply voltage, i th and switching frequency of 3.6 khz and cl...

Page 25

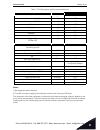

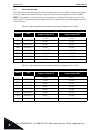

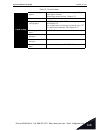

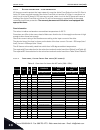

Technical data vacon • 23 4 4.2.2 inverter units 4.2.2.1 vacon nx liquid-cooled inverter unit – mains voltage 465—800 vdc i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadability or the process does not incl...

Page 26

4 vacon • 24 technical data *) c = power loss into coolant; a = power loss into air; t = total power loss. All power losses obtained using max. Supply voltage, i th and switching frequency of 3.6 khz and closed loop control mode. All power losses are worst case losses. If some other mains voltage is...

Page 27

Technical data vacon • 25 4 i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadability or the process does not include any load variation. I l = low overloadability current. Allows +10% load variation. 10% exc...

Page 28

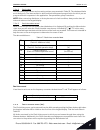

4 vacon • 26 technical data 4.3 technical data *) nx_8 ac drives only available as ch6x afe/bcu/inu units. Table 9. Technical data mains connection input voltage u in nx_5: 400…500 vac (–10%…+10%); 465…800 vdc (–0%…+0%) nx_6: 525…690 vac (–10%…+10%); 640…1100 vdc (–0%…+0%) nx_8: 525…690 vac (–10%…+1...

Page 29

Technical data vacon • 27 4 control characteristics control method frequency control u/f open loop sensorless vector control closed loop vector control switching frequency nx_5: nx_6/ nx_8: up to and including nx_0061: 1…16 khz; factory default 10 khz from nx_0072: 1…12 khz; factory default 3.6 khz ...

Page 30

4 vacon • 28 technical data ambient conditions ambient operating temperature –10 °c (no frost)…+50 °c (at i th ) the nx liquid cooled drives must be used in an heated indoor controlled environment. Installation temperature 0...+70 °c storage temperature –40 °c…+70 °c; no liquid in heatsink under 0 º...

Page 31

Technical data vacon • 29 4 control connections (apply to boards opt-a1, opt-a2 and opt-a3) analogue input voltage 0…+10 v, r i = 200 k Ω, (–10 v…+10 v joystick control) resolution 0.1%, accuracy ±1% analogue input current 0(4)…20 ma, ri = 250 w differential digital inputs (6) positive or negative l...

Page 32

4 vacon • 30 technical data liquid cooling allowed cooling agents drinking water (see specification on page 49). Water-glycol mixture. See derating specifications, chapter 5.3. Volume see page 51. Temperature of cooling agent 0…35 °c (i th )(input); 35…55 ºc: derating required, see chapter 5.3. Max....

Page 33

Installation vacon • 31 5 5. Installation 5.1 mounting vacon nx liquid-cooled drive modules must be installed into an enclosure. The drives consisting of one module will be mounted on the mounting plate. The drives that include two or three modules are mounted inside a mounting bracket (see) which w...

Page 34

5 vacon • 32 installation figure 4. Lifting of drive into a narrow mounting space to additionally stabilize the cabinet with the drive, we recommend to mount a fixing rail on the back of the cabinet, to which the top of the drive can be fastened with 5 or 6 m5 screws. The cut-out is compatible with ...

Page 35

Installation vacon • 33 5 figure 5. Securing the drive to the cabinet frame 2pcs m8 2pcs m8 pem 5-6pcs m5 fixing rail 11313_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 36

5 vacon • 34 installation 5.1.2 nx liquid-cooled dimensions 5.1.2.1 drives consisting of one module figure 6. Vacon nx liquid-cooled drive dimensions, ch3 table 10. One-module drive dimensions (mounting base included) chassis width height depth weight * *. Ac choke excluded. Ch3 160 431 246 15 ch4 1...

Page 37

Installation vacon • 35 5 figure 7. Vacon nx liquid-cooled drive dimensions (frequency converter), ch4 figure 8. Vacon nx liquid-cooled drive dimensions (inverter), ch4 11315_uk 11316_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 38

5 vacon • 36 installation figure 9. Vacon nx liquid-cooled dimensions, ch5 frequency converter figure 10. Vacon nx liquid-cooled dimensions, ch5 inverter 11317_uk 11318_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 39

Installation vacon • 37 5 figure 11. Vacon liquid-cooled frequency converter, ch61 figure 12. Vacon liquid-cooled inverter, ch61 11319_uk 11320_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 40

5 vacon • 38 installation figure 13. Vacon liquid-cooled inverter, ch62 11321_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 41

Installation vacon • 39 5 figure 14. Vacon liquid-cooled frequency converter (6-pulse), ch72 figure 15. Vacon liquid-cooled frequency converter (6-pulse) with internal brake chopper 11322_uk 11323_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 42

5 vacon • 40 installation figure 16. Vacon liquid-cooled frequency converter (12-pulse), ch72 5.1.2.2 drives consisting of several modules vacon nx liquid-cooled drives consisting of several modules are mounted in a mounting bracket as presented in figure 17. Figure 17. Drive mounted inside mounting...

Page 43

Installation vacon • 41 5 figure 18. Vacon liquid-cooled frequency converter with mounting bracket, ch63 11326_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 44

5 vacon • 42 installation figure 19. Vacon liquid-cooled inverter with mounting bracket, ch63 11327_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 45

Installation vacon • 43 5 figure 20. Vacon nx liquid-cooled inverter dimensions, ch64, ip00 11328_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 46

5 vacon • 44 installation figure 21. Vacon nx liquid-cooled frequency converter (6-pulse) dimensions, ch74, ip00 11329_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 47

Installation vacon • 45 5 figure 22. Vacon nx liquid-cooled frequency converter (6-pulse) with internal brake chopper di- mensions, ch74, ip00 11330_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 48

5 vacon • 46 installation figure 23. Vacon nx liquid-cooled frequency converter (12-pulse) with internal brake chopper di- mensions, ch74, ip00 11331_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 49

Installation vacon • 47 5 5.2 cooling instead of using air for cooling, vacon nx liquid-cooled drives are cooled with liquid. The liquid circulation of the drive is usually connected to a heat-exchanger (liquid-liquid/liquid-air) which cools down the liquid circulating in the cooling elements of the...

Page 50

5 vacon • 48 installation boron mg/l 1.0 bromate μg/l 10 cadmium μg/l 5.0 chromium μg/l 50 copper mg/l 2.0 cyanides μg/l 50 1,2-dichloroethane μg/l 3.0 epichlorohydrin μg/l 0.10 fluoride mg/l 1.5 lead μg/l 10 mercury μg/l 1.0 nickel μg/l 20 nitrate (no 3 - ) mg/l 50 nitrate-nitrogen (no 3 -n) mg/l 1...

Page 51

Installation vacon • 49 5 notes: 1) no aggressive water allowed. 2) to avoid corrosion of piping, the sulphate content must not exceed 150 mg/l. The cleanness of the heat exchanger, and therefore the heat exchanging capacity, depend on the purity of the process water. The more impure the water, the ...

Page 52

5 vacon • 50 installation specification: process water the design temperature of the cooling agent entering the drive module(s) is 35 °c. While circulating inside the cooling element, the liquid transfers the heat produced by the power semiconductors (and the capacitors). The design temperature rise...

Page 53

Installation vacon • 51 5 figure 24. Example of cooling system vacon recommends to equip the cooling system with pressure and flow supervision (fe). The flow supervision can be connected to digital input function external fault. If the coolant flow is found too low, the frequency converter will be s...

Page 54

5 vacon • 52 installation in tables below you will find the specifications related to the cooling agent and its circulation. See also table 9 on page 25. Note! Unless minimum liquid flow rate is ensured, air pockets may develop in the cooling elements. Automatic or manual de-airing of the cooling sy...

Page 55

Installation vacon • 53 5 5.2.1 condensation condensation on the cooling plate of the nx liquid-cooled drive must be avoided. Therefore, the temperature of the cooling liquid must be kept higher than the temperature of the electrical room. Use the graph below to determine if the drive operating cond...

Page 56

5 vacon • 54 installation example: if the temperature of the electric room is 30 °c, the relative humidity is 40% and the temperature of the cooling liquid is 20 °c (the lowest curve in figure 26), then the drive operating conditions are safe. However, if the room temperature were to rise to 35 °c a...

Page 57

Installation vacon • 55 5 figure 28. External thread of hose adapter for all other chasses (ch3, ch4), the standard delivery includes fast connectors of type 'tema', series 1300 or 1900. The fast connectors are available as option also for ch5, ch6, ch7. Table 17. Liquid connector types (all pressur...

Page 58

5 vacon • 56 installation 5.2.2.1 pressure losses figure 29. Pressure loss, ch6x table 18. Pressure losses; ch6x ch6x with standard 1.5m hoses and optional fast connectors tema volume flow rate (l/min) pressure loss; tema, inflow (bar) pressure loss; inflow hose (bar) pressure loss; element (bar) pr...

Page 59

Installation vacon • 57 5 figure 30. Pressure loss, ch7x the liquid carrying hoses from the network to the cooling elements of the drive must not be electrically conductive. Risk of electrical shock and device damage! To avoid electrochemical corrosion, it is necessary to add an inhibitor (e.G. Cort...

Page 60

5 vacon • 58 installation horizontal position. If mounted vertically, the mechanical sensor is affected by the earth’s gravity which reduces the accuracy according to the data given in table 20. Figure 31. Flow switch: hose connection, fast connector (electrical), fast connector lock screw, ca- ble ...

Page 61

Installation vacon • 59 5 figure 32. Direction of coolant circulation coolant inlet coolant outlet 11340_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 62

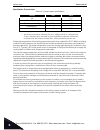

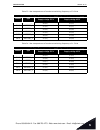

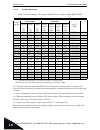

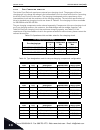

5 vacon • 60 installation 5.3 drive derating the tables below state the maximum coolant temperatures for vacon liquid-cooled drives at given switching frequencies. Drive derating is required if the maximum temperatures are exceeded. Note! If the heatsink is nickel-coated you must allow for a 2-degre...

Page 63

Installation vacon • 61 5 table 23. Max temperatures of coolant at switching frequency of 3.6 khz supply voltage 525-690 vac, switching frequency 3,6 khz chassis type max coolant temperature [°c] supply voltage 525 v max coolant temperature [°c] supply voltage 690 v ch61 nxp0261_6 45 (43) 1) 39 (37)...

Page 64

5 vacon • 62 installation 5.4 input chokes the input choke carries out several functions in the vacon nx liquid-cooled frequency converter. Connection of the input choke is necessary except if you have a component in your system that performs the same tasks (e.G. A transformer). The input choke is n...

Page 65

Installation vacon • 63 5 5.4.1 installation of input chokes there are two types of input choke connection in vacon nx liquid-cooled drives. The two smallest sizes (ch31, ch32; up to 61 a) have terminal block connection whereas bigger sizes use busbar connection. Examples of both connections and the...

Page 66

5 vacon • 64 installation figure 34. Example of input chokes for vacon nx liquid-cooled. Sizes 87 a…145 a and 590 a always connect the supply cables to the choke terminals marked with #1 (see figure 35). Choose the converter connection according to the table below: figure 35. Example of input chokes...

Page 67

Installation vacon • 65 5 if you have ordered the input chokes for vacon nx liquid-cooled separately pay attention to the following instructions: 1. Protect the chokes from dripping water. You may even need to use plexiglass for protection because jets of water may occur when working with the connec...

Page 68

6 vacon • 66 electrical cabling and connections 6. Electrical cabling and connections 6.1 power unit how the power connections of vacon nx liquid-cooled units are implemented depends on the size of the unit. The smallest nx liquid-cooled unit (ch3) has terminal blocks for the connections. In all oth...

Page 69

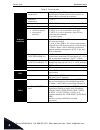

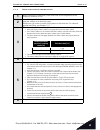

Electrical cabling and connections vacon • 67 6 6.1.1.3 motor cable data table 30. Cable types required to meet standards cable type level n/t mains cable 1 motor cable 1 control cable 4 1 = power cable intended for fixed installation and the specific mains voltage. Symmetrical shielded cable recomm...

Page 70

6 vacon • 68 electrical cabling and connections 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mains and motor ends if stiff cable type is used. Units with 6-pulse supply ...

Page 71

Electrical cabling and connections vacon • 69 6 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mains and motor ends if stiff cable type is used. * = number of bolt connect...

Page 72

6 vacon • 70 electrical cabling and connections 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mains and motor ends if stiff cable type is used. Data in italic refer to dr...

Page 73

Electrical cabling and connections vacon • 71 6 see the tightening torques of bolts in table 35. 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mains and motor ends if sti...

Page 74

6 vacon • 72 electrical cabling and connections we recommend a low-impedance earthing of the motor cable shield for better performance. Because of several possible cable installations and environmental conditions, it is very important to consider local regulations and the iec/en standards. 6.1.1.5 c...

Page 75

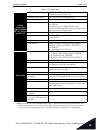

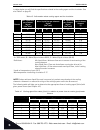

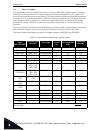

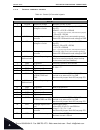

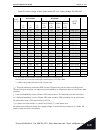

Electrical cabling and connections vacon • 73 6 6.1.3 fuse sizes the fuse sizing in the tables below is based on ferraz ar fuses. We primarily recommend you to use these fuses or corresponding bussman ar fuses (see appendix 3 on page 196). Sufficient protection against short-circuit cannot be guaran...

Page 76

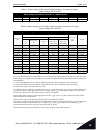

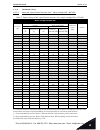

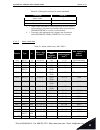

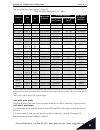

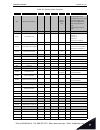

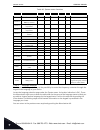

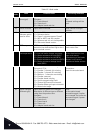

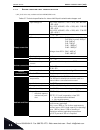

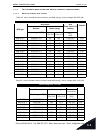

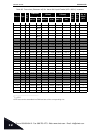

6 vacon • 74 electrical cabling and connections 6.1.3.1 frequency converters 1 fuse current (in) 50a for ttf ar fuse. 2 data in italic refer to drives with 12-pulse supply table 36. Fuse sizes for vacon nx liquid-cooled (500 v) frequency converters chass is type i th [a] fuse size din43620 din43653 ...

Page 77

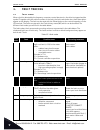

Electrical cabling and connections vacon • 75 6 1 data in italic refer to drives with 12-pulse supply fuse information the values in tables are based on max ambient temperature of +50 ºc. Fuse sizes can differ in the same chassis. Make sure that the isc of the supply transformer is high enough to bu...

Page 78

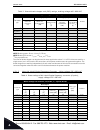

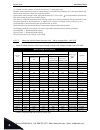

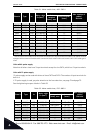

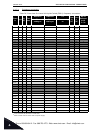

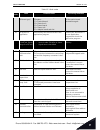

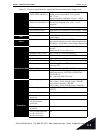

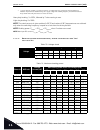

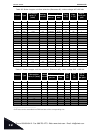

6 vacon • 76 electrical cabling and connections 6.1.3.2 fuse sizes, inverters each dc supply line must be equipped with an ar fuse according to the tables below. Table 38. Fuse sizes for vacon nx liquid-cooled (450—800 v) inverters chas sis type i th [a] din43620 "ttf" threaded end "7x" or size 83 w...

Page 79

Electrical cabling and connections vacon • 77 6 ch64 2060 2060 - - - pc73ud95v11ctf 8 pc87ud11 c38cp50 2 1100/ 3800 ch64 2300 2300 - - - pc73ud95v11ctf 8 pc87ud10 c44cp50 2 1100/ 4400 table 39. Fuse sizes for vacon nx liquid-cooled (640—1100 v) inverters chas sis type i th [a] din43620 "ttf" threade...

Page 80

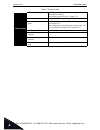

6 vacon • 78 electrical cabling and connections fuse information the values in tables are based on max ambient temperature of +50 ºc. Fuse sizes can differ in the same chassis. Fuses can be chosen according to the biggest current rating of the chassis to minimize fuse variants. Make sure that the i ...

Page 81

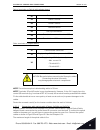

Electrical cabling and connections vacon • 79 6 6.1.4 cable installation instructions 1 before starting the installation, check that none of the components of the frequency converter is live. 2 vacon nx liquid-cooled drive must always be installed in an enclosure, a separate cubicle or an electrical...

Page 82

6 vacon • 80 electrical cabling and connections figure 36. Clamping the motor cables to cabinet frame 7 liquid cooling connection: the standard delivery of the vacon nx liquid-cooled drive includes hoses on the cooling element 1.5 m in length and 15 mm in diameter. The hoses are inserted in 1400-mm ...

Page 83

Electrical cabling and connections vacon • 81 6 figure 37. Maximum terminal stresses 6.1.5 supply busbars for inverter units in order to avoid excessive terminal stresses on busbar terminals on inverter units with dc-supply on top (ch61…ch64), use flexible busbar connection. See figure below. The ma...

Page 84

6 vacon • 82 electrical cabling and connections 6.1.6 installation space enough free space shall be left above and below the frequency converter/inverter to ensure practical and appropriate electrical and cooling connections. The minimum dimensions are given in the table below. The space left and ri...

Page 85

Electrical cabling and connections vacon • 83 6 6.1.8 installation of ferrite rings (option) on the motor cable slip only the phase conductors through the window; leave the cable screen below and outside the rings, see figure 40. Separate the pe conductor. In case of parallel motor cables, reserve a...

Page 86

6 vacon • 84 electrical cabling and connections 6.1.10 cable and motor insulation checks 1. Motor cable insulation checks disconnect the motor cable from terminals u, v and w of the frequency converter and from the motor. Measure the insulation resistance of the motor cable between each phase conduc...

Page 87

Electrical cabling and connections vacon • 85 6 6.2 control unit the control unit of vacon nx liquid-cooled frequency converter/inverter is installed into a mounting box. It contains the control board and additional boards (see figure 41 and figure 42) connected to the five slot connectors (a to e) ...

Page 88

6 vacon • 86 electrical cabling and connections usually, when the frequency converter is delivered from the factory, the control unit includes at least the standard compilation of two basic boards (i/o board and relay board) which are normally installed in slots a and b. On the next pages you will f...

Page 89

Electrical cabling and connections vacon • 87 6 6.2.1 control board power-up the control board can be powered (+24 v) in two different ways: either 1) directly from the power board asic, terminal x10 or/and 2) externally using the customer’s own power source. The two ways of supplying the board can ...

Page 90

6 vacon • 88 electrical cabling and connections figure 45.General wiring diagram of the basic relay board (opt-a2) 6.2.2.1 control cables the control cables shall be at least 0.5 mm 2 screened multicore cables, see table 30. The maximumterminal wire size is 2.5 mm 2 for the relay terminals and 1.5 m...

Page 91

Electrical cabling and connections vacon • 89 6 figure 46. Galvanic isolation barriers l1 l2 l3 u v w ro1/1 ro1/2 ro1/3 ro2/3 ro2/2 ro2/1 10vref gnd gnd +24v ai1 ai2+ ai2 - din1... Din3 cma din4... Din6 cmb ao1+ ao2 - do1 ti1+ ti1- control i/o ground digital input group a digital input group b analo...

Page 92

6 vacon • 90 electrical cabling and connections 6.2.3 control terminal signals table 41. Control i/o terminal signals terminal signal technical information opt-a1 1 +10 vref reference voltage maximum current 10 ma 2 ai1+ analogue input, voltage or current selection v or ma with jumper block x1 (see ...

Page 93

Electrical cabling and connections vacon • 91 6 6.2.3.1 digital input signal inversions the active signal level depends on which potential the common inputs cma and cmb (terminals 11 and 17) are connected to. The alternatives are either +24 v or ground (0 v). See figure 47. The 24-volt control volta...

Page 94

6 vacon • 92 electrical cabling and connections 6.2.3.2 jumper selections on the opt-a1 basic board the user is able to customise the functions of the frequency converter to better suit his needs by selecting certain positions for the jumpers on the opt-a1 board. The positions of the jumpers determi...

Page 95

Electrical cabling and connections vacon • 93 6 figure 49. Jumper selection for opt-a1 if you change the ai/ao signal content also remember to change the corresponding board parameter in menu m7. A b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d jum per block x 1 : ai1 ...

Page 96

6 vacon • 94 electrical cabling and connections 6.2.4 control unit mounting box figure 50. Control unit mounting box dimensions 6.2.4.1 installing the control unit mounting box the control unit of vacon nx liquid-cooled drive is mounted into a metal box which then can be placed inside the enclosure....

Page 97

Electrical cabling and connections vacon • 95 6 5. Mount the control unit mounting box in the front-left corner of the enclosure using two screws as shown in figure 5. Note! Do not install the mounting box floating (with e.G. Plastic screws). To ensure a proper grounding of the control unit box asse...

Page 98

6 vacon • 96 electrical cabling and connections 6.3 internal connections as a general rule, all internal electrical and communications connections are made at the factory. However, if modules have to be moved, for example, and the connections therefore removed, you will have to re-establish the conn...

Page 99

Electrical cabling and connections vacon • 97 6 figure 53. Terminals and connections between asic and driver boards (ch63) note! Terminals x9 and x15 are connected by default. The cable can be removed if the signal is receved from other source. Terminals on asic board gate driver signals from asic t...

Page 100

6 vacon • 98 electrical cabling and connections figure 54. Terminals and connections between asic and driver boards (ch64 and ch74) note! Terminals x9 and x15 are connected by default. The cable can be removed if the signal is receved from other source. Terminals on asic board gate driver signals fr...

Page 101

Electrical cabling and connections vacon • 99 6 6.3.2 connections between power unit asic and the control unit the communication connections between the nx liquid-cooled drive power unit and the control unit (see chapter 6.2) can be established using either the conventional round cable (standard in ...

Page 102

6 vacon • 100 electrical cabling and connections figure 56. Connecting the power supply and control cables to the control unit, ch6x figure 57. Connecting the power supply and control cables to the control unit, ch7x each fibre optic cable has a number 1...7 marked on the cable shield at both cable ...

Page 103

Electrical cabling and connections vacon • 101 6 optical terminals on optical cable adapter board: other terminals on adapter board: note! The minimum optical cable bending radius is 50 mm. Note! Terminals x2 and x3 can be in use simultaneously. However, if the +24 v supply from the control i/o term...

Page 104

6 vacon • 102 electrical cabling and connections the control unit uses 24 vdc supplied from the asic board, which is located on the left side of the power unit 1. To access the board, remove the protective cover in front of the power module. Con- nect the power supply cable to the x10 connector on t...

Page 105

Electrical cabling and connections vacon • 103 6 figure 59.Terminals and connections between the star-coupler board, asic boards and feedback boards (ch64 and ch74) note! The minimum optical cable bending radius is 50 mm. Note! Terminals x2 and x3 can be in use simultaneously. However, if the +24 v ...

Page 106

6 vacon • 104 electrical cabling and connections cooled inverter. Table 42. Connections from mains device to drive chassis type connection conductor cross section [mm 2 ] busbar size (flexible connection) busbar size (bare cu) ch3 0016_5 6 0022_5 0031_5 ch3 0038_5 10 0045_5 0061_5 ch4 0072_5 25 0087...

Page 107

Electrical cabling and connections vacon • 105 6 table 43. Connections from mains device to drive chassis type connection conductor cross section [mm 2 ] busbar size (flexible connection) busbar size (bare cu) ch61 0170_6 70 2*24*1 0208_6 95 0261_6 120 1*50*5 ch62 0325_6 2*70 5*32*1 0385_6 0416_6 2*...

Page 108

7 vacon • 106 control keypad 7. Control keypad the control keypad is the link between the vacon frequency converter and the user. The vacon nx control keypad features an alphanumeric display with seven indicators for the run status (run, , ready, stop, alarm, fault) and three indicators for the cont...

Page 109

Control keypad vacon • 107 7 7.1.2 control place indications the symbols i/o term, keypad and bus/comm (see figure 60) indicate the choice of control place made in the keypad control menu (see chapter 7.3.3). 7.1.3 status leds (green – green – red) the status leds light up in connection with the rea...

Page 110

7 vacon • 108 control keypad 7.2 keypad push-buttons the vacon alphanumeric control keypad features 9 push-buttons that are used for the control of the frequency converter (and motor), parameter setting and value monitoring. Figure 61. Keypad push-buttons 7.2.1 button descriptions = this button is u...

Page 111

Control keypad vacon • 109 7 7.2.1.1 swap between keypad control and another control as active control place with the i/o terminals or fieldbus selected as the active control place, it is also possible to change the control to the local keypad and back to the original control place. Irrespective of ...

Page 112

7 vacon • 110 control keypad figure 62. Keypad navigation chart 7.3.1 monitoring menu (m1) you can enter the monitoring menu from the main menu by pushing the menu button right when the location indication m1 is visible on the first line of the display. How to browse through the monitored values is ...

Page 113

Control keypad vacon • 111 7 figure 63. Monitoring menu note! The all in one applications embody more monitoring values. Table 44. Monitored signals code signal name unit description v1.1 output frequency hz frequency to the motor v1.2 frequency reference hz v1.3 motor speed rpm calculated motor spe...

Page 114

7 vacon • 112 control keypad 7.3.2 parameter menu (m2) parameters are the way of conveying the commands of the user to the frequency converter. The parameter values can be edited by entering the parameter menu from the main menu when the location indication m2 is visible on the first line of the dis...

Page 115

Control keypad vacon • 113 7 figure 64. Parameter value change procedure 7.3.3 keypad control menu (m3) in the keypad controls menu, you can choose the control place, edit the frequency reference and change the direction of the motor. Enter the submenu level with the menu button right. Table 45. Key...

Page 116

7 vacon • 114 control keypad 7.3.3.1 selection of control place there are three different places (sources) which the frequency converter can be controlled from. For each control place, a different symbol will appear on the alphanumeric display: change the control place by entering the edit mode with...

Page 117

Control keypad vacon • 115 7 7.3.3.4 stop button activated by default, pushing the stop button will always stop the motor regardless of the selected control place. You can disable this function by giving parameter 3.4 the value 0. If the value of this parameter is 0, the stop button will stop the mo...

Page 118

7 vacon • 116 control keypad 7.3.4.1 fault types in the nx frequency converter, there are four different types of faults. These types differ from each other on the basis of the subsequent behaviour of the drive. See table 46. Figure 66. Fault display table 46. Fault types fault type symbol meaning a...

Page 119

Control keypad vacon • 117 7 7.3.4.2 fault codes the fault codes, their causes and correcting actions are presented in table 55. The shadowed faults are a faults only. The items written in white on black background present faults for which you can program different responses in the application. See ...

Page 120

7 vacon • 118 control keypad the memory of the frequency converter can store a maximum of 30 faults in the order of appearance. The number of faults currently in the fault history is shown on the value line of the main page (h1h#). The order of the faults is indicated by the location indication in ...

Page 121

Control keypad vacon • 119 7 s6.2 application selection basic applica- tion basic application standard application local/remote control appl. Multi-step application pid control application multi-purpose control appl. Pump and fan control appl. S6.3 copy parameters s6.3.1 parameter sets store set 1 l...

Page 122

7 vacon • 120 control keypad 7.3.6.1 language selection the vacon control keypad offers you the possibility to control the frequency converter through the keypad in the language of your choice. Locate the language selection page under the system menu. Its location indication is s6.1. Press the menu ...

Page 123

Control keypad vacon • 121 7 figure 68. Selection of language 7.3.6.2 application selection the user can select the application desired by entering the application selection page (s6.2). This is done by pushing the menu button right when on the first page of the system menu. Change then the applicat...

Page 124

7 vacon • 122 control keypad figure 69. Change of application 7.3.6.3 copy parameters the parameter copy function is used when the operator wants to copy one or all parameter groups from one drive to another or to store parameter sets in the internal memory of the converter. All the parameter groups...

Page 125

Control keypad vacon • 123 7 figure 70. Storing and loading of parameter sets upload parameters to keypad (to keypad, s6.3.2) this function uploads all existing parameter groups to the keypad provided that the drive is stopped. Enter the to keypad page (s6.3.2) from the parameter copy menu. Push the...

Page 126

7 vacon • 124 control keypad automatic parameter backup (p6.3.4) on this page you can activate or inactivate the parameter backup function. Enter the edit mode by pressing the menu button right. Choose yes or no with the browser buttons. When the parameter backup function is activated vacon nx contr...

Page 127

Control keypad vacon • 125 7 7.3.6.5 security note! The security submenu is protected with a password. Store the password in a safe place! Password (s6.5.1) the application selection can be protected against unauthorised changes with the password function (s6.5.1). By default, the password function ...

Page 128

7 vacon • 126 control keypad start-up wizard (p6.5.3) the start-up wizard is a feature on the control keypad to facilitate the commissioning of the frequency converter. If selected active (default), the start-up wizard prompts the operator for the language and application of his/her choice plus for ...

Page 129

Control keypad vacon • 127 7 multimonitoring items (p6.5.4) vacon alpha-numeric keypad features a display where you can monitor even three actual values at the same time (see chapter 7.3.1 and chapter monitoring values in the manual of the application you are using). On page p6.5.4 of the system men...

Page 130

7 vacon • 128 control keypad default page in the operating menu (p6.6.2) here you can set the location (page) in the operating menu (in special applications only) to which the display automatically moves as the set timeout time (see below) has expired or as the power is switched on to the keypad. Se...

Page 131

Control keypad vacon • 129 7 example: • transfer delay between the frequency converter and the pc = 600 ms • the value of par. 6.7.3 is set to 1200 ms (2 x 600, sending delay + receiving delay) • the corresponding setting shall be entered in the [misc]-part of the file ncdrive.Ini: retries = 5 ackti...

Page 132

7 vacon • 130 control keypad trip counters (s6.8.) trip counters (menu s6.8.2) are counters the values of which can be reset i.E. Restored to zero. You have the following resettable counters at your disposal. See table 49 for examples. Note! The trip counters run only when the motor is running. The ...

Page 133

Control keypad vacon • 131 7 applications (s6.8.4) at location s6.8.4 you can find the applications submenu containing information about not only the application currently in use but also all other applications loaded into the frequency converter. The information available is: figure 82. Application...

Page 134

7 vacon • 132 control keypad hardware (s6.8.5) the hardware information page provides information on the following hardware-related topics: expander boards (s6.8.6) in the expander boards pages you find information about the basic and option boards connected to the control board (see chapter 6.1.2)....

Page 135

Control keypad vacon • 133 7 enter the following menu level (g#) with the menu button right. At this level, you can browse through slots (see page 84) a to e with the browser buttons to see what expander boards are connected. On the lowermost line of the display you also see the number of parameters...

Page 136

7 vacon • 134 control keypad 7.4 further keypad functions the vacon nx control keypad embodies additional application-related functions. See vacon nx application package for more information. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 137

Commissioning vacon • 135 8 8. Commissioning 8.1 safety before commissioning, note the following directions and warnings: internal components and circuit boards of the frequency converter are live when vacon nx liquid-cooled drive is connected to mains potential. Coming into contact with this voltag...

Page 138

8 vacon • 136 commissioning 8.2 commissioning of the frequency converter 1. Read carefully the safety instructions in chapter 1 and follow them. 2. After the installation, pay attention: - that both the frequency converter and the motor are grounded. - that the mains and motor cables comply with the...

Page 139

Commissioning vacon • 137 8 d) check in the monitoring menu (m1) that the value of output frequency changes according to the change of frequency reference. E) push the stop button on the keypad. 10. Run the start-up tests without the motor being connected to the process, if possible. If this is not ...

Page 140

9 vacon • 138 fault tracing 9. Fault tracing 9.1 fault codes when a fault is detected by the frequency converter control electronics, the drive is stopped and the symbol f together with the ordinal number of the fault, the fault code and a short fault description appear on the display. The fault can...

Page 141

Fault tracing vacon • 139 9 8 system fault - component failure - faulty operation note exceptional fault data record. Subcode in t.14: s1 = feedback of motor voltage s2 = reserved s3 = reserved s4 = asic trip s5 = disturbance in vaconbus s6 = feedback of charging switch s7 = charging switch s8 = no ...

Page 142

9 vacon • 140 fault tracing 14 frequency converter overtemperature 3) heatsink temperature is over 70 °c. Overtemperature warning is issued when the heatsink temperature exceeds 65 °c. 4) circuit board temperature is over 85 ºc. Overtemperature warning is issued when the board temperature exceeds 75...

Page 143

Fault tracing vacon • 141 9 25 microprocessor watchdog fault - faulty operation - component failure subcodes: s1 = cpu watchdog timer s2 = asic reset reset the fault and restart. Should the fault re-occur, contact your distributor. 26 startup prevented start-up of the drive has been prevented. Subco...

Page 144

9 vacon • 142 fault tracing 38 device added (same type) option board added. Subcodes: s1 = control board s4 = control unit s5 = adapter board and slot reset. Device is ready for use. Old board settings will be used. 39 device removed option board removed. Reset. Device no longer available. 40 device...

Page 145

Fault tracing vacon • 143 9 45 device added (different type) option board of different type added. Subcodes: s1 = control board s2 = control unit s3 = power board s4 = power unit s5 = adapter board and slot reset set the option board parameters again. 49 div by zero in application a division by zero...

Page 146

9 vacon • 144 fault tracing 9.2 load test with motor 1. Connect the motor cables and check the right phase order. Also check that the motor rotates freely. 2. Check liquid cooling system operation. 3. Turn on the supply voltage and ensure that all input phases are connected to the unit. 4. Check dc ...

Page 147

Fault tracing vacon • 145 9 9.3 dc link test (without motor) note! There will be dangerous voltages present during this test! 1. Read carefully the safety instructions in chapter 1 and follow them. 2. Connect a variable dc power supply to dc+ and dc– terminals. Make sure that all polarities are corr...

Page 148

10 vacon • 146 active front end (nxa) 10. Active front end (nxa) 10.1 introduction the vacon nx active front end is used to transfer power between the ac input and intermediate dc circuit. The vacon nx active front end has a two-way function. This means that when power is transferred from the ac inp...

Page 149

Active front end (nxa) vacon • 147 10 10.3 type designation code in vacon type designation code, the active front unit is characterized by the characters nxa and number 2, for example: figure 86. Active front end block diagram nxa 0300 5 a 0 t 0 2wf a1a2000000 power module control module b+ b- power...

Page 150

10 vacon • 148 active front end (nxa) 10.4 active front end unit technical data the technical data for the active front end unit, see table below. *) nx_8 ac drives only available as ch6x afe/bcu/inu units. Table 56. Technical data mains connection input voltage u in nx_5: 400…500 vac (–10%…+10%); 4...

Page 151

Active front end (nxa) vacon • 149 10 ambient conditions ambient operating temperature –10 °c (no frost)…+50 °c (at i th ) the nx liquid cooled drives must be used in an heated indoor controlled environment. Installation temperature 0...+70 °c storage temperature –40 °c…+70 °c; no liquid in heatsink...

Page 152

10 vacon • 150 active front end (nxa) control connections (apply to boards opt-a1, opt-a2 and opt-a3) analogue input voltage 0…+10 v, r i = 200 k Ω, (–10 v…+10 v joystick control) resolution 0.1%, accuracy ±1% analogue input current 0(4)…20 ma, ri = 250 w differential digital inputs (6) positive or ...

Page 153

Active front end (nxa) vacon • 151 10 liquid cooling allowed cooling agents drinking water (see specification on page 49) water-glycol mixture see derating specifications, chapter 5.3. Volume see page 51. Temperature of cooling agent 0…35 °c (i th )(input); 35…55 ºc: derating required, see chapter 5...

Page 154

10 vacon • 152 active front end (nxa) 10.5 power ratings *) c = power loss into coolant, a = power loss into air, t = total power loss. The enclosure class for all vacon nx liquid cooled frequency converters is ip00. I th = thermal maximum continuous rms current. Dimensioning can be done according t...

Page 155

Active front end (nxa) vacon • 153 10 *) c = power loss into coolant, a = power loss into air, t = total power loss. The enclosure class for all vacon nx liquid cooled frequency converters is ip00. ***) mains voltage 640-1200 vdc for nx_8 inverter units. I th = thermal maximum continuous rms current...

Page 156

10 vacon • 154 active front end (nxa) 10.6 liquid cooled rlc filters 10.6.1 introduction vacon‘s liquid cooled afe units can be used with either liquid cooled or air cooled lcl filters. The standard liquid cooled lcl filters are named rlc filter. The rlc filter type codes can be seen from table 57. ...

Page 157

Active front end (nxa) vacon • 155 10 10.6.3 power rating and dimensions figure 88. Example of l net choke of a vacon rlc filter table 59. Vacon rlc ratings, drive suitable and dimensions vacon nx liquid cooled regenerative line filters - ip00 lcl filter type thermal current i th [a] power loss c/a/...

Page 158

10 vacon • 156 active front end (nxa) figure 89. Example of l afe choke of a vacon rlc filter figure 90. Example of capacitor bank (c bank ) of a vacon rlc filter lifting points 25 h w d l in /l out l out1 /l in1 l out2 /l in2 3070a_uk connection: in/out (always connected) 400-500v in/out (l_in/l_ou...

Page 159

Active front end (nxa) vacon • 157 10 10.6.4 technical data 10.6.5 removing discharging resistors if the filter is used in a network fitted with an earth fault protection relay, the discharging resistors should be removed. If the discharging resistors are not removed, the earth fault monitoring devi...

Page 160

10 vacon • 158 active front end (nxa) figure 91. Wiring diagram of the alternative discharging circuit configuration 3074_uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 161

Active front end (nxa) vacon • 159 10 10.6.6 removing hf capacitors if a pwm modulated rectifier from another manufacturer is connected to the same input transformer, the capacitors must be removed! Otherwise the capacitors must not be removed. Figure 92 and figure 93 have a red marking on the lead ...

Page 162

10 vacon • 160 active front end (nxa) 10.7 active front end - fuse selection ac fuses are used to protect the input network in case the active front end unit or the lcl filter is faulty. Dc fuses are used to protect the active front end unit and the lcl filter in case there is a short circuit in the...

Page 163

Active front end (nxa) vacon • 161 10 for dc fuse selection use table for liquid cooled inverters (page 75). _____________________________ 1 quantity of fuses needed of ttf types pc4************ and pc8***********. Ch62 0730 730 din3 pc73ub69v1250pa pc33ud69v1250tf - 3 ch63 0820 820 din3 nh3ud69v800...

Page 164

10 vacon • 162 active front end (nxa) 10.8 pre-charcing circuit the active front end unit requires an external pre-charging circuit. The purpose of the pre- charging unit is to charge the voltage in the intermediate circuit to a level sufficient for connecting the active front end unit to the mains....

Page 165

Active front end (nxa) vacon • 163 10 the active front end unit must not be connected to mains without pre-charging. In order to ensure the correct operation of the pre-charging circuit, the input circuit-breaker or contactor, as well as the pre-charging circuit contactor, must be controlled by the ...

Page 166

10 vacon • 164 active front end (nxa) figure 95. Wiring diagram for control unit 3078.Emf 11402 uk phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 167

Active front end (nxa) vacon • 165 10 10.9 parelling the power of the input group can be increased by connecting several active front end units in parallel. Paralleling refers to active front end units connected in the same input transformer. Active front end units of different power ratings can als...

Page 168

10 vacon • 166 active front end (nxa) 10.10 common pre-charging circuit in case of paralleled active front end units, one common pre-charging circuit can be used, see figure 96. Standard pre-charging circuits can be used if the capacitance of the intermediate circuit not exceeds maximum value. If al...

Page 169

Active front end (nxa) vacon • 167 10 10.11 each active front end unit has the pre-charcing circuit each active front end can have an own pre-charging circuit, and each unit is controlling it’s own pre-charging and main contactor, see figure 97. One control switch can be used but if an active front ...

Page 170

11 vacon • 168 brake chopper unit (nxb) 11. Brake chopper unit (nxb) 11.1 introduction the vacon nxb (brake chopper unit) is a unidirectional power converter for the supply of excessive energy from a common dc bus drive line-up to resistors where the energy is dissipated as heat. External resistors ...

Page 171

Brake chopper unit (nxb) vacon • 169 11 11.3.2 nxb topologies and connection figure 99. Brake chopper unit topology figure 100. Vacon brake chopper unit connections dc+ dc- u/t1 v/t2 w/t3 resistor dc+ dc+ dc- u/l1 v/l2 resistor dc+ resistor dc- w/l3 nxb (brake chopper unit) + one resistor is a braki...

Page 172

11 vacon • 170 brake chopper unit (nxb) 11.4 brake chopper unit technical data *) nx_8 ac drives only available as ch6x afe/bcu/inu units. Table 65. Technical specification for vacon nxb liquid-cooled brake chopper unit supply connection input voltage u in nx_5: 400…500 vac (–10%…+10%); 465…800 vdc ...

Page 173

Brake chopper unit (nxb) vacon • 171 11 vibration en 50178/en 60068-2-6 5…150 hz displacement amplitude 0.25 mm (peak) at 3…31 hz max acceleration amplitude 1 g at 31…150 hz shock en 50178, en 60068-2-27 ups drop test (for applicable ups weights) storage and shipping: max 15 g, 11 ms (in package) co...

Page 174

11 vacon • 172 brake chopper unit (nxb) liquid cooling allowed cooling agents drinking water (see specification on page 46) water-glycol mixture see derating specifications, chapter 5.3. Volume see page 51. Temperature of cooling agent 0…35 °c (ibr)(input); 35…55 ºc: derating required, see chapter 5...

Page 175

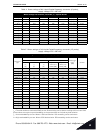

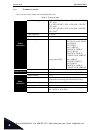

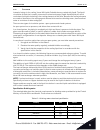

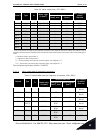

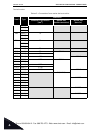

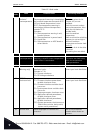

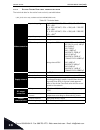

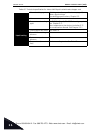

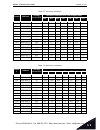

Brake chopper unit (nxb) vacon • 173 11 11.5 bcu power ratings 11.5.1 vacon nxb; dc voltage 460–800 v for dimensions of bcu units, see table 10. Note! The rated currents in given ambient (+50 °c) and coolant (+30°) temperatures are achieved only when the switching frequency is equal to or less than ...

Page 176

11 vacon • 174 brake chopper unit (nxb) 11.5.2 vacon nxb; dc voltage 640–1100 v for dimensions of bcu units, see table 10. Note! The rated currents in given ambient (+50 °c) and coolant (+30°) temperatures are achieved only when the switching frequency is equal to or less than the factory default. N...

Page 177

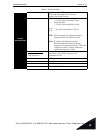

Brake chopper unit (nxb) vacon • 175 11 11.6 vacon brake resistors and brake chopper dimensioning 11.6.1 braking energy and losses table 68. Vacon standard brake resistors and nxb energy, mains voltage 465–800 vdc mains voltage 465-800 vdc bcu type bcu output bcu power loss at full braking chassis r...

Page 178

11 vacon • 176 brake chopper unit (nxb) heavy duty braking: 3 s 100%, followed by 7 s decreasing to zero light duty braking: 5 s 100% note! The rated currents in given ambient (+50 °c) and coolant (+30°) temperatures are achieved only when the switching frequency is equal to or less than the factory...

Page 179

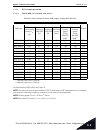

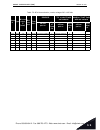

Brake chopper unit (nxb) vacon • 177 11 table 72. Minimum resistance chassis nxb unit thermal current [ith] minimum resistance at dc-link voltages [ohm] 605 637 669 701 733 765 797 ch3 nxb 0031_5 31 19,5 20,6 21,6 22,6 23,6 24,7 25,7 ch3 nxb 0061_5 61 9,9 10,4 11,0 11,5 12,0 12,5 13,1 ch4 nxb 0087_5...

Page 180

11 vacon • 178 brake chopper unit (nxb) 11.6.3 braking power and resistance, mains voltage 525–690 vac/ 840–1100 vdc note! The braking powers indicated in table 75 can only be achieved with minimum resistance. Table 74. Voltage levels voltage default +18% dc-link voltage level for braking vac 525 55...

Page 181

Brake chopper unit (nxb) vacon • 179 11 *. Only valid for nx_8 brake chopper units. Ch62 nxb 0325_6 325 12,9 13,5 14,1 14,7 15,4 16,2 16,9 17,5 ch62 nxb 0385_6 385 10,9 11,4 11,9 12,4 13,0 13,7 14,3 14,8 ch62 nxb 0416_6 416 10,1 10,5 11,0 11,5 12,1 12,6 13,2 13,7 ch62 nxb 0460_6 460 9,1 9,5 10,0 10,...

Page 182

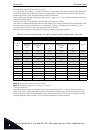

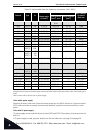

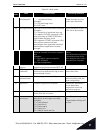

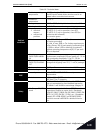

11 vacon • 180 brake chopper unit (nxb) 11.7 brake chopper unit – fuse selection table 78. Bcu fuse selection, mains voltage 465–800 vdc chas sis type min res. Value, 2* [ohm] brk curr ent fuse size* din43620 "ttf" threaded end "7x" or size 83 with end contacts "ttqf" threaded end size84 or "plaf" 2...

Page 183

Brake chopper unit (nxb) vacon • 181 11 table 79. Bcu fuse selection, mains voltage 640–1100 vdc chass is type min res. Value, 2* [ohm] brk curr ent fuse size* din43620 "ttf" threaded end "7x" or size 83 with end contacts "ttqf" threaded end size84 or "plaf" 2x84 with end contacts ar fuse part nr. Q...

Page 184: Ch3, Fc

12 vacon • 182 appendices 12. Appendices appendix 1 vacon nxw frequency converter and inverter main circuit and control diagrams l1 l2 l3 pe power board x3 x4 x5 w / t3 v / t2 u / t1 x17 j2 j1 j3 x2 b- b+ / r+ r- x10 pow dc - dc + measurements dc + dc - dc- dc+ r u v w skiip 81...83 ac skiip 81...83...

Page 185: Ch5, Fc

Appendices vacon • 183 12 l1 l2 l3 pe power board w / t3 v / t2 u / t1 measurements dc + dc - x4 x1 x6 x13 k1 k2 k3 x7 x8 x9 rectifier board u3 u2 u1 k1, k2, k3 x1 x2 x3 x6 x5 x10 x11 x13 x12 4 3 skim 5 2 4 4 4 x1 control panel option board d r a o b n o i t p o d r a o b n o i t p o d r a o b n o i...

Page 186

12 vacon • 184 appendices control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - rect / x13 driver / x13 driver / x14 driver / x15 driver / h4 driver / h5 driver / h6 driver / h9 driver / h7 driver / h8 + 24 v...

Page 187: Ch61, Inverter, Control

Appendices vacon • 185 12 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x13 driver / x14 driver / x15 driver / h4 driver / h5 driver / h6 driver / h9 driver / h7 driver / h8 + 24 v for intern...

Page 188: Ch62, Inverter, Control

12 vacon • 186 appendices control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x13 driver / x14 driver / x15 driver / h4 driver / h5 driver / h6 driver / h9 driver / h7 driver / h8 + 24 v for intern...

Page 189: Ch63, Fc, Control

Appendices vacon • 187 12 spu-024 pe measurement board 3 w / t3 dc+ dc- v / t2 measurement board 2 driver board v driver board w with option only x1/+ and x15/+: connected to dc+ if spu-024 not in use ch63, fc, module 2 11415_uk control board option board option board option board option board optio...

Page 190

12 vacon • 188 appendices pe u / t1 dc+ dc- measurement board 1 driver board u b+ b- ch63, inverter, module 1 11417_uk x1/+ and x15/+: spu-024 pe measurement board 3 w / t3 dc+ dc- v / t2 measurement board 2 driver board v driver board w with option only connected to dc+ if spu-024 not in use ch63, ...

Page 191: Ch63, Inverter, Control

Appendices vacon • 189 12 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver u / x6 driver v / x2 driver w / x6 driver u / h15 driver u / h16 driver v / h2 driver w / h16 driver v / h4 driver w / h1...

Page 192: Ch64, Inverter, Control

12 vacon • 190 appendices control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x1 driver / h2 driver / h4 driver / x1 driver / h2 driver / h4 driver / h4 driver / x1 driver / h2 phase module u phase...

Page 193: Ch72, Fc, Control

Appendices vacon • 191 12 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x13 driver / x14 driver / x15 driver / h4 driver / h5 driver / h6 driver / h9 driver / h7 driver / h8 + 24 v for intern...

Page 194: Ch74, Fc, Control

12 vacon • 192 appendices control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - rect / x13 driver / x1 driver / h2 driver / h4 driver / x1 driver / h2 driver / h4 driver / h4 driver / x1 driver / h2 phase mod...

Page 195

Appendices vacon • 193 12 appendix 2 oetl2500 + ofax3 + charging circuit for nx liquid-cooled inverters 1640_5 to 2300_5 (3 dia- grams) main circuit -f2.1 -a 1 2 3 4 pe -m1 m 3 ~ u1 1 v1 w1 2 pe th2 /2-5f th1 /2-5f -u1 dc+ dc- dc+ dc- dc+ dc- u w v x dc+ dc- -w1 3 2 4 1 11 12 13 14 23 24 -q1 1 2 3 4...

Page 196

12 vacon • 194 appendices 31 -x2 -v1 k a -f3 1 2 32 3 4 33 35 -x2 34 -a1 7 -a16 1 e0.0 -a11 1 +10vref 1 -x2 2 aia1+ 2 3 aia1- 3 -a12 nxopta3 2ro+ptc 4 aia2+ 4 5 aia2- 5 6 +24v 6 7 gnd 7 21 ro1 nc 21 -x2 22 ro1 c 22 23 ro1 no 23 24 control unit 8 din1 8 9 din2 9 10 din3 10 11 cma 11 -w13 2 1 x1 a b 2...

Page 197

Appendices vacon • 195 12 appendix 3 fuse sizes, bussman ar fuses fuse information max fuse ambient temperature +50 ºc. Fuse sizes can differ in the same chassis. Make sure that the isc of the supply transformer is high enough to burn fuses fast enough. Check the current rating of the fuse bases acc...

Page 198

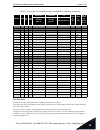

12 vacon • 196 appendices ____________________________ 1 tj = 25 °c 2 data in italic refer to drives with 12-pulse supply 3 sht fuses can be assembled into din fuse base of the corresponding size ch3 0061 61 170m1567 din000 170m1417 000t/80 690 100 1 ch4 0072 72 170m3815 din1 1 170m3065 1*tn/80 170m...

Page 199

Appendices vacon • 197 12 ____________________________ 1 tj = 25 °c 2 data in italic refer to drives with 12-pulse supply 3 sht fuses can be assembled into din fuse base of the corresponding size table 81. Fuse sizes (bussman ar) for vacon nx liquid-cooled (690 v) frequency converters chassis type i...

Page 200

12 vacon • 198 appendices ______________________________________ 1 tj = 25 °c 2 sht fuses can be assembled into din fuse base of the corresponding size table 82. Fuse sizes (bussman ar) for vacon nx liquid-cooled (450—800 v) inverters chassis type i th [a] din43620 din43653 (80mm) din43653 (110mm) f...

Page 201

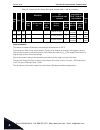

Appendices vacon • 199 12 1 sht fuses can be assembled into din fuse base of the corresponding size table 83. Fuse sizes (bussman ar) for vacon nx liquid-cooled (640—1100 v) inverters chassis type i th [a] din43620 din43653 (110mm) fuse u n [v] fuse i n [a] qty. Of fuses/ pole ar fuse part nr. Fuse ...

Page 202

12 vacon • 200 appendices ____________________________ 1 sht fuses can be assembled into din fuse base of the corresponding size ch62 0590 590 170m6277 3sht 170m8639 3tn/110 1100 1000 1 ch62 0650 650 170m6305 3sht 170m8636 3tn/110 1250 700 2 ch62 0730 730 170m6305 3sht 170m8636 3tn/110 1250 700 2 ch...

Page 203

Appendices vacon • 201 12 1 sht fuses can be assembled into din fuse base of the corresponding size table 85. Fuse sizes (bussman ar) for vacon nx afe units (525—690 v) chassis type i th [a] din43620 din43653 (110mm) fuse u n [v] fuse i n [a] qty. Of fuses / phase 3~ ar fuse part nr. Fuse size 1 ar ...

Page 204

12 vacon • 202 appendices _________________________ 1 sht fuses can be assembled into din fuse base of the corresponding size table 86. Brake chopper unit fuse selection (bussman ar), mains voltage 465–800 vdc chassis type min resistor value, 2* [ohm] braking current din43620 fuse u n [v] fuse i n [...

Page 205

Document id: rev. D phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.