- DL manuals

- Vacon

- Power Supply

- NX

- User Manual

Vacon NX User Manual

Summary of NX

Page 1

Vacon nx ac drives liquid-cooled drives user manual ®.

Page 3

Vacon • 1 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ t able of c ontents document: dpd00887e release date : 25/10/16 1. Safety ...............................................................................................................6 1.1 safety symbols used in the...

Page 4

Vacon • 2 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.2.3 control terminal signals ..................................................................................................98 6.2.4 control unit mounting box ........................................................

Page 5

Vacon • 3 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.2.1 non-regenerative front end unit wiring diagrams ......................................................175 11.3 installation of the nfe control cables ...............................................................

Page 6

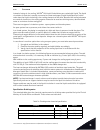

Vacon • 4 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ at least the following steps of the start-up quick guide must be performed during the installation and commissioning. If any problems occur, contact your local distributor. Start-up quick guide 1. Check that the deliv...

Page 7

Vacon • 5 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ about the vacon ® nx liquid-cooled ac drives user manual congratulations for choosing the smooth control provided by vacon ® nx_w liquid-cooled drives! This manual will provide you with the necessary information about...

Page 8

1 vacon • 6 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1. S afety only a competent electrician may carry out the electrical installation! 1.1 safety symbols used in the manual this manual contains warnings and cautions, which are identified with safety symbols. T...

Page 9

Safety vacon • 7 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 1.2 danger 1.3 warnings do not touch the components of the power unit when the drive is connected to mains. The components are live when the drive is connected to mains. A contact with this voltage is very da...

Page 10

1 vacon • 8 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1.4 grounding and earth fault protection the touch current of the drive is more than 3.5 ma ac. The standard en 61800-5-1 tells that 1 or more of these conditions for the protective circuit must be true. The ...

Page 11

Safety vacon • 9 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1 a) the protective grounding conductor must have a cross-sectional area of minimum 10 mm 2 cu or 16 mm 2 al. Or b) there must be an automatic disconnection of the mains, if the protective grounding conductor b...

Page 12

1 vacon • 10 safety local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1.5 running the motor motor run check list before you start the motor, check that it is mounted properly and make sure that the machine connected to the motor allows the motor to be started. Set the maximum ...

Page 13

Eu directive vacon • 11 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2 2. Eu directive 2.1 ce marking the ce marking on the product guarantees the free movement of the product within the eea (european economic area). Vacon ® nx ac drives carry the ce label as a proof of c...

Page 14

2 vacon • 12 eu directive local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2.2.4 explanations of voltage classes nx_5 = 380 - 500 vac drives -> dc link voltage = 465 - 800 vdc nx_6 = 525 - 690 vac drives -> dc link voltage = 640 - 1100 vdc nx_8 = 525 - 690 vac drives -> dc li...

Page 15: Eu Declaration of Conformity

Eu directive vacon • 13 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 2 2.2.5 manufacturer's declaration of conformity the following pages present the manufacturer's declarations of conformity assuring the compliance of vacon ® ac drives with the emc-directives. Date issue...

Page 16

3 vacon • 14 receipt of delivery local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3. R eceipt of delivery the standard delivery of vacon ® nx liquid-cooled ac drives includes all or part of the following components: vacon ® nx liquid-cooled ac drives have undergone scrupulous...

Page 17

Receipt of delivery vacon • 15 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 3.2 storage and shipping if the ac drive is to be kept in store before use make sure that the ambient conditions are acceptable: storing temperature –40…+70 ° c (no cooling liquid inside cooling...

Page 18

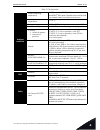

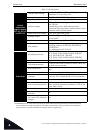

3 vacon • 16 receipt of delivery local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ main dc cooling fans and and internal cooling fans for elec- tronics 1 year 5 year replace parts according to service schedule or based on maintenance report recommendation. Dc-link capaci- tors...

Page 19

Receipt of delivery vacon • 17 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 coolant leakage 3 months based on inspection open the cubicle doors and check that there are no visible leaks on cooling unit or coolant manifold con- nections. If you find a leak, shut down the...

Page 20

3 vacon • 18 receipt of delivery local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3.4 warranty only manufacturing defects are covered by the warranty. The manufacturer assumes no responsibility for damages caused during or resulting from transport, receipt of the delivery, in...

Page 21

Technical data vacon • 19 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 4. T echnical data 4.1 introduction the vacon ® nx_w liquid-cooled product range consists of active front ends, inverters, brake choppers and ac drives. Figure 1 & figure 2 presents the block diagram...

Page 22

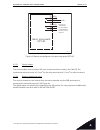

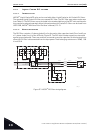

4 vacon • 20 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 1. Vacon ® nx liquid-cooled ac drive principal block diagram = = l1 l2 l3 pe u/t1 v/t2 w/t3 3~ 3~ rs 232 3065_uk mains motor measure- ments gate drivers motor control asic motor and applicatio...

Page 23

Technical data vacon • 21 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 figure 2. Vacon ® nx liquid-cooled inverter principal block diagram = pe u/t1 v/t2 w/t3 3~ rs 232 + - dc supply motor measure- ments gate drivers motor control asic motor and application control cont...

Page 24

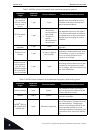

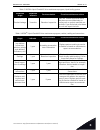

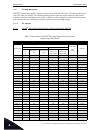

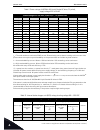

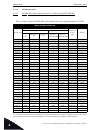

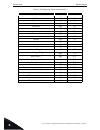

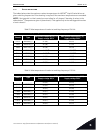

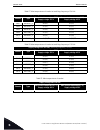

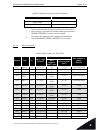

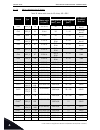

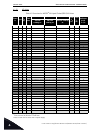

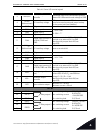

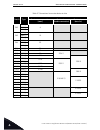

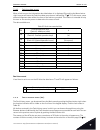

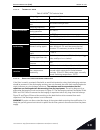

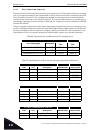

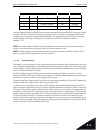

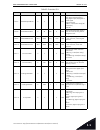

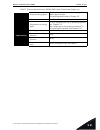

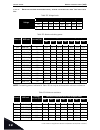

4 vacon • 22 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4.2 power ratings vacon ® liquid-cooled product range consists of both ac drives (ac input, ac output) and inverter units (dc input, ac output). The following tables present the drive output values f...

Page 25

Technical data vacon • 23 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadability or the process does not include any load variatio...

Page 26

4 vacon • 24 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ note! Braking power: p brake = u brake ^2 / r brake note! Braking dc current: i in_max = p brake_max / u brake 1) only 6 pulse drives the internal brake chopper can also be used in motor application ...

Page 27

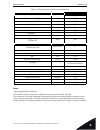

Technical data vacon • 25 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 4.2.1.2 vacon ® nx liquid-cooled ac drive – mains voltage 525—690 vac table 8. Power ratings of vacon ® nx liquid-cooled ac drive (6-pulse), supply voltage 525—690 vac mains voltage 525-690 vac, 50/6...

Page 28

4 vacon • 26 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadability or the process does not include any load variatio...

Page 29

Technical data vacon • 27 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 note! Braking power: p brake = u brake ^2 / r brake note! Braking dc current: i in_max = p brake_max / u brake 1) only 6 pulse drives the internal brake chopper can also be used in motor application ...

Page 30

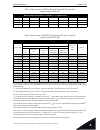

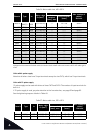

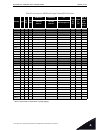

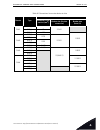

4 vacon • 28 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4.2.2 inverter units 4.2.2.1 vacon ® nx liquid-cooled inverter unit – mains voltage 465—800 vdc i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if th...

Page 31

Technical data vacon • 29 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 i l = low overloadability current. Allows +10% load variation. 10% exceeding can be continuous. I h = high overloadability current. Allows +50% load variation. 50% exceeding can be continuous. All va...

Page 32

4 vacon • 30 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ *) mains voltage 640-1200 vdc for nx_8 inverter units i th = thermal maximum continuous rms current. Dimensioning can be done according to this current if the process does not require any overloadabi...

Page 33

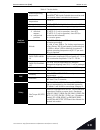

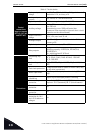

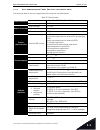

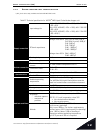

Technical data vacon • 31 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 4.3 technical data *) nx_8 ac drives only available as ch6x afe/bcu/inu units.* note: system software version table 13. Technical data mains connection input voltage u in nx_5: 400…500 vac (–10%…+10%...

Page 34

4 vacon • 32 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control characteristics control method frequency control u/f open loop sensorless vector control closed loop vector control switching frequency nx_5: nx_6/ nx_8: up to and including nx_0061: 1…16 khz...

Page 35

Technical data vacon • 33 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 ambient conditions ambient operating temperature –10 °c (no frost)…+50 °c (at i th ) the vacon ® nx liquid-cooled drives must be used in an heated indoor controlled environment. Installation temperat...

Page 36

4 vacon • 34 technical data local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control connections (apply to boards opt-a1, opt-a2 and opt-a3) analogue input voltage 0…+10 v, r i = 200 k Ω, (–10 v…+10 v joystick control) resolution 0.1%, accuracy ±1% analogue input current 0(4)...

Page 37

Technical data vacon • 35 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 4 liquid cooling allowed cooling agents drinking water (see specification on page 49). Water-glycol mixture. See derating specifications, chapter 5.3. Volume see page 51. Temperature of cooling agent 0...

Page 38

5 vacon • 36 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5. I nstallation 5.1 mounting vacon ® nx liquid-cooled drive modules must be installed into an enclosure. The drives consisting of one module will be mounted on the mounting plate. The drives that incl...

Page 39

Installation vacon • 37 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 in such case, follow the lifting procedure described in figure 4. The mounting becomes easier and safer if the drive can be laid on a supporting girder fixed on the cabinet frame. We also recommend to ...

Page 40

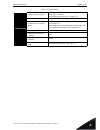

5 vacon • 38 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 5. Securing the drive to the cabinet frame 5.1.2 vacon ® nx liquid-cooled dimensions 5.1.2.1 drives consisting of one module table 14. One-module drive dimensions (mounting base included) chassi...

Page 41

Installation vacon • 39 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 6. Vacon ® nx liquid-cooled drive dimensions, ch3 figure 7. Vacon ® nx liquid-cooled drive dimensions (ac drive), ch4 terminals 11314_uk 11315_uk.

Page 42

5 vacon • 40 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 8. Vacon ® nx liquid-cooled drive dimensions (inverter), ch4 figure 9. Vacon ® nx liquid-cooled dimensions, ch5 ac drive 11316_uk 11317_uk.

Page 43

Installation vacon • 41 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 10. Vacon ® nx liquid-cooled dimensions, ch5 inverter figure 11. Vacon ® liquid-cooled ac drive, ch61 11318_uk 11319_uk.

Page 44

5 vacon • 42 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 12. Vacon ® liquid-cooled inverter, ch61 11320_uk.

Page 45

Installation vacon • 43 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 13. Vacon ® liquid-cooled inverter, ch62 11321_uk.

Page 46

5 vacon • 44 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 14. Vacon ® liquid-cooled ac drive (6-pulse), ch72 figure 15. Vacon ® liquid-cooled ac drive (6-pulse) with internal brake chopper 11322_uk 11323_uk.

Page 47

Installation vacon • 45 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 16. Vacon ® liquid-cooled ac drive (12-pulse), ch72 5.1.2.2 drives consisting of several modules vacon ® nx liquid-cooled drives consisting of several modules are mounted in a mounting bracket a...

Page 48

5 vacon • 46 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 17. Drive mounted inside mounting bracket 11325_00 table 15. Several-module drive dimensions (mounting bracket incl.) chassis width height depth weight ch63 505 924 375 120 ch64 746 924 375 180 ...

Page 49

Installation vacon • 47 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 18. Vacon ® liquid-cooled ac drive with mounting bracket, ch63 11326_uk.

Page 50

5 vacon • 48 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 19. Vacon ® liquid-cooled inverter with mounting bracket, ch63 11327_uk.

Page 51

Installation vacon • 49 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 20. Vacon ® nx liquid-cooled inverter dimensions, ch64, ip00 11328_uk.

Page 52

5 vacon • 50 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 21. Vacon ® nx liquid-cooled ac drive (6-pulse) dimensions, ch74, ip00 11329_uk.

Page 53

Installation vacon • 51 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 22. Vacon ® nx liquid-cooled ac drive (6-pulse) with internal brake chopper dimensions, ch74, ip00 11330_uk.

Page 54

5 vacon • 52 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 23. Vacon ® nx liquid-cooled ac drive (12-pulse) with internal brake chopper dimensions, ch74, ip00 11331_uk.

Page 55

Installation vacon • 53 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.2 cooling instead of using air for cooling, vacon ® nx liquid-cooled drives are cooled with liquid. The liquid circulation of the drive is usually connected to a heat-exchanger (liquid-liquid/liquid-...

Page 56

5 vacon • 54 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ benzopyrene μg/l 0.010 boron mg/l 1.0 bromate μg/l 10 cadmium μg/l 5.0 chromium μg/l 50 copper mg/l 2.0 cyanides μg/l 50 1,2-dichloroethane μg/l 3.0 epichlorohydrin μg/l 0.10 fluoride mg/l 1.5 lead μg/...

Page 57

Installation vacon • 55 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 notes: 1) no aggressive water allowed. 2) to avoid corrosion of piping, the sulphate content must not exceed 150 mg/l. The cleanness of the heat exchanger, and therefore the heat exchanging capacity, d...

Page 58

5 vacon • 56 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ specification: process water the design temperature of the cooling agent entering the drive module(s) is 35 °c. While circulating inside the cooling element, the liquid transfers the heat produced by t...

Page 59

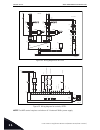

Installation vacon • 57 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 24. Example of cooling system we recommend to equip the cooling system with pressure and flow supervision (fe). The flow supervision can be connected to digital input function external fault. If...

Page 60

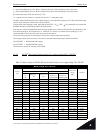

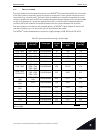

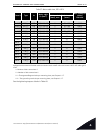

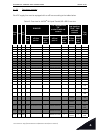

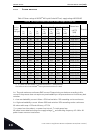

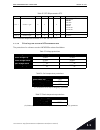

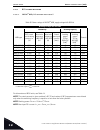

5 vacon • 58 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ in tables below you will find the specifications related to the cooling agent and its circulation. See also table 9 on page 25. Note! Unless minimum liquid flow rate is ensured, air pockets may develop...

Page 61

Installation vacon • 59 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 6 26.46 23.63 21.46 19.74 18.36 17.22 7 30.86 27.57 25.03 23.03 21.42 20.10 8 35.27 31.51 28.61 26.32 24.48 22.97 9 39.68 35.45 32.19 29.61 27.54 25.84 10 44.09 39.38 35.76 32.90 30.60 28.71 table 20. ...

Page 62

5 vacon • 60 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.2.1 condensation condensation on the cooling plate of the vacon ® nx liquid-cooled drive must be avoided. Therefore, the temperature of the cooling liquid must be kept higher than the temperature of ...

Page 63

Installation vacon • 61 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.2.2 cooling system connections the external cooling system must be connected to each one of the cooling elements of the inverter or ac drive. Note! Do not connect the cooling elements in series. The ...

Page 64

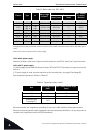

5 vacon • 62 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ for all other chasses (ch3, ch4), the standard delivery includes fast connectors of type 'tema', series 1300 or 1900. The fast connectors are available as option also for ch5, ch6, ch7. Table 21. Liqui...

Page 65

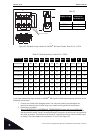

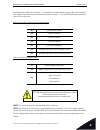

Installation vacon • 63 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.2.2.1 pressure losses figure 29. Pressure loss, ch6x table 22. Pressure losses; ch6x ch6x with standard 1.5m hoses and optional fast connectors tema volume flow rate (l/min) pressure loss; tema, infl...

Page 66

5 vacon • 64 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 30. Pressure loss, ch7x the liquid carrying hoses from the network to the cooling elements of the drive must not be electrically conductive. Risk of electrical shock and device damage! To avoid ...

Page 67

Installation vacon • 65 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 the hoses must tolerate a peak pressure of 30 bar. Connect the line hose to its counterpart (screw connector or fast connector) on the cooling element of the ac drive/inverter. The coolant inlet connec...

Page 68

5 vacon • 66 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 32. Direction of coolant circulation coolant inlet coolant outlet 11340_uk.

Page 69

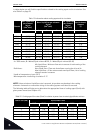

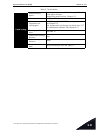

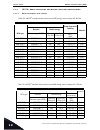

Installation vacon • 67 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.3 drive derating the tables below state the maximum coolant temperatures for vacon ® liquid-cooled drives at given switching frequencies. Drive derating is required if the maximum temperatures are ex...

Page 70

5 vacon • 68 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ table 27. Max temperatures of coolant at switching frequency of 3.6 khz supply voltage 525-690 vac, switching frequency 3.6 khz chassis type max coolant temperature [°c] supply voltage 525 v max coolan...

Page 71

Installation vacon • 69 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 5.4 input chokes the input choke carries out several functions in the vacon ® nx liquid-cooled ac drive. Connection of the input choke is necessary except if you have a component in your system that pe...

Page 72

5 vacon • 70 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5.4.1 installation of input chokes there are two types of input choke connection in vacon ® nx liquid-cooled drives. The two smallest sizes (ch31, ch32; up to 61 a) have terminal block connection where...

Page 73

Installation vacon • 71 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 figure 34. Example of input chokes for vacon ® nx liquid-cooled. Sizes 87 a…145 a and 590 a always connect the supply cables to the choke terminals marked with #1 (see figure 35). Choose the ac drive c...

Page 74

5 vacon • 72 installation local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 35. Example of input chokes for vacon ® nx liquid-cooled. Sizes 261 a…1150 a if you have ordered the input chokes for vacon ® nx liquid-cooled separately pay attention to the following instructi...

Page 75

Installation vacon • 73 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 5 example: if you connect the mains cable of one phase to terminal x, the other two phases must be connected to y and z. Accordingly, the choke output cables are connected to their corresponding input pa...

Page 76

6 vacon • 74 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6. E lectrical cabling and connections 6.1 power unit how the power connections of vacon ® nx liquid-cooled units are implemented depends on the size of the unit. The smallest vac...

Page 77

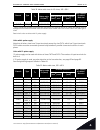

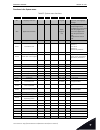

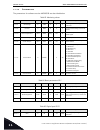

Electrical cabling and connections vacon • 75 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.1.1.3 motor cable data table 35. Cable types required to meet standards cable type level n/t mains cable 1 motor cable 1 control cable 4 1 = power cable intended for fixed insta...

Page 78

6 vacon • 76 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mai...

Page 79

Electrical cabling and connections vacon • 77 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mai...

Page 80

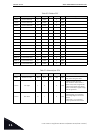

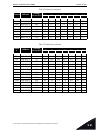

6 vacon • 78 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.1.1.4 mains cable data for ac drives table 38. Mains cable sizes for ac drives, 400—500 v chassis type i th mains cable cu [mm 2 ] terminal cable size max. Number of cables/ bol...

Page 81

Electrical cabling and connections vacon • 79 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mai...

Page 82

6 vacon • 80 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 1) due to insufficient number of terminal bolt connections for required amount of cables, the cabinet must be equipped with an external flexible cable connection block at both mai...

Page 83

Electrical cabling and connections vacon • 81 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.1.1.5 cable selection and unit installation in accordance with the ul standards to meet the ul (underwriters laboratories) regulations, use a ul-approved copper cable with a min...

Page 84

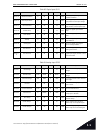

6 vacon • 82 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.1.3.1 ac drives 1 fuse current (in) 50a for ttf ar fuse. 2 data in italic refer to drives with 12-pulse supply table 41. Fuse sizes for vacon ® nx liquid-cooled (500 v) ac drive...

Page 85

Electrical cabling and connections vacon • 83 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 1 data in italic refer to drives with 12-pulse supply table 42. Fuse sizes for vacon ® nx liquid-cooled (690 v) ac drives chassis type i th [a] fuse size din43620 din43653 ttf fus...

Page 86

6 vacon • 84 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ fuse information the values in tables are based on max ambient temperature of +50 ºc. Fuse sizes can differ in the same chassis. Make sure that the isc of the supply transformer i...

Page 87

Electrical cabling and connections vacon • 85 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.1.3.2 fuse sizes, inverters each dc supply line must be equipped with an ar fuse according to the tables below. Table 43. Fuse sizes for vacon ® nx liquid-cooled (450—800 v) inv...

Page 88

6 vacon • 86 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ ch64 1640 1640 - - - pc73ud13c800tf 8 pc87ud12 c30cp50 2 800/ 3000 ch64 2060 2060 - - - pc73ud95v11ctf 8 pc87ud11 c38cp50 2 1100/ 3800 ch64 2300 2300 - - - pc73ud95v11ctf 8 pc87ud...

Page 89

Electrical cabling and connections vacon • 87 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 fuse information the values in tables are based on max ambient temperature of +50 ºc. Fuse sizes can differ in the same chassis. Fuses can be chosen according to the biggest curre...

Page 90

6 vacon • 88 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 3 place the motor cables far enough from other cables: • avoid placing the motor cables in long parallel lines with other cables • if the motor cables run in parallel with other c...

Page 91

Electrical cabling and connections vacon • 89 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 figure 36. Clamping the motor cables to cabinet frame figure 37. Maximum terminal stresses cable clamp armouring cable clamp for emc grounding 11344_uk 2,3 kn 2,3 kn 2,3 kn 2,3 kn...

Page 92

6 vacon • 90 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.1.5 supply busbars for inverter units in order to avoid excessive terminal stresses on busbar terminals on inverter units with dc-supply on top (ch61…ch64), use flexible busbar ...

Page 93

Electrical cabling and connections vacon • 91 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.1.6 installation space enough free space must be left above and below the ac drive/inverter to ensure practical and appropriate electrical and cooling connections. The minimum d...

Page 94

6 vacon • 92 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.1.8 installation of ferrite rings (option) on the motor cable slip only the phase conductors through the window; leave the cable screen below and outside the rings, see figure 4...

Page 95

Electrical cabling and connections vacon • 93 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.1.10 cable and motor insulation checks 1. Motor cable insulation checks disconnect the motor cable from terminals u, v and w of the ac drive and from the motor. Measure the insu...

Page 96

6 vacon • 94 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.2 control unit the control unit of vacon ® nx liquid-cooled ac drive/inverter is installed into a mounting box. It contains the control board and additional boards (see figure 4...

Page 97

Electrical cabling and connections vacon • 95 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 usually, when the ac drive is delivered from the factory, the control unit includes at least the standard compilation of two basic boards (i/o board and relay board) which are nor...

Page 98

6 vacon • 96 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.2.1 control board power-up the control board can be powered (+24 v) in two different ways: either 1) directly from the power board asic, terminal x10 or/and 2) externally using ...

Page 99

Electrical cabling and connections vacon • 97 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 figure 45. General wiring diagram of the basic relay board (opt-a2) 6.2.2.1 control cables the control cables must be at least 0.5 mm 2 screened multicore cables, see table 35. Th...

Page 100

6 vacon • 98 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 46. Galvanic isolation barriers 6.2.3 control terminal signals table 46. Control i/o terminal signals terminal signal technical information opt-a1 1 +10 vref reference volt...

Page 101

Electrical cabling and connections vacon • 99 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 5 gnd/ai2– analogue input common differential input if not connected to ground; allows ±20 v differential mode voltage to gnd 6 24 v out (bidirectional) 24 v auxiliary voltage ±15...

Page 102

6 vacon • 100 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.2.3.1 digital input signal inversions the active signal level depends on which potential the common inputs cma and cmb (terminals 11 and 17) are connected to. The alternatives ...

Page 103

Electrical cabling and connections vacon • 101 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 figure 48. Jumper blocks on opt-a1 11357_00

Page 104

6 vacon • 102 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 49. Jumper selection for opt-a1 a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d jum per block x 1 : ai1 m ode ai1 mode: voltage input; 0......

Page 105

Electrical cabling and connections vacon • 103 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 6.2.4 control unit mounting box figure 50. Control unit mounting box dimensions 6.2.4.1 installing the control unit mounting box the control unit of vacon ® nx liquid-cooled driv...

Page 106

6 vacon • 104 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ drive. The keypad is connected to the control unit with an rs232 cable and mounted on the enclosure door. Pay special attention to the grounding of the cable, see instructions be...

Page 107

Electrical cabling and connections vacon • 105 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 figure. 4 figure. 5 figure. 6 figure. 7 figure. 8 figure. 9 11363_00 11364_00 11365_00 vanxplc_1061_ins_uk 11366_00 11367_00 11368_00

Page 108

6 vacon • 106 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.3 internal connections as a general rule, all internal electrical and communications connections are made at the factory. However, if modules have to be moved, for example, and...

Page 109

Electrical cabling and connections vacon • 107 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 note! Terminals x9 and x15 are connected by default. The cable can be removed if the signal is receved from other source. Figure 53. Terminals and connections between asic and dr...

Page 110

6 vacon • 108 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ note! Terminals x9 and x15 are connected by default. The cable can be removed if the signal is receved from other source. Figure 54. Terminals and connections between asic and dr...

Page 111

Electrical cabling and connections vacon • 109 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 note! Terminals x9 and x15 are connected by default. The cable can be removed if the signal is receved from other source. 6.3.2 connections between power unit asic and the contro...

Page 112

6 vacon • 110 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6.3.2.2 connections with optical cable (chassis ch3, ch4, ch5, ch6x and ch7x) if optical cables are used to link the power unit and the control board, a special optical cable ada...

Page 113

Electrical cabling and connections vacon • 111 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 each fibre optic cable has a number 1...7 marked on the cable shield at both cable ends. Connect each cable to the connectors marked with the same number 1...7 on the asic board ...

Page 114

6 vacon • 112 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ fasten the removed cover(s) on the inverter module when the work is finished. 6.3.2.3 connections with optical cable (chassis 2xch64 and 2xch74) if optical cables are used to lin...

Page 115

Electrical cabling and connections vacon • 113 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 figure 59. Terminals and connections between the star-coupler board, asic boards and feedback boards (ch64 and ch74) note! The minimum optical cable bending radius is 50 mm. Note...

Page 116

6 vacon • 114 electrical cabling and connections local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ table 47. Connections from mains device to drive chassis type connection conductor cross section [mm 2 ] busbar size (flexible connection) busbar size (bare cu) ch3 0016_5 6 0022...

Page 117

Electrical cabling and connections vacon • 115 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 6 table 48. Connections from mains device to drive chassis type connection conductor cross section [mm 2 ] busbar size (flexible connection) busbar size (bare cu) ch61 0170_6 70 2*...

Page 118

7 vacon • 116 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7. C ontrol keypad the control keypad is the link between the vacon ® ac drive and the user. The vacon ® nx control keypad features an alphanumeric display with seven indicators for the run status (...

Page 119

Control keypad vacon • 117 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 7.1.2 control place indications the symbols i/o term, keypad and bus/comm (see figure 60) indicate the choice of control place made in the keypad control menu (see chapter 7.3.3). 7.1.3 status leds ...

Page 120

7 vacon • 118 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.2 keypad push-buttons the vacon ® alphanumeric control keypad features 9 push-buttons that are used for the control of the ac drive (and motor), parameter setting and value monitoring. Figure 61. ...

Page 121

Control keypad vacon • 119 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 7.2.1.1 swap between keypad control and another control as active control place with the i/o terminals or fieldbus selected as the active control place, it is also possible to change the control to ...

Page 122

7 vacon • 120 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 62. Keypad navigation chart 7.3.1 monitoring menu (m1) you can enter the monitoring menu from the main menu by pushing the menu button right when the location indication m1 is visible on the ...

Page 123

Control keypad vacon • 121 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 figure 63. Monitoring menu note! The all in one applications embody more monitoring values. Table 49. Monitored signals code signal name unit description v1.1 output frequency hz frequency to the mo...

Page 124

7 vacon • 122 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.3.2 parameter menu (m2) parameters are the way of conveying the commands of the user to the ac drive. The parameter values can be edited by entering the parameter menu from the main menu when the ...

Page 125

Control keypad vacon • 123 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 figure 64. Parameter value change procedure 7.3.3 keypad control menu (m3) in the keypad controls menu, you can choose the control place, edit the frequency reference and change the direction of the...

Page 126

7 vacon • 124 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ change the control place by entering the edit mode with the menu button right. The options can then be browsed through with the browser buttons. Select the desired control place with the enter butto...

Page 127

Control keypad vacon • 125 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 is 0, the stop button will stop the motor only when the keypad has been selected as the active control place. 7.3.4 active faults menu (m4) the active faults menu can be entered from the main menu b...

Page 128

7 vacon • 126 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.3.4.1 fault types in the vacon ® nx ac drive, there are four different types of faults. These types differ from each other on the basis of the subsequent behaviour of the drive. See table 51. Figu...

Page 129

Control keypad vacon • 127 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 7.3.4.3 fault time data record when a fault occurs the information described above in is displayed. By pushing the menu button right here you will enter the fault time data record menu indicated by ...

Page 130

7 vacon • 128 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ the order of the faults is indicated by the location indication in the upper left corner of the display. The latest fault carries the indication f5.1, the second latest f5.2 etc. If there are 30 unc...

Page 131

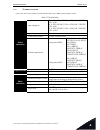

Control keypad vacon • 129 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 functions in the system menu table 53. System menu functions code function min max unit default cust selections s6.1 language selection english available selections depend on the language package. S...

Page 132

7 vacon • 130 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.3.6.1 language selection the vacon ® control keypad offers you the possibility to control the ac drive through the keypad in the language of your choice. Locate the language selection page under t...

Page 133

Control keypad vacon • 131 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 figure 68. Selection of language 7.3.6.2 application selection the user can select the application desired by entering the application selection page (s6.2). This is done by pushing the menu button ...

Page 134

7 vacon • 132 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7.3.6.3 copy parameters the parameter copy function is used when the operator wants to copy one or all parameter groups from one drive to another or to store parameter sets in the internal memory of...

Page 135

Control keypad vacon • 133 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 figure 71. Parameter copy to keypad download parameters to drive (from keypad, s6.3.3) this function downloads one or all parameter groups uploaded to the keypad to a drive provided that the drive i...

Page 136

7 vacon • 134 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ with symbol p (e.G. P1p5 = five deviating values). By pressing the menu button right once again you can still enter the pages where you can see both the actual value and the value it was compared t...

Page 137

Control keypad vacon • 135 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 deactivate the password function by entering the value 0. Figure 73. Password setting note! Store the password in a secure location! No changes can be made unless a valid password is entered! Parame...

Page 138

7 vacon • 136 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 75. Activation of start-up wizard multimonitoring items (p6.5.4) vacon ® alpha-numeric keypad features a display where you can monitor even three actual values at the same time (see chapter 7...

Page 139

Control keypad vacon • 137 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 repeat the procedure. Confirm the new default page value with the enter button. You can return to the previous step anytime by pushing the menu button left. Figure 78. Default page function default ...

Page 140

7 vacon • 138 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ hmi acknowledge timeout (p6.7.3) this function allows the user to change the timeout of the hmi acknowledgement time in cases where there is an additional delay in the rs-232 transmission due to use...

Page 141

Control keypad vacon • 139 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 total counters (s6.8.1) in the total counters page (s6.8.1) you can find information related to the ac drive operation times, i.E. The total numbers of mwh, operation days and operation hours passed...

Page 142

7 vacon • 140 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ software (s6.8.3) the software information page includes information on the following ac drive software related topics: applications (s6.8.4) at location s6.8.4 you can find the applications submenu...

Page 143

Control keypad vacon • 141 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 7 hardware (s6.8.5) the hardware information page provides information on the following hardware-related topics: expander boards (s6.8.6) in the expander boards pages you find information about the ba...

Page 144

7 vacon • 142 control keypad local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ enter the following menu level (g#) with the menu button right. At this level, you can browse through slots (see page 84) a to e with the browser buttons to see what expander boards are connected. O...

Page 145

Commissioning vacon • 143 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 8. C ommissioning 8.1 safety before commissioning, note the following directions and warnings: internal components and circuit boards of the ac drive are live when vacon ® nx liquid-cooled drive is c...

Page 146

8 vacon • 144 commissioning local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8.2 commissioning of the ac drive 1. Read carefully the safety instructions in chapter 1 and follow them. 2. After the installation, pay attention: - that both the ac drive and the motor are grounded...

Page 147

Commissioning vacon • 145 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 8 b) push the start button on the keypad. C) move over to the keypad control menu (m3) and keypad reference submenu (chapter 7.3.3.2) and change the frequency reference using the browser buttons d) che...

Page 148

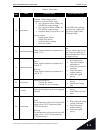

9 vacon • 146 fault tracing local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9. F ault tracing 9.1 fault codes when a fault is detected by the ac drive control electronics, the drive is stopped and the symbol f together with the ordinal number of the fault, the fault code and...

Page 149

Fault tracing vacon • 147 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 7 saturation trip various causes: - defective component - brake resistor short-circuit or overload cannot be reset from the keypad. Switch off power. Do not re-connect power! Contact your local distr...

Page 150

9 vacon • 148 fault tracing local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 14 frequency converter overtemperature 3) heatsink temperature is over 70 °c. Overtemperature warning is issued when the heatsink temperature exceeds 65 °c. 4) circuit board temperature is over 85 ºc...

Page 151

Fault tracing vacon • 149 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 25 microprocessor watchdog fault - faulty operation - component failure subcodes: s1 = cpu watchdog timer s2 = asic reset reset the fault and restart. Should the fault re-occur, contact your distribu...

Page 152

9 vacon • 150 fault tracing local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 38 device added (same type) option board added. Subcodes: s1 = control board s4 = control unit s5 = adapter board and slot reset. Device is ready for use. Old board settings will be used. 39 device r...

Page 153

Fault tracing vacon • 151 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 45 device added (different type) option board of different type added. Subcodes: s1 = control board s2 = control unit s3 = power board s4 = power unit s5 = adapter board and slot reset set the option...

Page 154

9 vacon • 152 fault tracing local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9.2 load test with motor 1. Connect the motor cables and check the right phase order. Also check that the motor rotates freely. 2. Check liquid cooling system operation. 3. Turn on the supply voltage...

Page 155

Fault tracing vacon • 153 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 9 9.3 dc link test (without motor) note! There will be dangerous voltages present during this test! 1. Read carefully the safety instructions in chapter 1 and follow them. 2. Connect a variable dc powe...

Page 156

10 vacon • 154 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10. A ctive front end (nxa) 10.1 introduction the vacon ® nx active front end is used to transfer power between the ac input and intermediate dc circuit. The vacon ® nx active front end has...

Page 157

Active front end (nxa) vacon • 155 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10.3 type designation code in vacon type designation code, the active front unit is characterized by the characters nxa and number 2, for example: figure 86. Active front end block diagram ...

Page 158

10 vacon • 156 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.4 active front end unit technical data the technical data for the active front end unit, see table below. *) nx_8 ac drives only available as ch6x afe/bcu/inu units. Table 61. Technical ...

Page 159

Active front end (nxa) vacon • 157 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 ambient conditions ambient operating temperature –10 °c (no frost)…+50 °c (at i th ) the vacon ® nx liquid-cooled drives must be used in an heated indoor controlled environment. Installatio...

Page 160

10 vacon • 158 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control connections (apply to boards opt-a1, opt-a2 and opt-a3) analogue input voltage 0…+10 v, r i = 200 k Ω, (–10 v…+10 v joystick control) resolution 0.1%, accuracy ±1% analogue input cu...

Page 161

Active front end (nxa) vacon • 159 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 liquid cooling allowed cooling agents drinking water (see specification on page 49) water-glycol mixture see derating specifications, chapter 5.3. Volume see table 19. Temperature of coolin...

Page 162

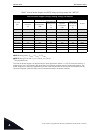

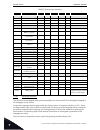

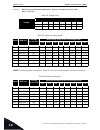

10 vacon • 160 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.5 power ratings *) c = power loss into coolant, a = power loss into air, t = total power loss. The enclosure class for all vacon ® nx liquid-cooled ac drives is ip00. I th = thermal maxi...

Page 163

Active front end (nxa) vacon • 161 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 *) c = power loss into coolant, a = power loss into air, t = total power loss. The enclosure class for all vacon ® nx liquid-cooled ac drives is ip00. ***) mains voltage 640-1200 vdc for nx...

Page 164

10 vacon • 162 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.6 liquid-cooled rlc filters 10.6.1 introduction vacon ® liquid-cooled afe units can be used with either liquid cooled or air cooled lcl filters. The standard liquid cooled lcl filters ar...

Page 165

Active front end (nxa) vacon • 163 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10.6.3 power rating and dimensions figure 88. Example of l net choke of a vacon ® rlc filter table 64. Vacon ® rlc ratings, drive suitable and dimensions vacon ® nx liquid-cooled regenerati...

Page 166

10 vacon • 164 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 89. Example of l afe choke of a vacon ® rlc filter figure 90. Example of capacitor bank (c bank ) of a vacon ® rlc filter lifting points 25 h w d l in /l out l out1 /l in1 l out2 /l ...

Page 167

Active front end (nxa) vacon • 165 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10.6.4 technical data 10.6.5 removing discharging resistors if the filter is used in a network fitted with an earth fault protection relay, the discharging resistors should be removed. If t...

Page 168

10 vacon • 166 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 91. Wiring diagram of the alternative discharging circuit configuration 10.6.6 removing hf capacitors if a pwm modulated rectifier from another manufacturer is connected to the same ...

Page 169

Active front end (nxa) vacon • 167 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 figure 92. Hf capacitors in rlc filters figure 93. Hf capacitors in rlc filters 11400_uk 11401_uk.

Page 170

10 vacon • 168 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.7 active front end - fuse selection ac fuses are used to protect the input network in case the active front end unit or the lcl filter is faulty. Dc fuses are used to protect the active ...

Page 171

Active front end (nxa) vacon • 169 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 for dc fuse selection use table for liquid cooled inverters (page 75). _____________________________ 1 quantity of fuses needed of ttf types pc4************ and pc8***********. Ch62 0650 65...

Page 172

10 vacon • 170 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.8 pre-charcing circuit the active front end unit requires an external pre-charging circuit. The purpose of the pre-charging unit is to charge the voltage in the intermediate circuit to a...

Page 173

Active front end (nxa) vacon • 171 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 the active front end unit must not be connected to mains without pre-charging. In order to ensure the correct operation of the pre-charging circuit, the input circuit-breaker or contactor, ...

Page 174

10 vacon • 172 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ note! Enough space must be reserved around the resistors to ensure sufficient cooling. Don’t place any heat sensitive components near the resistors. Figure 95. Wiring diagram for control un...

Page 175

Active front end (nxa) vacon • 173 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10 10.10 common pre-charging circuit in case of paralleled active front end units, one common pre-charging circuit can be used, see figure 96. Standard pre-charging circuits can be used if the...

Page 176

10 vacon • 174 active front end (nxa) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 10.11 each active front end unit has the pre-charcing circuit each active front end can have an own pre-charging circuit, and each unit is controlling it’s own pre- charging and main contac...

Page 177

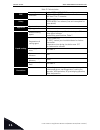

Non-regenerative front end vacon • 175 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 11. N on - regenerative front end 11.1 introduction the vacon ® nx non-regenerative front end (nfe) is used to transfer power from the ac input to the intermediate dc circuit to which t...

Page 178

11 vacon • 176 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ figure 98. Wiring diagram for nfe unit figure 99. Wiring diagram for controls, opta1. Note! The nxp control requires a minimum of 1a external 24vdc power supply. -ra1.1 l1.1 l2.1 l3.1 l...

Page 179

Non-regenerative front end vacon • 177 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 figure 100. Wiring diagram for controls, optbh, optb1 figure 101. Wiring diagram for controls, opta2 the nfe power unit, nxp control and the external control accessories need external 2...

Page 180

11 vacon • 178 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.3 installation of the nfe control cables a 24vdc power supply for fans, fan feedback signals and pt100 temperature sensor must be connected to the x100 connector at the nfe module. 1...

Page 181

Non-regenerative front end vacon • 179 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 11.4 type designation codes in vacon type designation code, the non-regenerative front unit is characterized by the characters nxn. The codes are given below: figure 102. Non-regenerati...

Page 182

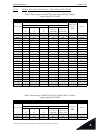

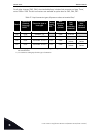

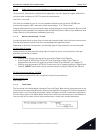

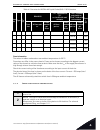

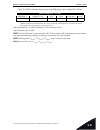

11 vacon • 180 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.5 power ratings table 70. Vacon ® nxn liquid-cooled non regenerative front-end, dc bus voltage 465-800 vdc ac drive type ac current dc power power loss c/a/t*) [kw] chassis thermal i...

Page 183

Non-regenerative front end vacon • 181 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 11.6 non-regenerative front end unit technical data the technical data for the non-regenerative front end unit, see table below. Table 72. Technical data mains connection input voltage ...

Page 184

11 vacon • 182 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ emc immunity fulfils iec/en 61800-3 emc immunity requirements. Emissions emc level n for tn/tt networks emc level t for it networks safety iec/en 61800-5-1 iec/en 60204-1 as relevant, (...

Page 185

Non-regenerative front end vacon • 183 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 11.7 dimensions figure 103. Vacon ® liquid-cooled non-regenerative front end, ch60 table 73. Non-regenerative front-end unit dimensions chassis width [mm] height [mm] depth [mm] weight ...

Page 186

11 vacon • 184 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.8 chokes *) losses for one choke. 2 chokes are needed for each l/c nfe, so total losses are 2x1.17 kw. Note! If you use other chokes than the recommended ones, contact your nearest d...

Page 187

Non-regenerative front end vacon • 185 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 figure 105. Example of flu-chk-1030-6-dl choke coolant connection g3/8” female thread. 11.9 non-regenerative front end - fuse selection ac fuses are used to protect the input network in...

Page 188

11 vacon • 186 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ the required ac fuse type for the non-regenerative front end unit can be found from table 78. The required dc fuse type for the non-regenerative front end unit can be found from table 7...

Page 189

Non-regenerative front end vacon • 187 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 correctly and stays in run mode. If any of them is not correct, the phase monitor relay's output does not activate and the control unit gives an input phase fault. 11.10.2 option board ...

Page 190

11 vacon • 188 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.11 dc pre-charging circuit each non-regenerative front end unit requires its own external pre-charging circuit. The purpose of the pre-charging unit is to charge the voltage in the i...

Page 191

Non-regenerative front end vacon • 189 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 the non-regenerative front end unit must not be connected to mains without pre-charging. In order to ensure the correct operation of the pre-charging circuit, the input circuit-breaker ...

Page 192

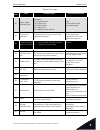

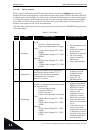

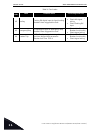

11 vacon • 190 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.13 parameters the parameters for software version ancnq100 are described below. Table 83. Monitoring values code parameter min max unit default id desciption v1.2.1 dc voltage 0 1500...

Page 193

Non-regenerative front end vacon • 191 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 p2.2.1.2 breakerfeedback 0 59 11 1916 select digital input signal for breaker feedback p2.2.1.3 miss input phase 0 59 12 1917 select digital input for missing input phase or low input v...

Page 194

11 vacon • 192 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ table 87. Digital output g2.3.1 code parameter min max unit default id desciption p2.3.1.1 running 0 59 10 1935 select for digital output signal mc running p2.3.1.2 close mcb 0 59 20 19...

Page 195

Non-regenerative front end vacon • 193 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 p2.4.7 choketempfaumode 0 3 1 1951 response to choke temp mode when temp measurement is using digital input (di)signals or pt100 signal 0=no action (di) 1=warn + fault (after delay) (di...

Page 196

11 vacon • 194 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ table 90. Fieldbus g2.5 code parameter min max unit default id desciption p2.5.1 process data in1 0 10000 0 876 p2.5.2 process data in2 0 10000 0 877 p2.5.3 process data in3 0 10000 0 8...

Page 197

Non-regenerative front end vacon • 195 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 nfe’s internal temperature sensor is pt100. Set 7.3.1.1 = 1. 11.14 ch60 liquid-cooled nfe protections the protections for software version ancnq100 are described below. (*1) temperature...

Page 198

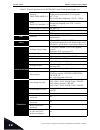

11 vacon • 196 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11.15 fault codes when a fault is detected by the nfe control electronics, the drive is stopped and main circuit breakers and the charging switch is controlled into open state, which wi...

Page 199

Non-regenerative front end vacon • 197 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 11 10 input phase external electronic monitoring relay have detected undervoltage, phase sequence or phase failure issue. • min. Threshold value: 360vac for 400-500vac supply voltage • min...

Page 200

11 vacon • 198 non-regenerative front end local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 60 cooling cooling ok digital input for liquid cooling feedback have triggered the fault • check liquid cooling • check the signal wiring • check cooling ok input 63 emergencystop e-sto...

Page 201

Brake chopper unit (nxb) vacon • 199 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 12. B rake chopper unit (nxb) 12.1 introduction the vacon ® nxb (brake chopper unit) is a unidirectional power converter for the supply of excessive energy from a common dc bus drive line...

Page 202

12 vacon • 200 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12.3.2 vacon ® nxb topologies and connection figure 107. Brake chopper unit topology figure 108. Vacon ® brake chopper unit connections dc+ dc- u/t1 v/t2 w/t3 resistor dc+ dc+ dc- u/l1 v/...

Page 203

Brake chopper unit (nxb) vacon • 201 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 12.4 brake chopper unit technical data *) nx_8 ac drives only available as ch6x afe/bcu/inu units. Table 97. Technical specification for vacon ® nxb liquid-cooled brake chopper unit suppl...

Page 204

12 vacon • 202 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ vibration en 50178/en 60068-2-6 5…150 hz displacement amplitude 0.25 mm (peak) at 3…31 hz max acceleration amplitude 1 g at 31…150 hz shock en 50178, en 60068-2-27 ups drop test (for appl...

Page 205

Brake chopper unit (nxb) vacon • 203 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 liquid cooling allowed cooling agents drinking water (see specification on page 46) water-glycol mixture see derating specifications, chapter 5.3. Volume see table 19. Temperature of cool...

Page 206

12 vacon • 204 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12.5 bcu power ratings 12.5.1 vacon ® nxb; dc voltage 460–800 v for dimensions of bcu units, see table 14. Note! The rated currents in given ambient (+50 °c) and coolant (+30°) temperatur...

Page 207

Brake chopper unit (nxb) vacon • 205 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 12.5.2 vacon ® nxb; dc voltage 640–1100 v for dimensions of bcu units, see table 10. Note! The rated currents in given ambient (+50 °c) and coolant (+30°) temperatures are achieved only w...

Page 208

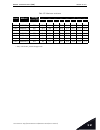

12 vacon • 206 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12.6 vacon ® brake resistors and brake chopper dimensioning 12.6.1 braking energy and losses table 100. Vacon ® standard brake resistors and nxb energy, mains voltage 465–800 vdc mains vo...

Page 209

Brake chopper unit (nxb) vacon • 207 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 heavy duty braking: 3 s 100%, followed by 7 s decreasing to zero light duty braking: 5 s 100% note! The rated currents in given ambient (+50 °c) and coolant (+30°) temperatures are achiev...

Page 210

12 vacon • 208 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12.6.2 braking power and resistance, mains voltage 380–500 vac/600–800 vdc note! The braking powers indicated in table 103 can only be achieved with minimum resistance. Table 102. Voltage...

Page 211

Brake chopper unit (nxb) vacon • 209 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 ch5 nxb 0261_5 261 2.3 2.4 2.6 2.7 2.8 2.9 3.1 ch61 nxb 0300_5 300 2.0 2.1 2.2 2.3 2.4 2.5 2.7 ch61 nxb 0385_5 385 1.6 1.7 1.7 1.8 1.9 2.0 2.1 ch62 nxb 0460_5 460 1.3 1.4 1.5 1.5 1.6 1.7 ...

Page 212

12 vacon • 210 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12.6.3 braking power and resistance, mains voltage 525–690 vac/ 840–1100 vdc note! The braking powers indicated in table 107 can only be achieved with minimum resistance. Table 106. Volta...

Page 213

Brake chopper unit (nxb) vacon • 211 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 *. Only valid for nx_8 brake chopper units. Table 109. Maximum resistance chassis nxb unit thermal current [ith] maximum resistance at dc-link voltages [ohm] 836 876 916 956 1004 1051 109...

Page 214

12 vacon • 212 brake chopper unit (nxb) local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12.7 brake chopper unit – fuse selection table 110. Bcu fuse selection, mains voltage 465–800 vdc chas sis type min res. Value, 2* [ohm] brk curr ent fuse size* din43620 "ttf" threaded en...

Page 215

Brake chopper unit (nxb) vacon • 213 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 12 table 111. Bcu fuse selection, mains voltage 640–1100 vdc chass is type min res. Value, 2* [ohm] brk curr ent fuse size* din43620 "ttf" threaded end "7x" or size 83 with end contacts "ttq...

Page 216: Ch3, Fc

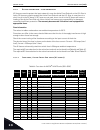

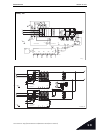

13 vacon • 214 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13. A ppendices appendix 1 vacon ® nx liquid-cooled ac drive and inverter main circuit and control diagrams l1 l2 l3 pe power board x3 x4 x5 w / t3 v / t2 u / t1 x17 j2 j1 j3 x2 b- b+ / r+ r- x10 pow d...

Page 217: Ch5, Fc

Appendices vacon • 215 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 l1 l2 l3 pe power board w / t3 v / t2 u / t1 measurements dc + dc - x4 x1 x6 x13 k1 k2 k3 x7 x8 x9 rectifier board u3 u2 u1 k1, k2, k3 x1 x2 x3 x6 x5 x10 x11 x13 x12 4 3 skim 5 2 4 4 4 x1 control panel...

Page 218

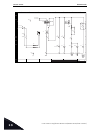

13 vacon • 216 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ l1 l2 l3 pe rectifier board measurement board 1 mains voltage supervision driver board module right side w / t3 u / t1 v / t2 with spu-024 option only x1/+: connected to dc+ if spu-024 not in use ch61,...

Page 219

Appendices vacon • 217 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - rect / x13 driver / x13 driver / x14 driver / x15 drive...

Page 220: Ch61, Inverter, Control

13 vacon • 218 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x13 driver / x14 driver / x15 driver / h4 driv...

Page 221: Ch62, Inverter, Control

Appendices vacon • 219 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x13 driver / x14 driver / x15 driver / h4 driv...

Page 222: Ch63, Fc, Control

13 vacon • 220 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ spu-024 pe measurement board 3 w / t3 dc+ dc- v / t2 measurement board 2 driver board v driver board w with option only x1/+ and x15/+: connected to dc+ if spu-024 not in use ch63, fc, module 2 11415_u...

Page 223

Appendices vacon • 221 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 pe u / t1 dc+ dc- measurement board 1 driver board u b+ b- ch63, inverter, module 1 11417_uk x1/+ and x15/+: spu-024 pe measurement board 3 w / t3 dc+ dc- v / t2 measurement board 2 driver board v driv...

Page 224: Ch63, Inverter, Control

13 vacon • 222 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver u / x6 driver v / x2 driver w / x6 driver u / h1...

Page 225: Ch64, Inverter, Control

Appendices vacon • 223 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x1 driver / h2 driver / h4 driver / x1 driver ...

Page 226: Ch72, Fc, Control

13 vacon • 224 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - driver / x13 driver / x14 driver / x15 driver / h4 driv...

Page 227: Ch74, Fc, Control

Appendices vacon • 225 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 control board option board option board option board option board option board control panel opto adapter board control unit asic board dc + dc - rect / x13 driver / x1 driver / h2 driver / h4 driver /...

Page 228

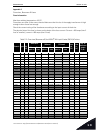

13 vacon • 226 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ appendix 2 oetl2500 + ofax3 + charging circuit for vacon ® nx liquid-cooled inverters 1640_5 to 2300_5 (3 diagrams) main circuit -f2.1 -a 1 2 3 4 pe -m1 m 3 ~ u1 1 v1 w1 2 pe th2 /2-5f th1 /2-5f -u1 dc...

Page 229

Appendices vacon • 227 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 31 -x2 -v1 k a -f3 1 2 32 3 4 33 35 -x2 34 -a1 7 -a16 1 e0.0 -a11 1 +10vref 1 -x2 2 aia1+ 2 3 aia1- 3 -a12 nxopta3 2ro+ptc 4 aia2+ 4 5 aia2- 5 6 +24v 6 7 gnd 7 21 ro1 nc 21 -x2 22 ro1 c 22 23 ro1 no 23...

Page 230

13 vacon • 228 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ -r3 -r4 -k10.1 1l1 2t1 -1c 13 14 -7b 21 22 a1 a2 -k11 12 11 14 -2f 22 4 2 1 2 -6d 32 4 3 1 3 -5d a1 a2 /1-5d ch1 /1-6d ch2 -q1 /1-1b 23 24 -u1.3 25 26 -k11 -8e 12 11 14 -q4 > i i > i > 1 2 3 4 5 6 -t4 ...

Page 231

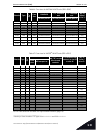

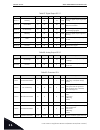

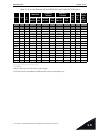

Appendices vacon • 229 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 appendix 3 fuse sizes, bussman ar fuses fuse information max fuse ambient temperature +50 ºc. Fuse sizes can differ in the same chassis. Make sure that the isc of the supply transformer is high enough ...

Page 232

13 vacon • 230 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ ____________________________ 1 tj = 25 °c 2 data in italic refer to drives with 12-pulse supply 3 sht fuses can be assembled into din fuse base of the corresponding size ch63 1030 1030 170m6814 din3 17...

Page 233

Appendices vacon • 231 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 ____________________________ 1 tj = 25 °c 2 data in italic refer to drives with 12-pulse supply 3 sht fuses can be assembled into din fuse base of the corresponding size ch63 0650 650 170m8547 3sht 3 1...

Page 234

13 vacon • 232 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ ______________________________________ 1 tj = 25 °c 2 sht fuses can be assembled into din fuse base of the corresponding size table 114. Fuse sizes (bussman ar) for vacon ® nx liquid-cooled (450—800 v)...

Page 235

Appendices vacon • 233 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 1 sht fuses can be assembled into din fuse base of the corresponding size fuse sizes (bussman ar) for vacon ® nx liquid-cooled (640—1100 v) inverters chassis type i th [a] din43620 din43653 (110mm) fus...

Page 236

13 vacon • 234 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ ____________________________ 1 sht fuses can be assembled into din fuse base of the corresponding size ch62 0460 460 170m6277 3sht 170m8639 3tn/110 1100 1000 1 ch62 0520 520 170m6277 3sht 170m8639 3tn/...

Page 237

Appendices vacon • 235 local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ 13 1 sht fuses can be assembled into din fuse base of the corresponding size table 116. Fuse sizes (bussman ar) for vacon ® nx afe units (525—690 v) chassis type i th [a] din43620 din43653 (110mm) fuse u ...

Page 238

13 vacon • 236 appendices local contacts: http://drives.Danfoss.Com/danfoss-drives/local-contacts/ _________________________ 1 sht fuses can be assembled into din fuse base of the corresponding size table 117. Brake chopper unit fuse selection (bussman ar), mains voltage 465–800 vdc chassis type min...

Page 239

Document id: dpd00887e rev. E sales code: doc-insnxplc+dluk vacon ltd member of the danfoss group runsorintie 7 65380 vaasa finland www.Danfoss.Com.