- DL manuals

- Vacon

- Power Supply

- NX

- User Manual

Vacon NX User Manual

Summary of NX

Page 1

Nx frequency converters user's manual mechanical brake control application asfiff17.

Page 2

2 • vacon introduction index document code: ud00803h date: 30/05/2007 index........................................................................................................................................................... 2 1. Introduction.......................................................

Page 3

Introduction vacon • 3 mechanical brake control application (asfiff17 v 1.11 or higher) 1. Introduction select the mechanical brake control application asfiff17 in menu m6 on page s6.1 . The mechanical brake control application is typically used in applications where brake control is needed. The har...

Page 4

4 • vacon programming principle of the digital input signals 2. Programming principle of the digital input signals the programming principle of the input signals in the mechanical brake control application as well as in the multipurpose control application (and partly in the other applications) is d...

Page 5

Programming principle of the digital input signals vacon • 5 2.1 defining an input for a certain function on keypad connecting a certain function (input signal) to a certain digital input is done by giving the parameter an appropriate value. The value is formed of the board slot on the vacon nx cont...

Page 6

6 • vacon programming principle of the digital input signals 2.2 defining a certain function with nc_drive programming tool if you use the ncdrive programming tool for parametrizing you will have to establish the connection between the function and input/output in the same way as with the control pa...

Page 7

Control i/o vacon • 7 3. Control i/o nxopta1 terminal signal description 1 +10v ref reference output voltage for potentiometer, etc. 2 ai1+ analogue input, voltage range 0—10v dc voltage input frequency reference 3 ai1- i/o ground ground for reference and controls 4 ai2+ 5 ai2- analogue input, curre...

Page 8

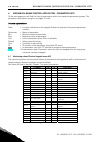

8 • vacon mechanical brake control application – parameter lists 4. Mechanical brake control application – parameter lists on the next pages you will find the lists of parameters within the respective parameter groups. The parameter descriptions are given on pages 21 to 64. Column explanations: code...

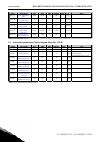

Page 9

Mechanical brake control application – parameter lists vacon • 9 4.2 basic parameters (control keypad: menu m2 Æ g2.1) code parameter min max unit default cust id note p2.1.1 min frequency 0,00 par. 2.1.2 hz 0,00 101 p2.1.2 max frequency par. 2.1.1 320,00 hz 50,00 102 note: if f max > than the motor...

Page 10

10 • vacon mechanical brake control application – parameter lists 2.1.22 fwd safe speed 0,00 par. 2.1.2 hz 10,00 1604 speed reference when digital input for fwd safe speed is activated 2.1.23 rev safe speed 0,00 par. 2.1.2 hz 10,00 1605 speed reference when digital input for rev safe speed is activa...

Page 11

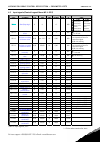

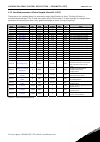

Mechanical brake control application – parameter lists vacon • 11 4.3 input signals (control keypad: menu m2 Æ g2.2) code parameter min max unit default cus id note din1 din2 p2.2.1 start/stop logic 0 6 0 300 0 1 2 3 4 5 6 start fwd start/stop start/stop start pulse fwd* start*/stop start*/stop star...

Page 12

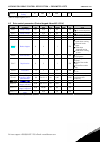

12 • vacon mechanical brake control application – parameter lists 4.4 output signals (control keypad: menu m2 Æ g2.3) code parameter min max unit default cust id note p2.3.1 analogue output function 0 8 1 307 0=not used 1=output freq. (0—f max ) 2=freq. Reference (0—f max ) 3=motor speed (0—motor no...

Page 13

Mechanical brake control application – parameter lists vacon • 13 p2.3.16 analogue output 2 scaling 10 1000 % 1000 476 table 5. Output signals, g2.3 4.5 drive control parameters (control keypad: menu m2 Æ g2.4) code parameter min max unit default cust id note p2.4.1 ramp 1 shape 0,0 10,0 s 0,0 500 0...

Page 14

14 • vacon mechanical brake control application – parameter lists 4.6 brake control parameters (control keypad: menu m2 Æ g2.5) code parameter min max unit default cust id note p2.5.1.X open loop parameters p2.5.1.1 current limit fwd 0,0 p2.1.9 a 0,0 1531 p2.5.12 current limit rev 0,0 p2.1.9 a 0,0 1...

Page 15

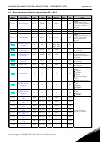

Mechanical brake control application – parameter lists vacon • 15 4.7 motor control parameters (control keypad: menu m2 Æ g2.6) code parameter min max unit default cust id note p2.6.1 motor control mode 0 1 0 600 0= ol, frequency control 1= ol, speed control 2= ol, torque control 3= cl, speed contro...

Page 16

16 • vacon mechanical brake control application – parameter lists p2.6.18.2 minimum current 0,0 100,0 % 80,0 622 p2.6.18.3 flux reference 0,0 100,0 % 80,0 623 p2.6.18.4 frequency limit 0,0 100,0 % 20,0 635 p2.6.18.5 stray flux current 0,0 100,0 % 40,0 624 p2.6.19.X speed optimization parameters p2.6...

Page 17

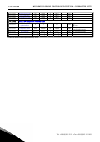

Mechanical brake control application – parameter lists vacon • 17 4.8 protections (control keypad: menu m2 Æ g2.7) code parameter min max unit default cus id note p2.7.1 response to reference fault 0 5 0 700 0=no response 1=warning 2=warning+old freq. 3=wrng+presetfreq 2.7.2 4=fault,stop acc. To 2.4...

Page 18

18 • vacon mechanical brake control application – parameter lists code parameter min max unit default cus id note p2.7.27 logic supervision time 0,00 10,00 s 5,00 1573 p2.7.28 response to under current fault 0 3 0 1574 p2.7.29 under current limit 0,0 p2.1.15 a 0,0 1575 p2.7.30 response to shaft spee...

Page 19

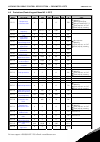

Mechanical brake control application – parameter lists vacon • 19 4.10 identified parameters (control keypad: menu m2 Æ g2.9) parameters are updated when the automatic motor identification is done. The identification is activated by parameter p2.6.15 and start order within 20 seconds. It is also pos...

Page 20

20 • vacon mechanical brake control application – parameter lists 4.11 keypad control (control keypad: menu m3) the parameters for the selection of control place and direction on the keypad are listed below. See the keypad control menu in the vacon nx user’s manual. Code parameter min max unit defau...

Page 21

Description of parameters vacon • 21 5. Description of parameters 5.1 basic parameters 2.1.1, 2.1.2 minimum/maximum frequency defines the frequency limits of the frequency converter. The maximum value for parameters 2.1.1 and 2.1.2 is 320 hz. The software will automatically check the values of param...

Page 22

22 • vacon description of parameters 2.1.11 i/o frequency reference selection defines which frequency reference source is selected when controlled from the i/o control place. Default value is 0. 0 = analogue voltage reference from terminals 2—3, e.G. Potentiometer 1 = analogue current reference from...

Page 23

Description of parameters vacon • 23 2.1.14-2.1.21 digital reference 000-111 the frequency is set according to the combination of 3 digital inputs, ( p2.2.7.9 - p2.2.7.11 ). Parameter values are automatically limited between the minimum and maximum frequencies (par. 2.1.1, 2.1.2) speed select input ...

Page 24

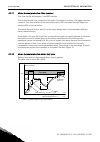

24 • vacon description of parameters 5.2 input signals 2.2.1 start/stop logic selection 0 din1: closed contact = start forward din2: closed contact = start reverse figure 3. Start forward/start reverse c the first selected direction has the highest priority. D when the din1 contact opens the directi...

Page 25

Description of parameters vacon • 25 2 din1: closed contact = start open contact = stop din2: closed contact = start enabled open contact = start disabled and drive stopped if running 3 3-wire connection (pulse control): din1: closed contact = start pulse din2: open contact = stop pulse (din3 can be...

Page 26

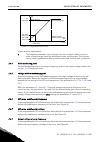

26 • vacon description of parameters 0 par. 2.2.4 par. 2.2.5 nx12k14 max freq. Par 2.1.2 output frequency analogue input max. Min freq. Par 2.1.1 % 100% 63% par. 2.2.7 t [s] nx12k15 filtered signal unfiltered signal 2.2.3 2.2.4 reference scaling, minimum value/maximum value setting value limits: 0 ≤...

Page 27

Description of parameters vacon • 27 2.2.7.X digital inputs all digital inputs (not din1 and din2) shall be programmed using the terminal to function method (ttf). See instructions on page 4. In other words, all functions (parameters) that you wish to use shall be connected to a certain input on a c...

Page 28

28 • vacon description of parameters 2.2.7.8 external brake supervision external supervision of the mechanical brake. The boolean value is forced to true if function is not connected to a digital input. Contact open: mechanical brake closed contact closed: mechanical brake opened 2.2.7.9-2.2.7.11 sp...

Page 29

Description of parameters vacon • 29 2.2.7.15 fwd safe speed when digital input (nc) is opened the frequency reference is limited to the value specified by parameter p2.1.22 . Causes the drive to ramp down to safe speed before reaching the end limit activated by digital input specified by p2.2.7.16....

Page 30

30 • vacon description of parameters 5.3 output signals % 100% 63% par. 2.3.2 t [s] nx12k16 filtered signal unfiltered signal 1.0 0 20 ma 4 ma 10 ma 0.5 0 ma param. 2.3.5 = 200% param. 2.3.5 = 100% param. 2.3.5 = 50% 12 ma nx12k17 analogue output current selected (para. 2.3.1) signal max. Value 2.3....

Page 31

Description of parameters vacon • 31 2.3.5 analogue output scale scaling factor for analogue output. Signal max. Value of the signal output frequency max frequency (par. 2.1.2) freq. Reference max frequency (par. 2.1.2) motor speed motor nom. Speed 1xn mmotor output current motor nom. Current 1xi nm...

Page 32

32 • vacon description of parameters 2.3.9 output frequency limit supervision function 0no supervision 1low limit supervision 2high limit supervision if the output frequency goes under/over the set limit (p 2.3.10) this function generates a warning message via the digital output do1 and via the rela...

Page 33

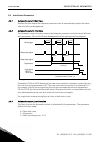

Description of parameters vacon • 33 5.4 drive control 2.4.1 acceleration/deceleration ramp 1 shape 2.4.2 acceleration/deceleration ramp 2 shape the start and end of acceleration and deceleration ramps can be smoothed with these parameters. Setting value 0 gives a linear ramp shape which causes acce...

Page 34

34 • vacon description of parameters 2.4.6 start function ramp: 0 the frequency converter starts from 0 hz and accelerates to the set reference frequency within the set acceleration time . (load inertia or starting friction may cause prolonged acceleration times). Flying start: 1 the frequency conve...

Page 35

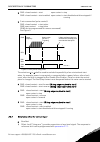

Description of parameters vacon • 35 2.5.1 2.5.2 nx12k24 reference [hz] output frequency [hz] fout [hz] par. 2.5.2 par. 2.5.1 par. 2.5.3 = 0,2 par. 2.5.3 = 1,2 2.4.11.X prohob t frequenc es i i . / i ti 2.4.11.1, 2 4.11.2 prohibit frequency area; low limit high l mit in some systems it may be necess...

Page 36

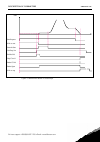

36 • vacon description of parameters 5.5 brake control mechanical brake control parameters are affecting the mechanical brake control, the smooth start and stop function and the safety functions. Mechanical brake can be set to release on current, on torque, on frequency or on external input. The clo...

Page 37

Description of parameters vacon • 37 run request 0 hz at start smooth start cur/freq lim br mec del freq close l brake cl del brake open 0 hz at stop f/hz figure 19 mechanical brake in c osed loop. L 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com.

Page 38

38 • vacon description of parameters r e s e t s e t brake open in g logic motor curren t motor torque motor freq pa ra m eter : curren t limit pa ra m eter : freq limit pa ra m eter : torque limit p2 .3 .3 .1 ext. Br ake in put sign al motor run n in g pa ra m eter : brake open delay mechan ical. B...

Page 39

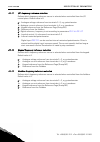

Description of parameters vacon • 39 2.5.1.X open loop brake control parameters l l l l l 2.5.1.1 current limit forward 2.5.1.2 current limit reverse these parameters defines the motor current limit that has to be exceeded before releasing the mechanical brake. If set to zero this condition is exclu...

Page 40

40 • vacon description of parameters 2.5.1.17 dc-braking time at stop determines if braking is on or off and the braking time of the dc-brake when the motor is stopping. The function of the dc-brake depends on the stop function, parameter 2.4.7. 0 dc-brake is not used >0 dc-brake is in use and its f...

Page 41

Description of parameters vacon • 41 t = par. 2.4.9 t par. 2.4.10 nx12k23 motor speed output frequency dc-braking run stop fout par. 2.4.7 = 1; stop function = ramp: after the stop command, the speed of the motor is reduced according to the set deceleration parameters, as fast as possible, to the sp...

Page 42

42 • vacon description of parameters 2.5.2.X closed loop brake control parameters 2.5.2.1 current limit this parameters defines the motor current limit that has to be exceeded before releasing the mechanical brake. If set to zero this condition is excluded. 2.5.2.2 torque limit this parameters defin...

Page 43

Description of parameters vacon • 43 2.5.2.12 smooth start frequency smooth start frequency is a reference frequency that is used with the smooth start time operation. Value should be set very small. 2.5.2.13 direction change mode if direction change situation have to be handled with the mechanical ...

Page 44

44 • vacon description of parameters 5.6 motor control 2.6.1 motor control mode 0frequency control: the i/o terminal and keypad references are frequency references and the frequency converter controls the output frequency (output frequency resolution = 0.01 hz) 1speed control: the i/o terminal and k...

Page 45

Description of parameters vacon • 45 2.6.3 u/f ratio selection linear: the voltage of the motor changes linearly with the frequency in the constant 0 flux area from 0 hz to the field weakening point where the nominal voltage is supplied to the motor. Linear u/f ratio should be used in constant torqu...

Page 46

46 • vacon description of parameters figure 24. Programmable u/f curve un par 2.6.5 par. 2.6.4 u[v] f[hz] nx12k08 par. 2.6.6 (def. 5 hz) par. 2.6.7 (def. 10%) par. 2.6.8 (def. 1.3%) default: nominal voltage of the motor field weakening point default: nominal frequency of the motor linear with flux o...

Page 47

Description of parameters vacon • 47 2.6.9 switching frequency motor noise can be minimised using a high switching frequency. Increasing the switching frequency reduces the capacity of the frequency converter unit. The range of this parameter depends on the size of the frequency converter: up to nx5...

Page 48

48 • vacon description of parameters resistance and parameters for auto torque boost are identified. The magnetizing current for closed loop is estimated. 2 = identification with motor run the drive is run with speed to identify the motor parameters. Same parameters as in identification without moto...

Page 49

Description of parameters vacon • 49 2.6.15.X closed loop parameters (nxp) l . L . 2.6.17.1 magnetizing current set here the rated magnetizing current for the motor. This parameter is used for adjusting the motor in no-load conditions. 2.6.17.2 speed control kp sets the gain for the speed controller...

Page 50

50 • vacon description of parameters 2.6.18.X advanced open loop parameters (nxp ) if the value of par. 2.6.1 = 5, the advanced open loop mode is selected. Value 6 is advanced open loop with slip compensation. These modes are designed e.G. For lift and hoisting applications to give smoother operatio...

Page 51

Description of parameters vacon • 51 2.6.19.X speed opt mization parameters i speed optimization is for running hoist faster during low loading conditions. Thus when there is no load in the crane this function can by utilized to set the motor run with higher speed within the limits specified by p2.6...

Page 52

52 • vacon description of parameters 2.6.19.1 enable speed optimization enables speed optimization function 0 = no 1 = yes 2.6.19.2 frequency limit above this limit speed optimization is active. 2.6.19.3 il limit up il current limit active in upwards direction. If output frequency is above p2.6.19.2...

Page 53

Description of parameters vacon • 53 5.7 protections 2.7.1 response to the reference fault 0 = no response 1 = warning 2 = warning, the frequency from 10 seconds back is set as reference 3 = warning, the preset frequency (par. 2.7.2) is set as reference 4 = fault, stop mode after fault according to ...

Page 54

54 • vacon description of parameters 2.7.5 response to undervoltage fau t l 1 = warning 2 = fault, stop mode after fault according to parameter 2.4.7 3 = fault, stop mode after fault always by coasting for the undervoltage limits see vacon nx user's manual, table 4-7. 2.7.6 output phase supervision ...

Page 55

Description of parameters vacon • 55 2.7.8 motor thermal protection 0 = no response 1 = warning 2 = fault, stop mode after fault according to parameter 2.4.7 3 = fault, stop mode after fault always by coasting if tripping is selected the drive will stop and activate the fault stage. Deactivating the...

Page 56

56 • vacon description of parameters 2.7.11 motor thermal protection: time constant this time can be set between 1 and 200 minutes. This is the thermal time constant of the motor. The bigger the motor, the bigger the time constant. The time constant is the time within which the calculated thermal st...

Page 57

Description of parameters vacon • 57 parameters 2.7.13—2.7.16, s all protection: t general the motor stall protection protects the motor from short time overload situations such as one caused by a stalled shaft. The reaction time of the stall protection can be set shorter than that of motor thermal ...

Page 58

58 • vacon description of parameters 2.7.16 max mum stall frequency par. 2.7.18 nx12k65 par. 2.7.19 f 5 hz underload area torque fieldweakening point par. 2.6.4 i l the frequency can be set between 1-f max (par. 2.1.2) . For a stall state to occur, the output frequency must have remained below this ...

Page 59

Description of parameters vacon • 59 2.7.19 underload protection, zero frequency load the torque limit can be set between 5.0—150.0 % x tnmotor. This parameter gives value for the minimum torque allowed with zero frequency. See figure 30 if you change the value of parameter 2.1.9 (motor nominal curr...

Page 60

60 • vacon description of parameters 2.7.24 response to brake supervision fault set here the response mode for brake supervision fault due to missing external brake supervision signal ( p2.2.7.8 ) after the brake is opened. Tel. +358 (0)201 2121 • fax +358 (0)201 212 205 2.7.25 brake supervision tim...

Page 61

Description of parameters vacon • 61 2.7.31 shaft speed supervision hysteresis the speed difference between encoder speed and the calculated speed that will cause a tripping according to the mode set by p2.7.30. 2.7.32 shaft speed supervision time supervision time for the shaft speed fault. 24-hour ...

Page 62

62 • vacon description of parameters 5.8 auto restart parameters 2.8.1 automatic restart: wait time defines the time before the frequency converter tries to automatically restart the motor after the fault has disappeared. 2.8.2 automatic restart: trial time the automatic restart function restarts th...

Page 63

Description of parameters vacon • 63 2.8.4 automatic restart: number of tries after undervoltage fault trip this parameter determines how many automatic restarts can be made during the trial time set by parameter 2.8.2 after an undervoltage trip. 0 = no automatic restart after undervoltage fault tri...

Page 64

64 • vacon description of parameters 5.9 identified parameters p2.9.1 – p2.9.15 f ux linearization points l l l flux 10…150% motor voltage corresponding to 10%….150% of flux as a percentage of nominal flux voltage. P2.9.20 ir add zero point voltage ir add voltage for zero frequency, used with automa...

Page 65

Description of parameters vacon • 65 5.10 keypad control parameters 3.1 control place the active control place can be changed with this parameter. For more information, see vacon nx user's manual, chapter 7.3.3.1. Pushing the start button for 3 seconds selects the control keypad as the active contro...

Page 66

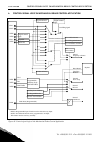

66 • vacon control signal logic in mechanical brake control application 6. Control signal logic in mechanical brake control application 1 internal fault reset din# internal reverse internal start / stop fault reset (programmable) keypad reset button programmable start/stop logic with run enable star...

Page 67

Fault tracing vacon • 67 7. Fault tracing when a fault is detected by the frequency converter control electronics, the drive is stopped and the symbol f together with the ordinal number of the fault, the fault code and a short fault description appear on the display. The fault can be reset with the ...

Page 68

68 • vacon fault tracing fault code fault possible cause 24 changed data warning changes may have occurred in the different counter data due to mains interruption 25 microprocessor watchdog fault - faulty operation - component failure 29 thermistor fault thermistor is broken. 37 device change option...

Page 69

Vaasa vacon plc (head office and production) runsorintie 7 65380 vaasa firstname.Lastname@vacon.Com telephone: +358 (0)201 2121 fax: +358 (0)201 212 205 helsinki vacon plc Äyritie 12 01510 vantaa telephone: +358 (0)201 212 600 fax: +358 (0)201 212 699 tampere vacon plc vehnämyllynkatu 18 33700 tampe...