- DL manuals

- Vega

- Radar

- VEGAPULS 63

- Operating Instructions Manual

Vega VEGAPULS 63 Operating Instructions Manual

Summary of VEGAPULS 63

Page 1

O perating i nstructions vegapuls 63 4 ... 20 m a / hart r adar.

Page 2: Ontents

C ontents 1 a bout this document 1 . 1 f unction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1 . 2 t arget group . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1 . 3 s ymbolism used . . . . . . . . . . . . . . . . . . . . . . . 5 2 f or your safety 2 . 1 a uthorised personnel ...

Page 3

6 . 4 s etup procedure . . . . . . . . . . . . . . . . . . . . . . . 33 6 . 5 m enu schematic . . . . . . . . . . . . . . . . . . . . . . . 40 6 . 6 s aving the parameter adjustment data . . . . . . . 42 7 s etup with pact ware ™ and other adjustment programs 7 . 1 c onnecting the pc . . . . . . . ....

Page 4

S upplementary operating instructions manuals i nformation : vegapuls 63 is available in many versions and is therefore supplied according to customer order . D epending on the selected version , supplementary operating instructions man - uals also come with the delivery . Y ou will fi nd the supple ...

Page 5: Bout This Document

1 a bout this document 1 . 1 f unction t his operating instructions manual has all the information you need for quick setup and safe operation . P lease read this manual before you start setup . 1 . 2 t arget group t his operating instructions manual is directed to trained , quali fi ed personnel . T...

Page 6: Or Your Safety

2 f or your safety 2 . 1 a uthorised personnel a ll operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator . F or safety and warranty reasons , any internal work on the instruments must be carried out only by per...

Page 7

L emc : en 61326 : 2004 - e mission : c lass b - s usceptibility : i ndustrial areas l r & tte directive : i - ets 300 - 440 e xpert opinion n o . 0043052 - 02 / see , n oti fi ed b ody n o . 0499 l lvd : en 61010 - 1 : 2002 2 . 6 f ul fi lling namur recommendations w ith regard to interference resist...

Page 8

M odi fi cations not expressly approved by vega will lead to expiry of the operating licence according to fcc / ic . Vegapuls 63 is in conformity with part 15 of the fcc directives and ful fi lls the rss - 210 regulations . N ote the corresponding regulations for operation : l t he instrument must not...

Page 9

L m ount and operate the instrument in such a way that no danger of ignition from electrostatic charges is to be expected . T he antenna , the process fi tting or the housing ( as the case may be depending on instrument version ) are made of electrically non - conductive plastic . L m ake sure that t...

Page 10: Roduct Description

3 p roduct description 3 . 1 c on fi guration t he vegapuls 63 radar sensor is available in two electronics versions : l s tandard electronics type ps 60 kh l e lectronics with increased sensitivity type ps 60 kd t he respective version can be determined by means of the type label on the electronics ...

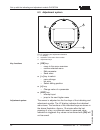

Page 11

3 2 1 f ig . 1 : vegapuls 63 , fl ange version with plastic housing 1 h ousing cover with integrated plicscom ( optional ) 2 h ousing with electronics 3 p rocess fi tting with encapsulated antenna system 3 . 2 p rinciple of operation vegapuls 63 is a radar sensor in k - band technology ( emitting freq...

Page 12

T he backlight of the indicating and adjustment module is powered by the sensor . T he prerequisite for this is a supply voltage at a certain level . T he exact voltage speci fi cations are stated in chapter " t echnical data " in the " s upplement " . T his function is available for instruments with...

Page 13: Ounting

4 m ounting 4 . 1 g eneral instructions s elect an installation position you can easily reach for mounting and connecting as well as later retro fi tting of an indicating and adjustment module . T he housing can be rotated by 330 ° without the use of any tools . Y ou can also install the indicating a...

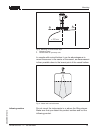

Page 14

1 3 2 100% 0% 4 f ig . 3 : m easuring range ( operating range ) and max . Measuring distance 1 full 2 empty ( max . Measuring distance ) 3 m easuring range 4 r eference plane m ake sure that the wetted parts of vegapuls 63 , especially the seal and process fi tting , are suitable for the existing pro...

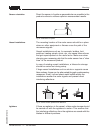

Page 15

1 2 > 200 mm f ig . 4 : m ounting on round vessel tops 1 r eference plane 2 v essel center or symmetry axis i n vessels with conical bottom it can be advantageous to mount the sensor in the center of the vessel , as measurement is then possible down to the lowest point of the vessel bottom . F ig . ...

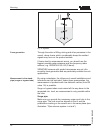

Page 16

F ig . 6 : i n fl owing liquid f lush mounting t he optimum installation location of the sensor , also in respect to the cleanability , is fl ush on a block fl ange ( fl ange without socket piece ) or with hygienic fi ttings , e . G . N eumo b iocontrol . M ounting on socket i f the re fl ective propertie...

Page 17

D irect the sensor in liquids as perpendicular as possible to the product surface to achieve optimum measurement results . F ig . 8 : o rientation in liquids t he mounting location of the radar sensor should be a place where no other equipment or fi xtures cross the path of the microwave signals . V ...

Page 18

F ig . 10 : a gitators t hrough the action of fi lling , stirring and other processes in the vessel , dense foams which considerably damp the emitted signals may form on the product surface . I f foams lead to measurement errors , you should use the biggest possible radar antennas and low frequency r...

Page 19

Max. Min. 2 1 f ig . 11 : p ipe antenna system in a tank . T he vent hole in the surge pipe must be in one plane with the polarisation marking on the sensor . 1 m arking of the polarisation direction 2 v ent holde max . ø 5 mm ( 0 . 2 in ) i f possible , the antenna diameter of the sensor should cor...

Page 20

100% 0% 1 > 300 mm f ig . 12 : vegapuls 63 in a bypass tube . T he polarisation marking on the process fi tting must be in one plane to the tube holes or the tube connection openings . 1 m arking of the polarisation direction w hen the sensor is mounted on a bypass tube , the distance from vegapuls 6...

Page 21: Onnecting To Power Supply

5 c onnecting to power supply 5 . 1 p reparing the connection a lways keep in mind the following safety instructions : l c onnect only in the complete absence of line voltage l i f overvoltage surges are expected , overvoltage arresters should be installed t ip : w e recommend using vega overvoltage...

Page 22

C aution : n o grease should be used when screwing the npt cable gland or steel tube into the threaded insert . S tandard grease can contain additives that corrode the connection between threaded insert and housing . T his would in fl uence the stability of the connection and the tightness of the hou...

Page 23

F ig . 13 : c onnection steps 6 and 7 8 p ress down the opening levers of the terminals , you will hear the terminal spring closing 9 c heck the hold of the wires in the terminals by lightly pulling on them 10 c onnect the screen to the internal ground terminal and the external ground terminal to po...

Page 24

1 4 4 4 2 3 f ig . 14 : m aterial versions , single chamber housing 1 p lastic 2 a luminium 3 s tainless steel 4 f ilter element for air pressure compensation of all material versions . B lind stopper with version ip 66 / ip 68 , 1 bar for a luminium and stainless steel i2c display 1 2 5 6 7 8 3 4 1...

Page 25

I2c display 1 1 2 5 6 7 8 f ig . 16 : w iring plan , single chamber housing 1 v oltage supply / s ignal output 5 . 4 w iring plan , double chamber housing t he following illustration apply to non - e x as well as e x ia versions . T he e xd version is described in the next subchapter . 1 2 3 4 5 f i...

Page 26

1 3 2 display 1 2 5 6 7 8 i2c f ig . 18 : e lectronics compartment , double chamber housing 1 p lug connector for vegaconnect ( i ² c interface ) 2 i nternal connection cable to the connection compartment 3 t erminals for vegadis 61 3 1 2 display 1 2 i²c f ig . 19 : c onnection compartment , double ...

Page 27

I2c 1 1 2 f ig . 20 : w iring plan , double chamber housing 1 v oltage supply / s ignal output 5 . 5 w iring plan , double chamber housing e xd 1 2 3 4 5 f ig . 21 : d ouble chamber housing 1 h ousing cover , connection compartment 2 b lind stopper or plug m 12 x 1 for vegadis 61 ( option ) 3 h ousi...

Page 28

1 3 2 display 1 2 5 6 7 8 i2c f ig . 22 : e lectronics compartment , double chamber housing 1 p lug connector for vegaconnect ( i ² c interface ) 2 i nternal connection cable to the connection compartment 3 t erminals for vegadis 61 1 2 1 2 f ig . 23 : c onnection compartment , double chamber housin...

Page 29

1 1 2 f ig . 24 : w iring plan , double chamber housing e xd 1 v oltage supply / s ignal output 5 . 6 w iring plan , version ip 66 / ip 68 , 1 bar + - 1 2 f ig . 25 : w ire assignment , connection cable 1 brown ( + ) and blue (-) to power supply or to the processing system 2 s creen 5 . 7 s witch - ...

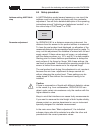

Page 30: Adjustment Module

6 s et up with the indicating and adjustment module plicscom 6 . 1 s hort description t he indicating and adjustment module is used for measured value display , adjustment and diagnosis . I t can be mounted in the following housing versions and instruments : l a ll sensors of the plics ® instrument ...

Page 31

R emoval is carried out in reverse order . T he indicating and adjustment module is powered by the sensor , an additional connection is not necessary . F ig . 26 : i nstallation of the indicating and adjustment module n ote : i f you intend to retro fi t vegapuls 63 with an indicating and adjustment ...

Page 32

6 . 3 a djustment system 1.1 2 3 1 f ig . 27 : i ndicating and adjustment elements 1 lc display 2 i ndication of the menu item number 3 a djustment keys l [ ok ] key : - move to the menu overview - con fi rm selected menu - e dit parameter - s ave value l [- > ] key to select : - menu change - list e...

Page 33

6 . 4 s etup procedure i n hart - m ultidrop mode ( several sensors on one input ) the address must be set before continuing with the parameter adjustment . Y ou will fi nd a detailed description in the operating instructions manual " i ndicating and adjustment module " or in the online help of pact ...

Page 34

S tart your parameter adjustment with the following menu items of the basic adjustment : p roceed as follows : 1 m ove from the measured value display to the main menu by pushing [ ok ] . ▶ b asic adjustment d isplay d iagnostics s ervice i nfo 2 s elect the menu item " b asic adjustment " with [- >...

Page 35

E ach product has di ff erent re fl ective properties . I n addition , there are various interfering factors which have to be taken into account : agitated product surfaces and foam generation ( with liquids ); dust generation , material cones and echoes from the vessel wall ( with solids ). T o adapt...

Page 36

Safety " , " s olid " is preset as factory setting . H owever , the instrument should be used preferably in liquids . I n such cases , the vessel form should be set to " s torage tank " during setup . E nter the requested parameter via the appropriate keys , save your settings and jump to the next m...

Page 37

G ating out of false signals c hange now ? P roceed as follows : 1 m ove from the measured value display to the main menu by pushing [ ok ] . 2 s elect the menu item " s ervice " with [- > ] and con fi rm with [ ok ] . N ow the menu item " f alse signal suppression " is displayed . 3 c on fi rm " f al...

Page 38

T he following data are read out or written with this function : l m easured value presentation l a djustment l m edium l i nner diameter of the standpipe ( with standpipe versions ) l v essel form l d amping l l inearisation curve l s ensor - tag l d isplayed value l d isplay unit l s caling l c ur...

Page 39

C urrent output - characteristics 4 … 20 m a c urrent output - max . Current 20 m a c urrent output - min . Current 4 m a c urrent output - failure 3 . 6 m a u nit of measurement m ( d ) t he values of the following functions are not reset to the reset values ( see chart ) with " r eset " : f unctio...

Page 40

6 . 5 m enu schematic i nformation : d epending on the version and application , the light - coloured menu windows are not always available or o ff er nor selection possibility . B asic adjustment 1 ▶ b asic adjustment d isplay d iagnostics s ervice i nfo 1 . 1 m in . Adjustment 0 . 00 % = 10 . 000 m...

Page 41

3 . 1 p ointer d istance min .: 0 . 234 m ( d ) d istance max .: 5 . 385 m ( d ) 3 . 2 m eas . Reliability 8 db s ensor status ok 3 . 3 c urve selection e cho curve 3 . 4 e cho curve p resentation of the echo curve s ervice 4 b asic adjustment d isplay d iagnostics ▶ s ervice i nfo 4 . 1 g ating out...

Page 42

6 . 6 s aving the parameter adjustment data i t is recommended noting the adjusted data , e . G . In this operating instructions manual and archive them afterwards . T hey are hence available for multiple use or service purposes . I f vegapuls 63 is equipped with an indicating and adjust - ment modu...

Page 43: Etup With

7 s etup with pact ware ™ and other adjustment programs 7 . 1 c onnecting the pc ~ = power supply vegaconnect 3 pactware / tm >pa 2 3 1 f ig . 28 : c onnection directly to the sensor 1 rs 232 connection 2 vegapuls 63 3 i ² c adapter cable for vegaconnect 3 n ecessary components : l vegapuls 63 l pc ...

Page 44

2 3 1 4 ~ = power supply vegaconnect 3 pactware / tm f ig . 29 : c onnecting the pc to the signal cable 1 rs 232 connection 2 vegapuls 63 3 hart adapter cable for vegaconnect 3 4 hart resistance 250 o hm n ecessary components : l vegapuls 63 l pc with pact ware ™ and suitable vega dtm l vegaconnect ...

Page 45

N ote : k eep in mind that for setup of vegapuls 63 , dtm - c ollection in the actual version must be used . A ll currently available vega dtm s are provided in the dtm c ollection on cd and can be obtained from the responsible vega agency for a token fee . T his cd includes also the up - to - date ...

Page 46: fi

8 m aintenance and fault recti fi cation 8 . 1 m aintenance w hen used as directed in normal operation , vegapuls 63 is completely maintenance free . 8 . 2 r emove interferences vegapuls 63 o ff ers maximum reliability . N evertheless faults can occur during operation . T hese may be caused by the fol...

Page 47

? 4 … 20 m a signal missing l w rong connection à c heck connection according to chapter " c onnection steps " and if necessary , correct according to chapter " w iring plan " l n o voltage supply à c heck cables for breaks ; repair if necessary l supply voltage too low or load resistance too high à...

Page 48

8 . 3 e xchange of the electronics module i f the electronics module is defective , it can be replaced by the user . I n e x applications , only an instrument and an electronics module with appropriate e x approval may be used . I f there is no electronics module available on site , one can be order...

Page 49

L ps - e . 60 kd d ( d = approvals kx , kf according to vega product list ) l ps - e . 60 kd e ( e = approvals cx , dx , ck , ci , dm , xm , cm , di , ex , gi , gx , ux , uf according to vega product list ) 8 . 4 i nstrument repair i f a repair is necessary , please proceed as follows : y ou can dow...

Page 50: Ismounting

9 d ismounting 9 . 1 d ismounting steps w arning : b efore dismounting , be aware of dangerous process con - ditions such as e . G . Pressure in the vessel , high temperatures , corrosive or toxic products etc . T ake note of chapters " m ounting " and " c onnecting to power supply " and carry out t...

Page 51: Upplement

10 s upplement 10 . 1 t echnical data g eneral data m aterials , wetted parts - p rocess fi tting 316 l - a ntenna encapsulated or hygieni - cally encapsulated ptfe ( tfm 1600 ), pfa plated , pvdf - p rocess seal with hygienically en - capsulated antenna v iton , epdm m aterials , non - wetted parts ...

Page 52

Min . Distance from fl ange 50 mm ( 1 . 969 in ) meas . Range depending on process fi tting - t ri - c lamp 2 " , 3 " up to 10 m ( 32 . 808 ft ) - bolting dn 50 , dn 80 up to 10 m ( 32 . 808 ft ) - fl ange dn 50 , ansi 2 " up to 10 m ( 32 . 808 ft ) - f lange dn 80 … dn 150 , t ri - c lamp 4 " , ansi 3...

Page 53

R eceived average emitted power reaching an object directly in front of the antenna - d istance 1 m ( 3 . 28 ft ) 108 n w per cm ² ( 108 - 9 w / cm ² ) or 108 n w per 0 . 155 in 2 ( 108 x 10 - 9 w / 0 . 155 in 2 ) - d istance 5 m ( 16 . 404 ft ) 4 . 3 n w per cm ² ( 4 . 3 - 9 w / cm ² ) or 4 . 3 n w...

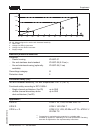

Page 54

1,0 m 20 m 30 mm 15 mm -15 mm -30 mm f ig . 32 : a ccuracy vegapuls 63 with increased sensitivity in mm , measuring range in m 3.280 ft 65.62 ft 1.180 in 0.590 in - 0.590 in - 1.180 in f ig . 33 : a ccuracy vegapuls 63 with increased sensitivity in i nch , measuring range in ft i n fl uence of the am...

Page 55

G as phase t emperature 1 bar / 14 . 5 psi 10 bar / 145 psi 50 bar / 725 psi h ydrogen 20 ° c / 68 ° f - 0 . 01 % 0 . 10 % 0 . 61 % h ydrogen 200 ° c / 392 ° f - 0 . 02 % 0 . 05 % 0 . 37 % w ater ( saturated steam ) 100 ° c / 212 ° f 0 . 20 % - - w ater ( saturated steam ) 180 ° c / 356 ° f - 2 . 1 ...

Page 56

E lectromechanical data - version ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar c able entry / plug 12 ) - s ingle chamber housing l 1 x cable entry m 20 x 1 . 5 ( cable - ø 5 … 9 mm ), 1 x blind stopper m 20 x 1 . 5 or : l 1 x cloasing cap m 20 x 1 . 5 , 1 x blind stopper m 20 x 1 . 5 or : l 1 x clos...

Page 57

- m ax . Length 1000 m ( 3280 ft ) - m in . Bending radius 25 mm ( 1 in ) at 25 ° c ( 77 ° f ) - d iameter approx . 8 mm ( 0 . 315 in ) - c olour - standard pe b lack - c olour - standard pur b lue - c olour - e x - version b lue i ndicating and adjustment module p ower supply and data transmission ...

Page 58

1000 750 500 250 14 18 16 20 22 24 26 28 30 32 34 36 Ω v 4 1 2 3 f ig . 34 : v oltage diagram 1 hart load 2 v oltage limit ee x ia instrument 3 v oltage limit non - e x / e x instrument 4 s upply voltage v oltage supply - v ersion with increased sensitivity s upply voltage - n on - e x instrument 15...

Page 59

1000 750 500 250 15 18 16 20 22 24 26 28 30 32 34 36 Ω v 4 1 2 3 f ig . 35 : v oltage diagram for version with increased sensitivity 1 hart load 2 v oltage limit ee x ia instrument 3 v oltage limit non - e x / e x instrument 4 s upply voltage e lectrical protective measures p rotection - p lastic ho...

Page 60

Atex d atex ii 1 / 2 g , 2 g ee x d ia iic t 6 atex d + d atex ii 1 / 2 g , 2 g ee xd ia iic t 5 + atex ii 1 / 2 d ip 6 x t iec ia iec e x ia iic t 6 iece x iec e x td a 20 / 21 ip 66 t , a 21 fm fm ci . I , d iv 2 ( ni ) + ci . Ii , iii , d iv 1 ( dip ); fm ci . I - iii , d iv 1 ( is ); fm ci . I -...

Page 61

10 . 2 d imensions h ousing in protection ip 66 / ip 67 and ip 66 / ip 68 ; 0 . 2 bar 112mm (4 13 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") 120mm (4 23 / 32 ") ~ 69mm (2 23 / 32 ") ø 77mm (3 1 / 32 ") ~ 69mm (2 23 / 32 ") ~ 116mm (4 9 / 16 ") ~ 87mm (3 27 / 64 ") ø 77mm (3 1 / 32 ") ø 84mm (3 5...

Page 62

Vegapuls 63 , fl ange version 100mm (3 15 / 16 ") 163mm (6 27 / 64 ") 4mm ( 5 / 32 ") 4mm ( 5 / 32 ") ø 44mm (1 47 / 64 ") ø 75mm (2 61 / 64 ") 4xø 3 / 4 " 4xø 3 / 4 " 8xø 55 / 64 " 8xø 3 / 4 " 8xø 7 / 8 " 4xø 45 / 64 " 8xø 45 / 64 " 8xø 45 / 64 " 4 3 / 4 " 4 59 / 64 " 6 19 / 64 " 5 7 / 16 " 6 7 / 32...

Page 63

Vegapuls 63 , low temperature fl ange version 201mm (7 29 / 32 ") 265mm (10 7 / 16 ") 4mm ( 5 / 32 ") 4mm ( 5 / 32 ") ø 44mm (1 47 / 64 ") ø 75mm (2 61 / 64 ") 4xø 3 / 4 " 4xø 3 / 4 " 8xø 55 / 64 " 8xø 3 / 4 " 8xø 7 / 8 " 4xø 45 / 64 " 8xø 45 / 64 " 8xø 45 / 64 " 4 3 / 4 " 4 59 / 64 " 6 19 / 64 " 5 7...

Page 64

Vegapuls 63 , hygienic fi tting 1 1 2 3 4 60mm (2 23 / 64 ") 46mm (1 13 / 16 ") ø 90mm (3 35 / 64 ") ø 66mm (2 19 / 32 ") 85mm (3 11 / 32 ") 20mm ( 25 / 32 ") ø 78mm (3 5 / 64 ") 60mm (2 23 / 64 ") 46mm (1 13 / 16 ") ø 50mm (1 31 / 32 ") ø 90mm (3 35 / 64 ") 100mm (3 15 / 16 ") f ig . 40 : vegapuls 6...

Page 65

Vegapuls 63 , hygienic fi tting 2 1 2 7mm ( 9 / 32 ") w w 99mm (3 57 / 64 ") 163mm (6 27 / 64 ") 12mm ( 15 / 32 ") dn 50 2” iso2852 dn 50 / 2” w clamp-stutzen clamp-socket din32676/ dn 50 / 2,5” dn 65 / 3” dn 80 / 3,5” dn 100 / 4” ø 64 ø 77,5 ø 91 ø 106 ø 119 dn 80 3,5” ≥ ≥ ≥ ≥ f ig . 41 : vegapuls 6...

Page 66

Vegapuls 63 , hygienic fi tting 3 1 2 3 4 8mm ( 5 / 16 ") ø 92mm (3 5 / 8 ") ø 124mm (4 7 / 8 ") 100mm (3 15 / 16 ") 163mm (6 27 / 64 ") 14mm ( 35 / 64 ") 8mm ( 5 / 16 ") ø 94mm (3 45 / 64 ") ø 133mm (5 15 / 64 ") 100mm (3 15 / 16 ") 163mm (6 27 / 64 ") 14mm ( 35 / 64 ") f ig . 42 : vegapuls 63 , hyg...

Page 67

Vegapuls 63 , hygienic fi tting 4 1 2 8mm ( 5 / 16 ") ø 84mm (3 5 / 16 ") ø 114mm (4 31 / 64 ") 100mm (3 15 / 16 ") 163mm (6 27 / 64 ") 14mm ( 35 / 64 ") f ig . 43 : vegapuls 63 , hygienic fi tting 4 1 sms dn 51 2 sms dn 76 s upplement vegapuls 63 - 4 ... 20 m a / hart 67 28436 - en - 070412.

Page 68

10 . 3 i ndustrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com . Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit gesch ü tzt durch gewerbliche schutzr...

Page 69

S upplement vegapuls 63 - 4 ... 20 m a / hart 69 28436 - en - 070412.

Page 70

S upplement 70 vegapuls 63 - 4 ... 20 m a / hart 28436 - en - 070412.

Page 71

S upplement vegapuls 63 - 4 ... 20 m a / hart 71 28436 - en - 070412.

Page 72

Vega g rieshaber kg a m h ohenstein 113 77761 s chiltach g ermany p hone + 49 7836 50 - 0 f ax + 49 7836 50 - 201 e - mail : info @ de . Vega . Com www . Vega . Com iso 9001 a ll statements concerning scope of delivery , application , practical use and operating conditions of the sensors and process...