- DL manuals

- Xerox

- Software

- Synergix 8825

- Service Manual

Xerox Synergix 8825 Service Manual

Summary of Synergix 8825

Page 1

Transmittal page product 8825/8830 printer title service manual part number 701p15051 status supersedes replaces 701p15050 dated may 1999 date january 2002.

Page 3: 8825/ 8830 Printer

8825/ 8830 printer service manual t he d ocument c ompany xerox caution certain components in the 8825/ 8830 printer are susceptible to damage from electrostatic dis- charge. Observe all esd procedures to avoid com- ponent damage. 701p15051 january 2002.

Page 4

Prepared by: xerox corporation 800 phillips road bldg. 845-17s webster, new york 14580-9791 usa © 1998, 1999, 2000, 2001, 2002 by xerox corporation. All rights reserved. Xerox®, xes®, accxes®, and the document company® are trademarks of xerox corporation. Xerox product names mentioned in this public...

Page 5

01/02 i 8825/8830 printer introduction introduction about this manual ........................................................................................................... Iii organization ............................................................................................................

Page 6

01/02 ii 8825/8830 printer introduction.

Page 7

01/02 iii 8825/8830 printer about this manual, organization introduction about this manual this manual is part of a documentation system that includes the training. This manual contains repair analysis procedures (raps), repair procedures, adjustment procedures, parts list, diagnostic procedures, in...

Page 8

01/02 iv 8825/8830 printer organization, how to use this manual introduction callback this service is performed when the cse has been called back to correct a problem that was thought to have been recently corrected. The callback is a short procedure performed on only that subsystem that caused the ...

Page 9

01/02 v 8825/8830 printer introduction repair analysis procedures (raps) a rap is either a table of faults and possible solutions, or a series of steps designed to lead you to the cause of a problem. In each step, you will perform an action or observe an occur- rence. For fault tree raps, at each st...

Page 10

01/02 vi 8825/8830 printer introduction.

Page 11

01/02 1-1 8825/8830 printer service call procedures 1 service call procedures introduction ..................................................................................................................... 1-3 call flow call flow procedure ............................................................

Page 12

01/02 1-2 8825/8830 printer service call procedures.

Page 13

01/02 1-3 8825/8830 printer introduction service call procedures introduction the service call procedures are designed to assist the service representative to identify printer faults, perform the necessary corrective action and perform the correct maintenance procedures. The service call procedures ...

Page 14

01/02 1-4 8825/8830 printer introduction service call procedures.

Page 15

01/02 1-5 8825/8830 printer call flow procedure, initial actions/systems service call procedures call flow procedure procedure perform the following: 1. Initial actions . There has been more than 5 customer work days or 500 feet (150 meters) since the last service call. Y n perform the following: 1....

Page 16

01/02 1-6 8825/8830 printer print defect isolation procedure, workstation check- service call procedures print defect isolation procedure procedure 1. Go to special tests 0955 in section 6 of this service manual. Select option 5 (600 mm print length on 36 inch wide paper) and make an internal test p...

Page 17

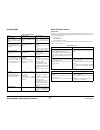

01/02 1-7 8825/8830 printer status code entry chart service call procedures status code entry chart table 1 status code entry chart status code description components bsd ref pl ref c1-01 c2-01 c3-01 no rap position sensor error the roll 1, 2, or 3 position sensor did not actuate or deactuate. Roll ...

Page 18

01/02 1-8 8825/8830 printer status code entry chart service call procedures c4-49 no rap this is a firmware problem this is a firmware problem. Press power off (0) then power on (1). If problem per- sists, replace the firmware. Pl 1.1a e2-01 no rap media registration sensor error the media trail edg...

Page 19

01/02 1-9 8825/8830 printer status code entry chart service call procedures e6-00 front door interlock switch error the c button was pressed while a print was being made in the roll feed mode. An oper- ator induced soft shutdown results in a complete print being made. The left side door must be open...

Page 20

01/02 1-10 8825/8830 printer status code entry chart service call procedures ll-12 no rap photoreceptor motor stall fault drum drive motor (a20mot3) driver pwb (a2) adj 8.4 media transport bsd 4.3 pl 1.1a pl 9.1 ll-21 no rap hvps charge error the charge scorotron fault signal was active for 1.5 sec-...

Page 21

01/02 1-11 8825/8830 printer status code entry chart, message display entry service call procedures message display entry chart ll-58 no rap power on self test extra “return value” from the operating system. Reboot (power off / power on). Install the control eprom main pwb (a3) pl 1.1a ll-60 no rap ...

Page 22

01/02 1-12 8825/8830 printer message display entry chart, maintenance proce- service call procedures note: substitute 1, 2, or 3 for x depending on which status code is displayed. Maintenance procedures all rolls are empty media registration sensor failed to sense media. Go to c1-04 . Table 1 messag...

Page 23

01/02 1-13 8825/8830 printer maintenance procedures service call procedures note: 1. Ensure that the vacuum does not contact the edge of the cleaner blade that touches the surface of the photoreceptor drum. Note: 2. Where possible, dust the drum and the cleaning blade with zinc stearate away from th...

Page 24

01/02 1-14 8825/8830 printer maintenance procedures service call procedures nor- mal call clean the transfer corotron improve toner transfer to media. Improve media tack. Remove the transfer corotron. Clean loose toner/debris with a brush. Use only a water-dampened cloth to remove contaminants from ...

Page 25

01/02 1-15 8825/8830 printer service call procedures callback procedure 1. Perform the subsystem checks for the subsystem that caused the problem. 2. Functional checks: a. Perform the initial actions . B. Check the recent faults listing (see section 6 - under system information). If any of the fault...

Page 26

01/02 1-16 8825/8830 printer service call procedures.

Page 27

01/02 1-17 8825/8830 printer system checkout / final action service call procedures system checkout / final action procedure enter diagnostic mode and make three (3) prints of internal test pattern from the controller (if present). If a controller is not present, print [0955-5] from the iot. Prints ...

Page 28

01/02 1-18 8825/8830 printer system checkout / final action service call procedures.

Page 29

01/02 2-1 8825/8830 printer status indicator raps 2 status indicator raps repair analysis procedures c1-04/c2-04/c3-04 rap ................................................................................................ 2-3 c1-59/ c2-59/ c3-59 rap .......................................................

Page 30

01/02 2-2 8825/8830 printer status indicator raps.

Page 31

01/02 2-3 8825/8830 printer c1-04/c2-04/c3-04 rap status indicator raps c1-04/c2-04/c3-04 rap note: roll x means roll 1, 2, or 3. The media drive motor (mot1, bsd 7.1 ) was trying to feed the roll x media forward to the registration position but the media registration sensor (a21q1, bsd 8.1 ) failed...

Page 32

01/02 2-4 8825/8830 printer c1-59/ c2-59/ c3-59 rap status indicator raps c1-59/ c2-59/ c3-59 rap note: c1, c2, c3 means roll 1, 2, or 3. The media drive motor (mot1, bsd 7.1 ) was trying to feed the roll x media forward to the registration position but the position sensor (q1, q2, or q3, bsd 7.2, 7...

Page 33

01/02 2-5 8825/8830 printer ll-41/ll-45 fuser warm-up fault rap status indicator raps ll-41/ll-45 fuser warm-up fault rap note: go to bsd 10.1 while using this rap. This rap is used when the fuser does not warm up when the control logic attempts to increase the heat. Ll-41 is displayed when the fuse...

Page 34

01/02 2-6 8825/8830 printer ll-41/ll-45 fuser warm-up fault rap, ll-42 ther- status indicator raps connect the (+) meter lead to a9p1-2 and leave the (-) meter lead connected to a1q1-mti. Pulses are present. Y n repair the wires. Check the wiring between the heat rod control pwb (a9) and the fuser t...

Page 35

01/02 2-7 8825/8830 printer ll-43 fuser over temperature rap status indicator raps ll-43 fuser over temperature rap note: refer to bsd 10.1 while using this rap. Warning dangerous voltage ll-43 is displayed when the logic detects that there is a problem with the fuser temperature and an overtemperat...

Page 36

01/02 2-8 8825/8830 printer ll-44 fuser too hot rap status indicator raps ll-44 fuser too hot rap note: refer to bsd 10.1 while using this rap. Warning dangerous voltage ll-44 is displayed when the fuser temperature exceeds 420º f (216º c), the maximum allowed temperature. The status code may also b...

Page 37

01/02 2-9 8825/8830 printer ll-60/ll-61 nvm fault rap status indicator raps ll-60/ll-61 nvm fault rap this rap is used for nvm (non-volatile memory) problems that are indicated by a status code or a message display. The control panel displays the message nvm fault call for assistance. Ll-60 or ll-61...

Page 38

01/02 2-10 8825/8830 printer ll-90 overtoned fault rap status indicator raps ll-90 overtoned fault rap note: go to bsd 9.7 while using this rap. The status code ll-90 is displayed when the logic detects that the toner concentration is signif- icantly greater than the control point value. The toner c...

Page 39

01/02 2-11 8825/8830 printer ll-90 overtoned fault rap, ll-91 undertoned status indicator raps procedure with the printer in an ll-90 fault condition, enter diagnostic code [9-22] and then press yes, in order to enable the printer to function with an ll-90 fault condition. Enter the code [0361] in o...

Page 40

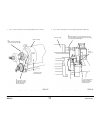

01/02 2-12 8825/8830 printer ll-91 undertoned fault rap status indicator raps figure 1 location of developer drive coupling the developer housing auger and drive gears are rotating as the prints are being made. Y n go to bsd 4.3 , drum drive, to repair the drive circuit. The ll-91 code is displayed ...

Page 41

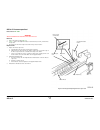

01/02 2-13 8825/8830 printer ll-91 undertoned fault rap status indicator raps figure 2 developer housing and auger drive gears ensure that the rear auger drive gear is positioned with the flange as shown. Ensure that the developer housing drive gear is positioned with the flange as shown. Ensure tha...

Page 42

01/02 2-14 8825/8830 printer ll-91 undertoned fault rap status indicator raps.

Page 43

01/02 2-15 8825/8830 printer of-1 control panel rap, of-2 power on self test status indicator raps of-1 control panel rap note: go to bsd 2.1 while using this rap, unless otherwise directed. This rap is used when the control panel does not operate, or when the control panel oper- ates incorrectly. I...

Page 44

01/02 2-16 8825/8830 printer of-3 fuser ballast rap status indicator raps of-3 fuser ballast rap procedure the customers lights flicker when the machine is switched on. Y n the fuser ballast is operating properly. The machine has tag 50 (50hz only) installed. Y n switch off the printer and disconnec...

Page 45

01/02 2-17 8825/8830 printer generic clutch rap status indicator raps generic clutch rap initial actions note: this procedure can be used to check any clutch. Due to the generic format of this rap there will be no specific adj, pl or diagnostic codes identified. Procedure ( figure 1 ): enter diagnos...

Page 46

01/02 2-18 8825/8830 printer generic sensor rap status indicator raps generic sensor rap initial actions note: this procedure can be used to check any sensor. Due to the generic format of this rap there will be no specific adj, pl or diagnostic codes identified. • ensure that the sensor is not block...

Page 47

01/02 2-19 8825/8830 printer generic switch rap status indicator raps generic switch rap initial actions note: this procedure can be used to check any switch. Due to the generic format of this rap there will be no specific adj, pl or diagnostic codes identified. Procedure ( figure 1 ): enter diagnos...

Page 48

01/02 2-20 8825/8830 printer generic switch rap status indicator raps.

Page 49

01/02 3-1 8825/8830 printer print quality 3 print quality print quality print quality initialization procedure ............................................................................... 3-3 print defects...............................................................................................

Page 50

01/02 3-2 8825/8830 printer print quality.

Page 51

01/02 3-3 8825/8830 printer print quality initialization procedure, print defects print quality print quality initialization procedure prior to any print quality troubleshooting, validate that the problem is in the iot by entering [9- 55]. Select test pattern 5. Examine the test print for defects. I...

Page 52

01/02 3-4 8825/8830 printer print quality definitions print quality print quality definitions the following terms are some of the most commonly used terms that describe image quality problems. Background background occurs as darkness or dirtiness on the non-image areas of the print. Black print this...

Page 53

01/02 3-5 8825/8830 printer print quality general diagnostics, print quality print quality print quality general diagnostics it is important to understand the orientation of prints in order to troubleshoot image quality problems. The following terms will be used when referring to prints made on the ...

Page 54

01/02 3-6 8825/8830 printer print quality specifications print quality background this term refers to the density of the print in any non-image area. Use a wide roll of media and run test pattern [9-55-5]. Examine the print using the background reference scale 302.02. Specification: all non-image ar...

Page 55

01/02 3-7 8825/8830 printer print quality specifications print quality linearity of lines linearity of lines refers to the straightness of the horizontal, vertical and diagonal lines. Use a wide roll of media and run test pattern [9-55-7]. Measure the straightness of a 50 block length in all three d...

Page 56

01/02 3-8 8825/8830 printer damaged media, media handling problems print quality damaged media media handling problems introduction experience has shown that many media transportation problems have more than one cause and must be handled using a systematic approach. Media transportation problems app...

Page 57

01/02 3-9 8825/8830 printer pq 1, pq 2 print quality pq 1 background pq 2 bands table 1 background symptom / check symptom / check contamination of the blank area by toner particles on the print probable cause corrective action 1. An incorrect electrostatic value 1a. Perform electrostatic series ( a...

Page 58

01/02 3-10 8825/8830 printer pq 3, pq 4 print quality pq 3 bands pq 4 black lines table 1 bands symptom / check symptom/ check bands are 1 mm or more and are perpendicular to the media feed direction. High density bands are called black lines. Probable cause corrective action 1. Defective or intermi...

Page 59

01/02 3-11 8825/8830 printer pq 5, pq 6 print quality pq 5 black prints pq 6 blank prints / partial image table 1 black prints symptom / check symptom/ check the print is totally black with no image. Probable cause corrective action 1. Defective charge scorotron 1. Clean or replace the screen/pins (...

Page 60

01/02 3-12 8825/8830 printer pq 7, pq 8 print quality pq 7 blurred image pq 8 deletions (bands) table 1 blurred image symptom / check symptom/ check the image is not clear or sharp. Probable cause corrective action 1. Defective/contaminated image module. 1a. Ensure the spacing rollers and drum ends ...

Page 61

01/02 3-13 8825/8830 printer pq 9, pq 10 print quality pq 9 deletions (bands) pq 10 deletions (in solid and halftone areas) table 1 deletions (bands) symptom / check symptom/ check deletion bands or very low image density perpendicular to the print feed direction. Probable cause corrective action 1....

Page 62

01/02 3-14 8825/8830 printer pq 11, pq 12 print quality pq 11 deletions (spots) pq 12 finger marks table 1 deletions (spots) symptom / check symptom/ check localized areas of deletion in the solid or halftone areas in the print feed direction. Probable cause corrective action 1. Damp media 1a. Refer...

Page 63

01/02 3-15 8825/8830 printer pq 13, pq 14 print quality pq 13 light image pq 14 misregistration table 1 light image symptom / check symptom/ check image area of a print has low density. Probable cause corrective action 1. Damp media 1a. Refer to bsd 7.1 and bsd 7.3 to check for correct operation of ...

Page 64

01/02 3-16 8825/8830 printer pq 15, pq 16 print quality pq 15 residual image pq 16 skewed image table 1 residual image symptom / check symptom/ check this is an image that is repeated on the same print or consecutive prints. The image can either be a ghost- ing of the original image or a toner image...

Page 65

01/02 3-17 8825/8830 printer pq 17, pq 17a print quality pq 17 smears pq 17a smudge table 1 smears symptom / check symptom/ check areas of the image on the print are blurred. This occurs at the image transfer area and is caused by a dif- ference of speed between the drum and the media. Location of s...

Page 66

01/02 3-18 8825/8830 printer pq 18, pq 19 print quality pq 18 spots pq 19 uneven density table 1 spots symptom / check symptom/ check circular black spots on the print. Probable cause corrective action perform panic stop/image on drum procedure (section 6), and examine the drum for the defect. 1. De...

Page 67

01/02 3-19 8825/8830 printer pq 20, pq 21 print quality pq 20 unfused prints pq 21 wrinkle table 1 unfused prints symptom / check symptom/ check characters and image are easily rubbed off a print. Probable cause corrective action 1. Damp media 1a. Refer to bsd 7.1 and bsd 7.3 to check for correct op...

Page 68

01/02 3-20 8825/8830 printer pq 22 print quality pq 22 offsetting table 1 offsetting symptom / check symptom/ check offsetting is the result of toner adhering to the fuser heat roll and transferring to subse- quent prints. Probable cause corrective action 1. There is insufficient fuser oil on the he...

Page 69

01/02 4-1 8825/8830 printer repairs and adjustments repairs/adjustments repairs electrical rep 3.1 main pwb ......................................................................................................... 4-3 rep 3.2 high voltage power supply ...................................................

Page 70

01/02 4-2 8825/8830 printer repairs and adjustments.

Page 71

01/02 4-3 8825/8830 printer rep 3.1 repairs and adjustments rep 3.1 main pwb parts list on pl 1.1a warning switch off the controller and the printer main power switches. Disconnect the printer power cord. Caution electrostatic discharge damage (esd) may occur. Use esd procedures and antistatic wrist...

Page 72

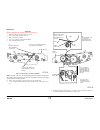

01/02 4-4 8825/8830 printer rep 3.1 repairs and adjustments 4. ( figure 2 ): disconnect the 10 connectors from the printer main pwb. Figure 2 ground connector location on main pwb 5. Pull the 8 plastic fasteners outward and remove the printer main pwb. 6. ( figure 3 ): remove the nvm integrated circ...

Page 73

01/02 4-5 8825/8830 printer rep 3.1 repairs and adjustments 7. ( figure 4 ): install the existing nvm integrated circuit into the socket on the new main pwb. Note: position the pin 1 locating dot as shown. Figure 4 installing the nvm integrated circuit on the new main pwb 8. Install the new main pwb...

Page 74

01/02 4-6 8825/8830 printer rep 3.1 repairs and adjustments 9. ( figure 5 ): connect the connectors: figure 5 connecting p307a to new main pwb 10. Connect the remaining connectors and the ground connector to the main pwb. 11. Check the xerox bbs to determine the current version of software to be ins...

Page 75

01/02 4-7 8825/8830 printer rep 3.2 repairs and adjustments rep 3.2 high voltage power supply parts list on pl 1.3 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. ( figure 1 ): remove the high voltage power supply. Replacem...

Page 76

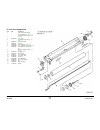

01/02 4-8 8825/8830 printer rep 7.1 repairs and adjustments rep 7.1 media supply drawer parts list on pl 7.1 warning switch off the main power switch. Disconnect the power cord. Note: all three roll supply drawer assemblies are removed the same way. The 8825 comes with media supply drawer 1 or 2. Th...

Page 77

01/02 4-9 8825/8830 printer rep 7.2 repairs and adjustments rep 7.2 rewind gear and rewind internal gear parts list on pl 7.3 warning switch off the main power switch. Disconnect the power cord. Note: all three rewind gears and rewind internal gear assemblies are removed the same way. Removal 1. Pul...

Page 78

01/02 4-10 8825/8830 printer rep 7.3 repairs and adjustments rep 7.3 roll feed pinch rolls parts list on pl 7.5 warning switch off the main power switch. Disconnect the power cord. Note: all three roll feed pinch roll assemblies are removed the same way. Removal 1. Open the media supply drawer and r...

Page 79

01/02 4-11 8825/8830 printer rep 7.4 repairs and adjustments rep 7.4 roll feed drive rolls parts list on pl 7.1 warning switch off the main power switch. Disconnect the power cord. Note: all three roll feed drive roll assemblies are removed the same way. Removal 1. Remove the appropriate media suppl...

Page 80

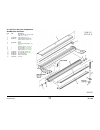

01/02 4-12 8825/8830 printer rep 7.5 repairs and adjustments rep 7.5 feed clutch parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. ( figure 1 ): remove the feed clutch. Figure 1 removing the feed clutch 4...

Page 81

01/02 4-13 8825/8830 printer rep 7.6 repairs and adjustments rep 7.6 rewind clutch parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. ( figure 1 ): remove the rewind clutch. Figure 1 removing the rewind cl...

Page 82

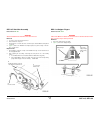

01/02 4-14 8825/8830 printer rep 7.7 repairs and adjustments rep 7.7 motion sensor parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Remove the rewind clutch ( rep 7.6 ). 3. ( figure 1 ): remove the motio...

Page 83

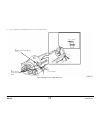

01/02 4-15 8825/8830 printer rep 7.9 repairs and adjustments rep 7.9 roll drive motor parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. ( figure 1 ): remove the roll drive motor assembly. Figure 1 removin...

Page 84

01/02 4-16 8825/8830 printer rep 7.9, rep 7.10a repairs and adjustments figure 2 removing the roll drive motor bracket rep 7.10a lower media roll heater parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2 re...

Page 85

01/02 4-17 8825/8830 printer rep 7.10a repairs and adjustments 2. ( figure 1 ): remove the lower media roll heater. Figure 1 removing the lower media roll heater 2 remove the screw 1 disconnect the connector 3 remove the lower media roll heater.

Page 86

01/02 4-18 8825/8830 printer rep 7.10b, rep 7.11 repairs and adjustments rep 7.10b upper media roll heater parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove media supply drawer 1 ( rep 7.1 ). Caution be sure to support the media roll heater/g...

Page 87

01/02 4-19 8825/8830 printer rep 7.11 repairs and adjustments parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Remove the rewind clutch ( rep 7.6 ). 3. ( figure 1 ): remove the encoder disk. Figure 1 rem...

Page 88

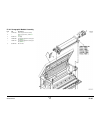

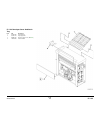

01/02 4-20 8825/8830 printer rep 8.1 repairs and adjustments rep 8.1 media transport assembly parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configurat...

Page 89

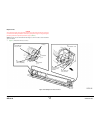

01/02 4-21 8825/8830 printer rep 8.1 repairs and adjustments 5. ( figure 3 ): remove the media transport assembly. Figure 3 removing the media transport assembly replacement 1. If a new media transport assembly is being installed, perform the media transport to drum spacing ( adj 8.4 ). 2. Open the ...

Page 90

01/02 4-22 8825/8830 printer rep 8.1 repairs and adjustments 3. ( figure 4 ): reinstall the media transport assembly. Figure 4 reinstalling the media transport assembly 1 place the pin on the ramp 2 install the turnaround baffle under the developer assembly shelf (both ends) 3 move the pin into the ...

Page 91

01/02 4-23 8825/8830 printer rep 8.2 repairs and adjustments rep 8.2 media exit switch parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2 ). 2. Remove the media transport assembly ( rep 8...

Page 92

01/02 4-24 8825/8830 printer rep 8.3 repairs and adjustments rep 8.3 buckle switch parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2 ). 2. Remove the media transport assembly ( rep 8.1 )...

Page 93

01/02 4-25 8825/8830 printer rep 8.4 repairs and adjustments rep 8.4 cut sheet media feed clutch - 8830 and 8825 with tag/mod 90 parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2 ). 2. R...

Page 94

01/02 4-26 8825/8830 printer rep 8.5 repairs and adjustments rep 8.5 pressure plates parts list on pl 10.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configuration exac...

Page 95

01/02 4-27 8825/8830 printer rep 8.5 repairs and adjustments replacement caution be careful not to damage the sheet media switch actuator while reinstalling the lower pres- sure plate. 1. ( figure 2 ): reinstall the lower pressure plate. Figure 2 reinstalling the lower pressure plate caution be sure...

Page 96

01/02 4-28 8825/8830 printer rep 8.6 repairs and adjustments rep 8.6 sheet drive roll - 8830 and 8825 with tag/mod 90 parts list on pl 8.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match ...

Page 97

01/02 4-29 8825/8830 printer rep 8.7 repairs and adjustments rep 8.7 sheet pinch rolls - 8830 and 8825 with tag/mod 90 parts list on pl 8.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match...

Page 98

01/02 4-30 8825/8830 printer rep 8.8 repairs and adjustments rep 8.8 media registration sensor parts list on pl 8.2 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configura...

Page 99

01/02 4-31 8825/8830 printer rep 8.9 repairs and adjustments rep 8.9 fabric guide parts list on pl 10.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configuration exactly...

Page 100

01/02 4-32 8825/8830 printer rep 8.9, rep 8.10 repairs and adjustments replacement 1. ( figure 2 ): reinstall the fabric guide. Figure 2 reinstalling the fabric guide rep 8.10 media transport drive motor parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Remova...

Page 101

01/02 4-33 8825/8830 printer rep 8.10 repairs and adjustments 6. ( figure 1 ): remove the media transport drive motor assembly. 7. ( figure 2 ): remove the motor from the mounting plate. Figure 1 removing the motor replacement 1. Ensure that the belt is over the idler pulley. 2. ( figure 2 ): if a n...

Page 102

01/02 4-34 8825/8830 printer rep 8.11, rep 8.12 repairs and adjustments rep 8.11 sheet feed switch - 8830 and 8825 with tag/mod 90 parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2 ). 2....

Page 103

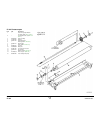

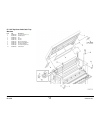

01/02 4-35 8825/8830 printer rep 8.12 repairs and adjustments 3. ( figure 1 ): remove the baffle. Figure 1 removing the baffle 4. ( figure 2 ): remove the registration pinch rolls. Figure 2 removing the registration pinch rolls 1 remove the two springs (one each end) 3 remove the screws (5) 2 remove...

Page 104

01/02 4-36 8825/8830 printer rep 8.12 repairs and adjustments replacement 1. Reinstall the rolls and retainers onto the shaft. 2. ( figure 3 ): reinstall the registration pinch roll assembly. Figure 3 reinstalling the registration pinch roll assembly 3. ( figure 4 ): reinstall the springs. 4. Comple...

Page 105

01/02 4-37 8825/8830 printer rep 8.12, rep 8.13 repairs and adjustments figure 4 reinstalling the springs rep 8.13 media feed drive belt parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2...

Page 106

01/02 4-38 8825/8830 printer rep 8.13 repairs and adjustments 6. ( figure 1 ): remove the media feed drive belt. Figure 1 removing the media feed drive belt replacement 1. Ensure that the belt is over the idler pulley. 1 disconnect the connector 2 remove the screws (3) 3 remove the motor assembly 4 ...

Page 107

01/02 4-39 8825/8830 printer rep 8.15 repairs and adjustments rep 8.15 cutter home sensor parts list on pl 7.8 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configuration ...

Page 108

01/02 4-40 8825/8830 printer rep 8.16 repairs and adjustments rep 8.16 exit roll parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2 ). 2. Remove the media transport assembly ( rep 8.1 ). ...

Page 109

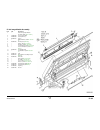

01/02 4-41 8825/8830 printer rep 8.17 repairs and adjustments rep 8.17 registration drive roll parts list on pl 8.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position ( rep 9.2 ). 2. Remove the media transport assembly...

Page 110

01/02 4-42 8825/8830 printer rep 8.17 repairs and adjustments 8. ( figure 2 ): remove the baffle. 9. Remove the registration drive roll by pushing the bearings out of the frame and moving the roll as required for removal. Figure 2 removing the baffle 1 remove the two springs (one each end) 3 remove ...

Page 111

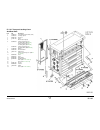

01/02 4-43 8825/8830 printer rep 9.1 repairs and adjustments rep 9.1 xerographic module parts list on pl 9.1 , pl 10.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Raise and latch the top cover. 3. Lift and rotate the im...

Page 112

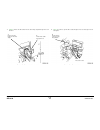

01/02 4-44 8825/8830 printer rep 9.1 repairs and adjustments note: in the following steps, “left” and “right” describe machine locations as observed when you are facing the xerographic module at the left side of the printer. 7. ( figure 2 ): install the handles onto the left and right side of the xe...

Page 113

01/02 4-45 8825/8830 printer rep 9.1 repairs and adjustments 9. ( figure 4 ): move the bearing out of the xerographic module frame (left side). Figure 4 moving the bearing (left side) 10. ( figure 5 ): move the bearing out of the xerographic module frame (right side). Figure 5 moving the bearing (ri...

Page 114

01/02 4-46 8825/8830 printer rep 9.1, rep 9.2 repairs and adjustments 11. ( figure 6 ): carefully remove the drum assembly from the printer and place it, gear box down, in a safe place on the floor. Figure 6 removing the drum assembly 12. Using the handles, lift the xerographic module out of the pri...

Page 115

01/02 4-47 8825/8830 printer rep 9.2 repairs and adjustments 5. ( figure 1 ): prepare the front and rear support brackets for raising the xerographic mod- ule to the service position. Figure 1 preparing the support bracket note: the latches that secure the xerographic module to the printer frame are...

Page 116

01/02 4-48 8825/8830 printer rep 9.2 repairs and adjustments 7. ( figure 3 ): move the bearing out of the xerographic module frame (left side). Figure 3 moving the bearing (left side) 8. ( figure 4 ): move the bearing out of the xerographic module frame (right side). Figure 4 moving the bearing (rig...

Page 117

01/02 4-49 8825/8830 printer rep 9.2, rep 9.3 repairs and adjustments 9. ( figure 5 ): carefully remove the drum assembly from the printer and place it, gear box down, in a safe place on the floor. Figure 5 removing the drum assembly rep 9.3 drum parts list on pl 9.2 warning switch off the main powe...

Page 118

01/02 4-50 8825/8830 printer rep 9.3, rep 9.4 repairs and adjustments 3. ( figure 2 ): remove the drum from the shaft assembly. Figure 2 removing the drum from the shaft assembly 4. If the drum is being replaced, install a cleaner blade kit ( rep 9.4 ). 5. Reassemble the drum assembly. 6. Perform gp...

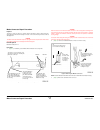

Page 119

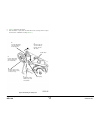

01/02 4-51 8825/8830 printer rep 9.4 repairs and adjustments figure 1 removing the cleaner blade cleaner blade photoreceptor seal channel photoreceptor seal right-hand seal xerographic module frame blade retainer (3).

Page 120

01/02 4-52 8825/8830 printer rep 9.4 repairs and adjustments replacement 1. ( figure 2 ): replace the photoreceptor seal. A. Carefully fold the photoreceptor seal along the perforations. B. Slide the photoreceptor seal into the channel, smaller side up, so that the edge of the photoreceptor seal for...

Page 121

01/02 4-53 8825/8830 printer rep 9.4 repairs and adjustments a. Insert the red stripe end of the left-hand seal underneath the folded photoreceptor seal. B. Install the seal fuzzy side up. C. Ensure that the seal is flush against the xerographic module frame. 7. Perform gp 4 drum cleaning enhancemen...

Page 122

01/02 4-54 8825/8830 printer rep 9.5 repairs and adjustments rep 9.5 developer module parts list on pl 9.8 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configuration exac...

Page 123

01/02 4-55 8825/8830 printer rep 9.5 repairs and adjustments 6. ( figure 2 ): remove the developer module. Figure 2 removing the developer module 1 move the lock into the groove on the gear while performing step 2 2 move the gear to disengage 3 disconnect a2pp1 4 press tab and swing down clamp bar (...

Page 124

01/02 4-56 8825/8830 printer rep 9.5 repairs and adjustments replacement 1. ( figure 3 ): reinstall the developer module. Figure 3 reinstalling the developer module caution ensure that the developer module is fully reinstalled in the brackets. Caution ensure that the gear is free to engage the devel...

Page 125

01/02 4-57 8825/8830 printer rep 9.5 repairs and adjustments 2. ( figure 4 ): reinstall the toner cartridge. 3. If new developer material has been installed, perform the toner sensor calibration code [09216]. Figure 4 reinstalling the toner cartridge 4 slide the top shield closed 3 remove the tape 2...

Page 126

01/02 4-58 8825/8830 printer rep 9.6 repairs and adjustments rep 9.6 cartridge drive motor parts list on pl 9.10 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configuratio...

Page 127

01/02 4-59 8825/8830 printer rep 9.7 repairs and adjustments rep 9.7 developer material parts list on (refer to svc.8830prt.17324 machine consumables, sec- tion 6.) warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous p...

Page 128

01/02 4-60 8825/8830 printer rep 9.7 repairs and adjustments 4. ( figure 2 ): dump the developer material. Figure 2 dumping the developer material 1 rotate the developer module 2 rotate the gear counterclockwise magnetic roll.

Page 129

01/02 4-61 8825/8830 printer rep 9.7 repairs and adjustments caution do not rotate the auger gears individually more than the slight amount required for removal or to mesh the teeth during reinstallation. If the factory setting of the augers is changed during the procedure, perform the adjustment pr...

Page 130

01/02 4-62 8825/8830 printer rep 9.7 repairs and adjustments replacement note: pour the developer material evenly over the full length of the augers. 1. ( figure 4 ): install the developer material and record the batch number in the machine log. Figure 4 installing the developer material caution do ...

Page 131

01/02 4-63 8825/8830 printer rep 9.7 repairs and adjustments 2. ( figure 5 ): reinstall the air pressure tubes. Figure 5 reinstalling the air pressure tubes 1 reinstall the air pressure tube 3 reinstall the gear 2 reinstall the gear 4 reinstall the gear and the grip ring 5 reinstall the air pressure...

Page 132

01/02 4-64 8825/8830 printer rep 9.7 repairs and adjustments 3. ( figure 6 ): reinstall the sump shield in the developer module. Figure 6 reinstalling the sump shield in the developer module 4. ( figure 7 ): reinstall the top shield, taking care not to overtighten the screws. Figure 7 reinstalling t...

Page 133

01/02 4-65 8825/8830 printer rep 9.7 repairs and adjustments 6. ( figure 8 ): reinstall the toner cartridge. 7. If new developer material has been installed, perform toner sensor calibration code [09216]. 8. Perform the electrostatic series ( adj 9.2 ). Figure 8 reinstalling the toner cartridge 5 sl...

Page 134

01/02 4-66 8825/8830 printer rep 9.8 repairs and adjustments rep 9.8 scorotron pin kit parts list on pl 9.3 note: these are the instructions to install the scorotron pin kit. The kit contains the following items: • pin array • torsion spring (2) • container warning switch off the main power switch. ...

Page 135

01/02 4-67 8825/8830 printer rep 9.8 repairs and adjustments warning disposal of the pin array is carefully controlled because it is made of a beryllium cop- per alloy. Package the old pin array as a returned part. Also, be especially careful of the very sharp tips on the pin array. 6. ( figure 3 ):...

Page 136

01/02 4-68 8825/8830 printer rep 9.9 repairs and adjustments rep 9.9 transfer / detack corotron parts list on pl 9.4 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configur...

Page 137

01/02 4-69 8825/8830 printer rep 9.11 repairs and adjustments rep 9.11 toner sensor parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 configuration exactl...

Page 138

01/02 4-70 8825/8830 printer rep 9.12 repairs and adjustments rep 9.12 toner cartridge home sensor parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 confi...

Page 139

01/02 4-71 8825/8830 printer rep 9.12 repairs and adjustments caution to avoid damage to the drive plate seal, always rotate the drive plate in the direction shown in figure 2 . 3. ( figure 2 ): reinstall the cartridge drive plate. Figure 2 reinstalling the cartridge drive plate 1 reinstall the cart...

Page 140

01/02 4-72 8825/8830 printer rep 9.12, rep 9.13 repairs and adjustments 4. ( figure 3 ): reinstall the top shield, taking care not to overtighten the screws. Figure 3 reinstalling the top shield 5. Reinstall the developer module ( rep 9.5 ). Rep 9.13 sump shield parts list on pl 9.9 warning switch o...

Page 141

01/02 4-73 8825/8830 printer rep 9.13 repairs and adjustments 2. ( figure 1 ): remove the sump shield. Figure 1 removing the sump shield from the developer module replacement caution ensure that the full length of the edge of the sump shield is under the edge of the housing. 1. ( figure 2 ): reinsta...

Page 142

01/02 4-74 8825/8830 printer rep 9.13, rep 9.14 repairs and adjustments figure 2 reinstalling the sump shield in the developer module rep 9.14 cartridge drive plate parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was dev...

Page 143

01/02 4-75 8825/8830 printer rep 9.14 repairs and adjustments 2. ( figure 1 ): remove the cartridge drive plate. Figure 1 removing the cartridge drive plate replacement caution to avoid damage to the drive plate seal, always rotate the drive plate in the direction shown in figure 2 . 5 remove the sc...

Page 144

01/02 4-76 8825/8830 printer rep 9.14 repairs and adjustments 1. ( figure 2 ): reinstall the cartridge drive plate. Figure 2 reinstalling the cartridge drive plate 1 reinstall the cartridge drive plate with the seal up 4 position the tab at the bottom 3 rotate while per- forming step 4 2 reinstall t...

Page 145

01/02 4-77 8825/8830 printer rep 9.14 repairs and adjustments 2. ( figure 3 ): reinstall the top shield, taking care not to overtighten the screws. Figure 3 reinstalling the top shield 3. Reinstall the developer module. 4 connect m1 1 reinstall the top shield 2 reinstall the screws (2) 3 tighten the...

Page 146

01/02 4-78 8825/8830 printer rep 9.17 repairs and adjustments rep 9.17 photoreceptor seal parts list on pl 9.5b warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove the drum assembly ( rep 9.2 ). 2. ( figure 1 ): remove the right-hand seal, the left-hand seal (not s...

Page 147

01/02 4-79 8825/8830 printer rep 9.18 repairs and adjustments rep 9.18 air pressure tubes parts list on pl 9.9 , pl 9.10 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8825/8830 conf...

Page 148

01/02 4-80 8825/8830 printer rep 9.18 repairs and adjustments replacement caution do not rotate the auger gears individually more than the slight amount required for removal or to mesh the teeth during reinstallation. If the factory setting of the augers is changed during the procedure, perform the ...

Page 149

01/02 4-81 8825/8830 printer rep 9.19, rep 9.20 repairs and adjustments rep 9.19 roller kit parts list on pl 9.3 note: these are the instructions to install roller kit 600k58740. The kit contains the following items: • rollers (2) • pins (2) warning switch off the main power switch. Disconnect the p...

Page 150

01/02 4-82 8825/8830 printer rep 9.20 repairs and adjustments 5. ( figure 1 ): prepare to remove the top cover (front). Figure 1 preparing to remove the top cover (front) note: ( figure 2 ): observe the way that the top cover pivot pin engages the hole in the inter- lock plate. This may be a difficu...

Page 151

01/02 4-83 8825/8830 printer rep 9.20 repairs and adjustments 9. ( figure 3 ): disconnect the video cable connector j307a from the main pwb and push the connector through the hole in the frame. Figure 3 disconnecting the video cable 10. ( figure 4 ): release the video cable from the cable clamps and...

Page 152

01/02 4-84 8825/8830 printer rep 9.20 repairs and adjustments 11. ( figure 5 ): release the video cable from the cable clamps and pull it through the hole in the frame. Figure 5 preparing the video cable for removal 12. ( figure 6 ): continue to pull the video cable through the hole after releasing ...

Page 153

01/02 4-85 8825/8830 printer rep 9.20 repairs and adjustments 13. ( figure 7 ): disconnect a5p2 from the low voltage power supply and release the harness from the cable clamps. Figure 7 preparing the harness for removal 14. ( figure 8 ): disconnect the ground wire and release the harness from the ca...

Page 154

01/02 4-86 8825/8830 printer rep 9.20 repairs and adjustments 15. ( figure 9 ): complete the removal preparation on the front area of the image module assembly. Figure 9 preparing to remove the image module assembly (view looking at the front from the right side) 16. ( figure 10 ): continue to pull ...

Page 155

01/02 4-87 8825/8830 printer rep 9.20 repairs and adjustments replacement 1. Reverse the removal steps for replacement of the image module assembly. 2. Perform electrostatic series ( adj 9.2 )..

Page 156

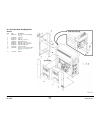

01/02 4-88 8825/8830 printer rep 10.1 repairs and adjustments rep 10.1 heat rod parts list on pl 10.2 warning switch off the main power switch. Disconnect the power cord. Allow the fuser assem- bly to cool before the procedure is performed. Removal 1. Remove the stripper finger assembly. 2. Perform ...

Page 157

01/02 4-89 8825/8830 printer rep 10.1 repairs and adjustments 4. ( figure 2 ): disconnect the heat rod and remove the bracket (left side). Figure 2 removing the bracket (left side) caution wear gloves or wrap a sheet of paper around the heat rod when handling the heat rod. Do not touch the glass sec...

Page 158

01/02 4-90 8825/8830 printer rep 10.1 repairs and adjustments 1. ( figure 4 ): reinstall the heat rod. Note: do not remove the connectors from the wires on the ends of the heat rod. A. Insert the red connector into the heat roll. B. While looking into the roll, push the red connector through the hol...

Page 159

01/02 4-91 8825/8830 printer rep 10.1 repairs and adjustments 2. ( figure 5 ): reinstall the bracket (left side). Figure 5 reinstalling the bracket (left side) 3. ( figure 6 ): reinstall the grommet and the bracket (right side). Figure 6 reinstalling the bracket (right side) 4. Ensure that the therm...

Page 160

01/02 4-92 8825/8830 printer rep 10.2, rep 10.3 repairs and adjustments rep 10.2 heat roll parts list on pl 10.2 warning switch off the main power switch. Disconnect the power cord. Allow the fuser assem- bly to cool before the procedure is performed. Note: the art used for this procedure was develo...

Page 161

01/02 4-93 8825/8830 printer rep 10.7, rep 10.8 repairs and adjustments rep 10.7 web oiler assembly parts list on pl 9.6 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Raise and latch the top cover. 3. Ensure that there is...

Page 162

01/02 4-94 8825/8830 printer rep 10.8, rep 10.9 repairs and adjustments replacement caution do not bend the stripper finger too far or it will break. 1. ( figure 2 ): reinstall the stripper fingers. Figure 2 reinstalling the stripper fingers rep 10.9 web oiler parts list on pl 9.7 warning switch off...

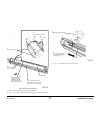

Page 163

01/02 4-95 8825/8830 printer rep 10.9 repairs and adjustments 3. ( figure 2 ): remove the takeup roll. Figure 2 removing the takeup roll replacement 1. ( figure 3 ): reinstall the supply roll. Figure 3 reinstalling the takeup roll 4 pull the stub shaft/ gear assembly from the takeup roll 1 disengage...

Page 164

01/02 4-96 8825/8830 printer rep 10.9 repairs and adjustments 2. ( figure 4 ): reinstall the takeup roll. 3. After reinstallation or replacement of the web oiler into the assembly, follow the replace- ment instructions in web oiler assembly ( rep 10.7 ). Figure 4 reinstalling the takeup roll 2 push ...

Page 165

01/02 4-97 8825/8830 printer adj 3.2, adj 8.1 repairs and adjustments adj 3.2 country configuration purpose warning the purpose is to set the line service (input power) and billing type (billing meter) con- figurations according to the customer’s requirements. Adjustment 1. Enter diagnostics. 2. Ent...

Page 166

01/02 4-98 8825/8830 printer adj 8.1 repairs and adjustments figure 2 media selection screen note: the range of adjustment is 0 to 40. Each step equals approximately 1 mm. 3. Adjust the vertical magnification using the previous / next buttons. A. Use the previous button to decrease the set point, wh...

Page 167

01/02 4-99 8825/8830 printer adj 8.2 repairs and adjustments adj 8.2 lead edge registration purpose the purpose is to adjust the print media to the image on the drum for lead edge registration within specification. Prerequisite 1. Check the following: a. Fuser temperature (nvm) ( adj 10.1 ) b. Verti...

Page 168

01/02 4-100 8825/8830 printer adj 8.3 repairs and adjustments adj 8.3 cut length purpose the purpose is to calibrate the printer to produce the correct length prints for each media type. Prerequisite 1. Check the following: a. Fuser temperature (nvm) ( adj 10.1 ) b. Vertical magnification ( adj 8.1 ...

Page 169

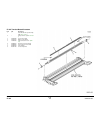

01/02 4-101 8825/8830 printer adj 8.4 repairs and adjustments adj 8.4 media transport purpose the purpose is to set the correct spacing between the media transport and the drum when a new media transport is installed. The correct spacing is obtained by adjusting the position of the lower turnaround ...

Page 170

01/02 4-102 8825/8830 printer adj 8.4 repairs and adjustments adjustment warning switch off the main power switch. Disconnect the power cord. 1. Remove the transfer / detack corotron ( rep 9.9 ). 2. Remove the developer module ( rep 9.5 ). 3. Remove the white toner shield. 4. ( figure 2 ): position ...

Page 171

01/02 4-103 8825/8830 printer adj 9.2 repairs and adjustments adj 9.2 electrostatic series purpose the purpose is to set the drum voltages to obtain good print quality as specified in section 3 of this service manual. On printers with tag 23 , it is necessary to establish the correct average light o...

Page 172

01/02 4-104 8825/8830 printer adj 9.2 repairs and adjustments figure 2 removing the plug note: failure to center the probe will cause incorrect v-lo readings. Note: run led test 9-21.5 to verify that all appropriate leds illuminate. Also verify that the electrometer probe is located within the cente...

Page 173

01/02 4-105 8825/8830 printer adj 9.2 repairs and adjustments 35 1.01 36 1.06 37 .95 38 .99 39 1.15 40 .87 41 1.02 42 1.05 43 1.10 44 1.06 45 .86 46 .87 47 .93 48 .85 49 .83 50 .90 51 .92 52 .91 53 .92 54 1.03 55 .94 56 .89 57 .95 58 .93 59 .97 60 .96 61 .95 62 .97 63 .96 64 .99 65 .99 66 .93 67 1.0...

Page 174

01/02 4-106 8825/8830 printer adj 9.2 repairs and adjustments 117 1.05 118 1.01 119 .95 120 .95 121 .95 122 .92 123 .89 124 .99 125 .98 126 .97 127 .91 128 .88 129 .92 130 .97 131 .88 132 .93 133 .83 134 .87 135 .93 136 .97 137 1.04 138 1.00 139 .94 140 .99 141 .99 142 .84 143 .93 144 .93 145 .91 14...

Page 175

01/02 4-107 8825/8830 printer adj 9.2 repairs and adjustments 202 1.19 203 1.00 204 .86 205 .85 206 .69 207 .75 208 .76 209 .71 210 .77 211 .72 212 .78 213 .58 214 .60 215 .66 216 .71 217 .75 218 .72 219 .75 220 .73 221 .76 222 .85 223 .59 224 .71 225 .59 226 1.03 238 .89 239 .91 240 .72 241 .69 242...

Page 176

01/02 4-108 8825/8830 printer adj 9.2 repairs and adjustments 295 .71 296 .85 297 .82 298 .86 299 .81 300 .92 301 1.01 302 .58 303 .60 304 .67 305 .72 306 .62 307 .83 308 .63 309 .64 310 .78 311 .67 312 .76 313 .80 314 .58 315 .86 316 .60 317 .66 318 .69 319 .70 320 .76 321 .74 322 .57 323 .63 324 ....

Page 177

01/02 4-109 8825/8830 printer adj 9.2 repairs and adjustments 377 .72 378 .90 379 .73 380 .97 381 1.06 382 .75 383 .58 384 .63 385 .66 386 .66 387 .69 388 .95 389 .95 390 .75 391 .95 392 1.00 393 1.06 394 1.07 395 .69 396 .70 397 .74 398 .62 399 .79 400 .93 401 .80 402 .66 403 .84 404 .74 405 .73 40...

Page 178

01/02 4-110 8825/8830 printer adj 9.2 repairs and adjustments 459 1.01 460 .73 461 .83 462 .79 463 .81 464 .83 465 .88 466 1.07 467 1.08 468 1.00 469 .82 470 .67 471 .79 472 .80 473 .86 474 .85 475 .89 476 .89 477 .82 478 .93 479 1.11 480 1.03 481 1.06 482 .98 483 .89 484 .69 485 .86 486 .84 487 1.0...

Page 179

01/02 4-111 8825/8830 printer adj 9.3 repairs and adjustments adj 9.3 image density purpose the purpose is to set the toner concentration to obtain good print quality as specified in section 3 of this service manual. Note: electrostatic series adj 9.2 must be performed before the image density is ad...

Page 180

01/02 4-112 8825/8830 printer adj 9.6 repairs and adjustments adj 9.6 augers purpose the purpose is to set the developer auger and the mix auger to the correct angles in order to ensure proper operation of the developer module. Warning switch off the main power switch. Disconnect the power cord. Che...

Page 181

01/02 4-113 8825/8830 printer adj 9.5 repairs and adjustments adj 9.5 toner cartridge home sensor purpose the purpose is to set the toner cartridge home sensor to the correct distance from the mag- net on the toner cartridge. Warning switch off the main power switch. Disconnect the power cord. Check...

Page 182

01/02 4-114 8825/8830 printer adj 9.5 repairs and adjustments 2. ( figure 2 ): adjust the toner cartridge home sensor to 2.5 ± 0.5 mm from the plate. Figure 2 adjusting the toner cartridge home sensor 2.5 +/- 0.5 mm 1 disconnect q2 3 straighten the wires and adjust the sensor 2 remove the wires from...

Page 183

01/02 4-115 8825/8830 printer adj 10.1 repairs and adjustments adj 10.1 fuser temperature (nvm) purpose the purpose is to adjust the temperature of the heat roll in order to obtain the correct fusing. Note: fuser temperature may also be checked using adj 10.2 fuser temperature (with probe) or adj 10...

Page 184

01/02 4-116 8825/8830 printer adj 10.1, adj 10.2 repairs and adjustments figure 5 film temperature note: the default set point for film media is 30. Adjust for 300 degrees f. 7. Adjust the film fusing temperature using the previous / next buttons. A. Use the previous button to decrease the set point...

Page 185

01/02 4-117 8825/8830 printer adj 10.2 repairs and adjustments 3. ( figure 2 ): connect the temperature probe to the dmm. Figure 2 connecting the temperature probe to the dmm 4. Switch on the dmm and then switch on the temperature probe. 5. Set the dmm to measure dc voltage. 6. Press the 20 volt ran...

Page 186

01/02 4-118 8825/8830 printer adj 10.3 repairs and adjustments adj 10.3 fuser temperature (with tape) purpose the purpose is to check the temperature of the heat roll, using temperature sensitive tape, in order to obtain the correct fusing. Check 1. Ensure that the fuser thermistor is in positive co...

Page 187

01/02 5-1 8825/8830 printer parts lists parts lists overview introduction ..................................................................................................................... 5-3 subsystem information .....................................................................................

Page 188

01/02 5-2 8825/8830 printer parts lists.

Page 189

01/02 5-3 8825/8830 printer introduction parts lists introduction overview the parts list section identifies all part numbers and the corresponding location of all spared subsystem components. Organization parts lists each item number in the part number listing corresponds to an item number in the r...

Page 190

01/02 5-4 8825/8830 printer subsystem information parts lists subsystem information use of the term "assembly" the term "assembly" will be used for items in the part number listing that include other itemized parts in the part number listing. When the word "assembly is found in the part number listi...

Page 191

01/02 5-5 8825/8830 printer symbology parts lists symbology a tag number within a circle pointing to an item number shows that the part has been changed by the tag number within the circle (figure 1). Information on the modification is in the change tag index. Figure 1 with tag symbol a tag number w...

Page 192

01/02 5-6 8825/8830 printer symbology parts lists a tag number within a circle with no apex shows that the entire drawing has been changed by the tag number within the circle (figure 3). Information on the modification is in the change tag index. Figure 3 entire drawing with tag symbol a tag number ...

Page 193

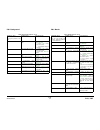

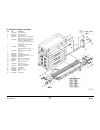

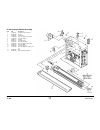

01/02 5-7 8825/8830 printer pl 1.1a parts lists pl 1.1a electrical control components/dc power generation (w/o tag 27) item part description 1 160k37310 a/b switch pwb (8830) (w/ tag 90 ) 2 162k28840 vpi harness (8830) (w/ tag 90 ) 3 162k41460 a/b switch to iot harness (8830) (w/ tag 90 ) 4 162k4144...

Page 194

01/02 5-8 8825/8830 printer pl 1.1b parts lists pl 1.1b electrical control components/dc power generation (w/tag 27) item part description 1 105k18273 dc low voltage power supply assembly (w/ tag 25 ) 2 160k33322 driver pwb (a2) (w/o tag 25 ) – 600k75311 driver pwb kit (a2) (w/ tag 25 ) 3 162k29730 ...

Page 195

01/02 5-9 8825/8830 printer pl 1.2a parts lists pl 1.2a ac electrical components (w/o tag 25) item part description 1 – ac module assembly (not spared) (50/60 hz) 2 142k01540 filter 3 – ac module housing (p/o pl 1.2a item 1 ) (50/60 hz) 4 109e01040 ac relay (k1/k3) 5 707w01652 fuser triac (q1) ( rep...

Page 196

01/02 5-10 8825/8830 printer pl 1.2b parts lists pl 1.2b ac electrical components (w/tag 25) item part description 1 – ac module assembly (not spared) (50/60 hz) 2 – pwb bracket (not spared) 3 160k59660 pwb 4 142k01540 filter 5 120e02160 twist clamp 6 109e01040 ac relay (k1) (50/60 hz), ac relay (k3...

Page 197

01/02 5-11 8825/8830 printer pl 1.3 parts lists pl 1.3 dc electrical components item part description 1 111k00021 media counter 2 – standoff (not spared) 3 105k13542 high voltage power supply ( rep 3.2 ) 4 054k12300 fan duct 5 127e11240 fan 6 092e36450 charge corotron label (red arrow) 7 600k60900 d...

Page 198

01/02 5-12 8825/8830 printer pl 1.4 parts lists pl 1.4 control console item part description 1 101k26083 control console assembly (8830) (w/ tag 32 ) – 101k40051 control console assembly (8825) (w/ tag 32 ) 2 096e78251 control console label (8830) (w/ o tag 32 ) – 891e70531 control console label (88...

Page 199

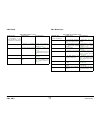

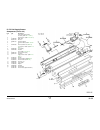

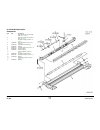

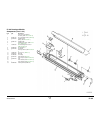

01/02 5-13 8825/8830 printer pl 7.1 parts lists pl 7.1 roll supply feed assembly item part description 1 130k51801 position sensor 2 130e02271 drawer interlock switch 3 050k53080 roll supply drawer assembly (sealed) ( rep 7.1 ) – 050k19612 roll supply drawer assembly ( rep 7.1 ) 4 010k01351 slide 5 ...

Page 200

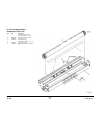

01/02 5-14 8825/8830 printer pl 7.2 parts lists pl 7.2 roll supply drives item part description 1 007k07561 roll drive motor assembly 2 127k04293 roll drive motor ( rep 7.9 ) 3 – bracket (p/o pl 7.2 item 1 ) 4 160k23870 drive motor pwb 5 007e16410 main drive sprocket (10t) 6 023e06750 chain (8830) –...

Page 201

01/02 5-15 8825/8830 printer pl 7.3 parts lists pl 7.3 roll supply drawer components (part 1 of 4) item part description 1 – part of roll supply drawer assembly (ref: pl 7.1 item 3 ) 2 022e11540 support roller 3 007e14650 rewind internal gear (20t) ( rep 7.2 ) 4 029e14760 lh support pin 5 – lh cradl...

Page 202

01/02 5-16 8825/8830 printer pl 7.4 parts lists pl 7.4 roll supply drawer components (part 2 of 4) item part description 1 – part of roll supply drawer assembly (ref: pl 7.1 item 3 ) 2 – rh roll lock (p/o pl 7.4 item 1 ) 3 003e17610 roll lock 4 009e27340 roll lock spring 5 – rh cradle bracket (p/o p...

Page 203

01/02 5-17 8825/8830 printer pl 7.5 parts lists pl 7.5 roll supply drawer components (part 3 of 4) item part description 1 – part of roll supply drawer assembly (ref: pl 7.1 item 3 ) 2 – drawer frame (p/o pl 7.5 item 1 ) 3 017e04250 baffle stop 4 068e17221 bracket 5 009e27351 pinch roll spring 6 – p...

Page 204

01/02 5-18 8825/8830 printer pl 7.6 parts lists pl 7.6 roll supply drawer components (part 4 of 4) item part description 1 – part of roll supply drawer assembly (ref: pl 7.1 item 3 ) 2 052k03580 roll support tube assembly 3 092e22541 label (push here) 4 092e36431 label (media lead) 5 – drawer frame ...

Page 205

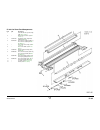

01/02 5-19 8825/8830 printer pl 7.7 parts lists pl 7.7 media cutter assembly item part description 1 037k01100 media cutter assembly 2 – media cutter (p/o pl 7.7 item 1 ) 3 – bracket (not spared) 4 003e18781 latch 5 010k01360 media cutter slide 6 110e02640 media cutter cover interlock switch (s1) 7 ...

Page 206

01/02 5-20 8825/8830 printer pl 7.8 parts lists pl 7.8 media cutter components item part description 1 – part of media cutter assembly (ref: pl 7.7 item 1 ) 2 038k06601 media exit guide 3 009e30860 lh spring 4 – cutter stationary bar (p/o pl 7.8 item 1 ) 5 009e30870 rh spring 6 028e07430 retaining r...

Page 207

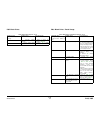

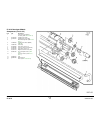

01/02 5-21 8825/8830 printer pl 8.1 parts lists pl 8.1 media transport assembly item part description 1 423w72201 sheet drive belt 2 020e13853 sheet drive pulley 3 026e11970 shoulder screw 4 022k63750 media transport assembly (8825) (w/o tag 89 ) ( rep 8.1 , adj 8.1 ) – 022k49205 media transport ass...

Page 208

01/02 5-22 8825/8830 printer pl 8.2 parts lists pl 8.2 media registration components item part description 1 – part of media transport assembly (ref: pl 8.1 item 4 ) 2 – registration support assembly (p/ o pl 8.2 item 1 ) 3 – registration support (p/o pl 8.2 item 2 ) 4 130e05990 media registration s...

Page 209

01/02 5-23 8825/8830 printer pl 8.3 parts lists pl 8.3 cut sheet feed components item part description 1 – part of media transport assembly (ref: pl 8.1 item 4 ) 2 – media transport frame (p/o pl 8.3 item 1 ) 3 019e14350 drag brake (8830), drag brake (8825) (w/ tag 90 ) 4 006k15682 sheet drive roll ...

Page 210

01/02 5-24 8825/8830 printer pl 8.4 parts lists pl 8.4 media transport components item part description 1 – part of media transport assembly (ref: pl 8.1 item 4 ) 2 110k08711 buckle switch (upper) (rep 8.4), buckle switch (lower) ( rep 8.2 ) 3 – sensor bracket (p/o pl 8.4 item 1 ) 4 – transport fram...

Page 211

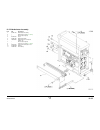

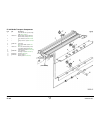

01/02 5-25 8825/8830 printer pl 9.1 parts lists pl 9.1 xerographic module assembly item part description 1 127k17882 photoreceptor drive assembly 2 – photoreceptor drive (p/o pl 9.1 item 1 ) 3 005k04151 coupling 4 126k05992 xerographic module assembly (60 hz) ( rep 9.1 ) – 126k07152 xerographic modu...

Page 212

01/02 5-26 8825/8830 printer pl 9.2 parts lists pl 9.2 photoreceptor item part description 1 – part of xerographic module assembly (ref: pl 9.1 item 4 ) 2 – xerographic frame (p/o pl 9.2 item 1 ) 3 006k15640 shaft assembly 4 013k00380 bearing 5 028e11470 bearing retainer 6 – bearing (p/o pl 9.2 item...

Page 213

01/02 5-27 8825/8830 printer pl 9.3 parts lists pl 9.3 image module assembly item part description 1 – part of xerographic module assembly (ref: pl 9.1 item 4 ) 2 125k02220 scorotron assembly 3 026e57690 screw (m4 x 30) 4 062e08051 screen 5 – right end block (p/o pl 9.3 item 2 ) 6 600k58750 pin arra...

Page 214

01/02 5-28 8825/8830 printer pl 9.4 parts lists pl 9.4 transfer/detack corotron item part description 1 – part of media transport assembly (ref: pl 8.1 item 4 ) 2 – transport frame (p/o pl 9.4 item 1 ) 3 019e16080 left corotron clamp 4 019e19971 right corotron clamp 5 125k02580 transfer/detack corot...

Page 215

01/02 5-29 8825/8830 printer pl 9.5a parts lists pl 9.5a drum cleaning (part 1 of 3) item part description 1 – part of xerographic module assembly (ref: pl 9.1 item 4 ) 2 – xerographic frame (p/o pl 9.5a item 1 ) 3 600k59060 cleaning blade kit ( rep 9.4 ) 4 – blade seal (p/o pl 9.5a item 3 ) 5 – cle...

Page 216

01/02 5-30 8825/8830 printer pl 9.5b parts lists pl 9.5b drum cleaning (part 2 of 3) item part description 1 – part of xerographic module assembly (ref: pl 9.1 item 4 ) 2 007e05221 auger gear pulley 3 023e01620 auger drive belt 4 020e04350 auger pulley 5 013e00803 auger bearing 6 094k00085 waste ton...

Page 217

01/02 5-31 8825/8830 printer pl 9.5c parts lists pl 9.5c drum cleaning (part 3 of 3) item part description 1 035k05950 toner exit seal 2 054e06533 toner waste tube 3 035k05941 waste bracket seal 4 093k02420 toner bottle.

Page 218

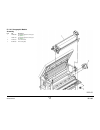

01/02 5-32 8825/8830 printer pl 9.6 parts lists pl 9.6 web oiler assembly item part description 1 – part of xerographic module assembly (ref: pl 9.1 item 4 ) 2 094k03301 web oiler assembly ( rep 10.7 ) 3 127k21990 web oiler motor 4 007k08920 oiler drive gear 5 007k08930 idler gear (40t/18t) 6 – xero...

Page 219

01/02 5-33 8825/8830 printer pl 9.7 parts lists pl 9.7 web oiler components item part description 1 – part of web oiler assembly (ref: pl 9.6 item 2 ) 2 022k49131 web oiler ( rep 10.9 ) 3 022k49380 pinch roll 4 – take up shaft (p/o pl 9.7 item 1 ) 5 009e75260 spring 6 007e42580 take up gear 7 – web ...

Page 220

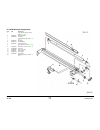

01/02 5-34 8825/8830 printer pl 9.8 parts lists pl 9.8 developer module assembly item part description 1 127e10341 drum/developer drive motor 2 035k05900 gasket 3 010e04190 trickle slide 4 014k04740 developer support (drive side) 5 014k04730 developer support 6 028e07771 retainer 7 009e41251 couplin...

Page 221

01/02 5-35 8825/8830 printer pl 9.9 parts lists pl 9.9 developer module components (part 1 of 2) item part description 1 – part of developer module assembly (ref: pl 9.8 item 12 ) 2 054e03181 pressure equilizer tube ( rep 9.8 ) 3 003e19330 cartridge knob 4 – spring (p/o pl 9.9 item 1 ) 5 005k01351 c...

Page 222

01/02 5-36 8825/8830 printer pl 9.10 parts lists pl 9.10 developer module components (part 2 of 2) item part description 1 – part of developer module assembly (ref: pl 9.8 item 12 ) 2 007e16330 cartridge gear (44t) 3 007e16341 cartridge drive gear (26t) 4 – motor mounting plate (p/o pl 9.10 item 1 )...

Page 223

01/02 5-37 8825/8830 printer pl 10.1 parts lists pl 10.1 xerographic module assembly item part description 1 126k05992 xerographic module assembly (60 hz) ( rep 9.1 ) – 126k07152 xerographic module assembly (50 hz) ( rep 9.1 ) 2 127e10331 fuser drive motor 3 007e44391 drive pulley (28t).

Page 224

01/02 5-38 8825/8830 printer pl 10.2 parts lists pl 10.2 fuser components item part description 1 – part of xerographic module assembly (ref: pl 10.1 item 1 ) 2 – xerographic frame (p/o pl 10.2 item 1 ) 3 005k03430 fuser hub 4 – lh lamp bracket (p/o pl 10.2 item 1 ) 5 005k02613 lh fuser bearing 6 06...

Page 225

01/02 5-39 8825/8830 printer pl 10.3 parts lists pl 10.3 fuser pressure components and moisture collection item part description 1 – part of media transport assembly (ref: pl 8.1 item 4 ) 2 023k00942 fabric guide ( rep 8.9 ) 3 003k09130 fabric guide retainer handle 4 – transport frame (p/o pl 10.3 i...

Page 226

01/02 5-40 8825/8830 printer pl 10.4 parts lists pl 10.4 fuser heat control and stripper fingers item part description 1 – part of xerographic module assembly (ref: pl 10.1 item 1 ) 2 – xerographic frame (p/o pl 10.4 item 1 ) 3 130k54730 thermistor 4 110e05500 stripper finger jam switch (s1) 5 130k5...

Page 227

01/02 5-41 8825/8830 printer pl 14.1 parts lists pl 14.1 transport latching cover and rear door item part description 1 130e02271 feed shelf interlock switch (s29) 2 014e20541 left hinge spacer 3 048k47700 rear door 4 017k01120 caster 5 – bracket (not spared) 6 030k55634 transport latching cover ass...

Page 228

01/02 5-42 8825/8830 printer pl 14.2 parts lists pl 14.2 front door and right side covers item part description 1 048k14304 front door cover assembly (w/ tag 32 ) 2 891e09080 logo plate 3 003e13010 keeper 4 048k47710 right side, left cover 5 014e20551 right hinge spacer 6 048k47681 right side, left ...

Page 229

01/02 5-43 8825/8830 printer pl 14.3 parts lists pl 14.3 developer cover and catch tray item part description 1 073e11800 catch tray kit 2 073e11710 tray support kit 3 048e51410 rear developer cover (w/ tag 6 ) 4 110k08970 interlock switch.

Page 230

01/02 5-44 8825/8830 printer pl 14.4 parts lists pl 14.4 top cover and catch tray brackets item part description 1 048k45054 top cover (w/ tag 32 ) 2 055e38100 shielding pad 3 029e23670 pin 4 035e37240 gasket 5 035e41150 gasket 6 030k57191 rh service bracket 7 030k57890 rh catch tray bracket 8 030k5...

Page 231

01/02 5-45 8825/8830 printer pl 14.5 parts lists pl 14.5 left side covers (8825 only) item part description 1 048k79480 left middle cover, left lower cover 2 048e39380 kickplate.

Page 232

01/02 5-46 8825/8830 printer pl 15.1 parts lists pl 15.1 miscellaneous electrical connectors and fasteners item part description 1 – contact socket (20-26 awg) (to be available at later date) 2 – contact pin (20-26 awg) (to be available at later date) 3 – wire and connector repair kit (to be availab...

Page 233

01/02 5-47 8825/8830 printer common hardware parts lists common hardware item part description a 112w11655 hex screw (6 x 16) b 112w07455 screw c 354w21052 retaining ring (7-9mm) d 354w21252 retaining ring (9-12mm) e 153w23352 screw f 132w00253 screw g 156w27555 screw h 156w27655 screw (4.2 x 16) j ...

Page 234

01/02 5-48 8825/8830 printer part number index parts lists part number index table 1 part number index part number part list 001r00535 pl 9.2 001e23080 pl 9.9 002k35642 pl 10.3 002e40470 pl 9.9 002k55230 pl 10.3 003k07581 pl 7.5 003k09130 pl 10.3 003e13010 pl 14.2 003e13020 pl 14.2 003e16521 pl 7.8 ...

Page 235

01/02 5-49 8825/8830 printer part number index parts lists 009e75260 pl 9.7 010k01351 pl 7.1 010k01360 pl 7.7 010e04190 pl 9.8 011e04470 pl 7.7 013k00380 pl 9.2 013e00803 pl 9.5b 014k04730 pl 9.8 014k04740 pl 9.8 014e20541 pl 14.1 014e20551 pl 14.2 015k10310 pl 8.1 015e17790 pl 9.10 016e06020 pl 8.2...

Page 236

01/02 5-50 8825/8830 printer part number index parts lists 030k56150 pl 9.8 030k56160 pl 9.8 030k57181 pl 14.4 030k57191 pl 14.4 030k57890 pl 14.4 030k57900 pl 14.4 030k64020 pl 14.1 032e10830 pl 8.4 033k02040 pl 10.3 033k02430 pl 10.3 035k04581 pl 9.10 035k05790 pl 9.5b 035k05900 pl 9.8 035k05941 p...

Page 237

01/02 5-51 8825/8830 printer part number index parts lists 096e78252 pl 1.4 101e12281 pl 1.4 101k25695 pl 1.2a 101k25780 pl 9.5a 101k26083 pl 1.4 101k27784 pl 1.2a 101k40051 pl 1.4 101k40571 pl 1.2b 101k42340 pl 1.2b 103e02721 pl 1.2a pl 1.2b 103e02731 pl 1.2a pl 1.2b 105k13542 pl 1.3 105e13850 pl 1...

Page 238

01/02 5-52 8825/8830 printer part number index parts lists 127k26580 pl 7.8 130e02271 pl 14.1 pl 7.1 130e03250 pl 7.2 pl 7.8 130e05990 pl 8.2 130k30381 pl 9.9 130k51801 pl 7.1 130k53300 pl 9.9 130k54730 pl 10.4 130k54841 pl 10.4 130k55130 pl 9.7 142k01540 pl 1.2a pl 1.2b 146k00461 pl 9.7 152k36231 p...

Page 239

01/02 5-53 8825/8830 printer part number index parts lists 891e70530 pl 1.4 891e70531 pl 1.4 table 1 part number index part number part list.

Page 240

01/02 5-54 8825/8830 printer part number index parts lists.

Page 241

01/02 6-1 8825/8830 printer general procedures 6 general procedures diagnostics to enter the diagnostic mode ....................................................................................... 6-3 to exit the diagnostic mode ..........................................................................

Page 242

01/02 6-2 8825/8830 printer general procedures.

Page 243

01/02 6-3 8825/8830 printer to enter the diagnostic mode general procedures to enter the diagnostic mode the diagnostic mode is entered by pressing and holding the zero (0) button while switching on the printer. The diagnostic mode may also be entered from the control panel by entering the printer m...

Page 244

01/02 6-4 8825/8830 printer to exit the diagnostic mode, input diagnostic test general procedures to exit the diagnostic mode enter the test [0361] or switch the printer power off, wait 5 seconds, then switch it on. Input diagnostic test procedure 1. Enter the diagnostic mode 2. Enter the test code ...

Page 245

01/02 6-5 8825/8830 printer input diagnostic test codes, output diagnostic general procedures input diagnostic test codes note: 8825: the media drawer 3 is not available on the 8825. The media roll drawer 2 is optional and is identified as tag/mod 89. Output diagnostic test procedure the output diag...

Page 246

01/02 6-6 8825/8830 printer output diagnostic test codes general procedures output diagnostic test codes note: 8825: the media drawer 3 is not available on the 8825. The media roll drawer 2 is optional and is identified as tag/mod 89. Caution do not run diagnostic code [0403] if the fuser is cold. P...

Page 247

01/02 6-7 8825/8830 printer stepper motor commands, to enter multiple tests general procedures stepper motor commands to enter multiple tests (chaining) the media button is used when entering more than one test. To chain one code to another, perform the following: 1. Enter the desired code for the f...

Page 248

01/02 6-8 8825/8830 printer to exit from multiple tests, special tests general procedures to exit from multiple tests multiple tests can be switched off by two methods. 1. Enter the codes in the reverse sequence from the way they were initially entered, press- ing the exit button after each code. 2....

Page 249

01/02 6-9 8825/8830 printer special tests general procedures [0362] diagnostic time-out interval. This code allows the adjustment of the time interval that the printer will stay in the diagnostic mode. The time interval range is 5 to 50 minutes. 5 min. [0363] nvm reset this code allows the nvm value...

Page 250

01/02 6-10 8825/8830 printer special tests general procedures [1010] fuser scorch sensor (thermistor rt2) 1 = fuser temperature less than or equal to 420 ° f (215 ° c) 0 = fuser temperature greater than 420 ° f (215 ° c) note: power must be switched off then on, in order to reset signal. [1026] rese...

Page 251

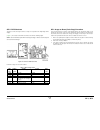

01/02 6-11 8825/8830 printer gp 1, gp 2 general procedures gp 1 hvps checkout the purpose of this checkout procedure is to verify correct operation of the high voltage power supply. ( figure 1 ): the location of the hvps test points is shown in the drawing at right. Note: use the 26v rtn test point ...

Page 252

01/02 6-12 8825/8830 printer gp 3 general procedures gp 3 drum maintenance warning when performing this drum maintenance, do the following: • ensure that there is adequate ventilation in the area. • use protective gloves at all times. • do not smoke. • wash your hands when the procedures are complet...

Page 253

01/02 6-13 8825/8830 printer gp 4, gp 5 general procedures gp 4 drum cleaning enhancement 1. Remove the drum assembly ( rep 9.2 ). 2. Use the dusting pouch (8r181) to apply a thin layer of zinc stearate over the entire sur- face of the drum. 3. With a new lint-free cloth (600s4372), wipe the entire ...

Page 254

01/02 6-14 8825/8830 printer gp 6 general procedures gp 6 downloading firmware from a laptop note: a point-to-point rs232 9-pin adaptor is required for this procedure. 1. Power on the printer, but do not power on the controller. 2. ( figure 1 ): connect a null-modem cable between the serial port of ...

Page 255

01/02 6-15 8825/8830 printer gp 7 general procedures gp 7 nvm dump of adjustable settings the purpose of this procedure is to enable the service representative to access a listing of cur- rent nvm (non-volatile memory) settings resident in the 8825/8830 printer. If desired, this information can then...

Page 256

01/02 6-16 8825/8830 printer gp 7 general procedures.

Page 257

01/02 6-17 8825/8830 printer transfer and developer bias voltages incorrect general procedures transfer and developer bias voltages incorrect (tag 19) problem transfer and developer voltages are set incorrectly. Cause late in the program it was determined that the developer bias should be set at -42...

Page 258

01/02 6-18 8825/8830 printer power cord outlet pulls out of ac module, pre-tag general procedures power cord outlet pulls out of ac module problem the power cord outlet may pull out of the ac module when trying to unplug the ac power cord. Cause the cut out in the ac power module for the power cord ...

Page 259

01/02 6-19 8825/8830 printer wavy lines when connected to xpc , ll-52 errors general procedures wavy lines when connected to xpc or non xerox controller problem the printer produces prints with wavy lines when connected to a xerox xpc or a non xerox controller. This problem does not occur with a xer...

Page 260

01/02 6-20 8825/8830 printer cooling fan not running, cleaning blade squeals general procedures cooling fan not running problem cooling fan not running. Cause early iot firmware could cause a cooling fan to start improperly. This problem only occurs with delta cooling fans. Solution check the label ...

Page 261

01/02 6-21 8825/8830 printer toner cleaning auger bound up, ll-22 general procedures toner cleaning auger bound up problem toner cleaning auger is bound up due to solidified toner. Cause excessive heat build up in the printer. Solution make sure both cooling fans are functioning properly. If they ar...

Page 262