- DL manuals

- EcoWater

- Water Dispenser

- ECR 3500R20

- Owner's Manual

EcoWater ECR 3500R20 Owner's Manual

Part No. 7291393 (Rev. D 6/11/07)

How to operate your

EcoWater Systems

Water Conditioner

EcoWater Systems Conditioner

with Remote (ECR)

EcoWater Systems Refiner

with Remote (ERR)

SERIES

3500 & 3502

EcoWater Systems LLC

P.O. Box 64420, St. Paul MN 55164-0420

OWNER’S MANUAL

PRINTED IN U.S.A.

ERR 3500R20 & ERR 3502R30 are Tested and

Certified by NSF International and WQA against

NSF/ANSI Standard 42 for chlorine taste and odor.

Systems Tested and Certified by NSF International and

WQA against NSF/ANSI Standard 44 for softener perform-

ance and the reduction of barium and radium 226/228.

Summary of ECR 3500R20

Page 1

Part no. 7291393 (rev. D 6/11/07) how to operate your ecowater systems water conditioner ecowater systems conditioner with remote (ecr) ecowater systems refiner with remote (err) series 3500 & 3502 ecowater systems llc p.O. Box 64420, st. Paul mn 55164-0420 owner’s manual printed in u.S.A. Err 3500r...

Page 2

2 safety guides follow the installation instructions carefully. Failure to install the ecowater systems conditioner properly voids the warranty. Before you begin installation, read this entire manual. Then, obtain all the materials and tools you will need to make the installation. Check local plumbi...

Page 3: Guarantee

3 limited warranty ecowater systems llc advantage warranty series ecr & err 3500 water system congratulations! You have just purchased the highest quality water conditioning product on the market. To register your warranty, complete the enclosed warranty registration card and mail it within 30 days ...

Page 4

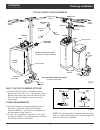

4 inlet / outlet plumbing options always install either an ecowater systems bypass valve #7214383, or a 3-valve bypass system. Bypass valves allow you to turn off water to the sof- tener for repairs if needed, but still have water in house pipes. Other requirements a drain is needed for recharge dis...

Page 5

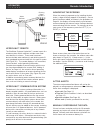

5 4. Installing three-valve bypass if installing a 3-valve bypass system, plumb as needed using figure 1 as a guide. When installing sweat cop- per, be sure to use lead-free solder and flux, required by federal and state codes. Use pipe joint compound on outside pipe threads. 5. Assemble inlet & out...

Page 6

6 b. Threaded pipe (1) apply pipe joint compound to all outside pipe threads. (2) tighten all threaded joints. (3) if soldering to the inlet and outlet tubes, observe step 6a above. C. Cpvc plastic pipe (1) clean, prime and cement all joints, following the manufacturer's instructions supplied with t...

Page 7

7 11. Pressure testing for leaks to prevent excessive air pressure in the ecowater systems conditioner and plumbing system, do the following steps exactly in order: a. Fully open two or more conditioned cold water faucets nearby the ecowater systems conditioner. B. Place the bypass valve(s) in bypas...

Page 8

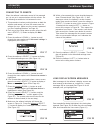

8 setup procedure when the ecowater systems softener is plugged in for the first time, a beep sounds and the display briefly shows a logo, followed by model information. Next, a series of six “wizard” screens prompts you to enter basic operating information: fig. 8 1. Language if the desired languag...

Page 9

9 during normal operation (status screens rolling), press the softener’s select ( ) button to display the main menu (see figure 16). This menu and its subsidiary screens are used to control these softener operations: recharge (see page 12) salt settings salt level (see page 11) low salt alarm (see p...

Page 10

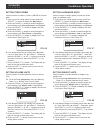

10 connecting to remote when the softener’s electronic control is first powered up, it is not yet in communication with the remote. Do the following to establish a link between the two: 1. This procedure involves pushing buttons on both the softener and remote, so have the remote near the softener f...

Page 11

Low salt alarm use this feature to program when the electronic control will display a low salt alarm. The number of days can be customized, or the feature can be turned off. The default is 30 days. 1-3. Go to the salt settings menu by following steps 1- 3 in “procedure for two-tank models” at left. ...

Page 12

12 recharging the softener this feature may be used to assure an adequate supply of softened water at times of unusually high water use. For example, if you have guests and the “water avail- able” screen (see page 16) is at or below 50%, you could deplete softened water capacity before the next auto...

Page 13

Setting recharge time when the softener’s electronic control is first powered up, the default time for starting an automatic recharge is 2:00 a.M. This is a good time in most households because water is not being used. To change this time: 1. From any of the rolling status screens, press the select ...

Page 14

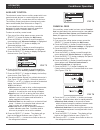

14 modifying rolling screens during normal softener operation, four status screens are shown in sequence (see “softener status screens” on page 9). When the softener’s electronic control is first powered up, the default is to show all four. You can turn on/off individual screens*: 1. From any of the...

Page 15

Setting time format use this feature to select a 12-hour (am/pm) or 24-hour clock. 1. From any of the rolling status screens, press the select ( ) button to display the main menu. 2. Press the down ( ) button to scroll through the menu options until user preferences is highlighted. 3. Press the sele...

Page 16

16 system information use these features to look up the following information about the softener and its operations: model information (model number and software version) water available (softened water ready for use) daily average water used water used today total water used (explained in step 6, b...

Page 17

Cycle times use these features to change the following softener operations: backwash time second backwash (turn on or off) second backwash time fast rinse time to display these screens: 1. From any of the rolling status screens, press the select ( ) button to display the main menu. 2. Press the down...

Page 18

18 special features use these features to change the following operations: efficiency mode maximum days between recharges auxiliary control (described on page 19) chemical feed volume* (described on page 19) chemical feed timer* (described on page 19) 97% feature service reminder (described on page ...

Page 19

19 fig. 75 fig. 76 fig. 73 auxiliary control the electronic control has an auxiliary output which can control external devices in a water treatment system. The signal is 24v ac, current draw 800 ma maximum. The auxiliary output terminals are located on the elec- tronic control board (see schematic o...

Page 20

20 fig. 78 fig. 79 service reminder (set / reset) use this feature to program the number of months (up to 24) before a “service overdue” message will appear instead of the rolling status screens (see figure 77). 8. Press the up ( ) or down () buttons to set the number of months until the service rem...

Page 21

21 diagnostics this feature allows a service technician to check the operating state of individual components in the softener (e.G. Valve position) to troubleshoot problems. If an error code is displayed in place of the rolling status screens, call your dealer for service. To view the diagnostics sc...

Page 22

22 unpacking the ecowater systems hydrolink™ remote is shipped from the factory in one carton. Thoroughly check for possible shipping damage and parts loss. Also note any damage to the shipping carton. Notify the trans- portation company if damage is present. Ecowater systems is not responsible for ...

Page 23

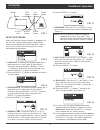

23 hydrolink™ remote the ecowater systems hydrolink™ remote is part of a wireless system which monitors multiple water treat- ment devices in a home. These water treatment devices include water softener(s) and drinking water fil- ter(s) equipped to communicate with this type of system (see figure 91...

Page 24

24 alert tm fig. 94 display left button right button up button down button alert led select button adding a device to initiate communication between the remote and a device such as a water softener, it is necessary to add the device to the remote by doing the following: 1. If no device has been adde...

Page 25

Fig. 99 fig. 100 fig. 101 2. Press the remote’s select ( ) button to display the device menu. 3. Press the down ( ) button to scroll through the menu options until rf signal strength is highlighted in a box (see figure 100). 4. Press the select ( ) button, and the screen shown in figure 101 will app...

Page 26

26 setting the language language is set independently on the remote and sof- tener (see page 14 to set the softener’s language). Fewer languages are available on the remote. To change the remote’s language: 1. Press the remote’s select ( ) button to display a menu screen. 2. Press the down ( ) butto...

Page 27

27 recharging the softener this feature may be used to assure an adequate supply of softened water at times of unusually high water use. For example, if you have guests and the “capacity remaining” line on the softener status screen is at or below 50%, you could deplete softened water capacity befor...

Page 28

28 changing which data items are dis- played in the status screens each device added to the remote (softener, drinking water system, etc.) has a status screen which the remote displays during normal operation. The status screen may be customized by turning items on or off. On the remote, the softene...

Page 29

29 changing which data items may be remotely controlled some devices (softeners, for example) have a list of data items which may be controlled by the remote. Remote control items may be customized, as follows: 1. Press the remote’s left ( ) or right () buttons to manually advance to the status scre...

Page 30

30 ecowater s y s t e m s remote operation fig. 123 fig. 125 fig. 127 fig. 124 fig. 126 2. Press the remote’s select ( ) button to display the device menu (see figure 124). 3. Press the down ( ) button to scroll through the menu options until delete current device is high- lighted in a box (see figu...

Page 31

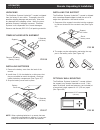

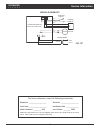

37 wiring schematic 1 24vdc motor aux out transformer 24vac 120v 60 hz back of faceplate control board on switch position no +5 gnd out turbine sensor red black red black white brown c green fig. 137 ecowater s y s t e m s service information for future reference, enter the following information: mo...

Page 32

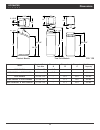

38 ecowater s y s t e m s dimensions in out 3--13/16” 32--1/2” 45--1/8” a in -- out in -- out 14” 20” 14” 14” c b 16” 16” 36--9/16” 32” fig. 138 model nominal resin tank size dimension a dimension b dimension c salt storage capacity ecr 3500r20 8” dia. X 35” 39.5” – – 225 lbs. Err 3500r20 & ecr 3500...

Page 33

Ecowater systems llc p.O. Box 64420, st. Paul, mn 55164-0420 1-800-86water ecowater s y s t e m s.