H0569300a installation and op er a tion man u al installation and operation data danger risk of electrical shock or electrocution. The electrical supply to this product must be installed by a licensed or certifi ed electrician in accordance with the national electrical code and applicable local code...

Page 1 section 1. General information ..................2 1.1 introduction.................................................. 2 1.2 consumer information and safety............... 2 1.2.1 spa/hot tub safety rules..................... 2 1.2.2 swimming pool energy saving tips ..... 3 1.3 warranty .........

Page 2 throughout the manual, safety warnings and cautions are identified by the “ “ symbol. Be sure to read and comply with all of the warnings and cautions. 1.2.1 spa/hot tub safety rules warning the u.S. Consumer product safety commission warns that elevated water temperature can be hazardous. Co...

Page 3 1. Spa or hot tub water temperature should never exceed 104°f (40°c). One hundred degrees fahrenheit (100°f [38°c]) is considered safe for a healthy adult. Special caution is recommended for young children. 2. The drinking of alcoholic beverages before or during spa or hot tub use can cause d...

Page 4 make all warranty claims to an authorized jandy dealer or directly to the factory. Claims must include the heat pump serial number and model (this information can be found on the rating plate), installation date, and name of the installer. Shipping costs are not included in the warranty cover...

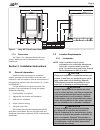

Page 5 2.2 location requirements 2.2.1 introduction note indoor installations require special considerations for condensate drainage and venting the cold air produced by the heat pump. Contact the jandy heat pump technical service department at (954) 970-4800. Caution when pool equipment is located ...

Page 6 avoid placing the heat pump in locations where it can cause damage by water or condensate leakage. If this is not possible, provide a suitable drain pan to catch and divert any leakage. All criteria given in the following sections reflect minimum clearances. However, each installation must al...

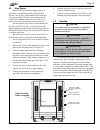

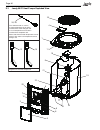

Page 7 2.2.7 installation of anchor clamps in florida, building codes require that the heat pump be anchored to the equipment pad or platform to withstand high wind pressures created during hurricanes. This heat pump was provided with anchor clamps designed to hold the unit to the equipment pad in h...

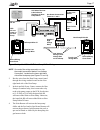

Page 8 the heat pump must be protected from back- siphoning of water. If there is any chance of back- siphoning, provide a check valve between the pool and the filter pump inlet. Arrangement of pool system components other than as illustrated in the preceding and following diagrams can affect the op...

Page 9 3.4 automatic flow control valve the inlet/outlet header of the ae-ti heat pump comes equipped with an internal automatic flow control valve. The automatic flow control valve maintains the proper flow through the heat pump at rates up to approximately 125 gpm (475 lpm). If the filter system f...

Page 10 figure 6. Two heat pump plumbing layout 12 inches min. Clearence around evap. 2" gate valve bypass flow meter pool pump to pool 12" note! Gate valves are optional on heater inlets but will help system balancing extend 12" past end heater inlet for hydraulic balancing minimum 2" pvc pipe 2" p...

Page 11 figure 8. Six heat pump plumbing layout 12 inches min. Clearance around evap. 12" 2" pvc to pool flow meter flow meter 4" gate valve bypass minimum 4"pvc pipe 4"pvc pipe note! Gate valves are required on heater inlets to help system balancing extend 16 to 20" past end heaters inlet for hydra...

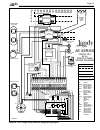

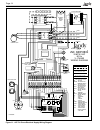

Page 12 4.1 general information wiring connections must be made exactly as shown in the wiring diagram found on the inside of the heat pump access panel (see figure 10 for single phase electrical wiring and figure 11 for 3-phase electrical wiring). The heat pump must include a definite means of grou...

Page 13 figure 10. Ae-ti single-phase electrical supply wiring diagram w no3 nc2 com 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 j-1harnessconnection j-2harnessconnection transformer primary (230 vac) secondary (24 vac) bk bk o r o bl bl y o w w br br remote air h20 t-4 t-3 t-7 fan j-2 j-1 digitalcont...

Page 14 no3 nc2 com 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 j-1harnessconnection j-2harnessconnection transformer primary (230 vac) secondary (24 vac) bk bk o o bl bl o w w br remote air h20 t-4 t-3 t-7 fan j-2 j-1 digitalcontrol t-8 t-1 t-2 t-6 t-5 a w/br bk/r w/v bk/w br bk/br w bl bk/g bk o w/g...

Page 15 4.2 main power electrical wiring to the heat pump must be in accordance with the latest edition of the national electric code (nec), ansi/national fire protection association (nfpa) 70 in the united states, and in canada, the canadian electrical code (cec) c22.1, unless local code requiremen...

Page 16 4.4 pump connection (auto-heat feature) (residential only) when connecting the time clock override parallel circuit, proper phasing must be maintained. Use 12 awg wire. Follow the wiring diagram on the service access panel of your heat pump, referring to the auto-contactor section (see figur...

Page 17 note one end of the wiring reserved to run into the conduit connection labeled “low voltage connection”, located on the lower right hand side of the heat pump (see figures 12 and 14). 2. Run the wires from the heat pump control panel through the wiring conduit located on the outer right hand...

Page 18 5.1 initial start-up precautions attention after starting the ae-ti heat pump, please note that there is a 5 minute delay before the compressor begins operation. The heat pump display will show the remaining delay time in minutes. Be sure that there is water in the pool and that the surface ...

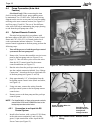

Page 19 figure 16. Main control panel 5.2.3 pool mode - (optional auto heat) if connected, the auto-heat mode allows the heat pump to monitor the temperature of the water 24 hours a day by turning the pool pump on and sampling the water temperature. When the water temperature drops below the program...

Page 20 5.3 operating features of units with optional chiller 5.3.1 pool mode - (normal cool) to operate in pool-cool mode, press pool . The led indicator will light and the unit will display the message pool temperature set-point = xx° for 5 seconds. After 5 seconds the display will read pool → hea...

Page 21 2. Press and hold the time/auto , up , and down arrow buttons for 5 seconds to enter the setup menu. The control panel will momentarily display setting 01 then it will display the language that is used for the display. Note in this mode, pressing and releasing the spa button will step though...

Page 22 on some installations, the piping from the heat pump to the pool is very short. The back pressure could be too low to trigger the pressure switch. If this happens, it may be necessary to install a directional fitting or elbows where the return line enters the pool. This will increase back pr...

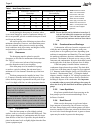

Page 23 test recommended level free chlorine or 1.0 to 3.0 ppm (3.0 to 5.0 spa) bromine 2.0 to 4.0 ppm (3.0 to 5.0 spa) ph 7.4 to 7.6 total alkalinity (ta) 80 to 120 ppm calcium hardness (ch) 200 to 400 ppm cyanuric acid 30 to 50 ppm total dissolved solids (tds) less than 2000 ppm copper 0 ppm * con...

Page 24 2. Keep all plants and shrubs trimmed and away from the heat pump. 3. Do not use this heat pump if any part has been under water. Immediately call a qualifi ed professional technician to inspect the heat pump and replace any part of the control system which has been submerged. The heat pump ...

Page 25 section 7. Professional maintenance and service 7.1 heat pump design the jandy air energy heat pump is one of the most efficient ways to heat a pool or spa. The heat pump transfers heat from the outside air to the pool or spa water by means of an internal heat exchanger. When the fan is turn...

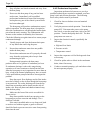

Page 26 symptom corrective action heat pump will not start, no control board display. Breaker or fuse may be tripped. Reset breaker or check fuse. If heat pump still does not run, call for service. Heat pump will not start, control board display working. Heat pump may be in delay count down of 5 min...

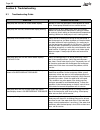

Page 27 diagnostic condition description low h2o flow low or restricted water flow through the heat pump. The external bypass valve is in the wrong position, or the water flow switch has malfunctioned. The water flow switch opens creating a fault and the heat pump shuts off. The lcd screen will disp...

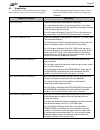

Page 28 diagnostic condition description low water temperature when the pool or spa temperature chills to 50°f or below there could be safety risks for anyone in the water. The water sensor will read this temperature and the control will shut off the chiller. The lcd display will show low h2o on the...

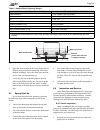

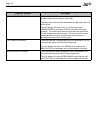

Page 29 key no. Description model no. Order part no. 1 top enclosure, jacket all r3000200 2 front panel, jacket 2000 r3000401 2 front panel, jacket 2500,3000 r3000403 3 service access panel all r3000500 4 control cover - smoked all r3000600 5 fan motor, 208 vac & 230 vac all r3000701 5 fan motor, 38...

Page 30 9.3 jandy ae-ti heat pumps exploded view 1 2 3 4 5 6 7 8 9 10 11 15 16 17 18 19 20 21 22 this 10k thermistor is used as a water temperature sensor when installed in the water inlet pipe and as an air temperature sensor when installed in the evaporator coil. 24, 26 13 12 re d w ire blue w ire...

Page 31 notes.

Page 32 notes.

Page 33.

Limited warranty thank you for purchasing jandy ® pool and spa products. Waterpik technologies (manufacturer of jandy products, including laars ® pool and spa heaters, air energy heat pumps, and clormatic electronic chlorine generators) warrants all parts to be free from manufacturing defects in mat...