- DL manuals

- Oki

- Storage

- C7200

- Service Manual

Oki C7200 Service Manual

Summary of C7200

Page 1

C7000 series color led page printer service manual this manual describes the procedures for the maintenance of the c7000 series of printers. The document is produced for maintenance personnel use. For details on the procedures for handling the c7000 series of printers, see its user documentation..

Page 2

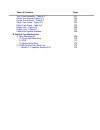

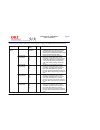

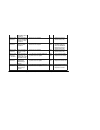

Table of contents page service guide - c7000 series preface 1 1 specifications 1.1 system configuration 2 1.2 printer configuration 3 1.3 option configuration 4 1.4 specifications 5 2 operation 2.0 operation 6 2.1 main board (crm pwb) 7 2.2 engine controller board (k71 pwb) 8 2.3 power units 9 2.4 m...

Page 3

Table of contents page 3.0 precaution in replacing parts 41 3.1 precaution in replacing parts 42 3.2 parts layout 43 ....Top cover assy 44 ....Printer unit 45 ....Cassette guide assy (l), (r) 46 ....Duplex unit 47 3.3 replacing parts 48 ....3.3.1 top cover 49 ....3.3.2 led assy / led assy spring 50 ...

Page 4

Table of contents page ....3.3.32 fuser latching handle (r) 80 ....3.3.33 main motor assy 81 ....3.3.34 main feeder drive motor 82 ....3.3.35 contact assy / left plate assy 83 ....3.3.36 low voltage power supply 84 ....3.3.37 high voltage power supply 85 ....3.3.38 main feed assy 86 ....3.3.39 casse...

Page 5

Table of contents page 6 troubleshooting procedures 6.1 before troubleshooting 123 6.2 checking before troubleshooting image problems 124 6.3 precautions in troubleshooting image problems 125 6.4 preparation for troubleshooting 126 6.5 troubleshooting 127 ....6.5.1 lcd messages list 128 ........Tabl...

Page 6

Table of contents page top cover assembly - table 8-2 161 printer unit chassis figure 8-3 162 printer unit chassis - table 8-3 163 paper tray guide - figure 8-4 164 paper tray guide - table 8-4 165 duplex unit - figure 8-5 166 duplex unit - table 8-5 167 centronics parallel interface 168 b 2nd/3rd t...

Page 7

Service guide - c7000 series chapter 0 introduction page: 1 preface this manual describes the procedures for the maintenance of the c7000 series of printers. The document is produced for maintenance personnel use. For details on the procedures for handling the c7000 series of printers, see its user ...

Page 8

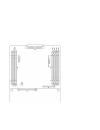

Service guide - c7000 series chapter 1 specifications page: 2 1.1 system configuration figure 1-1 shows the system configuration of the c7000 series of printers..

Page 10

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 11

Service guide - c7000 series chapter 1 specifications page: 3 1.2 printer configuration the inside of the printer is composed of the following: electrophotographic processor l paper paths l controller block (cu and pu) l operator panel l power units (high voltage unit and low voltage unit) l figure ...

Page 13

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 14

Service guide - c7000 series chapter 1 specifications page: 4 1.3 option configuration the following options are available for the c7000 series of printers. (1) 2nd tray / 3rd tray (2) duplex unit (3) expansion memory 64/128/256 mb.

Page 15

(4) internal hard disk (5) okilan 6200e nic copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 16

Service guide - c7000 series chapter 1 specifications page: 5 1.4 specifications (1) external dimensions height: 16.9 in. Width: 16.9 in. Length: 24.4 in. (2) weight 92.5 lbs. (3) papers type: ordinary paper, transparencies (recommended: mlohp01) size: postal card, legal 13" or 14", executive, a4, a...

Page 17

Image drum: 30,000 pages (continuous printing) (each of y, m, c and k) (11) parts replaced periodically fuser unit assy: every 60,000 pages transfer belt assy: equivalent of 60,000 pages (3 pages/job) (12) temperatures and relative humidities temperature temperature conditions fahrenheit celsius rem...

Page 18

Service guide - c7000 series chapter 2 operation page: 6 2.0 operation the c7000 series of printers, tandem color electrophotographic page printers, adopt technologies such as an led array, opc, dry single-component non-magnetic developing, roller transfer and heat-compression fusing. A black-writin...

Page 20

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 21

Service guide - c7000 series chapter 2 operation page: 7 2.1 main board (crm pwb) figure 2-2 provides the block diagram of the main control board (crm pwb)..

Page 23

(1) cpu the cpu is powerpc750, a 64-bit bus risc processor, which inputs an 80-mhz clk (=bus clk), and operates at 400mhz that is five times the input. (2) secondary cache sram sram is included as secondary cache of the cpu on the board. (3) rom rom is to be inserted into the three 168 pin dimm slot...

Page 24

Additional board: (connected to pci bus) / ethernet board copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 25

Service guide - c7000 series chapter 2 operation page: 8 2.2 engine controller board (k71 pwb).

Page 27

The engine control block (pu) is controlled by the engine controller board (k71 pwb) which consists of a cpu (msm66q577), general lsi chip, flash rom, eeprom, pulse motor drivers and a video memory (see figure 2-4). (1) cpu this, a 16-bit cpu with an ad converter containing 126-kbyte rom (oki msm66q...

Page 28

Service guide - c7000 series chapter 2 operation page: 9 2.3 power units there are a low voltage power unit consists of an ac filter circuit, low voltage power circuit and heater driver circuit, and a high voltage power unit organizes a high voltage power circuit. (1) low voltage power supply circui...

Page 29

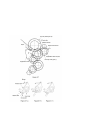

Service guide - c7000 series chapter 2 operation page: 10 2.4 mechanical processes figure 2-4 shows the mechanical processes of the c7000 series of printers..

Page 31

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 32

Service guide - c7000 series chapter 2 operation page: 11 2.4.1 electrphotographic process (1) electrophotographic processes (2) charging (3) exposure (4) developing (5) transfer (6) fusing (7) cleaning - waste toner area (8) cleaning - transfer belt copyright 1999, okidata, division of oki america,...

Page 33

Service guide - c7000 series chapter 2 operation page: 12 (1) electrophotographic processes (1) electrophotographic processes - the following is the outline of electrophotograhic process: (1) charging - dc voltage is applied to the charging roller and the surface of the opc drum is negatively and ev...

Page 34

Service guide - c7000 series chapter 2 operation page: 13 (2) charging (2) charging - negative dc voltage is applied to the charging roller contacting the surface of the opc drum. Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 35

Service guide - c7000 series chapter 2 operation page: 14 (3) exposure (3) exposure - the negatively charged surface of the opc drum is radiated with light from the led head. The negative charge of the radiated portions of the drum surface attenuates in response to the intensity of the light and a l...

Page 36

Service guide - c7000 series chapter 2 operation page: 15 (4) developing (4) developing - by the adhesion of toner to the latent electrostatic image on the drum surface, the image is changed to an image of its toner. The development is processed at the contact portion between the opc drum and the de...

Page 37

Service guide - c7000 series chapter 2 operation page: 16 (5) transfer (5) transfer - the transfer roller, which is made of conductive sponge, presses paper against the surface of the opc drum and brings the paper into intimate contact with the drum surface. The paper is placed on the drum surface, ...

Page 38

Service guide - c7000 series chapter 2 operation page: 17 (6) fusing (6) fusing - when passing through between the heat roller and the backup roller, the toner image transferred to the paper is fused into place by the application of heat and pressure to it. The built-in upper and lower halogen lamps...

Page 39

Service guide - c7000 series chapter 2 operation page: 18 (7) cleaning - waste toner area (7) cleaning - non-fused, residual toner on the opc drum is scraped with the cleaning blade and collected in the waste toner area of the toner cartridge. Copyright 1999, okidata, division of oki america, inc. A...

Page 40

Service guide - c7000 series chapter 2 operation page: 19 (8) cleaning - transfer belt (8) cleaning - residual toner on the transfer belt is scraped with the cleaning blade and collected in the waste toner box of the transfer belt unit. Copyright 1999, okidata, division of oki america, inc. All righ...

Page 41

Service guide - c7000 series chapter 2 operation page: 20 2.4.2 paper running process figure 2-5 shows the traveling of paper in the c7000 series of printers..

Page 42

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 43

Service guide - c7000 series chapter 2 operation page: 21 (1) paper feed from tray 1. The running of the feed motor in the arrow direction (a) drives the feed roller and the nudger roller. This operation feeds paper from the tray. 2. After the beginning of the paper turns the entrance cassette senso...

Page 45

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 46

Service guide - c7000 series chapter 2 operation page: 22 (2) paper feed from multi-purpose tray (mt) 1. The release lever usually pushes down the hopping plate to a position that turns microswitch on (figure 2-7-a). 2. The running of the motor in the (a) direction drives the mt feed roller and turn...

Page 48

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 49

Service guide - c7000 series chapter 2 operation page: 23 (3) transport belt 1. The running of the transport belt motor in the arrow direction (a) drives the transport belt. The belt unit sits with one transport roller immediately below each color's drum, and the transport belt between them. By the ...

Page 50

Service guide - c7000 series chapter 2 operation page: 24 (4) driving and up-and-down movements of i/d unit 1. The i/d unit driving and up-and-down movements are effected by a single-pulse motor. The running of the main motor in the arrow direction (a) turns the lever 1 to the left. Then, the lever ...

Page 53

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 54

Service guide - c7000 series chapter 2 operation page: 25 (5) fuser unit and paper ejection 1. A single-pulse motor drives the fuser unit and the eject rollers. In response to the running of the heat motor in the arrow direction (a), the heat roller turns. This roller fuses a toner image to paper by...

Page 56

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 57

Service guide - c7000 series chapter 2 operation page: 26 (6) duplex unit 1. When the duplex unit receives an instruction from the printer to print on both sides of a sheet of paper, the solenoid opens the separator after the completion of one side printing of a sheet of paper sent from the tray. Th...

Page 58

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 59

Service guide - c7000 series chapter 2 operation page: 27 2.5 sensor 2.5.1 paper related sensors 2.5.2 other sensors copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 60

Service guide - c7000 series chapter 2 operation page: 28 2.5.1 paper related sensors sensor function sensor status entrance mt sensor entrance cassette sensor detects the beginning of incoming paper to determine the timing for switching from hopping to transport. On: paper is present. Off: paper is...

Page 61

Duplex in sensor detects the beginning of paper that enters into the duplex unit, to determine the time taken until the reversed rollers turn in forward direction. On: paper is present. Off: paper is absent. Duplex rear sensor detects the beginning of reverses paper in the duplex unit. On: paper is ...

Page 62

Service guide - c7000 series chapter 2 operation page: 29 2.5.2 other sensors 1 paper empty sensor this sensor checks whether the paper cassette is empty. 2 paper near sensor this sensor checks whether the paper cassette is near empty. 3 mt paper empty sensor this sensor checks whether paper exists ...

Page 63

Upon correction of color misalignment, this sensor reads the alignment pattern printed at the right and left ends of the transfer belt (see section 2.13). Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 64

Service guide - c7000 series chapter 2 operation page: 30 2.6 color misalignment correction each of the c7000 series of printers is equipped with 4 id units and led heads, which can cause color misalignment. This color misalignment is automatically corrected as follows: (1) color alignment to be cor...

Page 65

Service guide - c7000 series chapter 2 operation page: 31 2.7 transfer control responds to environmental changes (room temperature and relative humidities) the c7000 series of printers measure the room temperature and the relative humidity using their room temperature sensors and humidity sensors. A...

Page 66

Service guide - c7000 series chapter 2 operation page: 32 2.8 paper jam detection the c7000 series of printers detect paper jams after power-on and during printing. When a paper jam occurs, the printing operation is immediately suspended. After the cover is opened and the jammed paper is removed, cl...

Page 67

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 68

Service guide - c7000 series chapter 2 operation page: 33 2.9 cover-open when the top cover of the printer is open, the cover-open microswitch turns off to cut the high voltage power and output of not less than 32v. At the same time, the cpu receives cvopn signals for indicating the status of the mi...

Page 70

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 71

Service guide - c7000 series chapter 2 operation page: 34 2.10 toner low detection structure l the toner low detection device consists of the stirring gear that revolves at a constant speed, the stirring bar, and the magnet on the stirring bar. The stirring bar turns in synchronization with the prot...

Page 72

Toner low condition the stirring bar reaches its highest position, then falls to its lowest position under its own weight because of the absence of toner resistance on the opposite side. In this situation, the bar-magnet contact time becomes long. By measuring the time, a toner low condition is dete...

Page 73

When the toner low condition is detected 20 consecutive times, toner low is determined. (the toner low message is displayed when about 500 a4 sheets at l 5% density have been printed after toner low had been detected.) when the toner full condition is detected 10 consecutive times, toner low is remo...

Page 74

Service guide - c7000 series chapter 2 operation page: 35 2.11 page size detection via the cam moves jointly with the paper guide of the paper cassette, the four tab pieces are driven according to the set position of the paper guide. Upon installation of the paper cassette, the microswitch detects t...

Page 75

Service guide - c7000 series chapter 2 operation page: 36 2.12 operation at power-on 2.12.1 self-diagnostic test (1) initial test the followings are automatically performed at power-on. (a) rom check (b) ram check (c) eeprom check (d) flash rom check (2) rom check rom is checked by calculating a has...

Page 76

Service guide - c7000 series chapter 2 operation page: 37 2.13 color misalignment detection reflection-type optical sensors for detecting color misalignment (z71-pcb) are mounted on the belt at the right and left ends, respectively, in front of the toner scraping (cleaning) blade which is at the bac...

Page 78

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 79

Service guide - c7000 series chapter 2 operation page: 38 2.14 version read of units replaced periodically the version of each of the i/d, fuser unit and belt unit which are replaced periodically is determined whether it is new or previous according to whether the fuse in it is conducting or out of ...

Page 80

Service guide - c7000 series chapter 2 operation page: 39 2.15 life count for units replaced periodically the life of each of the i/d, fuse unit and belt unit which are replaced periodically is counted as shown in the following table: unit name condition action i/d (image drum cartridge) the number ...

Page 81

Service guide - c7000 series chapter 2 operation page: 40 2.16 toner consumption detection the used toner amount is detected by counting the number of dots printed. The counting starts after toner low is removed. The sum of the counted values is stored in eeprom. Upon detection of toner low, the amo...

Page 82

Service guide - c7000 series chapter 3 disassembly page: 41 3.0 precaution in replacing parts this section describes the procedure for replacing the parts, assemblies and units in the field. The replacing procedure is given for detachment. To attach, use the reverse procedure. 3.1 precautions in rep...

Page 83

Service guide - c7000 series chapter 3 disassembly page: 42 3.1 precaution in replacing parts (1) before starting parts replacement, remove the ac cable and interface cable. (a) removing the ac cable i) turn off ("o") the power switch of the printer. Ii) disconnect the ac inlet plug of the ac cable ...

Page 84

Attached to the original positions. (7) when handling ics such as microprocessors, rom and ram, and circuit boards, follow standard electrostatic procedures. (8) do not place printed circuit boards directly on the equipment or floor. No. Service tools tools qty place of use remarks 1 no. 1-100 phili...

Page 85

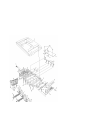

Service guide - c7000 series chapter 3 disassembly page: 43 3.2 parts layout.

Page 87

[top cover assy} [printer unit] [cassette guide assy (l), (r)] [duplex unit] copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 88

Service guide - c7000 series chapter 3 disassembly page: 44 top cover assy.

Page 90

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 91

Service guide - c7000 series chapter 3 disassembly page: 45 printer unit [printer unit 1/2].

Page 93

Printer unit 2/2].

Page 95

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 96

Service guide - c7000 series chapter 3 disassembly page: 46 cassette guide assy (l), (r).

Page 98

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 99

Service guide - c7000 series chapter 3 disassembly page: 47 duplex unit.

Page 102

Service guide - c7000 series chapter 3 disassembly page: 48 3.3 replacing parts this section described how to replace the parts and assemblies shown in the following disassembling system diagram. 3.3.1 top cover 3.3.2 led assy / led assy spring 3.3.3 top cover unit 3.3.4 control panel assy / control...

Page 103

3.3.20 color registration sensor assy 3.3.21 duplex guide assy 3.3.22 electrical chassis cooling fan 3.3.23 printer engine controller pwb 3.3.24 printer unit chassis 3.3.25 entrance cassette sensor actuator 3.3.26 entrance sensor pwb 3.3.27 entrance mt sensor actuator and entrance belt sensor actuat...

Page 104

3.3.43 duplex unit 3.3.44 guide rails (l) and (r) 3.3.45 duplex transport assembly 3.3.46 cu assy copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 105

Service guide - c7000 series chapter 3 disassembly page: 49 3.3.1 top cover (1) open the top cover assy. (2) remove the nine screws (1) to detach the top cover (2). Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 106

Service guide - c7000 series chapter 3 disassembly page: 50 3.3.2 led assy / led assy spring (1) open the top cover (1). (2) remove the three cables, and unhook the led assy (2) at two places to demount it (the two springs (3) become detached together with the led assy (2)). (3) remove the led conne...

Page 107

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 108

Service guide - c7000 series chapter 3 disassembly page: 51 3.3.3 top cover unit (1) remove the top cover (see section 3.3.1). (2) remove the rear cover (see section 3.3.10). (3) remove the left side cover (see section 3.3.12). (4) remove the right side cover (see section 3.3.13). (5) remove the shi...

Page 109

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 111

Service guide - c7000 series chapter 3 disassembly page: 52 3.3.4 control panel assy / control panel bezel / led control pwb / toner sensors / stacker full sensor / control panel / control panel tape harness / eject rollers (1) detach the control panel bezel placed in the control panel assy (2). (2)...

Page 112

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 113

Service guide - c7000 series chapter 3 disassembly page: 53 3.3.5 top cover handle / top cover latch / top cover latch spring (1) remove the two screws (1) to detach the top cover handle (2) and disengage the top cover latch (3) (at the same time, the two top cover latch springs (4) become detached)...

Page 115

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 116

Service guide - c7000 series chapter 3 disassembly page: 54 3.3.6 eject guide assy (1) remove the five screws (1) to detach the eject guide assy (2)..

Page 118

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 119

Service guide - c7000 series chapter 3 disassembly page: 55 3.3.7 cassette assy / front cover assy / front cover inner baffle (1) detach the cassette assy (1). (2) open the front cover (2), and disengage it at two places to detach it. (3) detach the front cover inner baffle (3)..

Page 120

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 121

Service guide - c7000 series chapter 3 disassembly page: 56 3.3.8 retard pad assy / retard pad assy spring (1) remove the cassette (1). (2) detach the retard pad assy (2) (at the same time, the spring (3) becomes detached)..

Page 123

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 124

Service guide - c7000 series chapter 3 disassembly page: 57 3.3.9 feed roller and nudger roller (1) remove the cassette (1). (2) unlatch and demount the feed roller (1). (3) unlatch and demount the nudger roller (2)..

Page 125

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 126

Service guide - c7000 series chapter 3 disassembly page: 58 3.3.10 rear cover (1) remove the left side cover (see section 3.3.12). (2) remove the four screws (2) to detach the rear cover (1). Note: when attaching the rear cover, take care not to allow the spring (3) to get caught in parts. Copyright...

Page 128

Service guide - c7000 series chapter 3 disassembly page: 59 3.3.11 face-up tray (1) open the face-up tray (1) in the arrow direction, and disengage it at two places to detach it..

Page 129

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 130

Service guide - c7000 series chapter 3 disassembly page: 60 3.3.12 left side cover (1) open the top cover (1). (2) open the front cover (2) and undo the screw (3). (3) remove the four screws (4) to detach the left side cover (5)..

Page 131

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 132

Service guide - c7000 series chapter 3 disassembly page: 61 3.3.13 right side cover (1) open the top cover (1). (2) open the front cover (2) and undo the screw (3). (3) remove the four screws (4) to detach the right side cover (5)..

Page 134

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 135

Service guide - c7000 series chapter 3 disassembly page: 62 3.3.14 multi-purpose tray assy / links multipurpose tray assy / multipurpose tray cover assy / links / multipurpose tray top cover / multipurpose tray drive gear (1) remove the left side cover (see section 3.3.12). (2) remove the right side...

Page 136

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 137

Service guide - c7000 series chapter 3 disassembly page: 63 3.3.15 drum contact assys (1) insert a flatblade screwdriver between the printer case and the drum contact assy (1) to demount the drum contact assy (1)..

Page 138

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 139

Service guide - c7000 series chapter 3 disassembly page: 64 3.3.16 registration roller assy (a) / registration drive gear (a) (1) remove the left side cover (see section 3.3.12). (2) remove the right side cover (see section 3.3.13). (3) remove the multipurpose tray (see section 3.3.14). (4) remove t...

Page 140

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 141

Service guide - c7000 series chapter 3 disassembly page: 65 3.3.17 registration roller assy (b) (1) remove the cassette assy. (2) open the front cover. (3) remove the right side cover (see section 3.3.13). (4) remove the left plate assy (see section 3.3.22). (5) remove the registration clutch (see s...

Page 143

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 144

Service guide - c7000 series chapter 3 disassembly page: 66 3.3.18 registration clutch and registration motor assy (1) remove the left side cover (see section 3.3.12). (2) remove the left plate assy (see section 3.3.22). (3) remove the connector and the e ring (1), then remove the two screws (3), th...

Page 145

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 146

Service guide - c7000 series chapter 3 disassembly page: 67 3.3.19 main cooling fan (1) unhook the connector (1), and remove the screw (2) and the cooling fan (3). Note: when attaching the cooling fan, observe its correct orientation..

Page 147

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 148

Service guide - c7000 series chapter 3 disassembly page: 68 3.3.20 color registration sensor assy (1) remove the two screws (1) and the two connectors to demount the color registration sensor assy (2). (2) remove the earth plate b (3)..

Page 149

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 151

Service guide - c7000 series chapter 3 disassembly page: 69 3.3.21 duplex guide assy (1) unlatch and demount the duplex guide (1)..

Page 153

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 154

Service guide - c7000 series chapter 3 disassembly page: 70 3.3.22 electrical chassis cooling fan (1) unscrew the screws (1) to remove the plate a (2). (2) unscrew the screws (3) to remove the shield plate b (4). (3) remove the printer engine controller pwb (see section 3.3.30). (4) unscrew the scre...

Page 155

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 156

Service guide - c7000 series chapter 3 disassembly page: 71 3.3.23 printer engine controller pwb (1) remove the right side cover (see section 3.3.13). (2) remove the left plate assy (see section 3.3.22). (3) remove the five screws (1) and all the connectors to demount the printer engine controller p...

Page 157

Service guide - c7000 series chapter 3 disassembly page: 72 3.3.24 printer unit chassis (1) unscrew the two screws (1) and remove the ac inlet (2). (2) unscrew the four black screws (3) and five screws (4) to detach the printer unit chassis (5). (3) unscrew the four black screws (6) and remove the l...

Page 159

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 160

Service guide - c7000 series chapter 3 disassembly page: 73 3.3.25 entrance cassette sensor actuator (1) remove the printer unit chassis (see section 3.3.24). (2) turn over the main chassis. (3) remove the two clamps with needlenose pliers to detach the entrance cassette sensor actuator (1)..

Page 161

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 162

Service guide - c7000 series chapter 3 disassembly page: 74 3.3.26 entrance sensor pwb (1) remove the registration roller assb (b) (see section 3.3.17). (2) remove the two screws (10 to detach the entrance sensor pwb (2). Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 164

Service guide - c7000 series chapter 3 disassembly page: 75 3.3.27 entrance mt sensor actuator and entrance belt sensor actuator (1) remove the entrance sensor pwb (r71) (see section 3.3.26). (2) unlatch and detach the entrance mt sensor actuator (1). (3) unlatch and detach the entrance belt actuato...

Page 165

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 166

Service guide - c7000 series chapter 3 disassembly page: 76 3.3.28 fuser exit roller (1) unscrew the two screws (1) to remove the duplex gate solenoid assy (2). (2) unscrew the screw (3) to remove the fuser exit roller contact (4). (3) remove the fuser drive gear -a (5) and fuser drive gear -a (6). ...

Page 167

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 169

Service guide - c7000 series chapter 3 disassembly page: 77 3.3.29 exit sensor assy (1) remove the fuser exit roller (see section 3.3.28). (2) remove the screw (1) and connector to detach the (red and blue) exit sensor assy (2)..

Page 170

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 172

Service guide - c7000 series chapter 3 disassembly page: 78 3.3.30 fuser latching handle (l) (1) remove the latching handle spring (1). (2) unscrew the screw (2) to detach the fuser latching handle (l) (3)..

Page 174

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 175

Service guide - c7000 series chapter 3 disassembly page: 79 3.3.31 belt motor assy (1) remove the fuser latching handle (r) (see section 3.3.32). (2) remove the two screws (1) to detach the two connectors (2). (3) detach the belt motor assy (3)..

Page 176

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 178

Service guide - c7000 series chapter 3 disassembly page: 80 3.3.32 fuser latching handle (r) (1) remove the printer unit chassis (see section 3.3.24). (2) remove the e ring (1). (3) remove the fuser latching handle spring (2) to detach the fuser latching handle (r) (3)..

Page 179

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 180

Service guide - c7000 series chapter 3 disassembly page: 81 3.3.33 main motor assy (1) remove the belt motor assy (see section 3.3.31). (2) remove all the connectors. (3) remove the four screws (1) to detach the main motor assy (2)..

Page 181

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 182

Service guide - c7000 series chapter 3 disassembly page: 82 3.3.34 main feeder drive motor (1) remove the two screws (1) to detach the main feeder drive motor (2). (2) unscrew the screw (3) to remove the main feeder drive motor bracket (4). (3) remove the main feeder drive motor gears a (5) and b (6...

Page 184

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 185

Service guide - c7000 series chapter 3 disassembly page: 83 3.3.35 contact assy / left plate assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the four screws (1) to detach the left plate assy (2). (3) remove the screw (3) to detach the contact assy (4)..

Page 186

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 187

Service guide - c7000 series chapter 3 disassembly page: 84 3.3.36 low voltage power supply (1) remove the printer unit chassis (see section 3.3.24). (2) unhook the connector (1). (3) unscrew the screw (2) to remove the earth cable (3). (4) unscrew the six screws (4) to detach the low voltage power ...

Page 188

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 189

Service guide - c7000 series chapter 3 disassembly page: 85 3.3.37 high voltage power supply (1) remove the contact assy (see section 3.3.35). (2) unhook the connector of the high voltage power supply (2). (3) remove the two screws (1) to detach the high voltage power supply (2) and the tape harness...

Page 191

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 192

Service guide - c7000 series chapter 3 disassembly page: 86 3.3.38 main feed assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the low voltage power supply and high voltage power supply (see sections 3.3.36 and 3.3.37). (3) unscrew the five screws (1) to remove the lower plat...

Page 194

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 195

Service guide - c7000 series chapter 3 disassembly page: 87 3.3.39 cassette / left guide assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the main feed assy (see section 3.3.38). (3) remove the three screws (1) to detach the left cassette guide assy (2). At the same time, th...

Page 197

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 198

Service guide - c7000 series chapter 3 disassembly page: 88 3.3.40 cassette / right guide assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the main feed assy (see section 3.3.38). (3) remove the five screws (1) to detach the right cassette guide assy (2). At the same time, t...

Page 199

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 201

Service guide - c7000 series chapter 3 disassembly page: 89 3.3.41 fuser unit (1) open the top cover (1). (2) push the right and left fuser levers (blue) (2) in the arrow direction to detach the fuser unit (3). Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 202

Service guide - c7000 series chapter 3 disassembly page: 90 3.3.42 belt unit (1) open the top cover (1). (2) remove the i/d unit. (3) push the lever (blue) (2) in the arrow direction, raise the handle (blue) and detach the belt unit (3)..

Page 203

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 204

Service guide - c7000 series chapter 3 disassembly page: 91 3.3.43 duplex unit (1) remove the cassette assy, the front cover assy and the front cover inner baffle. (2) unlatch the rear at the right and left, and pull the duplex unit 1 toward the front. Copyright 1999, okidata, division of oki americ...

Page 205

Service guide - c7000 series chapter 3 disassembly page: 92 3.3.44 guide rails (l) and (r) (1) remove the duplex unit (see section 3.3.43). (2) remove the six screws 1 to detach the guide rails (l) 2 and (r) 3. Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 207

Service guide - c7000 series chapter 3 disassembly page: 93 3.3.45 duplex transport assembly (1) turn over the duplex transport assy. (2) unscrew the three screws (1) and five screws (2) to detach the plate (3). (3) unplug the connector and detach the mold assy (4). (4) detach the two actuators (5)....

Page 209

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 210

Service guide - c7000 series chapter 3 disassembly page: 94 3.3.46 cu assy (1) pulling out controller board 1. Undo the two screws 1. 2. Pull the controller board 2 out. 3. Place the controller board 2 on a flat table. (2) detaching fan 1. Remove the connector 3. 2. Remove the two screws 4. 3. Detac...

Page 211

(3) removing the crm board.

Page 212

1. Unscrew the four screws (6) to remove the fan bracket (7). 2. Unscrew the four screws (8) to remove the plate support (9) and the guide rail a (10). 3. Unscrew the two screws (11) to remove the guide rail (11) . 4. Unscrew the two screws (12) and three screws (14), then detach the crm board (15)..

Page 214

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 215

Service guide - c7000 series chapter 4 adjustments page: 95 4.0 adjustments adjustments on the c7000 series of printers are made by key entry on the operator panel. In addition to a standard menu, there is a maintenance menu in each printer. Select the one that serves the purpose of intended adjustm...

Page 216

Service guide - c7000 series chapter 4 adjustments page: 96 4.1 maintenance modes and their functions 4.1.1 maintenance menu 4.1.2 engine maintenance menu 4.1.3 crm board adjustments copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 217

Service guide - c7000 series chapter 4 adjustments page: 97 4.1.1 maintenance menu the following menu category includes the maintenance menu category. The following can be set from this menu. Category item (1st line) value (2nd line) df functions power save mode enabled disabled * sets the power sav...

Page 218

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 219

Service guide - c7000 series chapter 4 adjustments page: 98 4.1.2 engine maintenance mode the engine maintenance mode includes three modes, levels 1 to 3. The level 1 aims to assist in checking the media transport systems and the basic operations of printing systems etc. The level 2, which sets the ...

Page 220

Service guide - c7000 series chapter 4 adjustments page: 99 4.1.2.1 operator panel operational descriptions about the self-diagnosis are premised on the following operator panel layout. Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 221

Service guide - c7000 series chapter 4 adjustments page: 100 4.1.2.2 general self-diagnosis mode (level 1) following is the menu of the general self-diagnosis mode. Switch scan test l led head test l motor and clutch tests l test pattern execution l nvm initialization l consumable counter display l ...

Page 222

Service guide - c7000 series chapter 4 adjustments page: 101 4.1.2.2.1 entering self-diagnosis mode (level 1) 1. Detach the main controller board. 2. While holding the 1 11 11 and 4 44 44 keys down at the same time, turn the power on to enter this mode. 3. "engine diag mode xx.Xx" appears in the upp...

Page 223

Service guide - c7000 series chapter 4 adjustments page: 102 4.1.2.2.2 exiting self-diagnosis mode 1. While "engine diag mode xx.Xx" is displayed, press the (0) key, or turn the power off and, after ten seconds, on again. Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 224

Service guide - c7000 series chapter 4 adjustments page: 103 4.1.2.3 switch scan test this self-diagnosis is used when the input sensor and the switch are checked. 1. Enter the general diagnosis mode, and press and hold the (1) and (5) keys down until "switch scan" appears on the upper display (the ...

Page 227

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 228

Service guide - c7000 series chapter 4 adjustments page: 104 4.1.2.4 motor and clutch test this self-check routine is used for testing the motor and clutch. 1. Go to the self-diagnosis (level 1) mode, and hold the (1) and (5) keys down until the upper display of "motor & clutch test" is brought up (...

Page 229

Unit name display driving constraints constraints display black-id motor remove all the ids (b, y, m and c) to drive the unit. Remove id yellow-id motor magenta-id remove all the ids (b, y, m and c) to drive the unit. Remove id motor remove all the ids (b, y, m and c) to drive the unit. Remove id cy...

Page 230

Registration motor - - main feeder motor remove the cassette 1 to drive the unit. Exit tray1 cassette registration clutch - - sensor shutter - - exit solenoid - - dup motor (option) - - dup rear clutch (option) - - cassette 2 motor (option) remove the cassette 2 to drive the unit. Exit tray2 cassett...

Page 231

Service guide - c7000 series chapter 4 adjustments page: 105 4.1.2.5 test printing this self-diagnostic routine is used when the internal test patterns of the pu are printed. Other test patterns are stored in the controller. 1. Go to the self-diagnosis (level 1) mode, and hold the (1) and (5) keys d...

Page 232

A value in the shaded section is initial. The set values are applicable only to this test mode (no writing into eeprom is performed.) l when the (3) key is pressed, with "print execute" on the lower display after step 2, the test printing is executed using the values designated in steps l 2 and 3. P...

Page 233

To suspend test printing, press key 7 77 77. At the start of or during test printing, if any alarm listed under the detail column in the table specified below is found, the corresponding alarm message appears on the operator panel and test printing is suspended. (for error details, see sec. 4.1.2.9 ...

Page 236

5. Steps 2 through 4 to be repeated on an as needed basis. 6. Touch the (4) key to end the test (the display is restored to step 1). Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 237

Service guide - c7000 series chapter 4 adjustments page: 106 4.1.2.6 nvm initialization the self-diagnosis is used to initialize non-volatile memory. 1. Enter the self-diagnosis (level 1) mode, and continue to press the (1) and (5) keys until "nv-ram initial" appears on the upper display (the (1) ke...

Page 238

Point x-axis magenta led cyan led the led head (yellow/magenta/cyan). Inch registration set. Point y-axis (left) yellow led magenta led cyan led initializes the y-axis left-correction value for the led head (yellow/magenta/cyan). 0 1/1200 inch registration set point y-axis (right) yellow led magenta...

Page 239

Service guide - c7000 series chapter 4 adjustments page: 107 4.1.2.7 consumable counter display the self-diagnosis is used to indicate the consumable consumption status. 1. After entering the general self-diagnosis mode, hold the (1) and (5) keys down until "consumable status" appears on the upper d...

Page 241

Service guide - c7000 series chapter 4 adjustments page: 108 4.1.2.8 consumable counter display - continuos the self-diagnosis is used to indicate the consumable life-cycle consumption status. The consumable life-cycle consumption status, a count not initialized even after the replacement of a consu...

Page 242

Service guide - c7000 series chapter 4 adjustments page: 109 4.1.2.9 error messages and their details error message details black drum up/down error black id up/down error black drum unit fuser cut error black id unit fuse cut error black toner sensor error black toner sensor error black led head er...

Page 243

Eeprom sum check error eeprom sum check error eeprom timeout eeprom timeout error env temp sensor error env temp sensor error engine life over engine life error f/w lost control f/w has lost its control front feeder stage position front feeder stage position error front cover open front cover is ope...

Page 244

Jam duplex reversal duplex unit reversal jam lower heater low temper lower heater low-temperature error lower heater high temper lower heater high-temperature error lower heater open error lower heater thermistor open-circuit error lower heater short error lower heater thermistor short-circuit error...

Page 245

Paper near end tray1 paper is going out in tray1 paper near end tray2 paper is going out in tray2 paper near end tray3 paper is going out in tray3 paper near end front feeder paper is going out at front feeder paper near end tray4 (px703) paper is going out in tray4 paper near end tray5 (px703) pape...

Page 246

Infeed: tray1 tray1 hopping error infeed: tray2 tray2 hopping error infeed: tray3 tray3 hopping error infeed: front feeder front feeder hopping error infeed: duplex duplex unit hopping error infeed: tray4 (px703) tray4 hopping error infeed: tray5 (px703) tray5 hopping error inpath --- information of...

Page 247

Service guide - c7000 series chapter 4 adjustments page: 110 4.1.3 crm board adjustments destination setting: the crm board, a main board, is a common rom among destinations. When using the board for maintenance, its destination must be set using the system maintenance mode. Placing printer in syste...

Page 248

Service guide - c7000 series chapter 4 adjustments page: 111 4.1.3.1 short plug settings the crm board has five short plugs that can be set as follows: short plug (we1, 3, 5 and 7) sets flash rom dimm to connect we signals. (1-2 short: disconnects we signals; 2-3 short: connects we signals.) factory...

Page 249

Service guide - c7000 series chapter 4 adjustments page: 112 4.1.3.2 printing menu reports menu map printing the program versions, the controller block configuration and other configurations and settings of the printer are printed. Operation: (press of switches) without hdd: "0" --> "3" --> "3" with...

Page 250

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 251

Service guide - c7000 series chapter 4 adjustments page: 113 4.2 adjustments after parts replacement adjustments to be implemented after each part replacement is described below. Adjustment and correction of color registration are always required for each part replacement. Replaced part adjustment l...

Page 252

Service guide - c7000 series chapter 4 adjustments page: 114 4.2.1 precautions in replacing engine controller board when replacing the engine controller board (71k pwb), remove the eeprom from the board and mount it on a new board (for errors other than those of engine eeprom). When the "service cal...

Page 253

Service guide - c7000 series chapter 4 adjustments page: 115 4.2.2 precautions in replacing eeprom when the eeprom is not removed from the board and placed on the new board at the time of (engine controller board (71k pwb)) replacement, or when the eeprom is replaced with new one, the version read (...

Page 254

Black impressions cyan impressions magenta impressions yellow impressions total number of pages printed the number of pages printed after the installation of a new id unit. Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 255

Service guide - c7000 series chapter 4 adjustments page: 116 4.2.3 eeprom replacement after crm board replacement to replace the crm board, remove the eeprom on the board and include the eeprom on a newly installed board (to allow a new board to inherit user-defined settings and font installation in...

Page 256

Service guide - c7000 series chapter 4 adjustments page: 117 4.3 color balance adjustment color balance has been adjusted appropriately when a printer is shipped from the plant. However, it may be out of the appropriate balance during use. In such a case, color balance should be modified. Note: dens...

Page 257

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 258

Service guide - c7000 series chapter 5 period maintenance page: 118 5.0 periodic maintenance 5.1 parts replaced periodically 5.2 cleaning 5.3 cleaning led lens array 5.4 cleaning pickup roller copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 259

Service guide - c7000 series chapter 5 period maintenance page: 119 5.1 parts replaced periodically it is recommended that the following parts be periodically replaced, as specified, by users (when they are not replaced, the print quality is not assured and printer problems may result. Parts name ti...

Page 260

Service guide - c7000 series chapter 5 period maintenance page: 120 5.2 cleaning clean the inside and outside of the printer with waste and a small vacuum cleaner (hand cleaner) as the case may be. Caution! Do not touch the terminals of the image drums, the led lens array and the led head connector....

Page 261

Service guide - c7000 series chapter 5 period maintenance page: 121 5.3 cleaning led lens array while white belts or lies (voice, light areas) run the length of a printed page, clean the led lens array. Caution! Be sure to use the led head cleaner to clean the led lens array (the led head cleaner is...

Page 262

Service guide - c7000 series chapter 5 period maintenance page: 122 5.4 cleaning pickup roller when lines run the length of a printed paper, clean the pick up roller. Caution! Use a soft cloth so as not to damage the roller surface. Copyright 1999, okidata, division of oki america, inc. All rights r...

Page 263

Service guide - c7000 series chapter 6 troubleshooting procedures page: 123 6.1 before troubleshooting (1) check the basic check items covered in the user's manual. (2) obtain as much information about problems from users as you can. (3) perform inspections in conditions close to those in which prob...

Page 264

Service guide - c7000 series chapter 6 troubleshooting procedures page: 124 6.2 checking before troubleshooting image problems (1) is the printer's operating environment correct? (2) have the consumables (toner, drum cartridges) been properly replaced? (3) is the correct media being used? Refer to t...

Page 265

Service guide - c7000 series chapter 6 troubleshooting procedures page: 125 6.3 precautions in troubleshooting image problems (1) do not touch the surface of the opc drum with hands or allow foreign matter to contact it. (2) do not expose the opc drum to direct sunlight. (3) do not touch the fuser u...

Page 266

Service guide - c7000 series chapter 6 troubleshooting procedures page: 126 6.4 preparation for troubleshooting (1) control panel display the failure status of the printer is provided on the lcd (liquid crystal display) of the operator panel. Take appropriate corrective actions according to messages...

Page 267

Service guide - c7000 series chapter 6 troubleshooting procedures page: 127 6.5 troubleshooting when problems occur in the printer, troubleshoot them using the following procedure: 6.5.1 lcd messages list copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 268

Service guide - c7000 series chapter 6 troubleshooting procedures page: 128 6.5.1 lcd messages list when detects unrecoverable errors, the printer provides the following service call error message: service call nnn : error note! Nnn is an error code. While a service call appears, an error code accom...

Page 269

Service guide - c7000 series chapter 6 troubleshooting procedures page: 129 table 6-1-1 operator alarms (1/2) message cause error description solutions service call 001: error ~ 011: error cpu exception is the error message displayed again? Is the error message displayed again? Yes yes turn the prin...

Page 270

Replace the crm board. (the eeprom needs replacement). Service call 034: error ram configuration error. The cu ram installation order was not followed. Is the installation order followed? Can the printer recover from the error by replacing the ram dimms? No yes no correct the installation order. Rep...

Page 271

Board. (the eeprom needs replacement). Service call 041: error u flash error. On-cu-board flash rom error does the error message appear again? Yes replace the crm board. (the eeprom needs replacement). Service call 050: error operator panel error does the error message appear again? Yes see the flow...

Page 272

Read/write when turned on. Service call 104: error error detected at engine eeprom checksum when turned on. Does the error repeat? Yes replace the engine control board (71k). Service call 105: error eeprom not detected when turned on. No eeprom? Does the error repeat? Yes yes confirm the existence o...

Page 273

Service guide - c7000 series chapter 6 troubleshooting procedures page: 130 6.5.2 lcd preparation for troubleshooting 1) display on operation panel the failure status of the printer is provided on the lcd (liquid crystal display) of the operator panel. Perform appropriate troubleshooting according t...

Page 274

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 275

Service guide - c7000 series chapter 6 troubleshooting procedures page: 131 (1) the printer does not operate properly after power-on..

Page 277

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 278

Service guide - c7000 series chapter 6 troubleshooting procedures page: 132 (2) jams 2-1 paper loading jam (1st tray) 2-2 paper loading jam (multi-purpose tray) 2-3 paper feed jam 2-4 paper exit jam 2-5 duplex jam copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 279

Service guide - c7000 series chapter 6 troubleshooting procedures page: 133 (2)-1 paper loading jam (1st tray).

Page 281

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 282

Service guide - c7000 series chapter 6 troubleshooting procedures page: 134 (2)-2 paper loading jam (multi-purpose tray).

Page 283

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 284

Service guide - c7000 series chapter 6 troubleshooting procedures page: 135 (2)-3 paper feed jam.

Page 286

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 287

Service guide - c7000 series chapter 6 troubleshooting procedures page: 136 (2)-4 paper exit jam.

Page 288

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 290

Service guide - c7000 series chapter 6 troubleshooting procedures page: 137 (2)-5 duplex jam.

Page 291

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 293

Service guide - c7000 series chapter 6 troubleshooting procedures page: 138 (3) paper size error.

Page 294

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 296

Service guide - c7000 series chapter 6 troubleshooting procedures page: 139 (4) image drum unit (id) up-and-down operation error copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 297

Service guide - c7000 series chapter 6 troubleshooting procedures page: 140 (5) fusing unit error.

Page 298

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 299

Service guide - c7000 series chapter 6 troubleshooting procedures page: 141 (6) motor fan error copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 300

Service guide - c7000 series chapter 6 troubleshooting procedures page: 142 6.5.3 troubleshooting image problems when the printout images are not satisfactory, follow the troubleshooting steps listed below. Printout problem flowchart no. Light or faded image on whole page, or color misalignment on w...

Page 301

(d) vertical black belt or line (e) defective image of regular interval (f) vertical white belt or line copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 302

Service guide - c7000 series chapter 6 troubleshooting procedures page: 143 (1) light or faded image on whole page, or color misalignment on whole page (figure 6-2 a).

Page 304

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 305

Service guide - c7000 series chapter 6 troubleshooting procedures page: 144 (2) dirty background (figure 6-2 b).

Page 307

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 308

Service guide - c7000 series chapter 6 troubleshooting procedures page: 145 (3) blank page (figure 6-2 c).

Page 310

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 311

Service guide - c7000 series chapter 6 troubleshooting procedures page: 146 (4) vertical belt or line (black or color belt, or black or color line) (figure 6-2 d) copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 313

Service guide - c7000 series chapter 6 troubleshooting procedures page: 147 (5) vertical white belt or line, or uneven-color belt or line (figure 6-2 f).

Page 314

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 315

Service guide - c7000 series chapter 6 troubleshooting procedures page: 148 (6) poor fusing (ink spreads or peels when touched with fingers).

Page 317

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 318

Service guide - c7000 series chapter 6 troubleshooting procedures page: 149 (7) defective image of regular interval (see figure 6-2 e) interval problem troubleshooting 3.709 inches image drum replace the image drum unit. 2.504 inches developing roller replace the image drum unit. 2.276 inches toner ...

Page 319

Service guide - c7000 series chapter 6 troubleshooting procedures page: 150 (8) missing image.

Page 321

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 322

Service guide - c7000 series chapter 6 troubleshooting procedures page: 151 (9) color misalignment.

Page 326

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 327

Service guide - c7000 series chapter 6 troubleshooting procedures page: 152 (10) color different from original one.

Page 329

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 330

Service guide - c7000 series chapter 6 troubleshooting procedures page: 153 figure 6-3 copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 331

Service guide - c7000 series chapter 7 wiring diagram page: 154 7.1 resistance check.

Page 335

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 337

Service guide - c7000 series chapter 7 wiring diagram page: 155 7.2 program/font rom location (1) printer engine controller pwb (71k-pwb).

Page 339

(2) main controller pwb.

Page 341

Note! The option sdram dimms must be inserted in descending order of the parenthesized type no. Appeared on the label of each dimm into the slots 1, 3, 2 and 4 (see the user documentation for details). (3) led control pwb (y71-pwb) (4) duplex control pwb (v71-pwb).

Page 342

(5) control panel pwb (x71-pwb) (6) n71-pwb (7) entrance sensor pwb (r71-pwb).

Page 343

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 344

Service guide - c7000 series chapter 8 parts list page: 156 main assembly - figure 8-2.

Page 346

Figure 8-1-1/3.

Page 348

Figure 8-1-2/3 figure 8-1-3/3 copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 349

Service guide - c7000 series chapter 8 parts list page: 157 main assembly - table 8-1 (1/3) no. Part # name qty remarks 1 40864601 front cover assy 1 2 41042501 front cover inner baffle 1 3 40866701 cassette assy 1 4 41438401 retard pad assy 1 5 1 6 40864301 rear cover 1 7 41374902 face up stacker a...

Page 350

31 41303901 belt unit 1 copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 351

Service guide - c7000 series chapter 8 parts list page: 158 main assembly - table 8-1 (2/3) no. Part # name qty remarks 32 41304105 image drum - yellow 1 41304106 image drum - magenta 1 41304107 image drum - cyan 1 41304108 image drum - black 1 33 41304205 toner - yellow 1 41304206 toner - magenta 1...

Page 352

Service guide - c7000 series chapter 8 parts list page: 159 main assembly - table 8-1 (3/3) no. Part # name qty remarks 34 41377401 plate - indicator 1 35 41356009 pcb assy - crm 1 36 eeprom (cu) 1 37 41469503 board - tny 1 38 39 41437418 board - memory 64mb 1 1200 dpi 40 41437419 board - memory 128...

Page 353

Service guide - c7000 series chapter 8 parts list page: 160 top cover assembly - figure 8-2.

Page 355

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 356

Service guide - c7000 series chapter 8 parts list page: 161 top cover assembly - table 8-2 no. Part # name qty remarks 1 40859701 top cover 1 2 41072401 led assy (1200 dpi) 4 1200 dpi 2 41072402 led assy (600 dpi) 4 600 dpi 3 40861001 led assy spring 8 4 41257901 led control pwb (y71) 1 5 40365404 s...

Page 357

Service guide - c7000 series chapter 8 parts list page: 162 printer unit chassis figure 8-3.

Page 361

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 362

Service guide - c7000 series chapter 8 parts list page: 163 printer unit chassis - table 8-3 no. Part # name qty remarks 1 41189701 drum contact assy 4 2 40844301 registration roller assy (a) 1 3 40844303 registration roller assy (b) 1 4 40845401 registration drive gear 1 5 41187101 registration clu...

Page 363

33 40841401 fuser latching handle (r) 1 34 35 40847301 main motor assy 1 36 40846001 main feeder drive motor 1 37 40848501 main feeder drive gear a 1 38 40848601 main feeder drive gear b 1 39 41303601 left plate assy 1 40 40850201 contact assy 1 41 40737401 power - unit ac - dc switching (115v) 1 41...

Page 364

Service guide - c7000 series chapter 8 parts list page: 164 paper tray guide - figure 8-4.

Page 366

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 367

Service guide - c7000 series chapter 8 parts list page: 165 paper tray guide - table 8-4 no. Part # name qty remarks 1 40839801 main feed assy 1 2 40371301 feed roller 1 3 40313201 nudger roller 1 4 40325401 main feeder drive gear 1 5 40839001 left cassette guide assy 1 6 40839401 right cassette gui...

Page 368

Service guide - c7000 series chapter 8 parts list page: 166 duplex unit - figure 8-5.

Page 370

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 371

Service guide - c7000 series chapter 8 parts list page: 167 duplex unit - table 8-5 no. Part # name qty remarks 1 41305301 duplex transport assy 1 2 screw (sp3x10) 2 3 screw (t3x10) 6 4 screw (t3x8) 15 5 screw (m3x6) 3 6 70037201 duplex unit 1 copyright 1999, okidata, division of oki america, inc. A...

Page 372

Service guide - c7000 series chapter a centronics parallel interface page: 168 centronics parallel interface 1) connector printer side : l 36-pin receptacle (single port) type 57re-40360-830b-d29a (made by daiichi denshi), or equivalent cable side : l 36-pin plug type 57-30360 (made by daiichi densh...

Page 374

Connector pin arrangement l 4) signal level low : 0 v to +0.8 v l high : +2.4 v to 5.0 v l 5) specifications item description mode compatibility mode, nibble mode, ecp mode data bit length 8 bits compatibility mode, 4 bits: nibble mode, 9 bits: ecp mode control handshaking control is performed in ea...

Page 375

B) on-line (off-line switching timing by on-line sw) c) off-line (on-line switching by on-line sw).

Page 376

D) nlnit timing (when set to the effective input prime signal) nibble mode l conforms to ieee 1284 specification compliant ecp mode l conforms to ieee 1284 specification compliant copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 377

Service guide - c7000 series chapter b 2nd/3rd tray maintenance page: 169 1. Parts replacement 1.1 cove ridle roller assy 1.2 pcb 1.3 feeder drive assy copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 378

Service guide - c7000 series chapter b 2nd/3rd tray maintenance page: 170 1.1 cover idle roller assy (1) unscrew the four screws (1) to remove the cover side (2) and the plate cover pcb (3). (2) unscrew the two screws (4) to demount the cover idle roller assy (5)..

Page 379

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 380

Service guide - c7000 series chapter b 2nd/3rd tray maintenance page: 171 1.2 pcb (1) unscrew the four screws (1) to remove the plate cover pcb (2). (2) remove the connectors (at seven places) and the two screws (3), then demount the board (4)..

Page 381

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 382

Service guide - c7000 series chapter b 2nd/3rd tray maintenance page: 172 1.3 feeder drive assy (1) remove the four screws (1), six screws (2) and the eight screws (3). (2) remove the cover sides (4) and (5), the plate cover pcb (6) and the frame hopping assy (7). (3) remove the e ring (8), the clut...

Page 384

Copyright 1999, okidata, division of oki america, inc. All rights reserved..

Page 385

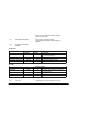

Service guide - c7000 series chapter b 2nd/3rd tray maintenance page: 173 2. C7000 2nd/3rd tray parts list.

Page 388

Chapter 6 troubleshooting procedures page: 174 table 6-1-1 operator alarms (2/2) message cause error description solutions service call 125: error error detected at the mt home position. 1) is the error message displayed? 2) does the error repeat? Yes yes turn off/on the printer. Replace the mt. Ser...

Page 389

Service call 172: error 176: error high temperature error detected at thermistor. 1) is the error message displayed? 2) does the error repeat? Yes yes turn off/on the printer. Replace the thermistor and turn off the printer. Leave it for 30 mins. Service call 173: error 177: error low temperature er...

Page 390

Paper reverse in the duplex unit. Duplex unit, or replace it. Check duplex 371: paper jam paper jam detected at the duplex unit 1) is a paper jammed in the duplex unit? Yes no remove the paper jam. Check the duplex unit, or replace it. Check duplex 372: paper jam paper jam detected during paper feed...

Page 391

410: yellow 411: magenta 412: cyan 413: black the four colors is running short. Almost empty? 2) does the toner sensor of the specified cartridge operate normally? No toner kit. Replace the toner sensor for the specified color. Remove printed papers 480: stacker full the stacker for ejected papers i...