- DL manuals

- Oki

- Storage

- C7400n

- Service Manual

Oki C7400n Service Manual

Summary of C7400n

Page 1

41316401th rev.4a 1 / 186 c7000 series color led page printer service manual okidata 01-23-2001 based on rev.4.

Page 2

41316401th rev.4 2 / 1 2000-05-29 issue e4 yamazaki 2 2000-05-31 e4 murakami 3 2000-12-04 nip9 yamazaki 4 2000-12-15 nip9 yamazaki rev.No. Date no. Corrected items page description of change person in charge document revision history.

Page 3: Preface

41316401th rev.4 3 / preface this manual describes the procedures for the maintenance of the c7000 series of printers. The document is produced for maintenance personnel use. For details on the procedures for handling the c7000 series of printers, see its user documentation. Note! • the descriptions...

Page 4: Contents

41316401th rev.4 4 / contents 1. Configurations ......................................................................................... 7 1.1 system configuration ....................................................................................................... 7 1.2 printer configuration ......

Page 5

41316401th rev.4 5 / 3.3.20 color registration sensor assy ........................................................................ 70 3.3.21 duplex guide assy ........................................................................................... 71 3.3.22 electrical chassis cooling fan ..........

Page 6

41316401th rev.4 6 / 6. Troubleshooting procedures ....................................................... 123 6.1 before troubleshooting ................................................................................................ 123 6.2 checking before troubleshooting image problems .............

Page 7

41316401th rev.4 7 / m m m m m m m m led head centronics i/f usb i/f 2 × option slots j unction board pulse motor engine control lo w v o ltage p o w e r unit fuser unit high v o ltage p o w e r unit 2nd/3rd t ra y duple x unit belt unit , switches and ther mistors> p aper siz e sensor (4 bits) p ap...

Page 8

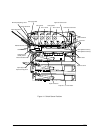

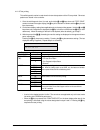

41316401th rev.4 8 / 1.2 printer configuration the inside of the printers is composed of the followings: • electrophotographic processor • paper paths • controller block (cu and pu) • operator panel • power units (high voltage unit and low voltage unit) figure 1-2 shows the printer configuration. Fi...

Page 9

41316401th rev.4 9 / 1.3 option configuration the following options are available for the c7000 series of printers. (1) 2nd tray/ 3rd tray (2) duplex unit (3) expansion memory 64/128/256 mb (4) internal hard disk (5) okilan 6200e nic.

Page 10

41316401th rev.4 10 / 1.4 specifications (1) external dimensions height: 16.9 in. Width: 16.9 in. Length: 24.4 in. (2) weight 92.5 lbs. (3) papers type: ordinary paper, transparencies (recommended: mlohp01) size: postal card, legal 13" or 14", executive, a4, a5, b5, a6 (only the 1st tray and the fro...

Page 11

41316401th rev.4 11 / (12) temperatures and relative humidities temperature temperature condition temperature (˚f) temperature (˚c) remark operation 50 to 89.6 10 to 32 17 to 27˚c (temperatures to assure full color print quality) non-operation 32 to 109.4 0 to 43 power-off storage (max. One year) -1...

Page 12

41316401th rev.4 12 / 2. Operation description the c7000 series of printers, tandem color electrophotographic page printers, adopt technologies such as an led array, opc, dry single-component non-magnetic developing, roller transfer and heat-compression fusing. A black-writing printing method by she...

Page 13

41316401th rev.4 13 / 2.1 main board (crm pwb) figure 2-2 provides the block diagram of the main control board (crm pwb). Figure 2-2 14.31818mhz cr ystal resonator cy2292 cy2308 delay cdc516 sdram dimm × 4 rom dimm × 3 fet sw 162212 flash rom imi530 fluctuation circuit lvc244 lvc245 eeprom c2 lsi mh...

Page 14

41316401th rev.4 14 / (1) cpu the cpu is powerpc750, a 64-bit bus risc processor, which inputs an 80-mhz clk (= bus clk), and operates at 400mhz that is five times the input. (2) secondary cache sram sram is included as secondary cache of the cpu on the board. (3) rom rom is to be inserted into the ...

Page 15

41316401th rev.4 15 / figure 2-3 the engine control block (pu) is controlled by the engine controller board (k71 pwb) which consists of a cpu (msm66q577), general lsi chip, flash rom, eeprom, pulse motor drivers and a video memory (see figure 2-4). (1) cpu this, a 16-bit cpu with an ad converter con...

Page 16

41316401th rev.4 16 / output voltage use for +3.8v cu lsi +3.8v led head +5 v logic circuit power supply, pu cpu +34 v motor, drive voltage and power supply voltage for high voltage power supply +12 v op amp, high voltage power supply (2) high voltage power unit this circuit generates the following ...

Page 17

41316401th rev.4 17 / 2.4 mechanical processes figure 2-4 shows the mechanical processes of the c7000 series of printers. Paper eject roller pape ejection (face down) power supply charging roller cleaning blade heat roller paper eject roller fusing backup roller control signals led head developing r...

Page 18

41316401th rev.4 18 / 2.4.1 electrophotographic process (1) electrophotographic process the following is the outline of electrophotographic process: 1 charging dc voltage is applied to the charging roller and the surface of the opc drum is negatively and evenly charged. 2 exposure the led head, unde...

Page 19

41316401th rev.4 19 / (3) exposure the negatively charged surface of the opc drum is radiated with light from the led head. The negative charge of the radiated portions of the drum surface attenuates in response to the intensity of the light and a latent electrostatic image responsive to the potenti...

Page 20

41316401th rev.4 20 / 2 the developing blade removes excess toner from the developing roller and a thin layer of toner remains and forms on the developing roller. 3 the toner is drawn by the latent electrostatic image at the contact portion between the opc drum and the developing roller. The latent ...

Page 21

41316401th rev.4 21 / (5) transfer the transfer roller, which is made of conductive sponge, presses paper against the surface of the opc drum and brings the paper into intimate contact with the drum surface. The paper is placed on the drum surface, and positively (opposite to the charge of the toner...

Page 22

41316401th rev.4 22 / (7) cleaning non-fused, residual toner on the opc drum is scraped with the cleaning blade and collected in the waste toner area of the toner cartridge. Cleaning blade waste toner box (8) cleaning residual toner on the transfer belt is scraped with the cleaning blade and collect...

Page 23

41316401th rev.4 23 / 2.4.2 paper running process figure 2-5 shows the traveling of paper in the c7000 series of printers. Figure 2-5 paper paths c m y k belt unit multipurpose tray face-down stacker fuser transfer roller × 4 backup roller high voltage power supply heat roller eject roller low volta...

Page 24

41316401th rev.4 24 / (1) paper feed from tray 1. The running of the feed motor in the arrow direction (a) drives the feed roller and the nudger roller. This operation feeds paper from the tray. 2. After the beginning of the paper turns the entrance cassette sensor on, the paper is advanced a fixed ...

Page 25

41316401th rev.4 25 / (2) paper feed from multipurpose tray (mt) 1. The release lever usually pushes down the hopping plate to a position that turns microswitch on (figure 2-7-a). 2. The running of the motor in the (a) direction drives the mt feed roller and turns the cam. The cam pushes the release...

Page 26

41316401th rev.4 26 / (3) transport belt 1. The running of the transport belt motor in the arrow direction (a) drives the transport belt. The belt unit sits with one transport roller immediately below each color’s drum, and the transport belt between them. By the application of a fixed voltage, the ...

Page 27

41316401th rev.4 27 / (4) driving and up-and-down movements of i/d unit 1. The i/d unit driving and up-and-down movements are effected by a single-pulse motor. The running of the main motor in the arrow direction (a) turns the lever 1 to the left. Then, the lever 2 that was lifted by the lever 1 low...

Page 28

41316401th rev.4 28 / plate pin spring up/down sensor board figure 2-9-c figure 2-9-d figure 2-9-e.

Page 29

41316401th rev.4 29 / (5) fuser unit and paper ejection 1. A single-pulse motor drives the fuser unit and the eject rollers. In response to the running of the heat motor in the arrow direction (a), the heat roller turns. This roller fuses a toner image to paper by heat and pressure. 2. At the same t...

Page 30

41316401th rev.4 30 / (6) duplex unit 1. When the duplex unit receives an instruction from the printer to print on both sides of a sheet of paper, the solenoid opens the separator after the completion of one side printing of a sheet of paper sent from the tray. The path is switched to that to the du...

Page 31

41316401th rev.4 31 / 2.5 sensor 2.5.1 paper related sensors paper eject roller heat roller c drum stacker full sensor k drum y drum m drum entrance belt sensor mt feed roller pinch roller 2 exit sensor backup roller duplex in sensor duplex roller duplex rear sensor duplex feed rollers duplex front ...

Page 32

41316401th rev.4 32 / 2.5.2 other sensors 1 paper empty sensor this sensor checks whether the paper cassette is empty. 2 paper near sensor this sensor checks whether the paper cassette is near empty. 3 mt paper empty sensor this sensor checks whether paper exists in the front feeder. 4 mt hopping sw...

Page 33

41316401th rev.4 33 / 2.6 color misalignment correction each of the c7000 series of printers is equipped with 4 id units and led heads, which can cause color misalignment. This color misalignment is automatically corrected as follows: (1) color alignment to be corrected 1 color misalignment in x-axi...

Page 34

41316401th rev.4 34 / 2.8 paper jam detection the c7000 series of printers detect paper jams after power-on and during printing. When a paper jam occurs, the printing operation is immediately suspended. After the cover is opened and the jammed paper is removed, closing the cover resumes the printing...

Page 35

41316401th rev.4 35 / 2.9 cover-open when the top cover of the printer is open, the cover-open microswitch turns off to cut the high voltage power and output of not less than 32v. At the same time, the cpu receives cvopn signals for indicating the status of the microswitch to handle the cover-open. ...

Page 36

41316401th rev.4 36 / 2.10 toner low detection • structure the toner low detection device consists of the stirring gear that revolves at a constant speed, the stirring bar, and the magnet on the stirring bar. The stirring bar turns in synchronization with the protrusion of the stirring gear. Toner f...

Page 37

41316401th rev.4 37 / • when the toner low condition is detected 20 consecutive times, toner low is determined. (the toner low message is displayed when about 500 a4 sheets at 5% density have been printed after toner low had been detected.) • when the toner full condition is detected 10 consecutive ...

Page 38

41316401th rev.4 38 / 2.12 operation at power-on 2.12.1 self-diagnostic test (1) initial test the followings are automatically performed at power-on. (a) rom check (b) ram check (c) eeprom check (d) flash rom check (2) rom check rom is checked by calculating a hash value. (3) ram check (a) rams are ...

Page 39

41316401th rev.4 39 / 2.13 color misalignment detection reflection-type optical sensors for detecting color misalignment (z71-pcb) are mounted on the belt at the right and left ends, respectively, in front of the toner scraping (cleaning) blade which is at the back of the belt unit. The color misali...

Page 40

41316401th rev.4 40 / 2.14 version read of units replaced periodically the version of each of the i/d, fuser unit and belt unit which are replaced periodically is determined whether it is new or previous according to whether the fuse in it is conducting or out of conduction. When the fuse is conduct...

Page 41

41316401th rev.4 41 / (2) do not disassemble the printer so long as it operates properly. (3) minimize the disassembly. Do not detach parts other than those shown in the replacing procedure. (4) for maintenance, use designated tools. (5) follow the order instructed to disassemble the printer. Incorr...

Page 42

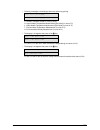

41316401th rev.4 42 / [maintenance tools] table 3-1 lists tools necessary to replace the fru's (field replaceable units). Table 3-1 maintenance tools no. No. 1-100 philips screwdriver q' ty use for remark maintenance tools 1 2 3 4 5 6 8 no. 2-200 philips magnetic screwdriver no. 3-100 screwdriver no...

Page 43

41316401th rev.4 43 / 3.2 parts layout figure 3-1 b a b a b a b.

Page 44

41316401th rev.4 44 / [top cover assy] figure 3-2.

Page 45

41316401th rev.4 45 / [printer unit-1/2] figure 3-3 a a.

Page 46

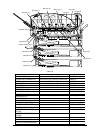

41316401th rev.4 46 / [printer unit-2/2] figure 3-4 45.

Page 47

41316401th rev.4 47 / [cassette guide assy (l),(r)] figure 3-5 a b b a c c’ c c’.

Page 48

41316401th rev.4 48 / [duplex unit] a b d c a b c d e e f g g f figure 3-6.

Page 49

41316401th rev.4 49 / 3.3 replacing parts this section describes how to replace the parts and assemblies shown in the following disassembling system diagram. C7000 41256201 print engine controller pwb (3.3.23) x 4 led assy (3.3.2) 40737401 low voltage power supply (3.3.36) 40737601 high voltage powe...

Page 50

41316401th rev.4 50 / 40859701 top cover (3.3.1) 4126001 control panel bezel (3.3.4) 40325101 multipurpose feeder drive gear (3.3.14) 41045802 × 2 link (3.3.14) 4yb4120-1137p001 mt paper empty sensor (3.3.14) 40863201 mt ohp sensor (3.3.14) 41276001 mt position sensor (3.3.14) top cover 40862002 mul...

Page 51

41316401th rev.4 51 / 2 1 1 1 3.3.1 top cover (1) open the top cover assy. (2) remove the nine screws 1 to detach the top cover 2 . Figure 3-3-1 top cover.

Page 52

41316401th rev.4 52 / 1 3 4 4 3 2 3.3.2 led assy/ led assy spring (1) open the top cover 1 . (2) remove the three cables, and unhook the led assy 2 at two places to demount it (the two springs 3 become detached together with the led assy 2 ). (3) remove the led connector 4 . When assembling, attach ...

Page 53

41316401th rev.4 53 / 3.3.3 top cover unit (1) remove the top cover (see section 3.3.1). (2) remove the rear cover (see section 3.3.10). (3) remove the left side cover (see section 3.3.12). (4) remove the right side cover (see section 3.3.13). (5) remove the shield plates a and b (see section 3.3.22...

Page 54

41316401th rev.4 54 / c g 3 7 6 f 5 5 2 e e 1 d b 3.3.4 control panel assy/ control panel bezel/ led control pwb/ toner sensors/ stacker full sensor/ control panel/ control panel tape harness/ eject rollers (1) detach the control panel bezel placed in the control panel assy 2 . (2) remove the screw ...

Page 55

41316401th rev.4 55 / 3 1 1 2 4 4 3.3.5 top cover handle/ top cover latch/ top cover latch spring (1) remove the two screws 1 to detach the top cover handle 2 and disengage the top cover latch 3 (at the same time, the two top cover latch springs 4 become detached). Figure 3-3-5 top cover handle/ top...

Page 56

41316401th rev.4 56 / 1 1 1 2 3.3.6 eject guide assy (1) remove the five screws 1 to detach the eject guide assy 2 . Figure 3-3-6 eject guide assy.

Page 57

41316401th rev.4 57 / 1 2 3 3.3.7 cassette assy/ front cover assy/ front cover inner baffle (1) detach the cassette assy 1 . (2) open the front cover 2 , and disengage it at two places to detach it. (3) detach the front cover inner baffle 3 . Figure 3-3-7 cassette assy/ front cover assy/ front cover...

Page 58

41316401th rev.4 58 / 1 3 2 3.3.8 retard pad assy/ retard pad assy spring (1) remove the cassette 1 . (2) detach the retard pad assy 2 (at the same time, the spring 3 becomes detached). Figure 3-3-8 retard pad assy/ retard pad assy spring.

Page 59

41316401th rev.4 59 / 1 2 3.3.9 feed roller and nudger roller (1) remove the cassette. (2) unlatch and demount the feed roller 1 . (3) unlatch and demount the nudger roller 2 . Figure 3-3-9 feed roller and nudger roller.

Page 60

41316401th rev.4 60 / 1 2 3 2 2 3.3.10 rear cover (1) remove the left side cover (see section 3.3.12). (2) remove the four screws 2 to detach the rear cover 1 . Note! When attaching the rear cover, take care not to allow the spring 3 to get caught in parts. Figure 3-3-10 rear cover.

Page 61

41316401th rev.4 61 / 1 3.3.11 face-up tray (1) open the face-up tray 1 in the arrow direction, and disengage it at two places to detach it. Figure 3-3-11 face-up tray.

Page 62

41316401th rev.4 62 / 4 4 1 4 5 3 2 3.3.12 left side cover (1) open the top cover 1 . (2) open the front cover 2 and undo the screw 3 . (3) remove the four screws 4 to detach the left side cover 5 . Figure 3-3-12 left side cover.

Page 63

41316401th rev.4 63 / 1 2 3 5 4 4 3.3.13 right side cover (1) open the top cover 1 . (2) open the front cover 2 and undo the screw 3 . (2) remove the four screws 4 to detach the right side cover 5 . Figure 3-3-13 right side cover.

Page 64

41316401th rev.4 64 / 3.3.14 multipurpose tray assy/ multipurpose tray cover assy/ links/ multipurpose tray top cover/ multipurpose tray drive gear (1) remove the left side cover (see section 3.3.12). (2) remove the right side cover (see section 3.3.13). (3) remove the left plate assy (see section 3...

Page 65

41316401th rev.4 65 / 1 3.3.15 drum contact assys (1) insert a flatblade screwdriver between the printer case and the drum contact assy 1 to demount the drum contact assy 1 . Figure 3-3-15 drum contact assys.

Page 66

41316401th rev.4 66 / 1 1 2 4 3 3.3.16 registration roller assy (a)/ registration drive gear (a) (1) remove the left side cover (see section 3.3.12). (2) remove the right side cover (see section 3.3.13). (3) remove the multipurpose tray (see section 3.3.14). (4) remove the four screws 1 to demount t...

Page 67

41316401th rev.4 67 / 1 2 1 1 3.3.17 registration roller assy (b) (1) remove the cassette assy. (2) open the front cover. (3) remove the right side cover (see section 3.3.13). (4) remove the left plate assy (see section 3.3.22). (5) remove the registration clutch (see section 3.3.18). (7) unscrew th...

Page 68

41316401th rev.4 68 / 6 3 5 3 1 2 5 4 3.3.18 registration clutch and registration motor assy (1) remove the left side cover (see section 3.3.12). (2) remove the left plate assy (see section 3.3.22). (3) remove the connector and the e ring 1 , then remove the two screws 3 , the earth 4 and the regist...

Page 69

41316401th rev.4 69 / 1 3 2 outlet 3.3.19 main cooling fan (1) unhook the connector (1), and remove the screw (2) and the cooling fan (3). Note! When attaching the cooling fan, observe its correct orientation. Figure 3-3-19 main cooling fan.

Page 70

41316401th rev.4 70 / 1 1 2 3 connectors 3.3.20 color registration sensor assy (1) remove the two screws 1 and the two connectors to demount the color registration sensor assy 2 . (2) remove the earth plate b 3 . Figure 3-3-20 color registration sensor assy.

Page 71

41316401th rev.4 71 / 1 main chassis (rear) 3.3.21 duplex guide assy (1) unlatch and demount the duplex guide 1 . Figure 3-3-21 duplex guide assy.

Page 72

41316401th rev.4 72 / outlet 1 2 1 5 5 5 5 3 3 4 6 8 7 3.3.22 electrical chassis cooling fan (1) unscrew the screws 1 to remove the plate a 2 . (2) unscrew the screws 3 to remove the shield plate b 4 . (3) remove the printer engine controller pwb (see section 3.3.30). (4) unscrew the screws 5 to rem...

Page 73

41316401th rev.4 73 / 1 1 2 3.3.23 printer engine controller pwb (1) remove the right side cover (see section 3.3.13). (2) remove the left plate assy (see section 3.3.22). (3) remove the five screws 1 and all the connectors to demount the printer engine controller pwb 2 . Figure 3-3-23 printer engin...

Page 74

41316401th rev.4 74 / 1 2 3 4 5 3 4 3 8 8 9 4 3 6 6 7 4 3.3.24 printer unit chassis (1) unscrew the two screws 1 and remove the ac inlet 2 . (2) unscrew the four black screws 3 and five screws 4 to detach the printer unit chassis 5 . (3) unscrew the four black screws 6 and remove the left top cover ...

Page 75

41316401th rev.4 75 / 1 main chassis 3.3.25 entrance cassette sensor actuator (1) remove the printer unit chassis (see section 3.3.24). (2) turn over the main chassis. (3) remove the two clamps with needlenose pliers to detach the entrance cassette sensor actuator 1 . Figure 3-3-25 entrance cassette...

Page 76

41316401th rev.4 76 / 1 2 3.3.26 entrance sensor pwb (1) remove the registration roller assy (b) (see section 3.3.17). (2) remove the two screws 1 to detach the entrance sensor pwb 2 . Figure 3-3-26 entrance sensor pwb.

Page 77

41316401th rev.4 77 / 2 1 3.3.27 entrance mt sensor actuator and entrance belt sensor actuator (1) remove the entrance sensor pwb (r71) (see section 3.3.26). (2) unlatch and detach the entrance mt sensor actuator 1 . (3) unlatch and detach the entrance belt actuator 2 . Figure 3-3-27 entrance mt sen...

Page 78

41316401th rev.4 78 / b a 7 8 9 0 6 1 2 4 3 5 3.3.28 fuser exit roller (1) unscrew the two screws 1 to remove the duplex gate solenoid assy 2 . (2) unscrew the screw 3 to remove the fuser exit roller contact 4 . (3) remove the fuser drive gear -a 5 and fuser drive gear -a 6 . (4) unscrew the screw 7...

Page 79

41316401th rev.4 79 / 1 2 3.3.29 exit sensor assy (1) remove the fuser exit roller (see section 3.3.28). (2) remove the screw 1 and connector to detach the (red and blue) exit sensor assy 2 . Figure 3-3-29 exit sensor assy.

Page 80

41316401th rev.4 80 / 3 1 2 3.3.30 fuser latching handle (l) (1) remove the latching handle spring 1 . (2) unscrew the screw 2 to detach the fuser latching handle (l) 3 . Figure 3-3-30 fuser latching handle (l).

Page 81

41316401th rev.4 81 / 2 1 3 1 3.3.31 belt motor assy (1) remove the fuser latching handle (r) (see section 3.3.32). (2) remove the two screws 1 to detach the two connectors 2 . (3) detach the blt motor assy 3 . Figure 3-3-31 belt motor assy.

Page 82

41316401th rev.4 82 / 3 1 2 3.3.32 fuser latching handle (r) (1) remove the printer unit chassis (see section 3.3.24). (2) remove the e ring 1 . (3) remove the fuser latching handle spring 2 to detach the fuser latching handle (r) 3 . Figure 3-3-32 fuser latching handle (r).

Page 83

41316401th rev.4 83 / 1 2 1 1 3.3.33 main motor assy (1) remove the belt motor assy (see section 3.3.31). (2) remove all the connectors. (3) remove the four screws 1 to detach the main motor assy 2 . Figure 3-3-33 main motor assy.

Page 84

41316401th rev.4 84 / 1 1 2 5 3 4 6 3.3.34 main feeder drive motor (1) remove the two screws 1 to detach the main feeder drive motor 2 . (2) unscrew the screw 3 to remove the main feeder drive motor bracket 4 . (3) remove the main feeder drive motor gears a 5 and b 6 . Figure 3-3-34 main feeder driv...

Page 85

41316401th rev.4 85 / 4 3 2 1 1 3.3.35 contact assy/ left plate assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the four screws 1 to detach the left plate assy 2 . (3) remove the screw 3 to detach the contact assy 4 . Figure 3-3-35 contact assy/ left plate assy.

Page 86

41316401th rev.4 86 / 4 1 4 2 5 4 3 3.3.36 low voltage power supply (1) remove the printer unit chassis (see section 3.3.24). (2) unhook the connector 1 . (3) unscrew the screw 2 to remove the earth cable 3 . (4) unscrew the six screws 4 to detach the low voltage power supply 5 . Figure 3-3-36 low v...

Page 87

41316401th rev.4 87 / 1 1 2 3 3.3.37 high voltage power supply (1) remove the contact assy (see section 3.3.35). (2) unhook the connector of the high voltage power supply 2 . (3) remove the two screws 1 to detach the high voltage power supply (2) and the tape harness 3 . Figure 3-3-37 high voltage p...

Page 88

41316401th rev.4 88 / 1 1 1 1 2 3 3 5 4 3.3.38 main feed assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the low voltage power supply and high voltage power supply (see sections 3.3.36 and 3.3.37). (3) unscrew the five screws 1 to remove the lower plate 2 . (4) unscrew the ...

Page 89

41316401th rev.4 89 / 1 1 8 8 0 9 3 6 7 4 5 2 3.3.39 cassette/ left guide assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the main feed assy (see section 3.3.38). (3) remove the three screws 1 to detach the left cassette guide assy 2 . At the same time, the earth plate 3 be...

Page 90

41316401th rev.4 90 / 1 h g 0 b a 3 a f e 6 7 2 4 5 9 8 1 c d 3.3.40 cassette/ right guide assy (1) remove the printer unit chassis (see section 3.3.24). (2) remove the main feed assy (see section 3.3.38). (3) remove the five screws 1 to detach the right cassette guide assy 2 . At the same time, the...

Page 91

41316401th rev.4 91 / 3 1 2 2 3.3.41 fuser unit (1) open the top cover 1 . (2) push the right and left fuser levers (blue) 2 in the arrow direction to detach the fuser unit 3 . Figure 3-3-41 fuser unit.

Page 92

41316401th rev.4 92 / 1 2 3 handle (blue) 3.3.42 belt unit (1) open the top cover 1 . (2) remove the i/d unit. (3) push the lever (blue) 2 in the arrow direction, raise the handle (blue) and detach the belt unit 3 . Figure 3-3-42 belt unit.

Page 93

41316401th rev.4 93 / 1 latch latch 3.3.43 duplex unit (1) remove the cassette assy, the front cover assy and the front cover inner baffle. (2) unlatch the rear at the right and left, and pull the duplex unit 1 toward the front. Figure 3-3-43 duplex unit.

Page 94

41316401th rev.4 94 / 1 1 3 2 1 1 3.3.44 guide rails (l) and (r) (1) remove the duplex unit (see section 3.3.43). (2) remove the six screws 1 to detach the guide rails (l) 2 and (r) 3 . Figure 3-3-44 guide rail (l), (r).

Page 95

41316401th rev.4 95 / 3.3.45 duplex transport assembly (1) turn over the duplex transport assy. (2) unscrew the three screws 1 and five screws 2 to detach the plate 3 . (3) unplug the connector and detach the mold assy 4 . (4) detach the two actuators 5 . (5) unscrew the screws 6 and 7 to remove the...

Page 96

41316401th rev.4 96 / a b d c a b c d e e f g g f duplex transport sensor × 2 2 3 2 2 v 4 f d e l m n k j y z t s a f 5 g c b ] \ [ 5 x 9 8 6 7 v u w e _ q i p o 0 a b c h g r d 1 idle roller spring duplex transfer assy cord duplex connector assy idle roller × 8 idle roller shaft × 8 figure 3-3-45 d...

Page 97

41316401th rev.4 97 / 3.3.46 cu assy (1) pulling out controller board 1. Undo the two screws 1 . 2. Pull the controller board 2 out. 3. Place the controller board 2 on a flat table. (2) detaching fan 1. Remove the connector 3 . 2. Remove the two screws 4 . 3. Detach the fan 5 . Figure 3-3-46 cu assy...

Page 98

41316401th rev.4 98 / (3) removing the crm board 1. Unscrew the four screws 6 to remove the fan bracket 7 . 2. Unscrew the four screws 8 to remove the plate support 9 and the guide rail a 0 . 3. Unscrew the two screws a to remove the guide rail b b . 4. Unscrew the two screws c and three screws d , ...

Page 99

41316401th rev.4 99 / 4. Adjustments adjustments on the c7000 series of printers are made by key entry on the operator panel. In addition to a standard menu, there is a maintenance menu in each printer. Select the one that serves the purpose of intended adjustment. 4.1 maintenance modes and their fu...

Page 100

41316401th rev.4 100 / 4.1.2 engine maintenance mode the engine maintenance mode includes three modes, levels 1 to 3. The level 1 aims to assist in checking the media transport systems and the basic operations of printing systems etc. The level 2, which sets the consumable counter and tests the colo...

Page 101

41316401th rev.4 101 / 4.1.2.3 switch scan test this self-diagnosis is used when the input sensor and the switch are checked. 1. Enter the general diagnosis mode, and press and hold the 1 1 1 1 1 and 5 5 5 5 5 keys down until “switch scan” appears on the upper display (the 1 1 1 1 1 key increments a...

Page 102

41316401th rev.4 102 / cover-upper switch mt-ohp (transparency) sensor toner k sensor toner y sensor toner m sensor toner c sensor upper fuser center sensor lower fuser center sensor starker full sensor exit sensor duplex-in sensor duplex rear sensor duplex front sensor color registration sensor (l)...

Page 103

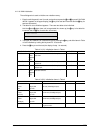

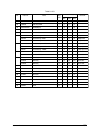

41316401th rev.4 103 / table 4-1 detailed switch scan scan ro w switch scan 00 switch scan 01 switch scan 02 switch scan 03 switch scan 04 switch scan 05 switch scan 06 switch scan 07 switch scan 08 switch scan 09 switch scan 10 switch scan 11 (option) switch scan 12 (option) switch scan 13 (option)...

Page 104

41316401th rev.4 104 / 4.1.2.4 motor and clutch test this self-check routine is used for testing the motor and clutch. 1. Go to the self-diagnosis (level 1) mode, and hold the 1 1 1 1 1 and 5 5 5 5 5 keys down until the upper display of “motor & clutch test” is brought up (the 1 1 1 1 1 key incremen...

Page 105

41316401th rev.4 105 / registration motor registration clutch cassette2 clutch cassette2 motor cassette3 clutch cassette3 motor main motor (k) cassette1 hopping motor main motor (y) main motor (c) main motor (h) belt motor fuser motor exit solenoid duplex motor sensor shutter figure 4-3 table 4-2 un...

Page 106

41316401th rev.4 106 / 4.1.2.5 test printing this self-diagnostic routine is used when the internal test patterns of the pu are printed. Other test patterns are stored in the controller. 1. Go to the self-diagnosis (level 1) mode, and hold the 1 1 1 1 1 and 5 5 5 5 5 keys down until “test print” com...

Page 107

41316401th rev.4 107 / • following messages are showing at warm-up and during printing. P: number of sheets printed for test (in prints) u: upper-heater temperature measurement [set value] (in units of ˚c) l: lower-heater temperature measurement [set value] (in units of ˚c) t: environmental temperat...

Page 108

41316401th rev.4 108 / kr=*.**kv yr=*.**kv mr=*.**kv cr=*.**kv 4. While "print execute" is indicated in the lower display after the item 2 procedure, press key (3) to start test printing with the values set in item 2 and 3 procedures. To suspend test printing, press key 7 7 7 7 7 . At the start of o...

Page 109

41316401th rev.4 109 / 5. Steps 2 through 4 to be repeated on an as needed basis. 6. Touch the (4) key to end the test (the display is restored to step 1). Pattern 5 pattern 6 pattern 7.

Page 110

41316401th rev.4 110 / 4.1.2.6 nvm initialization the self-diagnosis is used to initialize non-volatile memory. 1. Enter the self-diagnosis (level 1) mode, and continue to press the 1 1 1 1 1 and 5 5 5 5 5 keys until “nv-ram initial” appears on the upper display (the 1 1 1 1 1 key is for test item i...

Page 111

41316401th rev.4 111 / 4.1.2.7 consumable counter display the self-diagnosis is used to indicate the consumable consumption status. 1. After entering the general self-diagnosis mode, hold the 1 1 1 1 1 and 5 5 5 5 5 keys down until “consumable status” appears on the upper display (the 1 1 1 1 1 key ...

Page 112

41316401th rev.4 112 / 4.1.2.9 error messages and their details error messages. Error message black drum up/down error black drum unit fuse cut error black toner sensor error black led head error black toner low black toner empty black drum life over blance error belt life over belt unit fuse cut er...

Page 113

41316401th rev.4 113 / error message hopping error duplex hopping error tray4(px703) hopping error tray5(px703) inpath:feed inpath:transport inpath:exit inpath:duplex input inpath:duplex entry inpath:duplex reversal infeed:tray1 infeed:tray2 infeed:tray3 infeed:front feeder infeed:duplex infeed:tray...

Page 114

41316401th rev.4 114 / error message opecode trap error power lsi error panel i/f error pu fan motor error paper size error paper end selected tray paper end tray1 paper end tray2 paper end tray3 paper end front feeder paper end tray4(px703) paper end tray5(px703) paper near end tray1 paper near end...

Page 115

41316401th rev.4 115 / error message inpath:feed inpath:transport inpath:exit inpath:duplex input inpath:duplex entry inpath:reversal infeed:tray1 infeed:tray2 infeed:tray3 infeed:front feeder infeed:duplex infeed:tray4(px703) infeed:tray5(px703) details feed jam transport jam exit jam duplex unit i...

Page 116

41316401th rev.4 116 / 4.1.3 crm board adjustments destination setting: the crm board, a main board, is a common rom among destinations. When using the board for maintenance, its destination must be set using the system maintenance mode. Placing printer in system maintenance mode: (not on view of us...

Page 117

41316401th rev.4 117 / 4.1.3.1 short plug settings the crm board has five short plugs that can be set as follows: short plug (we1, 3, 5 and 7) sets flash rom dimm to connect we signals. (1-2 short: disconnects we signals; 2-3 short: connects we signals.) factory 2-3 short setting: re-programmable fl...

Page 118

41316401th rev.4 118 / 4.2 adjustments after parts replacement adjustment to be implemented after each part replacement is described below. Adjustment and correction of color registration are always required for each part replacement. * note: when the eeprom of the pu (k71 board) is replaced to a ne...

Page 119

41316401th rev.4 119 / note! The life information on the belt, toner, ids etc. Is cleared due to replacement of the eeprom. Take note that an error occurs in the each unit’s life count until the unit is replaced. Following is counts cleared after the replacement of the eeprom. Counts except the coun...

Page 120

41316401th rev.4 120 / 4.3 color balance adjustment color balance has been adjusted appropriately when a printer is shipped from the plant. However, it may be out of the appropriate balance during use. In such a case, color balance should be modified. Note: density of each color depends on each othe...

Page 121

41316401th rev.4 121 /.

Page 122

41316401th rev.4 122 / 5. Periodic maintenance 5.1 parts replaced periodically it is recommended that the following parts be periodically replaced, as specified, by users (when they are not replaced, the print quality is not assured and printer problems may result). Parts name large-capacity toner c...

Page 123

41316401th rev.4 123 / 6. Troubleshooting procedures 6.1 before troubleshooting (1) check the basic check items covered in the user’s manual. (2) obtain as much information about problems from users as you can. (3) perform inspections in conditions close to those in which problems occurred. 6.2 chec...

Page 124

41316401th rev.4 124 / 6.5.1 lcd messages list when detects unrecoverable errors, the printer provides the following service call error message: service call nnn : error note! Nnn is an error code. While a service call appears, an error code accompanied by its error information is shown on the lower...

Page 125

41316401th rev.4 125 / table 6-1-1 operator alarms (2/5) service call 040: error cu eeprom error can the printer recover from the error by replacing the eeprom on the cu board? Yes no replace the eeprom. (settings of the user must be restored on the new.) replace the crm board. (the eeprom needs rep...

Page 126

41316401th rev.4 126 / table 6-1-1 operator alarms (3/5) service call 125: error error detected at the mt home position. 1) is the error message displayed? 2) does the error repeat? Yes yes turn off/on the printer. Replace the mt. Service call 130: error temperature rise at the led head detected. 1)...

Page 127

41316401th rev.4 127 / table 6-1-1 operator alarms (4/5) install new drum 350: y drum life 351: m drum life 352: c drum life 353: k drum life end of the id unit life. More copies printed. Is it displayed soon after the id unit replacement? Yes no confirm the life of the id unit. Replace the id unit....

Page 128

41316401th rev.4 128 / table 6-1-1 operator alarms (5/5) load *** papers 490: no paper in the mp tray (*** = a4, b5 etc.) the specified cassette has no paper or is removed. Or, the cassette be ingused for printing has no more paper. 1) no paper in mt? 2) does the paper out sensor operate normally? Y...

Page 129

41316401th rev.4 129 / no. Failure flowchart no. 1 printer malfunction after turn-on 1 2 jam error paper loading jam (1st tray) 2 -1 paper loading jam (multipurpose tray) 2 -2 paper feed jam 2 -3 paper exit jam2-4 2 -4 duplex jam 2 -5 3 paper size error 3 4 i/d up-and-down operation error 4 5 fuser ...

Page 130

41316401th rev.4 130 / 1 the printer does not operate properly after power-on. • turn the printer off and on again. • is showing on the lcd (about for one second).? • no is the ac cable connected properly? No connect the ac cable correctly. ▼ • yes is +5v output to the panel connector (optn connecto...

Page 131

41316401th rev.4 131 / 2 -1 paper loading jam (1st tray) • has the paper loading jam occurred immediately after power-on? • yes is the paper jammed at the entrance cassette sensor or the entrance mt sensor? • yes remove the jammed paper. ▼ • no does the sensor lever (entrance cassette sensor, entran...

Page 132

41316401th rev.4 132 / 2 -2 paper loading jam (multipurpose tray) • has the paper loading jam occurred immediately after power-on? • yes is the paper jammed at the entrance cassette sensor or the entrance mt sensor? Yes remove the jammed paper. ▼ • no does the entrance mt sensor lever move properly?...

Page 133

41316401th rev.4 133 / a 2 -3 paper feed jam • has the paper feed jam occurred immediately after power-on? • yes is the paper jammed at the entrance belt sensor? Yes remove the jammed paper. ▼ • no does the write sensor lever move properly? No replace the write sensor lever. ▼ • yes does the entranc...

Page 134

41316401th rev.4 134 / 2 -4 paper exit jam • has the paper exit jam occurred immediately after power-on? • yes is the paper jammed at the exit sensor? Yes remove the jammed paper. ▼ • no does the sensor lever move properly? No replace the sensor lever. ▼ • yes does the exit sensor operate properly? ...

Page 135

41316401th rev.4 135 / a 2 -5 duplex jam • has the paper feed jam occurred immediately after power-on? • yes does the paper exist in the duplex unit? Yes remove the jammad paper. ▼ • no do the levers of the duplex-in, rear and front sensors move properly? No replace the defective sensor lever. ▼ • y...

Page 136

41316401th rev.4 136 / 3 paper size error • has the proper size paper used? No use the proper size paper. • yes has the jam occurred at the entrance ff sensor or the paper width sensor? Yes remove the jammed paper. ▼ • yes does the entrance ff sensor lever move properly? No replace the defective sen...

Page 137

41316401th rev.4 137 / 4 image drum unit (id) up-and-down operation error • turn the printer off and, after a few seconds, on again. • are all the id drums revolving properly during printing? • no does the resistance of the id motor lie at the rated value (approx. 4.0 Ω )? No replace the defective i...

Page 138

41316401th rev.4 138 / 5 fusing unit error • has the fuser error occurred immediately after power-on? • yes is the heat roller thermistor broken or short-circuited? (see figure 6-1.) (approx. 190k to 980k Ω at room temperatures of 0 to 43˚c) • yes replace the fuser unit. ▼ • no is the backup roller ...

Page 139

41316401th rev.4 139 / 6 motor fan error • does the low voltage power supply fan run after power-on? • no is 32v output to the fuse fu502 of the engine board (71k pwb)? • no is 32v output to the power connector of the engine board (71k pwb)? 32v: pins 7, 8, 9 and 10 no replace the low voltage power ...

Page 140

41316401th rev.4 140 / 6.5.3 troubleshooting image problems following is the troubleshooting for image problems illustrated below: light or faded image on whole page a vertical black belt or line d dirty background b defective image of regular interval e blank c vertical white belt or line f figure ...

Page 141

41316401th rev.4 141 / 1 light or faded image on whole page, or color misalignment on whole page (figure 6-2 a ) • are toners running short (is toner low displayed)? Yes supply toner(s). ▼ • no is proper paper used? No use proper paper. ▼ • yes are the led head lenses dirty? Yes clean the dirty lens...

Page 142

41316401th rev.4 142 / 2 dirty background (figure 6-2 b ) • were the image drums exposed to external light for a long time? Yes replace the id unit(s). ▼ • no is the roller of the fuser unit dirty? Yes replace the fuser unit. ▼ • no correct the paper type setting. Light: 60 g/m 2 medium light: 67.5 ...

Page 143

41316401th rev.4 143 / 3 blank page (figure 6-2 c ) • are the led head assys connected to the junction board (y71 pwb) and the engine board (71k pwb) properly? No connect the led assy(s) to the junction board (y71 pwb) and the engine board (71k pwb) properly, checking the cable connection. ▼ • yes i...

Page 144

41316401th rev.4 144 / 4 vertical belt or line (black or color belt, or black or color line) (figure 6-2 d ) • are the led head assys connected to the junction board (y71 pwb) properly? No connect the led head assy(s) to the junction board properly. ▼ • yes replace the led head assy(s) after checkin...

Page 145

41316401th rev.4 145 / 5 vertical white belt or line, or uneven-color belt or line (figure 6-2 f ) • are the led heads dirty? Yes clean the dirty led head(s). ▼ • no are the led head assys connected to the junction board (y71 pwb) properly? No connect the led head assy(s) to the junction board (y71 ...

Page 146

41316401th rev.4 146 / 6 poor fusing (ink spreads or peels when touched with fingers.) • is proper paper used? No use proper paper. ▼ • yes is the contact of the fuser unit connected properly? No connect the contact of the fuser unit properly. ▼ • yes is the roller of the fuser unit dirty? Yes repla...

Page 147

41316401th rev.4 147 / 7 defective image of regular interval (see figure 6-2 e ) interval problem troubleshooting 94.2 mm image drum replace the image drum unit. 63.6 mm developing roller replace the image drum unit. 57.8 mm toner supply roller replace the image drum unit. 44.0 mm charging roller re...

Page 148

41316401th rev.4 148 / 8 missing image • are led heads dirty? Yes clean the led head(s). ▼ • no are the led head assys connected to the junction board (y71 pwb) properly? No connect the led head assy(s) to the board, checking the cable connection between the led head(s) and the junction board. ▼ • y...

Page 149

41316401th rev.4 149 / 9 color misalignment • is the color menu of the user menu mode "automatic color-registration adjustment" off? Yes make it on. Recovered? Yes end ▼ • no "toner low" is displayed. Yes replenish toner. Recovered? Yes end ▼ • no execute the color registration test in the engine ma...

Page 150

41316401th rev.4 150 / (a) ▼ • no verify connection between the connector on z71-pwb (color-registration sensor board) and rsns/power connectors on 71k-pwb (engine board). Yes end ▼ • no replace z71-pwb. Recovered? Yes end ▼ • no replace the engine board. Recovered? Yes end ▼ • no replace the cable ...

Page 151

41316401th rev.4 151 / (b) ▼ • are there problems in the gears (the gear assys of the i/ds, multipurpose tray, belt unit or belt motor)? Yes replace the damaged gear assy(s). ▼ • no connect the led head unit(s) to the junction board properly. No connect the boards correctly. ▼ • yes replace the led ...

Page 152

41316401th rev.4 152 / 0 color different from original one • are the led head lenses dirty? Yes clean the led head lens(es). ▼ • no are the led head assys connected to the junction board (y71 pwb) properly? No connect the led head assy(s) to the junction board, checking the cable connection between ...

Page 153

41316401th rev.4 153 / figure 6-3 ground charging roller developing roller toner supply roller.

Page 154

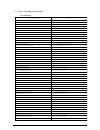

41316401th rev.4 154 / 7. Connection diagram 7.1 resistance checks unit circuit diagram illustration resistance between pins 1 and 2: 7.9 Ω between pins 3 and 4: 7.9 Ω between pins 1 and 2: 4 Ω between pins 3 and 4: 4 Ω between pins 1 and 2: 4 Ω between pins 3 and 4: 4 Ω transport belt motor main mo...

Page 155

41316401th rev.4 155 / unit circuit diagram illustration resistance between pins 1 and 2: 4 Ω between pins 3 and 4: 4 Ω between pins 1 and 2: 4 Ω between pins 3 and 4: 4 Ω between pins 1 and 2: 7.9 Ω between pins 3 and 4: 7.9 Ω main motor (c) main motor (k) registration motor m 1 2 3 4 m 1 2 3 4 m 1...

Page 156

41316401th rev.4 156 / red brown yellow blue m 1 2 3 4 unit circuit diagram illustration resistance between pins 1 and 2: 7.9 Ω between pins 3 and 4: 7.9 Ω between pins 1 and 2: 7.9 Ω between pins 3 and 4: 7.9 Ω fuser motor feeder motor between pins 1 and 2: 6.7 Ω between pins 3 and 4: 6.7 Ω duplex ...

Page 157

41316401th rev.4 157 / c d e f a b 1. Upper roller side 2. Backup roller side unit circuit diagram illustration resistance main cooling fan low voltage power unit electrical chassis cooling fan red black +32 v 1 fanalm-n 3 0 v 2 m white red black +32 v 1 fanalm-n 3 0 v 2 m yellow a 1 upper roller 1....

Page 158

41316401th rev.4 158 / 7.2 program/font rom layouts (1) print engine controller pwb (71k-pwb) sw1 cpufl1 fu4 fsens joden pa r ttemp rsns duplex psize hvolt covopn power eeprom fan2 fan1 humtmp cuif fan4 optn m1200 mpo w c1200 cpo w k1200 kpo w y1200 ypo w tr10 reg dcl bel thet shutter hopff rcl id f...

Page 159

41316401th rev.4 159 / (2) main controller pwb puif fan 3 84 84 84 1 1 1 85 168 c 1 85 168 b 85 168 a dimm 84 2 85 168 168 168 168 84 1 85 4 × dimm soc ke ts (f or sdram dimm (32mb to 256mb)) 3 × dimm soc ke ts (f or prog ram and f onts) 1 85 1 85 1 1 84 3 84 4 sdram sdmm1 sdmm2 sdmm3 sdmm4 rom cent...

Page 160

41316401th rev.4 160 / (3) led control pwb (y71-pwb) po wer stuck cpo w2 mpo w2 ypo w2 tnrsnsc tnrsnsm tnrsnsy optn kpo w 2 tnrsnsk pa n e l (4) duplex control pwb (v71-pwb) fu1 main fsens m oto r clutch rsens insens (5) control panel pwb (x71-pwb) sw4 cn1 sw8 sw3 sw7 sw2 sw6 sw1 sw5.

Page 161

41316401th rev.4 161 / (6) n71-pwb joden (7) entrance sensor pwb (r71-pwb) hum wrsns insns1 insns2 tnr fsns (8) paper size sensing pwb (pxc-pwb) cn11 sw3 sw1 sw2 sw4.

Page 162

41316401th rev.4 162 / figure 8-1-1/3 35 37 39, 40 4 22 34 3 7 6 20 30 18 14 1 12 11 26 a b a b 8 28 29 19 21 25 1 2 28 29 28 33 32 9 31 b a 29 29 28 a b 29 29 28 28 29 29 23 29 29 32 29 23 23 23 23 28 28 28 29 28 28 23 29 8. Parts list.

Page 163

41316401th rev.4 163 / a b a b c c c 13 29 23 c 29 10 24 24 23 23 figure 8-1-2/3.

Page 164

41316401th rev.4 164 / figure 8-1-3/3 47 43 48 42 49 50 48 41 44 45 46 36.

Page 165

41316401th rev.4 165 / no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 q’ty /unit 1 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1 1 2 14 2 2 1 13 42 1 1 1 1 1 patrs no. 40864601 41042501 40866701 41438401 40864301 41374902 40864401 40864501 40862001 40866301 41045801 403251...

Page 166

41316401th rev.4 166 / no. 32 33 q’ty /unit 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 patrs no. 41304105 41304106 41304107 41304108 41304109 41304110 41304111 41304112 41304205 41304206 41304207 41304208 41304209 41304210 41304211 41304212 41304213 41304214 41304215 41304216 41...

Page 167

41316401th rev.4 167 / no. 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 q’ty /unit 1 1 1 1 1 1 1 1 1 1 (1) (1) (1) (1) (1) 1 2 1 1 1 2 2 2 patrs no. 41377401 41356009 8164323m0000 41469503 41437418 41437414 41437410 41437419 41437415 41437411 41376902 41437302 41376005 41376004 41376002 412869...

Page 168

41316401th rev.4 168 / figure 8-2 1 5 14 19 3 14 14 4 15 6 11 3 8 3 2 2 2 2 3 7 3 3 9 3 3 10 20 17 18 20 20 20 21 21 21 21 21 21 21 21 21 21 21 16 13 13 21.

Page 169

41316401th rev.4 169 / table 8-2 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 q’ty /unit 1 4 4 8 1 1 1 1 1 1 1 1 8 4 1 1 1 1 1 4 19 parts no. 40859701 41072401 41072402 40861001 41257901 40365404 41316501 41309603 41309604 41309602 41309601 41593101 40316701 40860601 40866101 40866201 4...

Page 170

41316401th rev.4 170 / figure 8-3-1/2 3 16 19 18 5 6 17 2 4 47 21 25 26 8 13 7 12 14 28 23 27 1 10 9 11 51 15 30 31 29 22 22 24 1 50 51 51 51 51 51 51 51 51 51 51 51 51 51 51 51 a a 49.

Page 171

41316401th rev.4 171 / 31 33 44 40 41 48 39 36 43 45 37 38 32 35 47 47 47 47 47 47 47 47 47 47 47 47 47 47 47 47 47 figure 8-3-2/2.

Page 172

41316401th rev.4 172 / no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 q’ty /unit 4 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1 1 1 2 1 1 1 parts no. 41189701 40844301 40844303 40845401 41187101 40845801 3pb4076-5290p001 41346801 41253701 4...

Page 173

41316401th rev.4 173 / no. 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 q’ty /unit 1 1 1 1 1 1 1 1 1 1 26 1 2 1 29 parts no. 40846001 40848501 40848601 41303601 40850201 40737401 40737501 40737601 2381018p0001 41128101 4pb4013-3100p006 psw4-8c 41346301 41469001 4pb4083-2500p008 remarks name main ...

Page 174

41316401th rev.4 174 / a b b a c c’ c c’ 16 15 11 6 21 16 12 14 19 16 11 16 5 1 4 3 2 19 19 20 20 20 20 20 20 19 19 19 19 19 19 figure 8-4.

Page 175

41316401th rev.4 175 / table 8-4 no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 q’ty /unit 1 1 1 1 1 1 2 1 1 1 4 13 8 1 parts no. 40839801 40371301 40313201 40325401 40839001 40839401 40349701 40368304 4pp4076-5360p001 41309301 4pb4016-1960p002 4pb4083-2500p008 4pb4083-5670p002 41275901 r...

Page 176

41316401th rev.4 176 / a b d c a b c d e e f g g f 2 3 3 6 3 3 4 4 4 5 4 1 4 4 4 4 4 4 4 4 figure 8-5.

Page 177

41316401th rev.4 177 / table 8-5 no. 1 2 3 4 5 6 q’ty /unit 1 2 6 15 3 1 1 1 parts no. 41305301 4pb4043-4718p001 4pb4083-2500p010 4pb4083-2500p008 4pb4013-3100p006 41372901 41372903 41372907 remarks oda oel aps name duplex transport assy screw (sp3 × 10) screw (t3 × 10) screw (t3 × 8) screw (m3 × 6)...

Page 178

41316401th rev.4 178 / appendix a centronics parallel interface 1) connector • printer side: 36-pin receptacle (female) equivalent of type 57re-40360-830b-d29 (made by daiichi denshi kogyo) • cable side: 36-pin plug (male) equivalent of type 57-30360 (made by daiichi denshi kogyo) equivalent of plug...

Page 179

41316401th rev.4 179 / 3) a list of parallel i/f signals pin no. Signal name signal direction function 1 data strobe → pr parallel data sampling strobe 2 data bit - 1 3 data bit - 2 4 data bit - 3 5 data bit - 4 → pr parallel input data 6 data bit - 5 7 data bit - 6 8 data bit - 7 9 data bit - 8 10 ...

Page 180

41316401th rev.4 180 / parallel data (data bits 1 to 8) nstrobe nack busy ˚0.5 s min. 0.5 s min. 0.5 s min. 0.5 s max. 0.5 s min. 0 min. 0 min. 0.5 s to 3 s 0 min. On-line sw busy 100 ms max. Select item description mode compatibility mode, nibble mode, ecp mode data bit length compatibility: 8, nib...

Page 181

41316401th rev.4 181 / select acknowledge on-line sw busy input. Prime select acknowledge busy 50 s min. * by menu setting 5 s max. C) off-line timing for switching to on-line by on-line sw d) nlnit timing (under enabling input prime signal) nibble mode ieee-1284-specification compliant ecp mode iee...

Page 182

41316401th rev.4 182 / appendix b 2nd/3rd tray maintenance 1. Parts replacement 1.1 cover idle roller assy (1) unscrew the four screws 1 to remove the cover side 2 and the plate cover pcb 3 . (2) unscrew the two screws 4 to demount the cover idle roller assy 5 . 3 5 1 1 1 1 2 4 4.

Page 183

41316401th rev.4 183 / 3 4 2 1 1 1 1 2 1.2 pcb (1) unscrew the four screws 1 to remove the plate cover pcb 2 . (2) remove the connectors (at seven places) and the two screws 3 , then demount the board 4 ..

Page 184

41316401th rev.4 184 / 3 3 3 3 2 3 4 0 0 9 7 1 1 e c b a e f 8 d d 3 1 1 1 1 5 1.3 feeder drive assy (1) remove the four screws 1 , six screws 2 and the eight screws 3 . (2) remove the cover sides 4 and 5 , the plate cover pcb 6 and the frame hopping assy 7 . (3) remove the e ring 8 , the clutch 9 a...

Page 185

41316401th rev.4 185 / 1 2 3 4 8 5 6 7 2. C7000 2nd/3rd tray parts list.

Page 186

41316401th rev.4 186 / 186 no. 1 2 3 4 5 6 7 8 q’ty /unit 1 1 1 1 1 1 1 1 1 parts no. 41304501 41304503 41780302 41400502 41462301 41462201 41581101 40366501 41401001 remarks oda oel/aps name 2nd/3rd tray 500sheet feeder assembly 2nd/3rd tray 500sheet feeder assembly feeder control pwb cover-front o...