- DL manuals

- Vega

- Transmitter

- VEGABAR 81

- Operating Instructions Manual

Vega VEGABAR 81 Operating Instructions Manual

Summary of VEGABAR 81

Page 1

Operating instructions pressure transmitter with chemical seal vegabar 81 profibus pa document id: 45020

Page 2: Contents

2 contents vegabar 81 • profibus pa 45020-en-170522 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ................................................................

Page 3

3 contents vegabar 81 • profibus pa 45020-en-170522 7.3 saving the parameterisation data ................................................................................... 54 8 set up with other systems 8.1 dd adjustment programs ........................................................................

Page 4: 1 About This Document

4 1 about this document vegabar 81 • profibus pa 45020-en-170522 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tions for maintenance, fault rectification, the exchange of pa...

Page 5: 2 For Your Safety

5 2 for your safety vegabar 81 • profibus pa 45020-en-170522 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the req...

Page 6

6 2 for your safety vegabar 81 • profibus pa 45020-en-170522 to avoid any danger, the safety approval markings and safety tips on the device must also be observed and their meaning looked up in this operating instructions manual. 2.5 eu conformity the device fulfils the legal requirements of the app...

Page 7

7 2 for your safety vegabar 81 • profibus pa 45020-en-170522 with the goal of continuously improving company environmental pro- tection. The environment management system is certified according to din en iso 14001. Please help us fulfil this obligation by observing the environmental instructions in ...

Page 8: 3 Product Description

8 3 product description vegabar 81 • profibus pa 45020-en-170522 3 product description 3.1 configuration the type label contains the most important data for identification and use of the instrument: 2 1 13 14 12 10 11 5 3 6 4 7 8 9 fig. 1: layout of the type label (example) 1 instrument type 2 produ...

Page 9

9 3 product description vegabar 81 • profibus pa 45020-en-170522 this operating instructions manual applies to the following instrument versions: • hardware from 1.0.0 • software version from 1.2.0 note: you can find the hardware and software version of the instrument as follows: • on the type plate...

Page 10

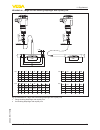

10 3 product description vegabar 81 • profibus pa 45020-en-170522 depending on the version, the vegabar 81 is also suitable for electronic differential pressure measurement. For this, the instrument is combined with a slave sensor. Fig. 3: electronic differential pressure measurement through master/...

Page 11

11 3 product description vegabar 81 • profibus pa 45020-en-170522 1 2 3 4 fig. 4: configuration of a chemical seal 1 sensor element 2 sealed screw 3 transmission liquid 4 stainless steel diaphragm the chemical seal is available in different versions, see chapter "dimensions". The process pressure ac...

Page 12

12 3 product description vegabar 81 • profibus pa 45020-en-170522 1 2 3 fig. 6: configuration of a measuring system with strain gauge (dms) sensor element 1 sensor element 2 process diaphragm 3 pressure cylinder the measuring cell design depends on the selected pressure type. Relative pressure: the ...

Page 13

13 3 product description vegabar 81 • profibus pa 45020-en-170522 3.4 packaging, transport and storage your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test based on iso 4180. The packaging of standard instruments consi...

Page 14

14 3 product description vegabar 81 • profibus pa 45020-en-170522 the interface adapter vegaconnect enables the connection of communication-capable instruments to the usb interface of a pc. For parameter adjustment of these instruments, the adjustment software pactware with vega-dtm is required. You...

Page 15

15 3 product description vegabar 81 • profibus pa 45020-en-170522 you can find further information in the operating instructions "elec- tronics module vegabar series 80" (document-id 45054). The supplementary electronics is a replacement part for sensors with profibus pa and double chamber housing. ...

Page 16: 4 Mounting

16 4 mounting vegabar 81 • profibus pa 45020-en-170522 4 mounting 4.1 general instructions make sure before mounting that all parts of the instrument exposed to the process are suitable for the existing process conditions. These are mainly: • active measuring component • process fitting • process se...

Page 17

17 4 mounting vegabar 81 • profibus pa 45020-en-170522 prior to setup you have to replace these protective caps with ap- proved cable glands or close the openings with suitable blind plugs. On instruments with threaded process fitting, the hexagon must be tightened with a suitable wrench. For the pr...

Page 18

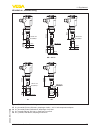

18 4 mounting vegabar 81 • profibus pa 45020-en-170522 caution: do not use a high-pressure cleaner. The filter element could be dam- aged, which would allow moisture into the housing. The following paragraphs describe how the filter element is arranged in the different instrument versions. The filte...

Page 19

19 4 mounting vegabar 81 • profibus pa 45020-en-170522 → turn the metal ring in such a way that the filter element points downward after installation of the instrument. This provides better protection against buildup. 2 1 3 4 3 4 fig. 9: position of the filter element - ex-d version 1 aluminium, sta...

Page 20

20 4 mounting vegabar 81 • profibus pa 45020-en-170522 1 2 1 2 fig. 10: position of the filter element - gastight leadthrough 1 filter element 2 gas-tight leadthrough the filter element is mounted into the electronics housing. It has the following functions: • ventilation of the electronics housing ...

Page 21

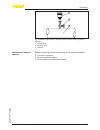

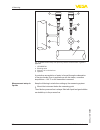

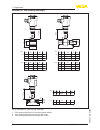

21 4 mounting vegabar 81 • profibus pa 45020-en-170522 1 2 3 fig. 12: measurement setup for process pressure measurement of gases in pipelines 1 vegabar 81 2 blocking valve 3 pipeline keep the following in mind when setting up the measuring system: • connect via a siphon • do not insulate the siphon...

Page 22

22 4 mounting vegabar 81 • profibus pa 45020-en-170522 1 4 3 2 1 2 3 4 fig. 13: measurement setup with process pressure measurement of gases in pipelines 1 vegabar 81 2 blocking valve 3 siphon in u or circular form 4 pipeline a protective accumulation of water is formed through condensation in the p...

Page 23

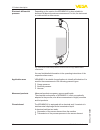

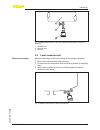

23 4 mounting vegabar 81 • profibus pa 45020-en-170522 3 1 2 fig. 14: measurement setup for process pressure measurement of liquids in pipelines 1 vegabar 81 2 blocking valve 3 pipeline 4.4 level measurement keep the following in mind when setting up the measuring system: • mount the instrument belo...

Page 24

24 4 mounting vegabar 81 • profibus pa 45020-en-170522 4.5 external housing 1 2 3 4 5 fig. 16: setup process assembly, external housing 1 pipeline 2 process assembly 3 connection cable process assembly - external housing 4 external housing 5 signal cable 1. Mark the holes according to the following ...

Page 25

25 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 5 connecting to the bus system 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carrie...

Page 26

26 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 max. Torque for all housings, see chapter "technical data". Make sure that the cable screen and grounding are carried out ac- cording to fieldbus specification. We recommend to connect the cable screen to ground potential on ...

Page 27

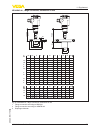

27 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 fig. 18: connection steps 5 and 6 - single chamber housing fig. 19: connection steps 5 and 6 - double chamber housing 6. Insert the wire ends into the terminals according to the wiring plan information: solid cores as well as...

Page 28

28 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 9. Tighten the compression nut of the cable entry gland. The seal ring must completely encircle the cable 10. Reinsert the display and adjustment module, if one was installed 11. Screw the housing lid back on the electrical c...

Page 29

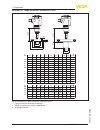

29 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 bus 5 1 2 + ( ) (-) 6 7 8 2 3 4 1 fig. 22: terminal compartment - double chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 for external display and adjustment unit 4 gr...

Page 30

30 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 bus 5 1 2 + ( ) (-) 6 7 8 2 3 4 1 fig. 24: terminal compartment - double chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 for external display and adjustment unit 4 gr...

Page 31

31 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 3 4 1 2 fig. 26: view to the plug connector m12 x 1 1 pin 1 2 pin 2 3 pin 3 4 pin 4 contact pin colour, connection ca- ble in the sensor terminal, electronics module pin 1 brown 5 pin 2 white 6 pin 3 blue 7 pin 4 black 8 5.7 ...

Page 32

32 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 5.8 external housing with version ip 68 (25 bar) 1 2 3 fig. 28: vegabar 81 in ip 68 version 25 bar with axial cable outlet, external housing 1 transmitter 2 connection cable 3 external housing 1 2 3 5 1 2 ( ) + (-) 6 7 8 4......

Page 33

33 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 1 2 3 4 6 3 4 1 2 5 fig. 30: connection of the sensor in the housing base 1 yellow 2 white 3 red 4 black 5 shielding 6 breather capillaries 5 0 0 5 1 6 2 7 3 8 4 9 0 5 1 6 2 7 3 8 4 9 1 0 1 6 7 8 bus 2 3 4 5 1 2 + ( ) (-) 1 f...

Page 34

34 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-170522 • output signal at instruments with current output jumps to the set fault current then the actual measured value is outputted to the signal cable. The value takes into account settings that have already been carried out, e.G....

Page 35: Module

35 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor and removed again at any time. You can choose any one...

Page 36

36 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 1 2 fig. 33: installing the display and adjustment module in the double chamber housing 1 in the electronics compartment 2 in the terminal compartment note: if you intend to retrofit the instrument with a dis...

Page 37

37 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 – move to the menu overview – confirm selected menu – edit parameter – save value • [->] key: – change measured value presentation – select list entry – select menu items in the quick setup menu – select edit...

Page 38

38 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 when the [+] and [->] keys are pressed quickly, the edited value, or the cursor, changes one value or position at a time. If the key is pressed longer than 1 s, the value or position changes continuously. Whe...

Page 39

39 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 after the last step, "quick setup terminated successfully" is displayed briefly. The return to the measured value indication is carried out through the [->] or [esc] keys or automatically after 3 s note: you ...

Page 40

40 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 • the address selection switch in the electronics compartment of the instrument (address setting via hardware) • the display and adjustment module (address setting via software) • pactware/dtm (address settin...

Page 41

41 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 enter the requested parameters via the appropriate keys, save your settings with [ok] and jump to the next menu item with the [esc] and the [->] key. In this menu item, the adjustment units of the instrument ...

Page 42

42 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 the position correction can be repeated as often as necessary. How- ever, if the sum of the corrective values exceeds 20 % of the nominal measuring range, then no position correction is possible. Vegabar 81 a...

Page 43

43 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 2. Edit the mbar value with [ok] and set the cursor to the requested position with [->]. 3. Set the requested mbar value with [+] and store with [ok]. 4. Go with [esc] and [->] to the span adjustment the zero...

Page 44

44 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 proceed as follows: 1. Select the menu item "setup" with [->] and confirm with [ok]. Now select with [->] the menu item "adjustment", then "min. Adjustment" and confirm with [ok]. 2. Edit the percentage value...

Page 45

45 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 caution: note the following, if the respective sensor is used as part of an over- fill protection system according to whg: if a linearisation curve is selected, the measuring signal is no longer necessarily l...

Page 46

46 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 to damp process-dependent measured value fluctuations, you can set a time of 0 … 999 s in this menu item. The damping applies to the level and interface measurement. The default setting is a damping of 0 s. I...

Page 47

47 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 • czech • turkish in the delivery status, the vegabar 81 is set to english or the or- dered national language. In this menu item, you define which measured value is displayed. The default setting for the disp...

Page 48

48 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 the respective min. And max. Measured values of the measuring cell and the electronics temperature are stored in the sensor. In menu item "peak value, temperature", both values are displayed. In another windo...

Page 49

49 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 defined linearisation curve as well as the measured value memory are deleted. Basic settings: resets the parameter settings, incl. Special param- eters, to the default values of the respective instrument. Any...

Page 50

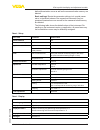

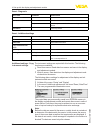

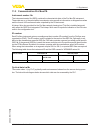

50 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 reset - diagnosis menu item parameter default value sensor status - peak value pressure actual measured value temperature actual temperature values from measuring cell, elec- tronics simulation process pressu...

Page 51

51 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 in this menu item you gain access to the protected area where you can enter special parameters. In exceptional cases, individual parameters can be modified in order to adapt the sensor to special requirements...

Page 52

52 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-170522 6.6 saving the parameterisation data we recommended writing down the adjustment data, e.G. In this op- erating instructions manual, and archiving them afterwards. They are thus available for multiple use or s...

Page 53: 7 Setup With Pactware

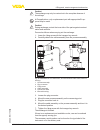

53 7 setup with pactware vegabar 81 • profibus pa 45020-en-170522 7 setup with pactware 7.1 connect the pc 3 1 2 fig. 37: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 3 sensor 7.2 parameter adjustment for parameter adjust...

Page 54

54 7 setup with pactware vegabar 81 • profibus pa 45020-en-170522 fig. 38: example of a dtm view all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assista...

Page 55

55 8 set up with other systems vegabar 81 • profibus pa 45020-en-170522 8 set up with other systems 8.1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. The files can be downloaded at www.Vega...

Page 56

56 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 9 diagnosis, asset management and service 9.1 maintenance if the device is used properly, no special maintenance is required in normal operation. In some applications, product buildup on the diaphragm can influence...

Page 57

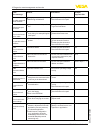

57 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 9.3 asset management function the instrument features self-monitoring and diagnostics according to ne 107 and vdi/vde 2650. In addition to the status messages in the following tables, detailed error messages are av...

Page 58

58 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 code text message reason rectification devspec diagnosis bits f013 no valid measured value available • gauge pressure or low pressure • measuring cell defective • exchange measuring cell • send instrument for repai...

Page 59

59 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 code text message reason rectification devspec diagnosis bits f265 measurement func- tion disturbed • sensor no longer carries out a measurement • carry out a reset • disconnect operating voltage briefly bit 11 the...

Page 60

60 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 code text message reason rectification devspec state in cmd 48 m507 error in the instru- ment settings • error during setup • error when carrying out a reset • carry out reset and repeat setup bit 22 9.4 rectify fa...

Page 61

61 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 caution: the exchange may only be carried out in the complete absence of line voltage. In ex applications, only a replacement part with appropriate ex ap- proval may be used. Caution: during exchange, protect the i...

Page 62

62 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-170522 9.7 software update the following components are required to update the instrument software: • instrument • voltage supply • interface adapter vegaconnect • pc with pactware • current instrument software as file yo...

Page 63: 10 Dismount

63 10 dismount vegabar 81 • profibus pa 45020-en-170522 10 dismount 10.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" and...

Page 64: 11 Supplement

64 11 supplement vegabar 81 • profibus pa 45020-en-170522 11 supplement 11.1 technical data note for approved instruments the technical data in the respective safety instructions are valid for approved instruments (e.G. With ex approval). These data can differ from the data listed herein, for exampl...

Page 65

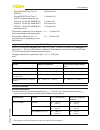

65 11 supplement vegabar 81 • profibus pa 45020-en-170522 weights total weight vegabar 81 approx. 0.8 … 8 kg (1.764 … 17.64 lbs), depending on process fitting and housing torques max. Torque for process fitting with thread 40 nm (29.50 lbf ft) max. Torque for npt cable glands and conduit tubes Ʋ pla...

Page 66

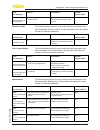

66 11 supplement vegabar 81 • profibus pa 45020-en-170522 nominal measuring ranges and overload capacity in psi nominal range overload capacity, max. Pressure overload capacity, min. Pressure gauge pressure 0 … +5 psig +15 psig -14.5 psig 0 … +15 psig +45 psig -14.5 psig 0 … +30 psig +90 psig -14.5 ...

Page 67

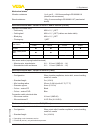

67 11 supplement vegabar 81 • profibus pa 45020-en-170522 output variable output signal digital output signal, format according to ieee-754 instrument address 126 (default setting) damping (63 % of the input variable) 0 … 999 s, adjustable profibus pa profile 3.02 number of fbs with ai (function blo...

Page 68

68 11 supplement vegabar 81 • profibus pa 45020-en-170522 process temperature reaction time +20 °c (+58 °f) approx. 3 s -20 °c (-4 °f) approx. 11 s damping (63 % of the input variable) 0 … 999 s, adjustable referenceconditionsandinfluencingvariables(accordingtodinen60770-1) reference conditions acco...

Page 69

69 11 supplement vegabar 81 • profibus pa 45020-en-170522 Ʋ flange dn 80 pn 40, form c, din 2501 0.25 mbar/10 k Ʋ flange dn 80 pn 40, form c, din 2501 with extension 50 mm 1.34 mbar/10 k Ʋ flange 2" 150 lbs rf, asme b16.5 1.2 mbar/10 k Ʋ flange 3" 150 lbs rf, asme b16.5 0.25 mbar/10 k Ʋ flange 3" 15...

Page 70

70 11 supplement vegabar 81 • profibus pa 45020-en-170522 isolating liquid version p abs > 1 bar/14.5 psi version for oxygen ap- plications silicone oil kn17 with cooling element -90 … +180 °c (- 130 … +356 °f -90 … +60 °c (- 130 … +140 °f) with capillaries 2 m high temperature oil kn32 with cooling...

Page 71

71 11 supplement vegabar 81 • profibus pa 45020-en-170522 mechanical stress 6) vibration resistance 1 to 4 g at 5 … 200 hz according to en 60068-2-6 (vibration with resonance) shock resistance 100 g, 6 ms according to en 60068-2-27 (mechanical shock) electromechanical data - version ip 66/ip 67 and ...

Page 72

72 11 supplement vegabar 81 • profibus pa 45020-en-170522 Ʋ max. Length 180 m (590.5 ft) Ʋ min. Bending radius at 25 °c/77 °f 25 mm (0.985 in) Ʋ diameter approx. 8 mm (0.315 in) Ʋ colour pe black Ʋ colour pur blue connection cable, electrical data Ʋ wire cross-section 0.5 mm² (awg 20) Ʋ wire resista...

Page 73

73 11 supplement vegabar 81 • profibus pa 45020-en-170522 max. Cable length 25 m integrated clock date format day.Month.Year time format 12 h/24 h time zone, factory setting cet max. Rate deviation 10.5 min/year additional output parameter - electronics temperature output of the values Ʋ analogue vi...

Page 74

74 11 supplement vegabar 81 • profibus pa 45020-en-170522 electrical protective measures 8) housing material version protection acc. To iec 60529 protection acc. To nema plastic single chamber ip 66/ip 67 type 4x double chamber aluminium single chamber ip 66/ip 68 (0.2 bar) ip 68 (1 bar) type 6p - d...

Page 75

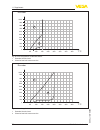

75 11 supplement vegabar 81 • profibus pa 45020-en-170522 depending on the temperature. This causes measurement deviations. For that reason, chemical seal systems can only be used to a limited extent in a vacuum, depending on the pressure transmission liquid, process temperature and pressure. To ext...

Page 76

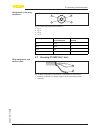

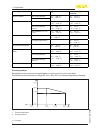

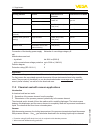

76 11 supplement vegabar 81 • profibus pa 45020-en-170522 5 100 200 300 400 500 600 700 800 900 1000 50 100 150 200 250 300 350 400 t °c p mbar abs 1 2 fig. 44: area of application for silicone oil kn 2.2 1 standard chemical seal 2 chemical seal with vacuum service 5 100 200 300 400 500 600 700 800 ...

Page 77

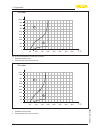

77 11 supplement vegabar 81 • profibus pa 45020-en-170522 5 100 200 300 400 500 600 700 800 900 1000 50 100 150 200 250 300 350 400 t °c p mbar abs 1 2 fig. 46: area of application for halocarbon oil kn21 1 standard chemical seal 2 chemical seal with vacuum service 5 100 200 300 400 500 600 700 800 ...

Page 78

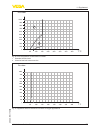

78 11 supplement vegabar 81 • profibus pa 45020-en-170522 5 100 200 300 400 500 600 700 800 900 1000 50 100 150 200 250 300 350 400 t °c p mbar abs 1 2 fig. 48: area of application for neobee kn 59 1 standard chemical seal 2 chemical seal with vacuum service 5 100 200 300 400 500 600 700 800 900 100...

Page 79

79 11 supplement vegabar 81 • profibus pa 45020-en-170522 11.3 communicationprofibuspa instrumentmasterfile the instrument master file (gsd) contains the characteristic data of the profibus pa instrument. These data are, e.G. The permissible transmission rates as well as information on diagnostics v...

Page 80

80 11 supplement vegabar 81 • profibus pa 45020-en-170522 fig. 50: vegabar 81: block diagram with ai fb 1 … ai fb 3 out values tb transducer block fb function block ai analogue input module of the pa sensors for the cyclic data traffic, vegabar 81 provides the following modules: • ai fb1 (out) – out...

Page 81

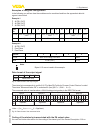

81 11 supplement vegabar 81 • profibus pa 45020-en-170522 examplesoftelegramconfiguration in the following you will see how the modules can be combined and how the appendant data tel- egram is structured. Example 1 • ai fb1 (out) • ai fb2 (out) • ai fb3 (out) byte- no. 1 2 3 4 5 6 7 8 9 10 11 12 13 ...

Page 82

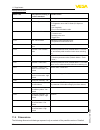

82 11 supplement vegabar 81 • profibus pa 45020-en-170522 www.Profibus.Com. Status code description according to profibusstandard possible cause 0 x 00 bad - non-specific flash-update active 0 x 04 bad - configuration error • adjustment error • configuration error with pv-scale (pv-span too small) •...

Page 83

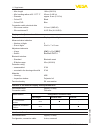

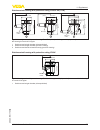

83 11 supplement vegabar 81 • profibus pa 45020-en-170522 dimensional drawings can be downloaded at www.Vega.Com under "downloads" and "drawings". Plastic housing ~ 69 mm (2.72") ø 79 mm (3.11") 112 mm (4.41") m20x1,5/ ½ npt ~ 84 mm (3.31") m16x1,5 112 mm (4.41") m20x1,5/ ½ npt 1 2 ø 79 mm (3.11") f...

Page 84

84 11 supplement vegabar 81 • profibus pa 45020-en-170522 aluminium housing with protection rating ip 66/ip 68 (1 bar) 120 mm (4.72") ~ 105 mm (4.13") 116 mm (4.57") ~ 150 mm (5.91") ø 86 mm (3.39") ø 86 mm (3.39") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 fig. 55: housing version with protection r...

Page 85

85 11 supplement vegabar 81 • profibus pa 45020-en-170522 stainless steel housing with protection rating ip 66/ip 68 (1 bar) 117 mm (4.61") ~ 103 mm (4.06") ø 79 mm (3.11") 120 mm (4.72") ~ 105 mm (4.13") ø 86 mm (3.39") m20x1,5 m20x1,5/ ½ npt m16x1,5 ~ 93 mm (3.66") ø 80 mm (3.15") 112 mm (4.41") m...

Page 86

86 11 supplement vegabar 81 • profibus pa 45020-en-170522 external housing on ip 68 version 1 2 3 4 5 82 mm (3.23") 80 mm (3.15") 108 mm (4.25") 41,6 mm (1.64") ~ 66 mm (2.60") 59 mm (2.32") 110 mm x 90 mm (4.33" x 3.54") 110 mm x 90 mm (4.33" x 3.54") 51 mm (2.01") 41,6 mm (1.64") fig. 59: vegabar ...

Page 87

87 11 supplement vegabar 81 • profibus pa 45020-en-170522 vegabar81,threadedfitting gk ge gl gn ge > 105° c ø 32 mm (1.26") sw 32 mm (1.26") g3/4 20 mm (0.79") 89 mm (3.5") ø 26 mm (1.02") sw 27 mm (1.06") g1/2 28 mm (1.1") ø 39 mm (1.54") sw 41 mm (1.61") g1 sw 55 mm (2.17") 30 mm (1.81") ø 60 mm (...

Page 88

88 11 supplement vegabar 81 • profibus pa 45020-en-170522 vegabar 81, tube isolating diaphragm 1.02" 1.26" 1.97" dn mm pn g1 l 25 40 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " g1 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " 128 mb 26 32 40 140 32 50 25 156 50 dn inch pn l 25 40 32 40 50 25 mb 1.12" 1.69...

Page 89

89 11 supplement vegabar 81 • profibus pa 45020-en-170522 vegabar81,flangeconnection,dimensionsinmm rl d5 dm dm 115 mm (4.53") 109 mm (4.29") d d4 d2 f b k dn pn d k b 25 40 115 18 85 40 40 150 18 110 50 40 165 20 125 d2 4 x ø14 4 x ø18 4 x ø18 d4 68 88 102 f 2 2 2 80 40 200 24 160 8 x ø18 138 2 50 ...

Page 90

90 11 supplement vegabar 81 • profibus pa 45020-en-170522 vegabar81,flangeconnection,dimensionsininch dn pn d k b 25 40 4.53" 0.71" 3.35" 40 40 5.91" 0.71" 4.33" 50 40 6.5" 0.79" 4.92" d2 4 x ø0.55" 4 x ø0.71" 4 x ø0.71" d4 2.68" 3.47" 4.02" f 0.08" 0.08" 0.08" 80 40 7.87" 0.95" 6.3" 8 x ø0.71" 5.43...

Page 91

91 11 supplement vegabar 81 • profibus pa 45020-en-170522 vegabar81,flangeandcellisolatingdiaphragmwithcapillaryline 4.53" 0.71" 0.71" 0.71" 0.55" 0.71" 0.71" 0.79" 0.79" 2.68" 5.91" 3.47" 6.5" 4.02" dn mm pn b d 25 40 115 18 d4 68 40 40 150 18 88 50 40 165 20 102 d2 k 85 14 110 18 125 18 80 40 200 ...

Page 92

92 11 supplement vegabar 81 • profibus pa 45020-en-170522 11.5 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen unt...

Page 93: Index

93 index vegabar 81 • profibus pa 45020-en-170522 index a adjust date/time 48 adjustment 44 – process pressure 42, 43 – system 37 – unit 41 ai fb1 function block 45 c change the language 46 channel 45 chemical seal 10 copy sensor settings 50 cyclical data traffic 79 d damping 46 data format, output ...

Page 94

94 notes vegabar 81 • profibus pa 45020-en-170522.

Page 95

95 notes vegabar 81 • profibus pa 45020-en-170522.

Page 96

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 45020-en-170522 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...