- DL manuals

- Vega

- Transmitter

- VEGABAR 81

- Operating instructions manual

Vega VEGABAR 81 Operating instructions manual

Summary of VEGABAR 81

Page 1

Operating instructions pressure transmitter with chemical seal vegabar 81 profibus pa document id: 45020

Page 2: Contents

2 contents vegabar 81 • profibus pa 45020-en-140710 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ................................................................

Page 3

3 contents vegabar 81 • profibus pa 45020-en-140710 8 set up with other systems 8.1 dd adjustment programs ............................................................................................... 51 9 diagnosis, asset management and service 9.1 maintenance .......................................

Page 4: 1 About This Document

4 1 about this document vegabar 81 • profibus pa 45020-en-140710 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tions for maintenance and fault rectification. Please read thi...

Page 5: 2 For Your Safety

5 2 for your safety vegabar 81 • profibus pa 45020-en-140710 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the req...

Page 6

6 2 for your safety vegabar 81 • profibus pa 45020-en-140710 this range may not be exceeded. This applies even if a measuring cell with a measuring range (order-related) higher than the permissible pressure range of the process fitting is installed. 2.7 namur recommendations namur is the automation ...

Page 7: 3 Product Description

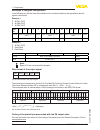

7 3 product description vegabar 81 • profibus pa 45020-en-140710 3 product description 3.1 configuration the type label contains the most important data for identification and use of the instrument: 2 1 14 15 16 17 13 11 12 5 3 6 4 7 8 9 10 fig. 1: layout of the type label (example) 1 instrument typ...

Page 8

8 3 product description vegabar 81 • profibus pa 45020-en-140710 • download the smartphone app "vega tools" from the "apple app store" or the "google play store" • scan the data matrix code on the type label of the instrument or • enter the serial number manually in the app this operating instructio...

Page 9

9 3 product description vegabar 81 • profibus pa 45020-en-140710 in combination with a slave sensor, vegabar 81 is also suitable for electronic differential pressure measurement. You can find detailed information in the operating instructions of the respective slave sensor. Vegabar 81 is suitable fo...

Page 10

10 3 product description vegabar 81 • profibus pa 45020-en-140710 3.3 supplementary cleaning procedures the vegabar 81 is also available in the version "oil, grease and silicone-free". These instruments have passed through a special cleaning procedure to remove oil, grease and paint-wetting impair- ...

Page 11

11 3 product description vegabar 81 • profibus pa 45020-en-140710 3.5 accessories and replacement parts the display and adjustment module plicscom is used for measured value indication, adjustment and diagnosis. It can be inserted into the sensor or the external display and adjustment unit and remov...

Page 12

12 3 product description vegabar 81 • profibus pa 45020-en-140710 the electronics module vegabar series 80 is a replacement part for pressure transmitters of vegabar series 80. There is a different version available for each type of signal output. You can find further information in the operating in...

Page 13: 4 Mounting

13 4 mounting vegabar 81 • profibus pa 45020-en-140710 4 mounting 4.1 general instructions for use of the instrument make sure that all parts of the instrument exposed to the process are suitable for the existing process conditions. These are mainly: • active measuring component • process fitting • ...

Page 14

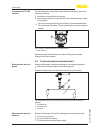

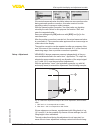

14 4 mounting vegabar 81 • profibus pa 45020-en-140710 1 2 fig. 4: temperature ranges 1 process temperature 2 ambient temperature 4.2 ventilation and pressure compensation ventilation and pressure compensation are carried out with ve- gabar 81 via a filter element. It is air permeable and moisture- ...

Page 15

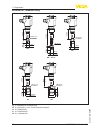

15 4 mounting vegabar 81 • profibus pa 45020-en-140710 1 2 3 4 4 4 fig. 5: position of the filter element - non-ex, ex-ia version 1 housing plastic, stainless steel precision casting 2 housing aluminium 3 housing stainless steel, electropolished 4 filter element with the following instruments a blin...

Page 16

16 4 mounting vegabar 81 • profibus pa 45020-en-140710 the filter element is mounted into the electronics housing. It has the following functions: • ventilation of the electronics housing • atmospheric pressure compensation (with relative pressure meas- uring ranges) → turn the housing so that the f...

Page 17

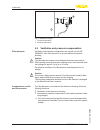

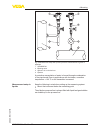

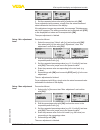

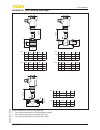

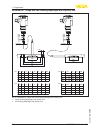

17 4 mounting vegabar 81 • profibus pa 45020-en-140710 1 4 3 2 1 2 3 4 fig. 9: measurement setup with process pressure measurement of gases in pipelines 1 vegabar 81 2 blocking valve 3 siphon in u or circular form 4 pipeline a protective accumulation of water is formed through condensation in the pi...

Page 18

18 4 mounting vegabar 81 • profibus pa 45020-en-140710 3 1 2 fig. 10: measurement setup for process pressure measurement of liquids in pipelines 1 vegabar 81 2 blocking valve 3 pipeline 4.4 level measurement keep the following in mind when setting up the measuring system: • mount the instrument belo...

Page 19

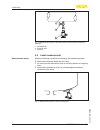

19 4 mounting vegabar 81 • profibus pa 45020-en-140710 4.5 external housing 1 2 3 4 5 fig. 12: setup process assembly, external housing 1 pipeline 2 process assembly 3 connection cable process assembly - external housing 4 external housing 5 signal cable 1. Mark the holes according to the following ...

Page 20

20 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 5 connecting to the bus system 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carrie...

Page 21

21 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 in systems without potential equalisation with cable screening on both sides, connect the cable screen directly to ground potential at the power supply unit and at the sensor. In the connection box or t-distributor, the scree...

Page 22

22 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 fig. 15: connection steps 5 and 6 - double chamber housing 6. Insert the wire ends into the terminals according to the wiring plan information: solid cores as well as flexible cores with wire end sleeves are insert- ed direct...

Page 23

23 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 5 0 0 5 1 6 2 7 3 8 4 9 0 5 1 6 2 7 3 8 4 9 1 0 1 6 7 8 bus 2 3 4 5 1 2 + ( ) (-) 1 fig. 16: electronics and terminal compartment, single chamber housing 1 voltage supply, signal output 2 for display and adjustment module or ...

Page 24

24 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 bus 5 1 2 + ( ) (-) 6 7 8 2 3 4 1 fig. 18: terminal compartment, double chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 for external display and adjustment unit 4 gro...

Page 25

25 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 bus 5 1 2 + ( ) (-) 6 7 8 2 3 4 1 fig. 20: terminal compartment, double chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 for external display and adjustment unit 4 gro...

Page 26

26 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 3 4 1 2 fig. 22: view to the plug connector m12 x 1 1 pin 1 2 pin 2 3 pin 3 4 pin 4 contact pin colour connection ca- ble in the sensor terminal, electronics module pin 1 brown 5 pin 2 white 6 pin 3 blue 7 pin 4 black 8 5.7 h...

Page 27

27 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 5.8 external housing with version ip 68 (25 bar) 1 2 3 fig. 24: vegabar 81 in ip 68 version 25 bar with axial cable outlet, external housing 1 transmitter 2 connection cable 3 external housing 1 2 3 5 1 2 ( ) + (-) 6 7 8 4......

Page 28

28 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 1 2 3 4 6 3 4 1 2 5 fig. 26: connection of the sensor in the housing base 1 yellow 2 white 3 red 4 black 5 shielding 6 breather capillaries 5 0 0 5 1 6 2 7 3 8 4 9 0 5 1 6 2 7 3 8 4 9 1 0 1 6 7 8 bus 2 3 4 5 1 2 + ( ) (-) 1 f...

Page 29

29 5 connecting to the bus system vegabar 81 • profibus pa 45020-en-140710 • indication of a status message on the display or pc • the output signal jumps to the set fault current then the actual measured value is outputted to the signal cable. The value takes into account settings that have already...

Page 30: Module

30 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor and removed again at any time. You can choose any one...

Page 31

31 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 1 2 fig. 29: installing the display and adjustment module in the double chamber housing 1 in the electronics compartment 2 in the terminal compartment (with ex-d-ia version not possible) note: if you intend t...

Page 32

32 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 – confirm selected menu – edit parameter – save value • [->] key: – presentation, change measured value – select list entry – select editing position • [+] key: – change value of the parameter • [esc] key: – ...

Page 33

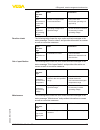

33 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 6.4 parameter adjustment - quick setup to quickly and easily adapt the sensor to the application, select the menu item "quick setup" in the start graphic on the display and adjustment module. Carry out the fo...

Page 34

34 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 5. Position correction in this menu item you compensate the influence of the installation position of the instrument (offset) on the measured value. 6. Max. Adjustment in this menu item you carry out the max....

Page 35

35 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 setup: settings, for example, to measurement loop name, applica- tion, units, position correction, adjustment, ai fb 1 channel - scaling - damping display: settings, e.G., for language, measured value display...

Page 36

36 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 • numbers from 0 … 9 • special characters +, -, /, - in this menu item you activate/deactivate the slave sensor for elec- tronic differential pressure and select the application. Vegabar 81 can be used for pr...

Page 37

37 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 if the actual measured value should be taken over as correction value during automatic position correction, this value must not be influ- enced by product coverage or static pressure. With the manual position...

Page 38

38 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 ing the product level. These settings can be made ahead of time without the instrument having to be installed. Note: if the adjustment ranges are exceeded, the entered value will not be accepted. Editing can ...

Page 39

39 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 3. Set the requested mbar value with [+] and store with [ok]. For an adjustment with pressure, simply enter the actual measured value indicated at the bottom of the display. If the adjustment ranges are excee...

Page 40

40 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 for an adjustment with filling, simply enter the actual measured value indicated at the bottom of the display. A linearization is necessary for all vessels in which the vessel volume does not increase linearl...

Page 41

41 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 min. Values for pv lin proc. And out scale process pressure in bar: max. Values for pv lin proc. And out scale process pressure in bar: to damp process-dependent measured value fluctuations, you can set a tim...

Page 42

42 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 the following languages are available: • german • english • french • spanish • russian • italian • dutch • portuguese • polish • czech • turkish in the delivery status, the vegabar 81 is set to the ordered na...

Page 43

43 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 the respective min. And max. Measured values of the measuring cell and the electronics temperature are stored in the sensor. In menu item "peak value, temperature", both values are displayed. In another windo...

Page 44

44 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 the following reset functions are available: delivery status: restores the parameter settings at the time of shipment from the factory, incl. The order-specific settings. Any user- defined linearisation curve...

Page 45

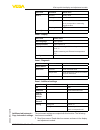

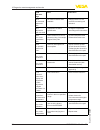

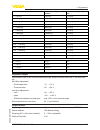

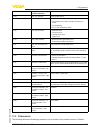

45 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 menu item parameter default value ai fb 1 channel primary value scaling format pressure scaling 0 % corresponds to 0 bar 100 % corresponds to measuring range final value damping pv ftime 0 s lock adjustment r...

Page 46

46 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 • write to sensor: save data from the display and adjustment mod- ule back into the sensor the following data or settings for adjustment of the display and ad- justment module are saved: • all data of the men...

Page 47

47 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 in this menu item, the hardware and software version of the sensor is displayed. In this menu item, the date of factory calibration of the sensor as well as the date of the last change of sensor parameters ar...

Page 48

48 6 set up with the display and adjustment module vegabar 81 • profibus pa 45020-en-140710 • in the menu "additional adjustments" the items "sensor-specific units, temperature unit and linearization" • the values of the user programmable linearization curve the function can also be used to transfer...

Page 49: 7 Setup With Pactware

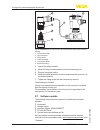

49 7 setup with pactware vegabar 81 • profibus pa 45020-en-140710 7 setup with pactware 7.1 connect the pc 3 1 2 fig. 32: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 3 sensor 7.2 parameter adjustment for parameter adjust...

Page 50

50 7 setup with pactware vegabar 81 • profibus pa 45020-en-140710 fig. 33: example of a dtm view all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assista...

Page 51

51 8 set up with other systems vegabar 81 • profibus pa 45020-en-140710 8 set up with other systems 8.1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. The files can be downloaded at www.Vega...

Page 52

52 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 9 diagnosis, asset management and service 9.1 maintenance if the instrument is used properly, no special maintenance is required in normal operation. In some applications, product buildup on the diaphragm can influ...

Page 53

53 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 9.3 asset management function the instrument features self-monitoring and diagnostics according to ne 107 and vdi/vde 2650. In addition to the status messages in the following tables there are more detailed error m...

Page 54

54 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 code text mes- sage cause rectification f013 no measured value avail- able – no valid measured value available – gauge pressure or low pressure, measuring cell defective f017 adjustment span too small – adjustment ...

Page 55

55 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 code text mes- sage cause rectification f265 measurement function dis- turbed – sensor no longer carries out a measurement – carry out a reset – disconnect operating volt- age briefly f266 impermissi- ble operating...

Page 56

56 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 code text mes- sage cause rectification m501 error in the non-active linearization table – index markers are not con- tinuously rising, for example illogical value pairs – check linearization table – delete table/c...

Page 57

57 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 in ex applications, only instruments and electronics modules with ap- propriate ex approval may be used. If there is no electronics module available on site, one can be ordered from the agency serving you. You can ...

Page 58

58 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 1 2 3 6 4 5 fig. 35: vegabar 81 in ip 68 version, 25 bar and lateral cable outlet, external housing 1 process assembly 2 plug connector 3 fixing screw 4 cable assembly 5 connection cable 6 external housing 3. Loose...

Page 59

59 9 diagnosis, asset management and service vegabar 81 • profibus pa 45020-en-140710 caution: instruments with approvals can be bound to certain software versions. Therefore make sure that the approval is still effective after a software update is carried out. You can find detailed information at w...

Page 60: 10 Dismount

60 10 dismount vegabar 81 • profibus pa 45020-en-140710 10 dismount 10.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" and...

Page 61: 11 Supplement

61 11 supplement vegabar 81 • profibus pa 45020-en-140710 11 supplement 11.1 technical data materials and weights materials, wetted parts process fitting 316l diaphragm 316l, alloy c276 (2.4819), alloy c22 (2.4602), monel 400 (2.4360), tantalum, titanium, 316l ptfe coated, 316l ectfe coated, 1.4435 ...

Page 62

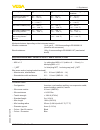

62 11 supplement vegabar 81 • profibus pa 45020-en-140710 inputvariable-piezoresistive/thinfilmmeasuringcell nominal measuring ranges and overload capability in bar/kpa the specifications are only an overview and refer to the measuring cell. Limitations due to the material and version of the process...

Page 63

63 11 supplement vegabar 81 • profibus pa 45020-en-140710 nominal range overload capacity, max. Pressure overload capacity, min. Pres- sure 0 … +30 psig +120 psig -14.5 psig 0 … +150 psig +450 psig -14.5 psig 0 … +300 psig +600 psig -14.5 psig 0 … +600 psig +1200 psig -14.5 psig 0 … +1500 psig +3000...

Page 64

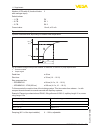

64 11 supplement vegabar 81 • profibus pa 45020-en-140710 number of fbs with ai (function blocks with analogue input) 3 default values Ʋ 1. Fb pv Ʋ 2. Fb sv 1 Ʋ 3. Fb sv 2 current value 10 ma, ±0.5 ma dynamic behaviour output dynamic characteristics depending on medium and temperature 90 % 100 % 10 ...

Page 65

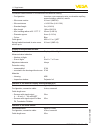

65 11 supplement vegabar 81 • profibus pa 45020-en-140710 reference conditions and actuating variables (according to din en 60770-1) reference conditions according to din en 61298-1 Ʋ temperature +18 … +30 °c (+64 … +86 °f) Ʋ relative humidity 45 … 75 % Ʋ air pressure 860 … 1060 mbar/86 … 106 kpa (1...

Page 66

66 11 supplement vegabar 81 • profibus pa 45020-en-140710 temperature coefficient of a cooling ele- ment, depending on the diaphragm-ø 0.1 … 1.5 mbar/10 k temperature coefficient of a 1 m long capillary line, depending on the diaphragm-ø 0.1 … 15 mbar/10 k long-term stability (according to din 16086...

Page 67

67 11 supplement vegabar 81 • profibus pa 45020-en-140710 isolating liquid p abs > 1 bar/14.5 psi p abs version for oxygen ap- plications halocarbon oil kn21 for oxygen applications -40 … +60 °c (40 … +140 °f) -40 … +60 °c (40 … +140 °f) -40 … +60 °c (- 40 … +140 °f) silicone-free liquid kn70 -40 … ...

Page 68

68 11 supplement vegabar 81 • profibus pa 45020-en-140710 electromechanical data - version ip 68 (25 bar) connection cable between ip 68 instrument and external housing Ʋ configuration four wires, one suspension wire, one breather capillary, screen braiding, metal foil, mantle Ʋ wire cross-section 0...

Page 69

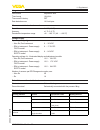

69 11 supplement vegabar 81 • profibus pa 45020-en-140710 integrated clock date format day.Month.Year time format 12 h/24 h time zone ex factory cet rate deviation max. 10.5 min/year measurement electronics temerature resolution 0.1 °c (1.8 °f) accuracy ±1 °c (1.8 °f) permissible temperature range -...

Page 70

70 11 supplement vegabar 81 • profibus pa 45020-en-140710 housing material version ip-protection class nema protection stainless steel, precision casting single chamber ip 66/ip 67 ip 68 (1 bar) nema 6p - double chamber ip 66/ip 67 nema 6p stainless steel transmitter, version with external housing i...

Page 71

71 11 supplement vegabar 81 • profibus pa 45020-en-140710 fig. 37: vegabar 81: block diagram with ai fb 1 … ai fb 3 out values tb transducer block fb function block ai analogue input module of the pa sensors for the cyclic data traffic, vegabar 81 provides the following modules: • ai fb1 (out) – out...

Page 72

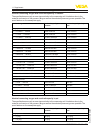

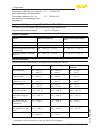

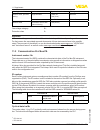

72 11 supplement vegabar 81 • profibus pa 45020-en-140710 examplesoftelegramconfiguration in the following you will see how the modules can be combined and how the appendant data tel- egram is structured. Example 1 • ai fb1 (out) • ai fb2 (out) • ai fb3 (out) byte- no. 1 2 3 4 5 6 7 8 9 10 11 12 13 ...

Page 73

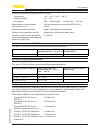

73 11 supplement vegabar 81 • profibus pa 45020-en-140710 status code description according to profibusstandard possible cause 0 x 00 bad - non-specific flash-update active 0 x 04 bad - configuration error – adjustment error – configuration error with pv-scale (pv-span too small) – unit irregularity...

Page 74

74 11 supplement vegabar 81 • profibus pa 45020-en-140710 dimensional drawings can be downloaded at www.Vega.Com under "downloads" and "drawings". Plastic housing ~ 69 mm (2.72") ø 79 mm (3.11") 112 mm (4.41") m20x1,5/ ½ npt ~ 84 mm (3.31") m16x1,5 112 mm (4.41") m20x1,5/ ½ npt 1 2 ø 79 mm (3.11") f...

Page 75

75 11 supplement vegabar 81 • profibus pa 45020-en-140710 aluminium housing with protection rating ip 66/ip 68 (1 bar) 120 mm (4.72") ~ 105 mm (4.13") 116 mm (4.57") ~ 150 mm (5.91") ø 86 mm (3.39") ø 86 mm (3.39") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 fig. 42: housing versions with protection ...

Page 76

76 11 supplement vegabar 81 • profibus pa 45020-en-140710 stainless steel housing with protection rating ip 66/ip 68 (1 bar) 117 mm (4.61") ~ 103 mm (4.06") ø 79 mm (3.11") 120 mm (4.72") ~ 105 mm (4.13") ø 86 mm (3.39") m20x1,5 m20x1,5/ ½ npt m16x1,5 ~ 93 mm (3.66") ø 80 mm (3.15") 112 mm (4.41") m...

Page 77

77 11 supplement vegabar 81 • profibus pa 45020-en-140710 external housing with ip 68 (25 bar) version 1 2 3 4 5 82 mm (3.23") 80 mm (3.15") 108 mm (4.25") 41,6 mm (1.64") ~ 66 mm (2.60") 59 mm (2.32") 110 mm x 90 mm (4.33" x 3.54") 110 mm x 90 mm (4.33" x 3.54") 51 mm (2.01") 41,6 mm (1.64") fig. 4...

Page 78

78 11 supplement vegabar 81 • profibus pa 45020-en-140710 vegabar81,threadedfitting gk ge gl gn ge > 105° c ø 32 mm (1.26") sw 32 mm (1.26") g3/4 20 mm (0.79") 89 mm (3.5") ø 26 mm (1.02") sw 27 mm (1.06") g1/2 28 mm (1.1") ø 39 mm (1.54") sw 41 mm (1.61") g1 sw 55 mm (2.17") 30 mm (1.81") ø 60 mm (...

Page 79

79 11 supplement vegabar 81 • profibus pa 45020-en-140710 vegabar 81, tube isolating diaphragm 1.02" 1.26" 1.97" dn mm pn g1 l 25 40 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " g1 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " 128 mb 26 32 40 140 32 50 25 156 50 dn inch pn l 25 40 32 40 50 25 mb 1.12" 1.69...

Page 80

80 11 supplement vegabar 81 • profibus pa 45020-en-140710 vegabar81,flangeconnection,dimensionsinmm rl d5 dm dm 115 mm (4.53") 109 mm (4.29") d d4 d2 f b k dn pn d k b 25 40 115 18 85 40 40 150 18 110 50 40 165 20 125 d2 4 x ø14 4 x ø18 4 x ø18 d4 68 88 102 f 2 2 2 80 40 200 24 160 8 x ø18 138 2 50 ...

Page 81

81 11 supplement vegabar 81 • profibus pa 45020-en-140710 vegabar81,flangeconnection,dimensionsininch dn pn d k b 25 40 4.53" 0.71" 3.35" 40 40 5.91" 0.71" 4.33" 50 40 6.5" 0.79" 4.92" d2 4 x ø0.55" 4 x ø0.71" 4 x ø0.71" d4 2.68" 3.47" 4.02" f 0.08" 0.08" 0.08" 80 40 7.87" 0.95" 6.3" 8 x ø0.71" 5.43...

Page 82

82 11 supplement vegabar 81 • profibus pa 45020-en-140710 vegabar81,flangeandcellisolatingdiaphragmwithcapillaryline 4.53" 0.71" 0.71" 0.71" 0.55" 0.71" 0.71" 0.79" 0.79" 2.68" 5.91" 3.47" 6.5" 4.02" dn mm pn b d 25 40 115 18 d4 68 40 40 150 18 88 50 40 165 20 102 d2 k 85 14 110 18 125 18 80 40 200 ...

Page 83

83 11 supplement vegabar 81 • profibus pa 45020-en-140710 11.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind...

Page 84: Index

84 index vegabar 81 • profibus pa 45020-en-140710 index a adjust date/time 43 adjustment – level 39 – process pressure 38 – unit 36 adjust the indication 42 ai fb1 function block 40 c change the language 41 channel 40 connecting – electrically 21 – to the pc 49 connection – steps 21 – technology 21 ...

Page 85

85 index vegabar 81 • profibus pa 45020-en-140710 t telegram configuration 72.

Page 86

86 notes vegabar 81 • profibus pa 45020-en-140710

Page 87

87 notes vegabar 81 • profibus pa 45020-en-140710

Page 88

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 45020-en-140710 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...