- DL manuals

- Vega

- Transmitter

- VEGABAR 81

- Operating Instructions Manual

Vega VEGABAR 81 Operating Instructions Manual

Summary of VEGABAR 81

Page 1

Operating instructions pressure transmitter with chemical seal vegabar 81 4 … 20 ma document id: 45025.

Page 2: Contents

2 contents vegabar 81 • 4 … 20 ma 45025-en-180111 contents 1 about this document ............................................................................................................... 4 1.1 function ...............................................................................................

Page 3

3 contents vegabar 81 • 4 … 20 ma 45025-en-180111 8 set up with other systems .................................................................................................... 48 8.1 dd adjustment programs ..............................................................................................

Page 4: 1 About This Document

4 1 about this document vegabar 81 • 4 … 20 ma 45025-en-180111 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructionsformaintenance,faultrectification,theexchangeofparts and the ...

Page 5: 2 For Your Safety

5 2 for your safety vegabar 81 • 4 … 20 ma 45025-en-180111 2 for your safety 2.1 authorised personnel all operations described in this documentation must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the required personal pro...

Page 6

6 2 for your safety vegabar 81 • 4 … 20 ma 45025-en-180111 2.5 eu conformity thedevicefulfilsthelegalrequirementsoftheapplicableeudirec- tives.Byaffixingthecemarking,weconfirmtheconformityofthe instrument with these directives. Youcanfindtheeuconformitydeclarationonourwebsiteunder www.Vega.Com/downl...

Page 7

7 2 for your safety vegabar 81 • 4 … 20 ma 45025-en-180111 with the goal of continuously improving company environmental pro- tection.Theenvironmentmanagementsystemiscertifiedaccording to din en iso 14001. Pleasehelpusfulfilthisobligationbyobservingtheenvironmental instructions in this manual: • cha...

Page 8: 3 Product Description

8 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 3 product description 3.1 configuration thetypelabelcontainsthemostimportantdataforidentificationand use of the instrument: 2 1 13 14 12 10 11 5 3 6 4 7 8 9 fig. 1: layout of the type label (example) 1 instrument type 2 product code 3 fi...

Page 9

9 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 this operating instructions manual applies to the following instrument versions: • hardware from 1.0.0 • software from 1.3.2 note: youcanfindthehardwareandsoftwareversionoftheinstrumentas follows: • on the type plate of the electronics m...

Page 10

10 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 fig. 3: electronic differential pressure measurement through master/slave combination youcanfinddetailedinformationintheoperatinginstructionsofthe respective slave sensor. Vegabar 81 is suitable for applications in virtually all industr...

Page 11

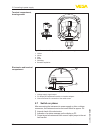

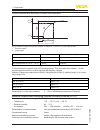

11 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 3 4 fig. 4: configuration of a chemical seal 1 sensor element 2 sealed screw 3 transmission liquid 4 stainless steel diaphragm thechemicalsealisavailableindifferentversions,seechapter "dimensions". The process pressure acts on the s...

Page 12

12 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 3 fig. 6: configuration of a measuring system with strain gauge (dms) sensor element 1 sensor element 2 process diaphragm 3 pressure cylinder the measuring cell design depends on the selected pressure type. Relative pressure: the me...

Page 13

13 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 3.4 packaging, transport and storage your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test based on iso 4180. The packaging of standard instruments consist...

Page 14

14 3 product description vegabar 81 • 4 … 20 ma 45025-en-180111 the interface adapter vegaconnect enables the connection of communication-capable instruments to the usb interface of a pc. For parameter adjustment of these instruments, the adjustment software pactware with vega-dtm is required. Youca...

Page 15: 4 Mounting

15 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 4 mounting 4.1 general instructions make sure before mounting that all parts of the instrument exposed to the process are suitable for the existing process conditions. These are mainly: • active measuring component • processfitting • process seal ...

Page 16

16 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 the permissible process pressure range is stated on the type label. The instrument should only be operated with these pressures if the mountingaccessoryusedalsofulfilsthesevalues.Thisshouldbeen- suredbysuitableflanges,weldedsockets,tensionringswit...

Page 17

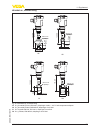

17 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 3 6 6 6 6 6 5 4 fig. 8: position of the filter element 1 plastic, stainless steel single chamber (precision casting) 2 aluminium - single chamber 3 stainless steel single chamber (electropolished) 4 plastic double chamber 5 aluminium, stainles...

Page 18

18 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 the second line of defense (slod) is a second level of the process separation in form of a gas-tight leadthrough in the housing neck, preventing products from penetrating into the housing. With these instruments, the process assembly is completely...

Page 19

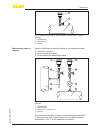

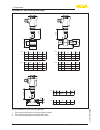

19 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 3 fig. 12: measurement setup for process pressure measurement of gases in pipelines 1 vegabar 81 2 blocking valve 3 pipeline keep the following in mind when setting up the measuring system: • connect via a siphon • do not insulate the siphon •...

Page 20

20 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 keep the following in mind when setting up the measuring system: • mount the instrument below the measuring point theeffectivepressurelineisalwaysfilledwithliquidandgasbubbles can bubble up to the process line. 3 1 2 fig. 14: measurement setup for...

Page 21

21 4 mounting vegabar 81 • 4 … 20 ma 45025-en-180111 4.5 external housing 1 2 3 4 5 fig. 16: configuration, process module, external housing 1 pipeline 2 process module 3 connection cable process assembly - external housing 4 external housing 5 signal cable 1. Mark the holes according to the followi...

Page 22

22 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried out ...

Page 23

23 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 prior to setup you have to replace these protective caps with ap- proved cable glands or close the openings with suitable blind plugs. On plastic housings, the npt cable gland or the conduit steel tube must be screwed into the th...

Page 24

24 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 fig. 18: connection steps 5 and 6 - single chamber housing 6. Insert the wire ends into the terminals according to the wiring plan information: solidcoresaswellasflexiblecoreswithwireendsleevesareinsert- eddirectlyintotheterminal...

Page 25

25 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 + ( ) (-) 4...20ma 2 3 1 fig. 19: electronics and terminal compartment - single chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 ground terminal for connection of the ...

Page 26

26 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 4...20ma 1 2 + ( ) (-) 2 1 fig. 21: connection compartment - ex-d-ia double chamber housing 1 voltage supply, signal output 2 ground terminal for connection of the cable screen 5.5 housing ip 66/ip 68 (1 bar) 1 2 fig. 22: wire as...

Page 27

27 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 5.6 external housing with version ip 68 (25 bar) 1 2 3 fig. 23: vegabar 81 in ip 68 version 25 bar with axial cable outlet, external housing 1 transmitter 2 connection cable 3 external housing 1 2 3 5 1 2 ( ) + (-) 6 7 8 4...20ma...

Page 28

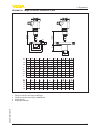

28 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 3 4 6 3 4 1 2 5 fig. 25: connection of the process component in the housing base 1 yellow 2 white 3 red 4 black 5 shielding 6 breather capillaries 1 2 + ( ) (-) 4...20ma 2 3 1 fig. 26: electronics and terminal compartment - s...

Page 29

29 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-180111 then the actual measured value is outputted to the signal cable. The value takes into account settings that have already been carried out, e.G. Default setting..

Page 30: Module

30 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor andremovedagainatanytime.Youcanchooseanyoneoffourdiffer...

Page 31

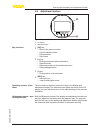

31 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 6.2 adjustment system 1 2 fig. 28: display and adjustment elements 1 lc display 2 adjustment keys • [ok] key: – move to the menu overview – confirmselectedmenu – edit parameter – save value • [->] key: – change...

Page 32

32 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 4 5 3 fig. 29: display and adjustment elements - with adjustment via magnetic pen 1 lc display 2 magnetic pen 3 adjustment keys 4 bluetooth symbol 5 lid with inspection window when the [+] and [->] keys are...

Page 33

33 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 with the "[->]" button, you can select the requested language, with "ok"youconfirmtheselectionandmovetothemainmenu. You can change your selection afterwards with the menu item "setup - display, menu language". ...

Page 34

34 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 additional adjustments: pin, date/time, reset, copy function info: instrument name, hardware and software version, date of manu- facture, sensor features note: for optimum adjustment of the measuring point, the...

Page 35

35 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 unit of measurement: if the level should be adjusted in a height unit, the density of the me- dium must also be entered later during the adjustment. Inaddition,thetemperatureunitoftheinstrumentisspecified.The s...

Page 36

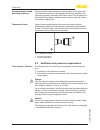

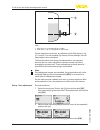

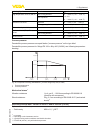

36 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 2 1 100% 0% 5 m (196.9 ") fig. 30: parameter adjustment example "min./max. Adjustment, level measure- ment" 1 min. Level = 0 % corresponds to 0.0 mbar 2 max. Level = 100 % corresponds to 490.5 mbar ifthesevalue...

Page 37

37 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 4. Go with [esc] and [->] to the span adjustment thezeroadjustmentisfinished. Information: the zero adjustment shifts the value of the span adjustment. The span,i.E.Thedifferencebetweenthesevalues,however,remai...

Page 38

38 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 5. Save settings with [ok] and move with [esc] and [->] to the max. Adjustment. Themin.Adjustmentisfinished. Foranadjustmentwithfilling,simplyentertheactualmeasuredvalue indicated at the bottom of the display. ...

Page 39

39 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 user especially when setting the switching point on the limit signal transmitter. In the menu item "current output mode" you determine the output characteristics and reaction of the current output in case of fa...

Page 40

40 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 • russian • italian • dutch • portuguese • japanese • chinese • polish • czech • turkish in delivery status, the vegabar 81 is set to english. Inthismenuitem,youdefinewhichmeasuredvalueisdisplayed. The default ...

Page 41

41 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 in another window you can carry out a reset of the peak values separately. The respective min. And max. Measured values of the measuring cell and the electronics temperature are stored in the sensor. In menu it...

Page 42

42 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 delivery status: restores the parameter settings at the time of shipmentfromthefactory,incl.Theorder-specificsettings.Anyuser- definedlinearisationcurveaswellasthemeasuredvaluememoryare deleted. Basic settings:...

Page 43

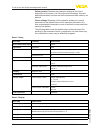

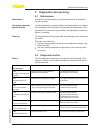

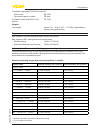

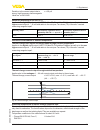

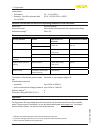

43 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 reset - diagnosis menu item parameter default value sensor status - peak value pressure actual measured value temperature actual temperature values from measuring cell, elec- tronics simulation process pressure...

Page 44

44 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 note: before the data are saved in the sensor, a safety check is carried out to determine if the data match the sensor. In the process the sensor type of the source data as well as the target sensor are display...

Page 45

45 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-180111 in this menu item, you can read out the instrument name and the instrument serial number: in this menu item, the hardware and software version of the sensor is displayed. In this menu item, the date of factory ...

Page 46: 7 Setup With Pactware

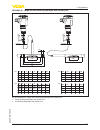

46 7 setup with pactware vegabar 81 • 4 … 20 ma 45025-en-180111 7 setup with pactware 7.1 connect the pc 3 1 2 fig. 31: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 3 sensor 7.2 parameter adjustment for parameter adjustme...

Page 47

47 7 setup with pactware vegabar 81 • 4 … 20 ma 45025-en-180111 fig. 32: example of a dtm view all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assistant...

Page 48

48 8 set up with other systems vegabar 81 • 4 … 20 ma 45025-en-180111 8 set up with other systems 8.1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. Thefilescanbedownloadedatwww.Vega.Com/dow...

Page 49

49 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-180111 9 diagnostics and servicing 9.1 maintenance if the device is used properly, no special maintenance is required in normal operation. Insomeapplications,productbuilduponthediaphragmcaninfluence the measuring result. Depending on the...

Page 50

50 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-180111 code text message cause rectification f105 measured value is deter- mined • the instrument is still in the start phase, the measured value could not yet be determined • wait for the end of the switch-on phase f113 communication er...

Page 51

51 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-180111 code text message cause rectification s605 impermissible pressure value • measured process pressure below or above the adjustment range • check nominal measuring range of the instrument • if necessary, use an instrument with a hig...

Page 52

52 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-180111 error cause rectification 4 … 20 ma signal missing • electrical connection faulty • check connection according to chapter "connection steps" and if necessary, correct according to chapter "wiring plan" • voltage supply missing • c...

Page 53

53 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-180111 1 2 3 6 4 5 fig. 33: vegabar 81 in ip 68 version, 25 bar and lateral cable outlet, external housing 1 process module 2 plug connector 3 fixing screw 4 cable assembly 5 connection cable 6 external housing 3. Loosen the plug connect...

Page 54

54 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-180111 caution: instruments with approvals can be bound to certain software versions. Thereforemakesurethattheapprovalisstilleffectiveafterasoftware update is carried out. Youcanfinddetailedinformationinthedownloadareaat www.Vega.Com. 9....

Page 55: 10 Dismount

55 10 dismount vegabar 81 • 4 … 20 ma 45025-en-180111 10 dismount 10.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" and "...

Page 56: 11 Supplement

56 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 11 supplement 11.1 technical data note for approved instruments the technical data in the respective safety instructions are valid for approved instruments (e.G. With exapproval).Thesedatacandifferfromthedatalistedherein,forexampleregardingthep...

Page 57

57 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 connection cable with ip 68 (25 bar) version 2) Ʋ cable cover pe, pur Ʋ type label support on cable pe hard connection cable with ip 68 (1 bar) version 3) pe, pur weights total weight approx. 0.8 … 8 kg (1.764 … 17.64 lbs), depending on process...

Page 58

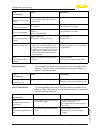

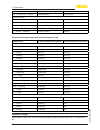

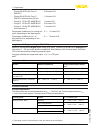

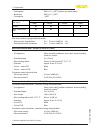

58 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 nominal range overload capacity, max. Pressure overload capacity, min. Pressure -0.5 … +0.5 bar/-50 … +50 kpa +3 bar/+300 kpa -1 bar/-100 kpa absolute pressure 0 … 1 bar/0 … 100 kpa 3 bar/300 kpa 0 bar abs. 0 … 2.5 bar/0 … 250 kpa 7.5 bar/750 k...

Page 59

59 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 min./max. Adjustment: Ʋ percentage value -10 … 110 % Ʋ pressure value -20 … 120 % zero/span adjustment: Ʋ zero -20 … +95 % Ʋ span -120 … +120 % Ʋ differencebetweenzeroandspan max. 120 % of the nominal range max. Permissible turn down unlimited ...

Page 60

60 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 dynamic behaviour output dynamic characteristics depending on medium and temperature 90 % 100 % 10 % t t t a t t s 2 1 fig. 34: sudden change of the process variable. T t : dead time; t a : rise time; t s : jump response time 1 process variable...

Page 61

61 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 deviation in the current output due to strong, high-frequency electromagnetic fieldsacc.Toen61326 deviation (according to iec 60770-1) applies to the digitalsignaloutput(hart,profibuspa,foundationfieldbus)aswellastotheana- logue current output ...

Page 62

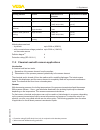

62 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 Ʋ flange dn 80 pn 40, form c, din 2501 0.25 mbar/10 k Ʋ flange dn 80 pn 40, form c, din 2501 with extension 50 mm 1.34 mbar/10 k Ʋ flange 2" 150 lbs rf, asme b16.5 1.2 mbar/10 k Ʋ flange 3" 150 lbs rf, asme b16.5 0.25 mbar/10 k Ʋ flange 3" 150 ...

Page 63

63 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 isolating liquid version p abs > 1 bar/14.5 psi high temperature oil ve 32, kn 32 with cooling element -10 … +320 °c (+14 … +752 °f) up to 10 h: -10 … +400 °c (+14 … +608 °f) with capillaries halocarbon oil kn 21 standard -40 … +150 °c (-40 … +...

Page 64

64 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 Ʋ cable gland m20x1.5,½npt(cableøseebelowtable) Ʋ blind plug m20x1.5;½npt Ʋ closing cap ½npt material cable gland/ seal insert cable diameter 5 … 9 mm 6 … 12 mm 7 … 12 mm 10 … 14 mm pa/nbr ● ● – ● brass, nickel-plated/ nbr ● ● – – stainless ste...

Page 65

65 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 display and adjustment module display element display with backlight measured value indication Ʋ number of digits 5 Ʋ sizeofdigits w x h = 7 x 13 mm adjustment elements Ʋ 4 keys [ok], [->], [+], [esc] Ʋ switch bluetoothon/off bluetooth interfac...

Page 66

66 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 load resistor Ʋ calculation (u b - u min )/0.022 a Ʋ example - non-ex instrument with u b = 24 v dc (24v-9.6v)/0.022a=655Ω potential connections and electrical separating measures in the instrument electronics notnon-floating ground terminal ga...

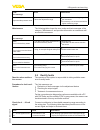

Page 67

67 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 electrical protective measures 14) housing material version protection acc. To iec 60529 protection acc. To nema plastic single chamber ip 66/ip 67 type 6p aluminium single chamber ip 66/ip 67 ip 66/ip 68 (0.2 bar) type 6p type 6p stainless ste...

Page 68

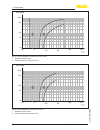

68 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 10 100 50 500 1000 -100 0 100 200 300 400 t °c p mbar abs 1 2 fig. 37: area of application for silicone oil ve 2, kn 2 1 standard chemical seal 2 chemical seal with vacuum service 10 100 50 500 1000 -100 0 100 200 300 400 t °c p mbar abs 1 2 fi...

Page 69

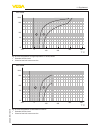

69 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 10 100 50 500 1000 -100 0 100 200 300 400 t °c p mbar abs 1 2 fig. 39: area of application for high temperature oil ve 32, kn 32 1 standard chemical seal 2 chemical seal with vacuum service 10 100 50 500 1000 -100 0 100 200 300 400 t °c p mbar ...

Page 70

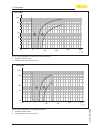

70 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 10 100 50 500 1000 -100 0 100 200 300 400 t °c p mbar abs 1 2 fig. 41: area of application for med. White oil ve 92, kn 92 1 standard chemical seal 2 chemical seal with vacuum service 1 2 10 100 50 500 1000 -100 0 100 200 300 400 t °c p mbar ab...

Page 71

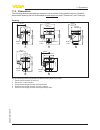

71 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 11.3 dimensions the following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded at www.Vega.Com under "downloads" and "drawings". Housing ~ 69 mm (2.72") ø 79 mm (3.11") 112...

Page 72

72 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 external housing on ip 68 version 1 2 3 4 5 82 mm (3.23") 80 mm (3.15") 108 mm (4.25") 41,6 mm (1.64") ~ 66 mm (2.60") 59 mm (2.32") 110 mm x 90 mm (4.33" x 3.54") 110 mm x 90 mm (4.33" x 3.54") 51 mm (2.01") 41,6 mm (1.64") fig. 44: vegabar 81...

Page 73

73 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 vegabar81,threadedfitting gk ge gl gn ø 32 mm (1.26") sw 32 mm (1.26") g3/4 20 mm (0.79" ) 20 mm (0.79") 164 mm (6.46" ) ø 64 mm (2.52") sw 27 mm (1.06") g1/2 21 mm (0.83" ) ø 39 mm (1.54") sw 41 mm (1.61") g1 sw 55 mm (2.17") 31,5 mm (1.24" ) ...

Page 74

74 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 vegabar 81, tube isolating diaphragm 1.02" 1.26" 1.97" dn mm pn g1 l 25 40 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " g1 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " 128 mb 26 32 40 140 32 50 25 156 50 dn inch pn l 25 40 32 40 50 25 mb 1.12" 1.69" ...

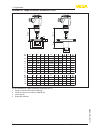

Page 75

75 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 vegabar81,flangeconnection,dimensionsinmm rl d5 dm dm 115 mm (4.53") 109 mm (4.29") d d4 d2 f b k dn pn d k b 25 40 115 18 85 40 40 170 26 125 50 40 165 20 125 d2 4 x ø14 4 x ø22 4 x ø18 d4 68 88 102 f 2 2 2 50 40 165 20 125 80 40 200 24 160 4 ...

Page 76

76 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 vegabar81,flangeconnection,dimensionsininch dn pn d k b 25 40 4.53" 0.71" 3.35" 40 40 6.69" 1.02" 4.92" 50 40 6.5" 0.79" 4.92" d2 4 x ø0.55" 4 x ø0.87" 4 x ø0.71" d4 2.68" 3.47" 4.02" f 0.08" 0.08" 0.08" 50 40 6.5" 0.79" 4.92" 80 40 7.87" 0.95"...

Page 77

77 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 vegabar81,flangeandcellisolatingdiaphragmwithcapillaryline 4.53" 0.71" 0.71" 0.71" 0.55" 0.71" 0.71" 0.79" 0.79" 2.68" 5.91" 3.47" 6.5" 4.02" dn mm pn b d 25 40 115 18 d4 68 40 40 150 18 88 50 40 165 20 102 d2 k 85 14 110 18 125 18 80 40 200 20...

Page 78

78 11 supplement vegabar 81 • 4 … 20 ma 45025-en-180111 11.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen unter...

Page 79: Index

79 index vegabar 81 • 4 … 20 ma 45025-en-180111 index a adjustment 33, 37, 38 – process pressure 36, 37 – system 31 – unit 34 c change the language 39 check output signal 51 chemical seal 10 connection cable 22 connection procedure 23 connection technology 23 copy sensor settings 43 current output 3...

Page 80

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 45025-en-1801 11 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subje...