- DL manuals

- Vega

- Transmitter

- VEGABAR 81

- Operating Instructions Manual

Vega VEGABAR 81 Operating Instructions Manual

Summary of VEGABAR 81

Page 1

Operating instructions pressure transmitter with chemical seal vegabar 81 4 … 20 ma document id: 45025.

Page 2: Contents

2 contents vegabar 81 • 4 … 20 ma 45025-en-160128 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ..................................................................

Page 3

3 contents vegabar 81 • 4 … 20 ma 45025-en-160128 8.1 dd adjustment programs ............................................................................................... 46 8.2 field communicator 375, 475 ........................................................................................ 46 ...

Page 4: 1 About This Document

4 1 about this document vegabar 81 • 4 … 20 ma 45025-en-160128 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tionsformaintenanceandfaultrectification.Pleasereadthisinforma- ...

Page 5: 2 For Your Safety

5 2 for your safety vegabar 81 • 4 … 20 ma 45025-en-160128 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the requi...

Page 6

6 2 for your safety vegabar 81 • 4 … 20 ma 45025-en-160128 2.6 permissible process pressure thepermissibleprocesspressureisspecifiedonthetypelabelwith "process pressure", see chapter "configuration". For safety reasons, this range may not be exceeded. This applies even if a measuring cell with a mea...

Page 7: 3 Product Description

7 3 product description vegabar 81 • 4 … 20 ma 45025-en-160128 3 product description 3.1 configuration thetypelabelcontainsthemostimportantdataforidentificationand use of the instrument: 2 1 13 14 12 10 11 5 3 6 4 7 8 9 fig. 1: layout of the type label (example) 1 instrument type 2 product code 3 fi...

Page 8

8 3 product description vegabar 81 • 4 … 20 ma 45025-en-160128 this operating instructions manual applies to the following instrument versions: • hardware from 1.0.0 • software version from 1.2.0 note: youcanfindthehardwareandsoftwareversionoftheinstrumentas follows: • on the type plate of the elect...

Page 9

9 3 product description vegabar 81 • 4 … 20 ma 45025-en-160128 in combination with a slave sensor, vegabar 81 is also suitable for electronicdifferentialpressuremeasurement. Youcanfinddetailedinformationintheoperatinginstructionsofthe respective slave sensor. Vegabar 81 is suitable for applications ...

Page 10

10 3 product description vegabar 81 • 4 … 20 ma 45025-en-160128 measuringrangesupto40bar:piezoresistivesensorelementwith a transmission liquid, measuring ranges from 100 bar: a dry strain gauge (dms) sensor element. 1 3 4 2 fig. 4: configuration of a measuring system with piezoresistive sensor eleme...

Page 11

11 3 product description vegabar 81 • 4 … 20 ma 45025-en-160128 3.4 packaging, transport and storage your instrument was protected by packaging during transport. Its capacity to handle normal loads during transport is assured by a test based on iso 4180. The packaging of standard instruments consist...

Page 12

12 3 product description vegabar 81 • 4 … 20 ma 45025-en-160128 youcanfindfurtherinformationintheoperatinginstructions"ve- gadis 82" (document-id 45300). The overvoltage protection module is an accessory part for 4 … 20 ma and 4 … 20 ma/hart sensors. Youcanfindfurtherinformationintheoperatinginstruc...

Page 13: 4 Mounting

13 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 4 mounting 4.1 general instructions make sure that all parts of the instrument exposed to the process are suitable for the existing process conditions. These are mainly: • active measuring component • processfitting • process seal process conditio...

Page 14

14 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 warning: the housing must not be used to screw the instrument in! Applying tightening force can damage internal parts of the housing. If there is strong vibration at the mounting location, the instrument version with external housing should be use...

Page 15

15 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 → turnthehousingsothatthefilterelementpointsdownwardafter the instrument is installed. This provides better protection against buildup. 1 2 3 4 4 4 fig. 6: position of the filter element - non-ex, ex-ia version 1 housing plastic, stainless steel p...

Page 16

16 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 instruments with absolute pressure have a blind plug mounted insteadofthefilterelement. Thefilterelementismountedintotheelectronicshousing.Ithasthe following functions: • ventilation of the electronics housing • atmospheric pressure compensation (...

Page 17

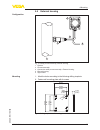

17 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 • connect via a siphon • do not insulate the siphon • fill the siphon with water before setup 1 4 3 2 1 2 3 4 fig. 10: measurement setup with process pressure measurement of gases in pipelines 1 vegabar 81 2 blocking valve 3 siphon in u or circula...

Page 18

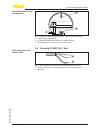

18 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 3 1 2 fig. 11: measurement setup for process pressure measurement of liquids in pipelines 1 vegabar 81 2 blocking valve 3 pipeline 4.4 level measurement keep the following in mind when setting up the measuring system: • mount the instrument below ...

Page 19

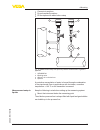

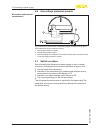

19 4 mounting vegabar 81 • 4 … 20 ma 45025-en-160128 4.5 external housing 1 2 3 4 5 fig. 13: setup process assembly, external housing 1 pipeline 2 process assembly 3 connection cable process assembly - external housing 4 external housing 5 signal cable 1. Mark the holes according to the following dr...

Page 20

20 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried out ...

Page 21

21 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 with plastic housing, the npt cable gland or the conduit steel tube must be screwed without grease into the threaded insert. Max. Torque for all housings, see chapter "technical data". If screened cable is required, we recommend ...

Page 22

22 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 fig. 15: connection steps 5 and 6 - single chamber housing 6. Insert the wire ends into the terminals according to the wiring plan information: solidcoresaswellasflexiblecoreswithwireendsleevesareinsert- eddirectlyintotheterminal...

Page 23

23 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 1 2 + ( ) (-) 4...20ma 2 3 1 fig. 16: electronics and terminal compartment, single chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 ground terminal for connection of the c...

Page 24

24 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 5.5 external housing with version ip 68 (25 bar) 1 2 3 fig. 18: vegabar 81 in ip 68 version 25 bar with axial cable outlet, external housing 1 transmitter 2 connection cable 3 external housing 1 2 3 5 1 2 ( ) + (-) 6 7 8 4...20ma...

Page 25

25 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 1 2 3 4 6 3 4 1 2 5 fig. 20: connection of the sensor in the housing base 1 yellow 2 white 3 red 4 black 5 shielding 6 breather capillaries 1 2 + ( ) (-) 4...20ma 2 3 1 fig. 21: electronics and terminal compartment, single chambe...

Page 26

26 5 connecting to power supply vegabar 81 • 4 … 20 ma 45025-en-160128 5.6 overvoltage protection module b81-35 1 2 + ( ) (-) 4...20ma 1 3 2 fig. 22: electronics and terminal compartment, single chamber housing, termi- nal compartment, double chamber housing 1 overvoltage protection module 2 voltage...

Page 27: Module

27 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor andremovedagainatanytime.Youcanchooseanyoneoffourdiffer...

Page 28

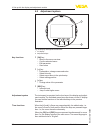

28 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 6.2 adjustment system 1 2 fig. 24: display and adjustment elements 1 lc display 2 adjustment keys • [ok] key: – move to the menu overview – confirmselectedmenu – edit parameter – save value • [->] key: – presen...

Page 29

29 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 approx. 60 minutes after the last pressing of a key, an automatic reset tomeasuredvalueindicationistriggered.Anyvaluesnotconfirmed with [ok] will not be saved. 6.3 measured value indication with the [->]keyyouc...

Page 30

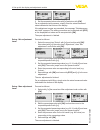

30 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 6.5 parameter adjustment - extended adjustment for technically demanding measuring points, you can carry out extended settings in "extended adjustment". Themainmenuisdividedintofivesectionswiththefollowingfunc-...

Page 31

31 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 in this menu item you activate/deactivate the slave sensor for elec- tronicdifferentialpressureandselecttheapplication. Vegabar 81 can be used for process pressure and level measure- ment. Default setting is pr...

Page 32

32 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 is taken over automatically. With relative pressure measuring cells a manualoffsetcanalsobecarriedout. If the actual measured value should be taken over as correction value duringautomaticpositioncorrection,thi...

Page 33

33 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 the actual product level during this adjustment is not important, because the min./max. Adjustment is always carried out without changing the product level. These settings can be made ahead of time without the ...

Page 34

34 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 3. Set the requested mbar value with [+] and store with [ok]. For an adjustment with pressure, simply enter the actual measured value indicated at the bottom of the display. If the adjustment ranges are exceede...

Page 35

35 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 foranadjustmentwithfilling,simplyentertheactualmeasuredvalue indicated at the bottom of the display. Todampprocess-dependentmeasuredvaluefluctuations,setan integration time of 0 … 999 s in this menu item. The i...

Page 36

36 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 the default setting is min. Current 3.8 ma and max. Current 20.5 ma. In the menu item "lock/unlock adjustment", you can protect the sen- sorparametersagainstunauthorizedorinadvertentmodification.The pin is acti...

Page 37

37 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 the default setting for the display value is "lin. Percent". Inthismenuitemyoudefinethenumberofdecimalpositionswith which the measured value is displayed. The default setting for the display format is "automati...

Page 38

38 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 in this menu item you can simulate measured values. This allows the signal path to be tested, e.G. Through downstream indicating instru- ments or the input card of the control system. Select the requested simul...

Page 39

39 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 definedlinearisationcurveaswellasthemeasuredvaluememoryare deleted. Basic settings: resetting of the parameter settings incl. Special parameters to the default values of the respective instrument. Any userprogr...

Page 40

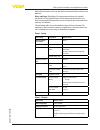

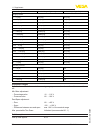

40 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 menu item default value display format 1 and 2 number of positions after the decimal point, auto- matically backlight switched on reset - diagnosis menu item parameter default value sensor status - peak value p...

Page 41

41 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 the copied data are permanently saved in an eeprom memory in the display and adjustment module and remain there even in case of power failure. From there, they can be written into one or more sen- sors or kept ...

Page 42

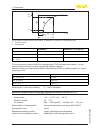

42 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 • percentlinearized • measuring cell temperature (ceramic measuring cell) • electronics temperature depending on the selected measured variable, you assign in the menu item "current output, adjustment" the meas...

Page 43

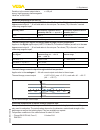

43 6 set up with the display and adjustment module vegabar 81 • 4 … 20 ma 45025-en-160128 6.6 saving the parameter adjustment data we recommended noting the adjusted data, e.G. In this operating instructions manual, and archiving them afterwards. They are thus available for multiple use or service p...

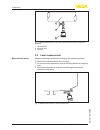

Page 44: 7 Setup With Pactware

44 7 setup with pactware vegabar 81 • 4 … 20 ma 45025-en-160128 7 setup with pactware 7.1 connect the pc 3 1 2 fig. 26: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 3 sensor 7.2 parameter adjustment for parameter adjustme...

Page 45

45 7 setup with pactware vegabar 81 • 4 … 20 ma 45025-en-160128 fig. 27: example of a dtm view all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assistant...

Page 46

46 8 set up with other systems vegabar 81 • 4 … 20 ma 45025-en-160128 8 set up with other systems 8.1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. Thefilescanbedownloadedatwww.Vega.Com/dow...

Page 47

47 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-160128 9 diagnostics and servicing 9.1 maintenance if the instrument is used properly, no special maintenance is required in normal operation. Insomeapplications,productbuilduponthediaphragmcaninfluence the measuring result. Depending on...

Page 48

48 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-160128 sinceweofferthisserviceworldwide,thesupportisprovidedin english. The service itself is free of charge, the only costs involved are the normal call charges. 9.3 exchanging the electronics module in case of a defect, the user can re...

Page 49

49 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-160128 1 2 3 6 4 5 fig. 28: vegabar 81 in ip 68 version, 25 bar and lateral cable outlet, external housing 1 process assembly 2 plug connector 3 fixing screw 4 cable assembly 5 connection cable 6 external housing 3. Loosen the plug conne...

Page 50

50 9 diagnostics and servicing vegabar 81 • 4 … 20 ma 45025-en-160128 caution: instruments with approvals can be bound to certain software versions. Thereforemakesurethattheapprovalisstilleffectiveafterasoftware update is carried out. Youcanfinddetailedinformationinthedownloadareaat www.Vega.Com. 9....

Page 51: 10 Dismount

51 10 dismount vegabar 81 • 4 … 20 ma 45025-en-160128 10 dismount 10.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" and "...

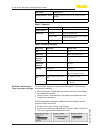

Page 52: 11 Supplement

52 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 11 supplement 11.1 technical data materials and weights materials, wetted parts processfitting 316l diaphragm 316l, alloy c276 (2.4819), alloy c22 (2.4602), monel 400 (2.4360), tantalum, titanium, 316l ectfe coated, 1.4435 with gold coating (25...

Page 53

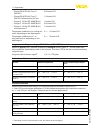

53 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 torques max.Torqueforprocessfittingwiththread 40 nm (29.50 lbf ft) max. Torque for npt cable glands and conduit tubes Ʋ plastic housing 10 nm (7.376 lbf ft) Ʋ aluminium/stainless steel housing 50 nm (36.88 lbf ft) inputvariable-piezoresistive/t...

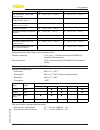

Page 54

54 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 nominal range overload capacity, max. Pressure overload capacity, min. Pressure gauge pressure 0 … +5 psig +15 psig -14.5 psig 0 … +15 psig +45 psig -14.5 psig 0 … +30 psig +90 psig -14.5 psig 0 … +150 psig +450 psig -14.5 psig 0 … +300 psig +6...

Page 55

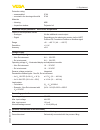

55 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 starting current Ʋ for 5 ms after switching on ≤10ma Ʋ for run-up time ≤3.6ma output variable output signal 4 … 20 ma range of the output signal 3.55 … 22.0 ma (default setting) signal resolution 0.3 µa failure signal current output (adjustable...

Page 56

56 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 90 % 100 % 10 % t t t a t t s 2 1 fig. 29: sudden change of the process variable. T t : dead time; t a : rise time; t s : jump response time 1 process variable 2 output signal vegabar 81 vegabar 81 - ip 68 (25 bar) dead time ≤25ms ≤50ms rise ti...

Page 57

57 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 deviation in the current output due to strong, high-frequency electromagnetic fieldsacc.Toen61326 deviation (according to iec 60770) applies to the digitalsignaloutput(hart,profibuspa,foundationfieldbus)aswellastotheana- logue current output 4 ...

Page 58

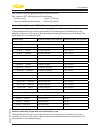

58 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 Ʋ flange dn 80 pn 40, form c, din 2501 0.25 mbar/10 k Ʋ flange dn 80 pn 40, form c, din 2501 with extension 50 mm 1.34 mbar/10 k Ʋ flange 2" 150 lbs rf, asme b16.5 1.2 mbar/10 k Ʋ flange 3" 150 lbs rf, asme b16.5 0.25 mbar/10 k Ʋ flange 3" 150 ...

Page 59

59 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 isolating liquid p abs > 1 bar/14.5 psi version for oxygen applications high temperature oil kn3.2 with cooling element -10 … +330 °c (+14 … +626 °f) -10 … +60 °c (+14 … +140 °f) high temperature oil kn3.2 with cooling element 300 mm -10 … +400...

Page 60

60 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 electromechanical data - version ip 66/ip 68 (1 bar) connection cable, mechanical data Ʋ configuration wires, breather capillaries, strain relief, screen braiding, metal foil, mantle Ʋ standard length 5 m (16.4 ft) Ʋ min. Bending radius 25 mm (...

Page 61

61 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 protection rating Ʋ unassembled ip 20 Ʋ mounted in the housing without lid ip 40 materials Ʋ housing abs Ʋ inspection window polyester foil additional output parameter - electronics temperature output of the temperature values Ʋ analogue via th...

Page 62

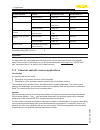

62 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 electrical protective measures housing material version ip-protection class nema protection plastic single chamber ip 66/ip 67 nema 6p double chamber ip 66/ip 67 nema 6p aluminium single chamber ip 66/ip 67 ip 68 (1 bar) nema 6p - double chambe...

Page 63

63 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 5 100 200 300 400 500 600 700 800 900 1000 50 100 150 200 250 300 350 400 t °c p mbar abs 1 2 fig. 31: area of application for high temperature oil kn 32 1 standard chemical seal 2 chemical seal with vacuum service 5 100 200 300 400 500 600 700...

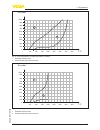

Page 64

64 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 5 100 200 300 400 500 600 700 800 900 1000 50 100 150 200 250 300 350 400 t °c p mbar abs 1 2 fig. 33: area of application for silicone oil kn 17 1 standard chemical seal 2 chemical seal with vacuum service 5 100 200 300 400 500 600 700 800 900...

Page 65

65 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 5 100 200 300 400 500 600 700 800 900 1000 50 100 150 200 250 300 350 400 t °c p mbar abs 1 2 fig. 35: area of application for neobee kn 59 1 standard chemical seal 2 chemical seal with vacuum service 5 100 200 300 400 500 600 700 800 900 1000 ...

Page 66

66 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 11.3 dimensions the following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded at www.Vega.Com under "downloads" and "drawings". Housing ~ 69 mm (2.72") ø 79 mm (3.11") 112...

Page 67

67 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 external housing with ip 68 (25 bar) version 1 2 3 4 5 82 mm (3.23") 80 mm (3.15") 108 mm (4.25") 41,6 mm (1.64") ~ 66 mm (2.60") 59 mm (2.32") 110 mm x 90 mm (4.33" x 3.54") 110 mm x 90 mm (4.33" x 3.54") 51 mm (2.01") 41,6 mm (1.64") fig. 38:...

Page 68

68 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 vegabar81,threadedfitting gk ge gl gn ge > 105° c ø 32 mm (1.26") sw 32 mm (1.26") g3/4 20 mm (0.79") 89 mm (3.5") ø 26 mm (1.02") sw 27 mm (1.06") g1/2 28 mm (1.1") ø 39 mm (1.54") sw 41 mm (1.61") g1 sw 55 mm (2.17") 30 mm (1.81") ø 60 mm (2....

Page 69

69 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 vegabar 81, tube isolating diaphragm 1.02" 1.26" 1.97" dn mm pn g1 l 25 40 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " g1 rd52x 1 / 6 " rd58x 1 / 6 " rd78x 1 / 6 " 128 mb 26 32 40 140 32 50 25 156 50 dn inch pn l 25 40 32 40 50 25 mb 1.12" 1.69" ...

Page 70

70 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 vegabar81,flangeconnection,dimensionsinmm rl d5 dm dm 115 mm (4.53") 109 mm (4.29") d d4 d2 f b k dn pn d k b 25 40 115 18 85 40 40 150 18 110 50 40 165 20 125 d2 4 x ø14 4 x ø18 4 x ø18 d4 68 88 102 f 2 2 2 80 40 200 24 160 8 x ø18 138 2 50 40...

Page 71

71 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 vegabar81,flangeconnection,dimensionsininch dn pn d k b 25 40 4.53" 0.71" 3.35" 40 40 5.91" 0.71" 4.33" 50 40 6.5" 0.79" 4.92" d2 4 x ø0.55" 4 x ø0.71" 4 x ø0.71" d4 2.68" 3.47" 4.02" f 0.08" 0.08" 0.08" 80 40 7.87" 0.95" 6.3" 8 x ø0.71" 5.43" ...

Page 72

72 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 vegabar81,flangeandcellisolatingdiaphragmwithcapillaryline 4.53" 0.71" 0.71" 0.71" 0.55" 0.71" 0.71" 0.79" 0.79" 2.68" 5.91" 3.47" 6.5" 4.02" dn mm pn b d 25 40 115 18 d4 68 40 40 150 18 88 50 40 165 20 102 d2 k 85 14 110 18 125 18 80 40 200 20...

Page 73

73 11 supplement vegabar 81 • 4 … 20 ma 45025-en-160128 11.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen unter...

Page 74: Index

74 index vegabar 81 • 4 … 20 ma 45025-en-160128 index a additional current output 35, 41, 42 adjust date/time 38 adjustment – level 34 – process pressure 33 – unit 31 c change the language 36 check output signal 47 chemical seal 9 connection cable 20 connection procedure 21 connection technology 21 ...

Page 75

75 notes vegabar 81 • 4 … 20 ma 45025-en-160128.

Page 76

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 45025-en-160128 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...