- DL manuals

- Xerox

- Software

- Wide Format 6030

- User Manual

Xerox Wide Format 6030 User Manual

Summary of Wide Format 6030

Page 1

Version 3.0 january 2006 xerox 6030/6050 wide format printer user guide 701p46753.

Page 2

Xerox corporation global knowledge & language services 800 phillips road bldg. 845-17s webster, ny 14580 copyright © 2006 xerox corporation. All rights reserved. Printed in the united states of america. Copyright protection claimed includes all forms and matters of copy- righted material and informa...

Page 3

Preface thank you for using the xerox 6030/6050 wide format copier/printer user guide (hereinafter known as 6030/6050 wide format). This user guide describes the basic operations and the detailed functions of the xerox 6030/6050 wide format copier, printer, and integrated scanner. It also includes u...

Page 4

Conventions this user guide uses the following symbols and conventions: key indicates the keys on the keyboard. Press the key. [ ] indicates the menus and display items on the screens. Select either the [on] or [off] buttons to display [job name], [owner], and [reason] in that order. " " indicates a...

Page 5: Warning Markings

Safety notes read these safety notes carefully before using this product to ensure you operate the equipment safely. Your xerox product and recommended supplies have been designed and tested to meet strict safety requirements. These include safety agency approval, and compliance with established env...

Page 6

Warning shielded cables must be used with this equipment to maintain compliance with council directive 89/336/eec. Electricity at work regulations the electricity at work regulation 1989 came into force in england and wales on the 1 april 1990. This 1989 regulation places a duty on all employers and...

Page 7: Electrical Supply

Question: is the xerox equipment in my premises safe? Answer: all xerox equipment supplied by xerox and its authorized distributors conform to all rele- vant safety legislation and standards. However, like all electrical equipment, they have to be regularly serviced and maintained by competent perso...

Page 8: Operator Accessible Areas

This product must be connected to a protective earth circuit. This product is supplied with a plug that has a protective earth pin. This plug will fit only into an earthed electrical outlet. This is a safety feature. To avoid risk of elec- tric shock, contact your electrician to replace the electric...

Page 9: Emergency Power Off

Ensure that the power connection for your machine satisfies these require- ments • use only the power cord supplied with this equipment. • the socket outlet shall be installed near the equipment and shall be easily accessible. • plug the power cord directly into a grounded electrical outlet. Do not ...

Page 10: Disconnect Device

Disconnect device the power cable is the disconnect device for this equipment. It is attached to the back of the machine as a plug-in device. To remove all electrical power from the equipment, disconnect the power cable from the electrical outlet. Xerox equipment and supplies have been designed and ...

Page 11

• never remove covers or guards that are fastened with screws. There are no operator serviceable areas within these covers. • never locate the equipment near a radiator or any other heat source. • never push objects of any kind into the ventilation openings. • never override or "cheat" any of the el...

Page 12: New Zealand

Store all consumables in accordance with the instructions given on the package or container. • keep all consumables away from the reach of children. • never throw toner, toner cartridges, or toner containers into an open flame. United states, canada, europe, australia/ new zealand this equipment has...

Page 13

This product is certified by the following agencies using the safety standards listed. Agency standard tuv rheinland of north america, inc. Ul60950:2000 (usa) can/csa-c22.2 no. 60950-00 (canada) tuv rheinland japan ltd. Iec60950:1999 product safety certification.

Page 14: Ce Mark

Regulatory information ce mark the ce mark applied to this product symbolizes xerox's declaration of conformity with the following applicable directives of the european union as of the dates indi- cated: january 1, 1995: council directive 72/23/eec amended by council directive 93/ 68/eec, approximat...

Page 15: Usa - Energy Star

Environmental compliance usa - energy star as an energy star partner, xerox corporation/fuji xerox has determined that (the basic configuration of) this product meets the energy star guidelines for energy efficiency. The energy star and energy star mark are registered united states trademarks. The e...

Page 16: Usa

Product recycling and disposal usa xerox operates a world wide equipment take back and reuse/recycle program. Contact your xerox sales representative (1-800-ask-xerox) to determine whether this xerox product is part of the program. For more information about xerox environmental programs, visit www.X...

Page 17: Usa

Illegal copies and printouts usa congress, by statute, has forbidden the reproduction of the following subjects under certain circumstances. Penalties of fine or imprisonment may be imposed on those guilty of making such reproductions. 1. Obligations or securities of the united states government, su...

Page 18

1. Stamps and other representatives of value, of whatever denomination, which have been or may be issued under any act of congress. 2. Adjusted compensation certificates for veterans of the world wars. 3. Obligations or securities of any foreign government, bank, or corporation. 4. Copyrighted mater...

Page 19: Canada

Canada parliament, by statute, has forbidden the reproduction of the following subjects under certain circumstances. Penalties of fine or imprisonment may be imposed on those guilty of making such reproductions. 1. Current bank notes or current paper money. 2. Obligations or securities of a governme...

Page 20: Other Countries

Other countries copying certain documents may be illegal in your country. Penalties of fine or imprisonment may be imposed on those found guilty of making such reproductions. - currency notes - bank notes and cheques - bank and government bonds and securities - passports and identification cards - c...

Page 21

Table of contents chapter 1 product overview 1.1 product configurations ................................................................................................................... 2 1.2 major components.............................................................................................

Page 22

3.2 communication parameter setup (printer control panel)............................................................ 64 3.3 communication parameter setup (print services on web) .......................................................... 70 3.4 system parameter setup (printer control panel)............

Page 23

Ps command.......................................................................................................................... 143 eop command....................................................................................................................... 144 vcgl pen style (vcgl define ...

Page 24

5.6 billing meter confirmation ........................................................................................................ 199 5.7 print setup menu ........................................................................................................................ 200 setting up med...

Page 25

9.2 media specifications................................................................................................................... 252 9.3 machine specifications............................................................................................................... 253 command list ....

Page 27

Chapter chapter 0 1 product overview chapter 1.

Page 28: 1.1

1.1 product configurations the following product configurations and options are available for the xerox 6030/6050 wide format printer and the xerox 6030/6050 wide format copier/ printer. Xerox 6030/6050 wide format printer this unit is a printer only. Refer to the printer sections of this guide for ...

Page 30

Xerox 6030/6050 wide format printer with scan system this unit features copier and printer functionality, plus the synergix ® scanner and the accxes ® controller. Xerox 6030/6050 wide format options you may acquire additional hardware and software options for all units. Contact your xerox sales repr...

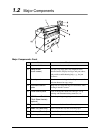

Page 31: 1.2

1.2 major components major components: front name function 1 document table documents to be scanned are inserted here. 2 setup screen (touch screen) used to set up copy jobs, map originals to the installed media, display messages and procedures, and provide troubleshooting help, e.G., for jam cleara...

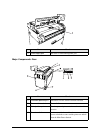

Page 32

Major components: rear name function 1 toner supply port the toner is refilled through this port. Name function 1 document ejection port documents exit the scanner from this location. 2 power outlet socket not available 3 print ejection port fused copies and prints exit the machine from this locatio...

Page 33

5 interface connector the connector to which the printer is connected. 6 serial port connector used by the service representative for maintenance. 7 circuit breaker switch provides circuit breaker protection for the copier/ printer or printer. 8 paper heater switch switches the paper heaters on and ...

Page 34: 1.3

1.3 power on/off the scanner and the printer are each equipped with a power switch. The circuit breaker switch must be in the on position to switch the printer and scanner power on and off. No power is consumed when the circuit breaker switch is in the off position, even though the power plug is con...

Page 35

Powering off switch off the power following the steps below. 1 switch off the main power switch. 2 switch off the scanner power switch. 3 switch the circuit breaker switch to the off position. Never switch off the power while the machine is printing. Failure to observe this precaution may result in ...

Page 36: 1.4

1.4 power save mode the power save mode automatically lowers the power consumption of the machine by reducing the fuser power. The machine will enter the power save mode when no prints or copies have been made for a preset period of time. • low power mode 1 this mode reduces the temperature of the f...

Page 37: 1.5

1.5 printer control panel overview both the printer and the copier/printer versions of the 6030/6050 wide format are equipped with a printer control panel. This section provides an overview of this device. Refer to section "2.2 printer control panel usage" and "chapter 5 additional operations from t...

Page 38

Used for setting up the various functions. Displays various messages. [online] lamp (green) [processing] lamp (green) printer display indicates the data processing status. On ready to print. Blinking moving to the offline mode. Off the offline mode. Printing is not possible. [error] lamp (red) indic...

Page 39: 1.6

1.6 print services on web overview print services on web is web server software which is pre-installed in the 6030/ 6050 wide format printer and copier/printer. Print services on web provides a user-friendly way to perform printer setup, communication (port) setup, job and error log management, and ...

Page 40

Operating modes user mode the user mode interface (user page) is shown in the image below. This page displays immediately after a user logs on to print services on web. The selections on the tabs enable the user to do the following. [job and log] tab check the status of a print job. View and print a...

Page 41

Administrator mode to enter the administrator mode, log on to print services on web, select the [administrator page] button, and then enter the administrator login and password when prompted to do so. The administrator page displays two additional tabs, [properties] and [tools], and expands the capa...

Page 42: 1.7

1.7 logical printers overview a logical printer (virtual printer) is a group of saved print job settings for a particular data format, i.E., hp-gl, versatec, tiff, cals, and ps/pdf. These saved settings, which are created using print services on web, may include pen attributes, media type, print qua...

Page 43: 1.8

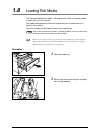

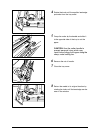

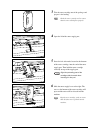

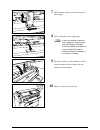

1.8 loading roll media the message ‘replace xxx media." will display when there is no media loaded or when the roll in use runs out. The media size displayed on the control panel will turn off when there is no media in the machine. Two rolls of media can be loaded in each of the media trays. Procedu...

Page 44

3 while pulling on the lever located in the end of the roll paper shaft, remove the paper core in the direction of the arrow. 4 while pulling the lever located in the end of the roll paper shaft, align the roll paper with the paper size marks on the shaft and set the roll in place. 5 align the roll ...

Page 45

6 rotate the roll media until the lead edge is gripped in the roller. 7 gently but firmly close the media tray. The led on the front of the tray will illuminate, and the roll paper will feed automatically to its starting position. 8 set up the media parameters on the copier control panel. Rotate the...

Page 46

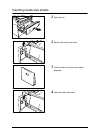

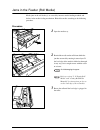

1 . 9 drawer media size indicators the media size indictors help the user identify the media that is loaded in each of the drawers. These indicators are visible on the right hand side of the drawers. Usage instructions begin on the next page. The following types are available. • standard size a • in...

Page 47

Inserting media size sheets 1 open the tray. 2 remove the media size sheet. 3 fold the sheet so that the size loaded is displayed. 4 insert the media size sheet..

Page 48

5 gently but firmly close the media tray..

Page 49: 1.10

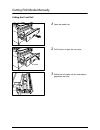

1.10 loading media for manual feeding 1 adjust the (msi) multi sheet inserter/ manual feed unit's side guides to fit the size of the media that is to be printed. 2 place the side of the media to be printed face up, and align it with the (msi) multi sheet inserter/manual feed unit's side guides. 3 pu...

Page 50: 1.11

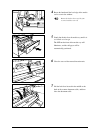

1.11 cutting roll media the lead edge of the media should be cut when the media is loaded, on recovery from a media jam, and when the lead edge of the roll is damaged. There are two methods for cutting the lead edge of the roll media: • automatic cut: this involves making selections on the printer c...

Page 51

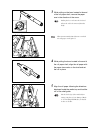

Cutting roll media manually cutting the front roll 1 open the media tray. 2 pull the lever to open the tray cover. 3 rotate the roll media until the lead edge is gripped by the roller. Lever.

Page 52

4 rotate the knob until the media's lead edge protrudes from the tray outlet. 5 grasp the cutter by the handle and slide it to the opposite side of the tray to cut the paper. Caution: use the cutter handle to prevent personal injury which may result from sliding your fingers along the sharp, metal c...

Page 53

9 close the media tray..

Page 54

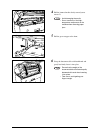

Cutting the rear roll 1 open the media tray. 2 rotate the roll paper until the lead edge is gripped by the roller. 3 rotate the knob until the media's lead edge protrudes from the tray outlet. 4 pull the lever to open the tray cover. 5 rotate the knob until the paper passes through the tray outlet..

Page 55

6 grasping the cutter by the handle, slide the cutter to the opposite side of the tray to cut the paper. Caution: use the cutter handle to prevent personal injury which may result from sliding your fingers along the sharp, metal cutting bar. 7 remove the media that was cut off. 8 close the tray cove...

Page 57

Chapter chapter 0 2 printer overview chapter 2.

Page 58: 2.1

2.1 overview of the 6030/6050 wide format print service this section provides an overview of the 6030/6050 wide format print service. What is the 6030/6050 wide format print service? The 6030/6050 wide format print service is software that processes print jobs that it receives from a client. The 603...

Page 59

Printing methods documents may be submitted from a client to the 6030/6050 wide format printer using any of the following. • ethernet (direct) printing this capability is for unix systems. Printing takes place over tcp/ip networks using the ftp and lpr commands. • wide format windows driver the micr...

Page 60

Print service operations the printer control panel and print services on web are the two main features that enable users to set up and perform print service operations. Printer control panel the printer control panel can be used to perform a variety of tasks, among them: • media setup for roll media...

Page 61

Print services on web print services on web is web server software which is pre-installed in the 6030/ 6050 wide format. Print services on web provides a user-friendly way to perform printer setup, communication (port) setup, log management, and other procedures via a web browser. Print services on ...

Page 62

Main printing functions this section describes the main printing functions which are available with the 6030/6050 wide format printer and copier/printer. Logical printers a logical (virtual) printer is a group of saved print job settings for a particular data format, i.E., hp-gl, versatec, tiff, cal...

Page 63

Document size input the following two methods are available for judging the size of the input document: • automatic calculates the coordinates of the input document and automatically selects the closest size. • size specificationenables the user to manually select the media size of the input image. ...

Page 64

Size mapping size mapping is the process of setting up a table that establishes relationships between input document sizes and output image sizes. When size mapping is finished (must be done prior to printing), documents can be enlarged or reduced automatically based on the table entries. Media mapp...

Page 65

Plot area, auto-layout, and offset it is possible to print a specified area of an input document. The specified area can be printed in the center of the media or moved to another position (auto- layout, offset). Mirror image, 90-degree rotation these functions perform mirroring (mirror image) or 90-...

Page 66

Split drawing (image fragmentation) long images (those that exceed 1,189 mm in length) may be split into several parts and printed. Positioning marks can be added to the split prints for positioning purposes. Printing the output time the date and time a document is printed can be added to the edge o...

Page 67

Canceling jobs jobs transmitted to the 6030/6050 wide format can be deleted by pressing the key on the printer control panel. It is also possible to cancel jobs from print services on web. Meter display the billing meters can be checked from both print services on web and the printer control panel. ...

Page 68: 2.2

2.2 printer control panel usage this section describes the names and functions of the printer control panel components. Press the > and > keys simultaneously to reset the printer when an error code is displayed. Used for setting up the various functions. Displays various messages. [online] lamp (gre...

Page 69

Basic printer control panel operations the printer must be in the offline mode before settings can be changed. Pressing the the menu screen. Button functions the following buttons are used to navigate the menu screen. Switches the printer to the offline mode and displays the menu screen. The printer...

Page 70

Overview of the operation menu the printer control panel’s operation menu is depicted in the image below. Descriptions of the sub-menus follow. System parameter menu sets up the system management information, such as the system date and power save mode settings. Refer to "8.4 system parameter setup ...

Page 71

Port setting menu sets up the communication parameters that are required for connecting to the host. Test plot menu prints test patterns to help verify printer operation. Job logging menu prints job and error logs. Offline plot menu reprints the most recently printed job. Billing info menu displays ...

Page 72

Operation examples this section provides examples of how to select menu items. 1 press the the machine will enter the offline mode. 2 press the > key. The top selection in the [network/port set] menu will display. 3 press the > key. The menu items will display in order. 4 press the > key. The sub-me...

Page 73

Setting up a value this section provides an example of setting up a value. 1 select the menu item that you want to set up so that it displays on the screen. 2 press the > key. The current value will display. 3 use the > and > keys to change the setting. 4 press the key to specify and confirm the new...

Page 74

Entering numbers and characters this section provides examples of how to enter numbers and characters. 1 select the menu item that you want to set up. 2 press the > key. The current setting for the selected item will display. 3 set up the first number using the > and > keys. The value will increase ...

Page 75: 2.3

2.3 print services on web print services on web is web server software which is pre-installed in the 6030/ 6050 wide format. Print services on web enables the user to perform the following procedures from a workstation using a web browser. • set up communication parameters • set up logical printers ...

Page 76

Starting and exiting print services on web this section explains how to start and exit print services on web. Start print services on web 1 start the browser. 2 enter the url for the 6030/6050 wide format (http://home name or ip address) in the browser's address field, and then press the key. Exit p...

Page 77

Print services on web organization this section explains the various pages contained within print services on web. User page this is the first page displayed when connecting with the print services on web. The user page allows users to do the following. Administrator page the administrator page (see...

Page 78

The administrator page permits the following. [job and log] tab • check the status of jobs in the print queue. • view and print the job log and the error log. • cancel a print job. • change the priority of a print job. [status tab] • check the status of the printer or copier/printer. • stop and star...

Page 79

Online help click the help [?] button displayed at the top, right corner of the window to display the online help. The online help enables you to answer many questions related to using print services on web..

Page 81

Chapter chapter 0 3 printer setup chapter 3.

Page 82: 3.1

3.1 communication parameters the 6030/6050 wide format printer and copier/printer must be connected to a host pc before printing can be performed. Once the printer or copier/printer is connected to the network, the communication parameters must be set up. The communication parameters can be set up f...

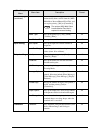

Page 83

Tcp/ip the following tcp/ip communication parameters must be set up. The communication parameter nomenclature on the printer control panel will sometimes differ from the nomenclature on print services on web. The print service on web nomenclature appears in bold type in the table below. Menu item de...

Page 84

*the routing table can be edited if [static routing] is set to [enable]. A maximum of 512 items can be saved in the routing table. The [registration not possible] screen will display if the number of items exceeds 512. Menu item description routing table select [add] to enter additional routing info...

Page 85

Serial the serial communication parameters are listed below. The communication parameter nomenclature on the printer control panel will sometimes differ from the nomenclature on print services on web. The print service on web nomenclature appears in bold type in the table below. Menu item descriptio...

Page 86

Job separation (page limit) sets up the job separation option. The default setting is [no]. [yes] starts data conversion once the command that recognizes the end of the data is received, even if it occurs midway through the file. [no] spools data on the hard disk until the timeout is issued. Menu it...

Page 87

Centronics (optional) the centronics communication parameters are presented below. Menu item description ack mode the ack mode is selected from [mode0], [mode1], [mode2], [mode3], and [mode7]. The default setting is [mode0]. Dma timeout the timeout value for data input is entered within a range of 1...

Page 88

Vpi (optional) the following vpi communication parameters must be set up. Menu item description report offline determines if the host will be notified offline of the media running out. The default setting is [no]. [yes] issues offline notification. [no] does not issue offline notification. Eop timeo...

Page 89

Snmp the communication parameters listed below must be set up. Snmp must be set up in print services on web. The communication parameter nomenclature on the printer control panel will sometimes differ from the nomenclature on print services on web. The print service on web nomenclature appears in bo...

Page 90: 3.2

3.2 communication parameter setup (printer control panel) this section explains the procedures for setting up the communication parameters from the printer control panel. Procedure 1 press the > key with [port setting] displayed. 2 select the interface that is to be set up with the use of the > and ...

Page 91

Tcp/ip setup 1 display [tcp/ip] on the selection screen, and then press the > key. 2 select the item that is to be set up with the use of the > and > keys, and then press the > key. [ethernet setting], [default parser], [ip address], [mask value], [e-net address], [dynamic routing], and [static rout...

Page 92

1. Select [on] for [static routing], and then press the key. Now press the > key. 2. Select [add] for the [routing table], and then press the > key. 3. Enter the destination address, and then press the key. After setting up the destination address, move the cursor to the right-hand side and press th...

Page 93

Serial setup 1 display [serial] on the setup item selection screen, and then press the > key. 2 select the item that is to be set up with the use of the > and > keys, and then press the > key. [handshake], [baud rate], [parity], [data bit], [stop bit], [eop timeout], [output response], and [job sepa...

Page 94

Centronics (optional) setup 1 display [centro] on the setup item selection screen, and then press the > key. 2 select the item that is to be set up with the use of the > and > keys, and then press the > key. [ack mode], [dma timeout], [eop timeout], and [job separation] will display, in that order. ...

Page 95

Vpi (optional) setup 1 display [vpi] on the setup item selection screen, and then press the > key. 2 select the item that is to be set up with the use of the > and > keys, and then press the > key. [report offline], [eop timeout], and [job separation] will display, in that order. 3 select the parame...

Page 96: 3.3

3.3 communication parameter setup (print services on web) the communication parameters for tcp/ip, serial, centronics (optional), vpi (optional), and snmp can be set up from print services on web. These procedures are explained below. Procedure 1 start print services on web, enter the administrator ...

Page 97

2 select the interface or protocol ([tcp/ip], [serial], [centro], [vpi], [snmp]) to be set up from the [system parameters] menu. The setup selections will display in the right-hand pane of the window. In the example below, [serial] has been selected. 3 set up each of the parameters as required, and ...

Page 98

4 to print a list of the settings, drag the right scroll bar to the bottom, and then select the [print] button. 5 after setting up all of the parameters, switch the main power switch off and then on to enable the changes to take effect..

Page 99: 3.4

3.4 system parameter setup (printer control panel) the following system parameters can be set up from the printer control panel. These parameters can be set up on the copier control panel on the xerox 6030/6050 copier/printers. If the parameters are set up on both the printer control panel and the c...

Page 100

Print density sets up the default print density level. The density setting is a numeric value between -99 and 99. Job recovery determines how the jobs that were in the print queue when the printer power was shut off will be processed when the printer is switched back on. The default setting is [off]...

Page 101

Procedure 1 press the > key with [menu]/[system parameter] displayed. 2 scroll to the item you wish to set up using the > and > keys. [set date], [auto roll], [spa paper width], [smoothing], [low power mode1], [low power mode2], [sleep mode], [attention light], [print density], [job recovery], and [...

Page 102: 3.5

3.5 system parameter setup (print services on web) the system parameters listed below can be set up from print services on web. These procedures are performed on the administrator page. Refer to "3.3 communication parameter setup (print services on web)" for information about setting up the [tcp/ip]...

Page 103

Job recovery determines how the jobs that were in the print queue when the printer power was shut off will be processed when the printer is switched back on. The default setting is [off]. [off] jobs that had not been output when the power was shut off are canceled (not printed). [queued] prints out ...

Page 104

Procedure 1 start print services on web, log in as administrator, and display the [properties] tab. 2 select the item that is to be set up from the [system parameter menu], for example, [priority], [replot], [print density], [paper width for special a], [job recovery], [exclusive access time out], [...

Page 105

Setting up [priority] 1 select [priority] from the [system parameters] menu. The [priority] selections will display in the right pane. 2 select the queuing standard from [qin_fopen] or [qin_fclose]. 3 press the [apply] button to save the new setting, [cancel] to revert to the existing setting, or [r...

Page 106

Setting up [replot] 1 select [replot] from the [system parameters] menu. The replot setup selections will display in the right pane. 2 the parameter is enabled by default. De-select the checkbox to disable the feature. Disabling the feature will render the reprinting function inoperative. 3 press th...

Page 107

Setting up [print density] 1 select [print density] from the [system parameters] menu. The print density selections will display in the right pane. 2 enter a positive or a negative number between -99 and +99 to set up the default print density. Larger negative numbers lighten the prints. Higher posi...

Page 108

Setting up [paper width for special a] 1 select [paper width for special a] from the [system parameters] menu. The paper width for special a selections will display in the right pane. 2 select the required paper width for special a1 and special a2 paper from the available selections. 3 press the [ap...

Page 109

Setting up [job recovery] 1 select [job recovery] from the [system parameters] menu. The job recovery selections will display in the right pane. 2 select the option that will determine how jobs that are in the print queue when the printer power is shut off will be processed when the power is switche...

Page 110

Setting up [extension] 1 select [extension] from the [system parameters] menu. The extension selections will display in the right pane. 2 select the required format from [data format]. 3 as required, add or delete an extension: add an extension to add a new extension, enter an extension name of eigh...

Page 111

Setting up [set date] 1 select [set date] from the [system parameters] menu. The set date selections will display in the right pane. 2 enter the date. 3 enter the time. 4 press the [apply] button to save the new setting, or press [cancel] to revert to the existing setting. If the time selections are...

Page 112: 3.6

3.6 user management (print services on web) the user management menu on the [properties] tab of print services on web enables the administrator to perform the user management functions described in this section. Changing user passwords 1 select [user list (ftp)] from the [user management] menu. A li...

Page 113

The change password fields will display in the right pane of the window. 3 enter the new password in the [new password] field. 4 confirm the new password in the [confirm new password] field. 5 click the [apply] button to save the change, or [cancel] to undo it. Adding users 1 select [add user (ftp)]...

Page 114

Deleting users 1 select [user list (ftp)] from the [user management] menu. A list of all current ftp users will display in the right pane, including the default username [ftpusr] which is set up within the system and cannot be deleted..

Page 115

2 select the [delete] button for the ftp username that you wish to delete. A warning popup will display if you attempt to delete [ftpusr]..

Page 116: 3.7

3.7 printing a configuration list the procedures below explain how to print a configuration list that shows the hardware and software configuration, communication parameter (port) settings, and system parameter settings of the printer. This list may be printed from either the printer control panel o...

Page 117

From print services on web 1 start print services on web, log in as administrator, and select the [properties] tab. 2 select [print settings] in the system parameters menu. The current print settings will display in the right pane. 3 using the scrollbar on the right side of the window, scroll to the...

Page 118

An example of the configuration list (settings printout) is shown below..

Page 119

Description of the configuration list contents the contents of configuration list are explained below. Displayed item description h/w config model product name software version installed version of the printer software ram total displays the amount of memory installed in the printer. Segment memory ...

Page 120: 3.8

3.8 software option the [software option] selection on the print services on web [properties] tab displays all installed optional software and related feature key (key install key) information, for example, for the postscript driver..

Page 121: 3.9

3.9 change password the [change password] selection on the print services on web [properties] tab can be used to change the password that is used to log in to the administrator page. 1 select the [change password] selection on the [properties] tab. The [change web administrator password] fields will...

Page 122: 3.10

3.10 change default language the [change default language] selection on the print services on web [properties] tab can be used to change the language that is displayed when print services on web is started. The language can be changed to english, french, italian, german, spanish, or portuguese. This...

Page 123

Chapter chapter 0 4 logical printer setup and operation chapter 4.

Page 124: 4.1

4.1 creating a new logical printer one hundred logical (virtual) printers, numbered from 00 to 99, can be set up for each of the available data formats (hp-gl, versatec, tiff, cals, ps/pdf). The procedure below explains how to create a new logical printer. 1 start the web browser and log in to print...

Page 125

3 select the data format for the new logical printer from the [data format] menu. The selections include [versatec], [hp-gl], [tiff], [cals], and optionally, [ps/pdf]. The logical printers are pre-configured in the factory to their default print settings. These defaults, as well as the options you c...

Page 126

4 select an unused logical printer. To do this, select a range of numbers in the [detail] list at the left side of the screen, beginning with [00-09]. The ten logical printers will appear in the right pane of the screen. 5 continue selecting the ranges of numbers, as required, until you locate an un...

Page 127: 4.2

4.2 defining the print settings the next step, after creating a logical printer, is to set up the parameters that define how it will process print jobs. These parameters are located at the left side of the screen in the [print setup] menus ([media setting], [input setting], [output setting], [transf...

Page 128: 4.3

4.3 logical printer print settings this section describes the print settings for the logical printers. Logical printer parameters by data format the logical printer parameters will vary by data format, as indicated in the table below. Parameters common to all data formats the following table lists t...

Page 129

Media setting (continued) media source determines whether the paper is to be fed automatically from a roll or from the (msi) multi sheet inserter/manual feed unit, and sets up the priority ([job] or [controller]). The optional (msi) multi sheet inserter/manual feed unit is required for manual feedin...

Page 130

Parameters unique to data formats [print setup] menu menu item description data format output setting plot area sets the print range, centering, and offset. All (see note) color option enables or disables the white mode (white line) function. Hpgl, versatec tiff option sets up the sorting and output...

Page 131

Media series this parameter sets up the media size series for the input size, output size, and media size. Each item can be set to a different media size series. Settings the settings are as follows. All of the default settings are [iso a]. Menu item description input size sets up the media group fo...

Page 132

The media types that can be set for each paper group are shown below. • input size, output size • media size media series standard size iso a a0 to a4, u0 to u4, a0l to a4l iso b input size: b0 to b4, bu0 to bu4, b0l to b4l output size: b1 to b4, bu1 to bu4, b1l to b4l special a sa0 to sa3, su0 to s...

Page 133

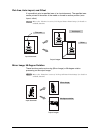

Size/media mapping standard size images and user-defined images can be enlarged and reduced to fit standard and user-defined output sizes. This is known as "size mapping". It is also possible to specify which roll media is to be used based on the output size. This function is known as "media mapping...

Page 134

Media mapping settings the settings for this function are as follows. Menu item description auto mapping sets whether the automatic mapping functions is to be enabled or not. The output paper size that best matches the output image size will be determined automatically when this function is set to [...

Page 135

Example when the mapping table is set up as shown below, an image with an input size of a3 will be printed as follows. C size mapping is applied to the image with an input size of a3, which is then enlarged to an a2 output size (enlarged by 141.4%). D media mapping is applied as the output size is a...

Page 136

Media source this setting determines whether the media will automatically feed from a roll or from the manual feed tray (cut sheet). The priority sequence when automatic selection is specified is [roll1], [roll2], [roll3], and [roll4], in that order. Settings the settings for this function are as fo...

Page 137

Media type determines the default media type selection for printing. This setting is valid when a different type of media of the same size is loaded in the printer. [any] is set for this under normal circumstances. Settings the settings for this function are as follows. When the media type specifica...

Page 138

User-defined size the user-defined sizes are used for printing long images and non-standard size media. User-defined sizes can be specified for each standard size. It is possible to uniformly output all images that exceed the standard sizes but are within the specified user-defined sizes. Settings t...

Page 139

Input option sets up the input image size. Two judgment methods are available for input image size. • automatic (auto) calculates the coordinates of the input image and automatically determines the nearest media size. • specify size enables the user to manually select the media size of the input ima...

Page 140

Settings the settings for this function are as follows. Menu item description media size this parameter can be selected from either [auto] or one of the listed media sizes. The default setting is [auto]. The media size selections will differ based on the [input size] parameter that is set up for the...

Page 141

Input size margin specifies the top, bottom, left, and right margin settings for determining input sizes. Plus (+) values represent margins outside of the media size, and minus (–) values represent margins inside the media size. The size that includes (excludes) these margins is established as the i...

Page 142

Settings the settings for this function are as follows. Example the media margin settings are determined according to the following for input data consisting of 300 x 420 mm. Menu item description x sets the left and right margin values within a range of –99 to 99 mm. The default settings is [5 mm]....

Page 143

Plot area enables the print range (the plot area) to be specified based on the input image information. The plot area can be set up so that the image prints in the center of the media (auto layout) or is offset (set offset value). If part of the image overlaps the margin when offset is specified, it...

Page 144

Settings the settings for this function are as follows. When [disable] is selected for [auto layout], specify the desired offset value for the media size to be used. For example, if the following settings have been made, an image with an a2 output size will be printed with an offset of 20 mm in the ...

Page 145

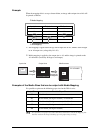

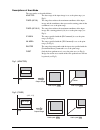

Descriptions of area mode the area modes are described below. Adapted the data range of the input image is set as the print range (see fig.1). Fixed (hp-gl) the range that encloses the maximum coordinate of the input image and the coordinates that represent the starting point of that coordinate is s...

Page 146

Fig.3. (ip area and iw area) fig.4. (first) fig.5. (first ) input image (0,0) offset output image the area specified with the [ip command] or [iw command]. Auto layout: [no] auto layout: [yes] (0,0) output image offset auto layout: [no] auto layout: [yes] (0,0) input image output image.

Page 147

Priority sets up the printing priority. This function increases the priority of a job to print it out sooner when the job queue is congested. Settings the settings for this function are as follows. Menu item description priority sets one of the following as the printing priority. The default setting...

Page 148

Title block the setting determines whether or not to rotate images 180 degrees. This setting is used to change the image orientation to ensure correct folding. Settings the available settings are as follows. Menu item description media size determines whether or not to rotate images for each media s...

Page 149

Split drawing when an image exceeds 1,189mm in length, it can be split (fragmented) and printed in sections. This function also enables you to add positioning marks on each split section. A maximum of 30 such sections is possible. Settings the settings for split drawing are as follows. Item descript...

Page 150

Page margin determines whether or not the page margin will be present, and sets the margin where the pages are joined within a range of 0 to 90 mm. The default settings is [0 mm]. Alignment mark printing determines whether or not to print positioning marks. The default setting is [off]. Item descrip...

Page 151

Message option determines whether or not to print error messages, label messages, and date messages on the print. The size of the characters used in the messages is fixed at a height of 2 mm regardless of the enlargement or reduction. Settings the settings are as follows. Menu item description error...

Page 152

Date message determines whether or not to print date messages. The default setting is [off]. The date format is [year/month/day hour:minutes]. Example: [2006/01/02 14:56] display position sets up the location where the message(s) will be printed. [upper left] prints the message(s) at the top left-ha...

Page 153

Printed copy sets up the default number of copies to be printed. Settings the settings for this function are as follows. The [priority] parameter can only be set for versatec data. Menu item description printed copy sets up the number of copies to be printed, in a range from 1 to 99. The default set...

Page 154

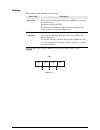

Output option sets up the output size. The following two judgment methods are available for output image size. • automatic (auto, other, mix, mix2) determines the most suitable output size based on the input size and the size mapping table. It also determines the roll media size to use based on the ...

Page 155

Settings the settings for this function are as follows. Menu item description media size this parameter can be selected from [auto], [other], [mix], [mix2], or any of the standard media sizes. The default setting is [auto]. [auto] the standard shape priority mode. If the length of the document excee...

Page 156

Input image that is longer than the standard size output image in the case of [auto] output in a size that is the standard shape increased in a multiple of integers. In the case of [other] the same size as the input image is output. 4a3 connect = 3 a3 a3 a3 a3 paper feed direction top margin bottom ...

Page 157

Size recognition size recognition determines whether images that are less that an a0 size in length (1,189 mm), but that are larger than a standard size, will be printed on media that is one size larger, or on standard size that has been increased in length. This setting is useful when all images wi...

Page 158

Settings the settings for this function are as follows. Menu item description size recognition sets up the size recognition priority mode. The default value is [standard long size output]. [standard long size output] outputs images that are within the a0 size, but exceed the standard size, on one si...

Page 159

Color option sets the pen drawing color at a specified density or at black when a color command other than black is specified. Settings the settings for this function are as follows. This setting is only valid for hp-gl and versatec data. Menu item description white mode determines how lines will be...

Page 160

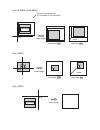

Transform enables or disables the auto scale (automatic enlargement/reduction), mirror image, and 90-degree rotation functions. Auto scale mirror image input image output image input image output image.

Page 161

90-degree rotation settings the settings for this function are as follows. Menu item description auto scale determines whether or not to automatically enlarge or reduce sizes when the input size and output size are different. The default setting is [enable]. [enable] automatically enlarges or reduce...

Page 162

Define single pen defines the width, color, end style, and joint style pen attributes for hp-gl data. Click the [change] button to edit the attributes of a pen. The screen below will display. Click [apply] to save your changes..

Page 163

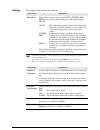

Settings the settings for this function are as follows. Menu item description pen no. Sets up the pen number, in a range from 0 to 98. Width sets the line width in a range from 0 to 511, where a setting of 1 = 0.0635 mm. The actual width of the line will be n × 0.0635, with the line width set to n. ...

Page 164

End style square the normal method for ending lines. Round rounds off both ends of the line with a half radius of the line width. Extend extends both ends by half the line width. Triangle adds a triangle that is half of the line width in length to both ends of the line. Half the line width half the ...

Page 165

Joint style unjoint does not join the lines. Bevel joins the outside corner of one line to the outside corner of the other line. Miter extends the outside corners of both lines until they meet in a miter. Round rounds off the area where the two lines meet. Triangle extends the joint by half the line...

Page 166

Define multi pen sets up the line width, color, end style, and joint style pen attributes for hp-gl data for multiple pens. The same parameters will be set for all other pen numbers within the specified range. Settings the settings for this function are as follows. Menu item description pen no. Spec...

Page 167

Pen option determines whether or not to change the ratio of the pen thickness based on the enlargement/reduction ratio. Settings the setting for this function is as follows. This setting is valid for hp-gl data and versatec data only. Menu item description enlarge/reduce pen width [enable] changes t...

Page 168

Emulation selects the processing language for the hp-gl format only. Settings the settings for this function are as follows. Menu item description emulation sets the processing language at either [hp-gl] or [hp-gl/2]. The default setting is [hp-gl]..

Page 169

Ps command enables or disables the ps command. Settings the available settings are as follows. These settings are valid with hp-gl data only. Menu item description ps command [do not ignore] enables the ps command. [ignore] disables the ps command. The default setting is [do not ignore]..

Page 170

Eop command enables and disables the eop command for hp-gl data only. Settings the settings for this function are as follows. The default value for all parameters is [enable]. Menu item description sp:pen0 enables or disables the sp:pen0 command. Pg:adv page enables or disables the adv page command....

Page 171

Vcgl pen style (vcgl define pen) sets up the pen specifications for vcgl data only. Settings the settings for this function are as follows. Menu item description joint style sets up the joint processing for lines to [unjoint], [bevel], [miter], or [round]. The default setting is [unjoint]. Refer to ...

Page 172

Dashstyle no wrap each dot represents the start of the broken line. Lines printed with the use of the broken line style shown in the example will be printed as a non-broken line, as shown in the illustration on the left. This is due to the fact that the dot appears before the line is broken, and thi...

Page 173

Vcgl pen width sets up the width of the vcgl pen only. Settings the setting for this function is as follows. Menu item description width sets the line width in a range from 0 to 511. 1 = 0.0635 mm. The actual width of the line will be n × 0.0635, with the line width set to n. The default setting is ...

Page 174

Vrf define pen (define single pen) sets the pen attributes for vrf data only. Click the [change] button to define the attributes for a pen. The vrf define pen menus will display on the right side of the screen. Settings the settings for this function are as follows. Menu item description no. Sets th...

Page 175

End style sets the end of the line to [square], [round], [extend], or [triangle]. The default setting is [square]. Refer to "end style" for further details. Color sets the line color to [black] or [white]. The default setting is [black]. Although it is also possible to set the [width] from print ser...

Page 176

Vrf define multi pen sets the pen attributes for multiple pens for vrf data only. The same parameters will be set for all other pen numbers within the specification range. Settings the settings for this function are as follows. Menu item description pen no. Specifies the starting number and ending n...

Page 177

Tiff option sets up the sorting and output sequence, and the resolution priority for tiff data. Settings the settings for this function are as follows. These settings are only valid with tiff data. Menu item description sort mode determines whether or not to sort the output data. The default setting...

Page 178

Cals option determines whether to enable or disable the [rotate] command for cals data only. Settings the settings for this function are as follows. Menu item description specify output direction [enable] enables the [rotate] command. [disable] disables the [rotate] command. The default setting is [...

Page 179

Ps/pdf option the available selections set up the default media size, roll, and dms for ps/pdf data. Settings the settings for this function are as follows. Menu item description default media size if media size information is not included in the print data, and no media is loaded in any trays, the ...

Page 180: 4.4

4.4 logical printer operations this section explains the procedures for performing the following using print services on web. • selecting the media type • using media other than the default series • changing output roll media for an entire job • reduction and enlargement using size mapping • printin...

Page 181

Selecting the media type the media type for the logical printers is set up using the [media type] selection. The available selections include [any], [bond], [vellum], and [film]. [any] typically is selected as the media type. Specify the media type manually if the media is limited to a particular ty...

Page 182

Using media other than the default series the media size series is set up using the [media series] selection. The available selections include [iso a series], [iso b series], [sp. A series], [arch series], [ansi series], and [arch-30 series]. The [input size], [output size], and [media size] paramet...

Page 183

Changing output roll media for an entire job by setting the [output option] [size] selection to [auto], the output media is determined by the settings in the logical printer's [media mapping] table. If a media mapping table is prepared for each job, the output roll media can be changed for each job....

Page 184

Reduction and enlargement using size mapping reduction and enlargement can be performed using the size mapping table. The size mapping table establishes relationships between input image sizes and output image sizes. It enables users to enlarge or reduce prints automatically. The size mapping table ...

Page 185

Printing long documents the media cut mode can be set to either the standard a0 format (1,189 mm), the standard shape increased in length, or the synchronized cut. This parameter is set up using the logical printer [output option] feature. [auto] : the standard shape priority mode. If the length of ...

Page 186: 4.5

4.5 print services on web: job and log the print services on web [job and log] tab enables the user to perform the following. • display the print queue • cancel and change the priority of jobs • manage the job and error logs display the print queue perform the procedure below to display a list of th...

Page 187

2 select [job not completed]. A list of print jobs will display on the right side of the window. If the administrator page is displayed, the jobs that are waiting to print will display a [ change ] link at the right side. A job that is printing can not be changed, that is, it can not be canceled or ...

Page 188

Size displays the size of the job in kb. Change job changes the priority of or cancels a job. (on the administrator page only) displayed item description.

Page 189

Cancel and change the priority of jobs use this procedure to cancel a print job or change its priority. Procedure 1 start print services on web, log on as administrator, and select the [job and log] tab. 2 select [job not completed]. A list of all jobs that are printing and queued will display on th...

Page 190

3 click the [change] link located on the right side of the job that you want to cancel or change. The [change job] page will display. 4 to cancel the job, click the [execute] button. 5 to change the priority of the job, select either [high], [normal], or [low] from the [priority] menu, and then clic...

Page 191

Manage the job and error logs this function allows the user to print and delete the job log and the error log. Job log the job log is a record of all completed print jobs. A variety of information is recorded here, including job numbers, the number of copies/prints, the input and output sizes, and t...

Page 192

2 select [job log] from the [log list] menu. A list of processed jobs will display on the right side of the screen. To display a subset of the logged print jobs: • enter a range in the [job number] fields, and then click the [update] button - or - • enter the inclusive dates in the [print log from:]...

Page 193

Print the job log (manually) 1 start print services on web, log on as administrator, and display the [job and log] tab..

Page 194

2 select [job log] from the [log list] menu. A list of completed jobs will display on the right side of the screen. To display a subset of the logged print jobs, enter a range in [job number] or specify the period in the [print log from:] fields, and then click the [update] button. The list of the s...

Page 195

Print the job log (automatically) 1 start print services on web, log on as administrator, and display the [job and log] tab. 2 select [job log] from the [log list] menu. A list of log information will display in the right pane..

Page 196

3 click [change settings]. The [job log setup] screen will display. 4 select [on] as the [auto print setup] selection, and then click [apply]. The job log will print automatically whenever sufficient job log entries accumulate..

Page 197

Delete the job log 1 start print services on web, log on as administrator, and display the [job and log] tab. 2 select [job log] from the [log list] menu. The job log will display in the right pane..

Page 198

3 click the [delete log] button. A confirmation popup will display. 4 select the [ok] button to delete the job log, or [cancel] to retain the log..

Page 199

Save the job log 1 start print services on web, log on as administrator, and display the [job and log] tab. 2 select [job log] from the [log list] menu. The job log will display in the right pane..

Page 200

3 further define the job log, if necessary, using the [print log from], [job number], [date], and [display] selections, and then click the [save into file] link. The job log will be saved in a comma-separated value (csv) format, and displayed as in the figure below..

Page 201

Display the error log the error log is a record of information about the errors that occurred during job processing. Procedure 1 start print services on web and display the [job and log] tab on either the user page or the administrator page. 2 select [error log] from the [log list] menu. The error l...

Page 202

Saving, deleting, printing the error log the procedures for saving, deleting, and printing the error log(s) are the same as those for managing the job log(s). Refer to the relevant job log procedure when you need to change or save the error log data..

Page 203: 4.6

4.6 print services on web: status the following operations can be performed using print services on web. • display printer status • start and stop job reception, printing, and the print service display printer status this function displays the status of the 6030/6050 wide format printer and copier/ ...

Page 204

2 click the [update] button at the upper right corner of the tab to update the display. The current status of the machine will display. Use the right scroll bar to see the remaining details. Items displayed on the status tab the following items are displayed on the status tab. You may select an inte...

Page 205

Iot status details the following messages are displayed for the iot status. Displayed item description idle the printer is in standby mode, ready to receive a print job. Printing the printer is printing. Warm-up the printer is warming up. Power off the printer is powered off. Lower power mode the pr...

Page 206

Start and stop job reception, printing, and the print service this function enables the following procedures to be performed. • stop job reception stops job reception from clients. • start job reception starts job reception. • stop printing jobs received from clients are placed in a [queued] status ...

Page 207: 4.7

4.7 print services on web: tools the print services on web [tools] tab enables you to do the following: • print a test pattern • print a diagnostic report print a test pattern procedure 1 start print services on web, log on as administrator, and select the [tools] tab. 2 select [test printing]. "sel...

Page 208

Print a diagnostic report procedure 1 start print services on web, log on as administrator, and select the [tools] tab. 2 select [diag report]. 3 "diag report" will appear on the right side of the screen. 4 specify the inclusive report dates using the [range (date: yymmdd):] field, and then click [s...

Page 209: 4.8

4.8 manual feed printing manual feed printing is performed on cut sheet media that has been loaded in the msi (multi sheet inserter/manual feed unit). The job information from the client must specify manual feeding. Manual feed printing is also possible using the following procedure. Procedure 1 set...

Page 211

Chapter chapter 0 5 additional operations from the printer menu chapter 5.

Page 212: 5.1

5.1 introduction the printer control panel’s menus enable the user to perform the following major tasks: • set up the system parameters using the [system parameters] submenu. • set up the communication parameters using the [port setting] submenus. • print a test print using the [test plot] submenu. ...

Page 213: 5.2

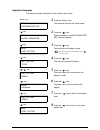

5.2 printer control panel menu the following is a list of the menus and submenus which can be accessed by pressing the offline mode, the first of two top level menus displays, that is, the [network port/set] menu. From this menu the user can define the system parameters, perform port (communication)...

Page 214

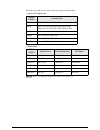

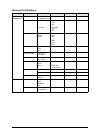

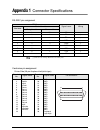

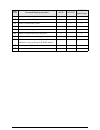

[network port/set] menu level 1 level 2 level 3 level 4 level 5 level 6 system parameter set date set date * yy/mm/dd hh: mm auto roll roll Ætray roll Ætray * off * on tray Æroll tray Æroll * off * on spa paper width spa paper width * sp a1 * sp a2 sp a1 * 620 * 625 sp a2 * 435 * 440 smoothing smoot...

Page 215

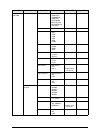

Port setting tcp/ip ethernet setting ethernet setting * auto * 10base_t * 100base_t default parser default parser * hpgl * tiff * cals * versatec *ps/pdf ip address ip address * xxx.Xxx.Xxx.Xxx mask value mask value * xxx.Xxx.Xxx.Xxx e-net address e-net address (display only) dynamic routing dynamic...

Page 216

Port setting serial handshake handshake * xon/xoff * hardware * enq-ack * software (enq-ack and software only with hpgl) default parser hpgl baud rate baud rate * 300 * 1200 * 2400 * 4800 * 9600 * 19200 parity parity * none * even * odd data bit data bit * 7_bits * 8_bits stop bit stop bit * 1_bit *...

Page 217

Port setting vpi (optional) report offline report offline * no * yes eop timeout eop timeout * no_timeout * timeout Ö timeout value * 1 to 255 sec job separation job separation * no * yes print config set: to print. Test plot test plot plot size plot size * a0 to a4 test plot set: to print. Job logg...

Page 218

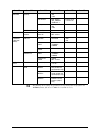

[print setup] menu the print setup menu should be used immediately after loading new media or changing the type and/or size of media in the media drawers or the bypass (msi). Level 1 level 2 level 3 level 4 level 5 level 6 print setup media *roll1 *roll2 *roll3 *roll4 *bypass media/roll 1,2,3,4 bypa...

Page 219: 5.3

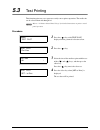

5.3 test printing this function prints out a test pattern to verify correct printer operation. The media size can be selected from a0 through a4. Procedure 1 press the > key with [test plot] displayed on the parameter selection screen. 2 press the > key. 3 select the size of the media to print with ...

Page 220: 5.4

5.4 managing the job and error logs log data for print jobs is saved in the following two logs. • job log • error log the user can perform the following log management tasks from the printer control panel. • set up the system to print the job log automatically. • print the log data. • delete (clear)...

Page 221

2. Select either [on] or [off] with the use of the > and > keys when [auto mode] has been specified, and then press the key. 1. Select the starting date and ending date (yy, mm, dd) of the relevant jobs with the use of the > and > keys, and then press the key. Move the cursor to the right-hand side ...

Page 222

Error log this section explains the procedures for printing and clearing the error log. Procedure 1 press the > key with [job logging] displayed. 2 display the [error log] with the use of the > key, and then press the > key. 3 select the desired operation ([print] or [clear]) using the > and > keys,...

Page 223

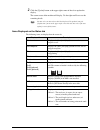

Press the key when [set: to clear.] is displayed. The error log will be deleted. Sample error log list clear set : to clear. When [clear] is selected [errorlog : page 1] [xerox 6050wf version 2.X.Xx] jobno data&time task name errno errorlevel error log error data 1 02/04/17 15:49:30 output 38 error ...

Page 224: 5.5

5.5 reprinting this function reprints the file that was most recently printed. The copy quantity (1 to 99) also can be specified. Procedure 1 press the > key with [offline plot] displayed on the parameter selection screen. 2 press the > key. 3 press the > key. 4 select the print quantity with the > ...

Page 225: 5.6

5.6 billing meter confirmation this feature displays the billing meters on the printer control panel. Quantities of up to nine digits can be displayed. Procedure 1 press the > key with [billing info] displayed. 2 press the > key. 3 select the meter you wish to display ([meter 1], [meter 2], or [mete...

Page 226: 5.7

5.7 print setup menu this section explains the items which can be set up from the [print setup] menu on the printer control panel. Menu item description media sets up the type, size, weight, and other parameters for the media that are loaded in the machine. Tray used to isolate the system from the m...

Page 227

Setting up media the media type, weight, and size series must be set up whenever you load new media in the machine or change the type and/or size of the media in the trays or in the msi/(multi sheet inserter/manual feed bypass). These settings can be made at the printer control panel using the print...

Page 228

The media [weight] can been specified as follows: sp. A-1 series sp. A-0 (880 × 1,230 mm) sp. A-0 roll media (880 mm wide) sp. A-1 (625 × 880 mm) sp. A-1 roll media (625 mm wide) sp. A-2 (440 × 625 mm) sp. A-2 roll media (440 mm wide) sp. A-3 (312 × 440 mm) sp. A-3 roll media (312 mm wide) sp. A-2 s...

Page 229

Procedure 1 press the the machine will enter the offline mode and the [network/port set] menu will display. 2 press the > key. The [print setup] menu will display. 3 press the > key. The submenu items will display. 4 press the > key. The menu items on the same level will display, in order. 5 press t...

Page 230

Selecting values this section provides an example of setting up a media value. The procedures for setting up other media values are similar. 1 the menu items will display. 2 press the > key. The specified value will display. 3 change the setting with the use of the > and > keys. 4 press the key to s...

Page 231

Tray this normally is set to [auto] and should not be changed by the user. Consult your xerox service representative before changing this setting. Fuser this normally is set to [auto] and should not be changed by the user. Consult with your xerox service representative before changing this setting..

Page 232: 5.8

5.8 automatic cut using the printer control panel this section describes how to cut the lead edge of the roll media. Procedure 1 select [media] from the menu displayed on the printer control panel. 2 press the > key. The level from which the desired media is to be selected will be displayed. 3 press...

Page 233

Chapter chapter 0 6 ethernet print service (for unix) chapter 6.

Page 234: 6.1

6.1 overview of the ethernet print service use the ftp command or the lpr command to print from the xerox 6030/6050 wide format when running on unix. This section explains how to set up the ftp and lpr commands and their formats. The file to be printed should be in a data format that the xerox 6030/...

Page 235: 6.2

6.2 registering the xerox 6030/6050 wide format printer system to print from the xerox 6030/6050 wide format printer system, the xerox 6030/ 6050 wide format printer system should be registered on the tcp/ip network. Host system registration when the network information is managed by a name service ...

Page 236

Registering the remote printer for printing using the lpr command, both the host system and the remote printer must be registered on the client workstation. Although the registration information depends on the system, the logical device names on the workstation must correspond with the logical print...

Page 237

Aix 3.2.X for aix 3.2.X, register the remote printer in the [/etc/qconfig] file defining the printer- unique attributes. • editing the /etc/qconfig file in the example below, the xerox 6030/6050 wide format printer system called [oklahoma] is registered in the [/etc/qconfig] file. With this setting,...

Page 238: 6.3

6.3 printing using the ftp command details of the ftp command are explained below. Printing this section explains the printing procedure using the ftp command. Procedure 1 enter the ftp command and the network that is registered with a xerox 6030/6050 wide format host name (example: 6050wf) at the c...

Page 239

3 enter the password of the user logged in at step 2 . If the user information registered in the xerox 6030/6050 wide format matches the logged-in user password, the login acceptance message is displayed. 4 specify a logical printer (example: plt00h). Enter the logical printer name using the cd subc...

Page 240

7 specify the end. Enter the bye subcommand. A message indicating that ftp command has completed will be displayed. Ftp> bye 221 bye...See you later %.

Page 241

Other subcommands this section explains the ftp subcommands. Ascii: sets transfer data to the ascii format. Bin: sets transfer data to the binary format. Bye: terminates ftp processing. Cd: change directory; will display logical printer. Dir: displays directory; will display logical printers set fro...

Page 242

Message list this section explains messages that may be displayed during printing using the ftp command. Status: cannot establish connection for data transfer. Action: wait a few moments and try again. Status: cannot create a control file using the stor command. Action: wait a few moments and try ag...

Page 243

Status: a data connection error occurred during file transfer. Action: establish the connection and transfer the file again. Status: a non-existent directory (logical printer) is specified. Action: specify the correct directory (logical printer). Status: an error occurred in an output file during tr...

Page 244

Status: failed to transfer the file. Action: wait a few moments and try again. Status: failed to receive the file transfer end message. Action: wait a few moments and try again. Status: failed to receive the file transfer permission message. Action: wait a few moments and try again. Status: failed t...

Page 245

Status: the user name and password do not match. Action: log in again with the correct user name and password. Status: failed to open the directory by the list command. Action: wait a few moments and transfer the command again. Status: ascii or binary is not specified by the type command. Action: sp...

Page 246

Status: transfer by an unsupported type was attempted. Action: specify [ image (binary) ] or [ ascii ] with the type command. Status: logged in with a user name that is not registered. Action: log in with a registered user name. In the factory, only [ ftpusr ] is registered as the user name. Status:...

Page 247: 6.4

6.4 printing using the lp/lpr command details of each command are explained. Printing (lpr command) this section explains the printing procedure using the lpr command. Format -p specify a logical printer name immediately after p (with no space) to output data to the specified printer. If no logical ...

Page 248

Usage examples the printing procedure using the lpr command is as explained below. Example 1:to print one copy of the file [drawa.Hpgl] by logical printer [plt00h]. Example 2:to print two copies each of the files [drawb.Hpgl] and [drawc.Hpgl] by logical printer plt00h. Example 3:to print one copy of...

Page 249

Printing (lp command) (for sunos 5.X) this section explains the printing procedure using the lp command. Format lp [-d data is output to the specified printer. -n specify the number of copies by entering a numeric value from 1 to 99. If 100 or more is specified, an error message is displayed and the...

Page 250

Status display (lpq command) this section explains how to display the status of a file that has been specified for printing using the lpr command. Format -p enter the name of the logical printer immediately after the p (with no space). After doing this, the status of the file(s) being processed by t...

Page 251

Example 3:display the status of a file transferred to logical printer [plt01h]. When the transfer of the file [drawd.Hpgl] to the xerox 6030/6050 wide format is completed, and the xerox 6030/6050 wide format has received the next job, the following message will be displayed. Example 4:display the st...

Page 252

Cancel (lprm command) this section explains how to cancel a print job submitted from the network. Format -p specify a logical printer name immediately after the p (with no space) to cancel a print job that is being processed by the specified printer. If no logical printer name is specified, the prin...

Page 253

Example 2:displays the status of logical printer [plt01h] and the canceling of job id [123] this print job cannot be canceled because it is already in progress. Example 3:displays the status of logical printer [plt01h] and the canceling of job id [417] in the client queue % lpq -pplt01h job id sent ...

Page 254

Example 4:displays the status of logical printer [plt01h] and the canceling of job id [416] in the client queue if the file transfer to the xerox 6030/6050 wide format completes before the job in the client queue is canceled, the print job cannot be canceled. Display the xerox 6030/6050 wide format ...

Page 255

Message list this section explains messages that may be displayed during printing using the lpr command. These messages depend on the system because they are output from the client workstation. Status: the lpd daemon on the client failed to create a control file. Action: check the spool directory. S...

Page 256

Status: failed to delete a job from logical printer pltxx on the print service side. Action: check by the lpq command whether the specified job has already changed from the wait status in the queue to the processing status. Status: failed to establish connection for data transfer. Action: no action ...

Page 257

Chapter chapter 0 7 maintenance chapter 7.

Page 258: 7.1

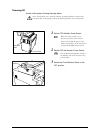

7.1 loading toner observe the following precautions when handling the toner. • handle the toner carefully to avoid spilling it on your clothing or around the machine. • never throw a used toner cartridge in an open flame. Load the toner as described below. Procedure 1 lift the scanner document table...

Page 259

3 take the toner cartridge out of the package and prepare it for loading. 4 open the lid of the toner supply port. 5 insert the left side notch, located at the bottom of the toner cartridge, into the end of the toner supply port. Then hold the toner cartridge vertically on top of the supply port. 6 ...

Page 260

7 slide the toner supply lever back and remove the cartridge. 8 close the lid on the toner supply port. 9 pull up the lock lever in the middle rear of the scanner document table and then close the document insertion guide. 10 pull the scanner back to the front. • if the toner splashes around the ton...

Page 261

Chapter chapter 0 8 problem solving chapter 8.

Page 262: 8.1

8.1 check the control panel(s) when a machine failure is suspected, for example, when a print cannot be made or the image quality is defective, first check for error messages or error codes on the printer control panel. When an error code is displayed, press the > and > keys on the printer control p...

Page 263: 8.2

8.2 poor image quality perform the following corrective measures if the copies or prints display one of the image quality defects listed below. Image quality defect corrective measure the print displays excessive background verify that the image density setting is correct. Check the quality of the o...

Page 264: 8.3

8.3 other problems follow the instructions provided in the table to recover from the errors which are listed. Error recovery nothing is displayed on the printer control panel. • verify that the machine is connected to a correctly rated power supply, that the power plug is plugged in, and that the po...

Page 265: 8.4

8.4 printer troubleshooting this section provides recovery methods for problems which are associated with printing. Paper size #1was mistakenly selected. Ö there are cases where it is possible to override this with the [media margin] settings. The [media margin] settings are the values that set the ...

Page 266