- DL manuals

- Yamaha

- Toy

- YZF-R1

- Kit Manual

Yamaha YZF-R1 Kit Manual

Summary of YZF-R1

Page 2: Introduction

Introduction • this manual is intended for persons with knowledge and experience of motorcycles. Please refer to the yzf-r1 service manual, which shall be published from yamaha motor co. Ltd., for information on part assembly and maintenance. • the design of the yzf-r1 racing kit is based on yzf-r1,...

Page 3: Contents

Contents 1 enginespecifications ................................................................................. 1 2 kit parts ........................................................................................................ 2 2-1 installing electrical parts ....................................

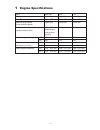

Page 4: Enginespecifications

– 1 – 1 enginespecifications spec sbk/jsb stk std displacement 998cm 3 998cm 3 998cm 3 bore/stroke 79.0 × 50.9 mm 79.0 × 50.9 mm 79.0 × 50.9 mm maximum engine speed (limiter controlled speed) 14500 rpm 14500 rpm 14500 rpm compression ratio (recommended value) 13.0 – 13.4 depending on head surface gr...

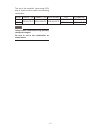

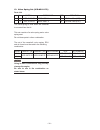

Page 5: Kitparts

– 2 – 2 kitparts 2-1installingelectricalparts 1. Ecu set (2cr-8591a-71) parts list no. Part no. Part name q'ty remarks 1 2cr-8591a-71 ecu 1 2 2cr-2818y-71 cd 1 yms soft & manual '16 ver. • use of this set and a wire harness included in the kit enables regulation (or setting) of fuel injection and ig...

Page 6

– 3 – the set of the camshaft, valve spring, ecu and air funnel must be used in the following combination. Notice using in other combinations may possibly damage the engine. Be sure to use in the combination as stated above. Model camshaft (in) camshaft (ex) valve spring ecu air funnel set 2015 2cr-...

Page 7

– 4 – 2. Cableinterface(2cr-8533a-70) parts list no. Part no. Part name q'ty remarks 1 2cr-8533a-70 cable, interface 1 usb 2 2cr-n81cd-70 cd 1 usb driver windows 8 supported • this cable connects the kit wire harness to the personal computer on which yec fi matching system (yms) is installed. • plea...

Page 8

– 5 – self-diagnosis functions the ecu is equipped with a self-diagnostic function in order to ensure that the fuel injection system is operating normally. If this function detects a malfunction in the system, it immediately operates the engine under substitute characteristics and illuminates the en...

Page 9

– 6 – 3. Wireharnessset(2cr-f2590-70) parts list no. Part no. Part name q'ty remarks 1 2cr-82590-70 wire harness assy. 1 main harness ° 2 2cr-82386-70 wire, sub-lead 1 th injector ° 3 2cr-82318-70 wire, sub-lead 1 ac injector ° 4 2cr-82309-70 wire, sub-lead 1 ignition coil ° 5 2cr-8231y-70 wire, lea...

Page 10

– 7 – installing wire harness: 1. Remove the std wire harness from the chassis. 2. Cut the shaded area off the battery box (to provide an installation area for fixing for brkt.,4 12 seat). 13 14 11 7 3 20 r6 3. Install plug 13 to brkt.,4 12 . By using the std battery box installation bolt and bolt 1...

Page 11

– 8 – 4. Cut the shaded area off the lh side cover (to provide an installation area for sixing for brkt., regulator 1 7 seat). 102 44 22 r20 49 r20 5. Remove from the chassis the std rectifier/regulator that is installed on the right side of the radiator. Install the rectifier/regulator using the br...

Page 12

– 9 – 7. Install the wire harness of the kit as the diagram. Pc i/f 2ks std rcu fuse box1 rr.Wheel sensor abs ecu imu ecu1/2 st relay1 relay assy. Power supply acm oil sw shift sw select sw crank shaft sensor vi motor handle sw lh&rh e-sd solenoid meter sub lead fr.Wheel sensor aps throttle motor pr...

Page 13

– 10 – main sw air temp sensor meter crank shaft sensor meter sub lead rec/regu tps select sw shift sw oil sw fr.Wheel sensor aps throttle motor pressure sensor(pa) pressure sensor(pb) vi motor handle sw lh handle sw rh power supply 2 2ks sub lead main sw e-sd solenoid acm fuse box1 rr.Wheel sensor ...

Page 14

– 11 – pressure sensor(pa) pressure sensor(pb) vi motor fr.Wheel sensor throttle motor aps , indicate the names of parts to be connected..

Page 15

– 12 – ecu2 2ks-2161e-70 brkt.,4 12 main fuse ecu1 power supply st relay relay assy. Abs ecu fuse box1 imu rr.Wheel sensor , indicate the names of parts to be connected..

Page 16

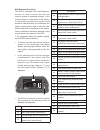

– 13 – the name and function of each switch lap switch keep the switch at low position hi position→the lap switch becomes non-functional pit road limiter on on push=off not used mode switch up button center button down button map select →map 1 →map 2 starter switch/engine stop switch wheel switch.

Page 17

– 14 – yrc : yamaha ride control yamaha ride control is a system that controls the engine output based on data received from the sensors and imu. The functions listed below represent individual yrc items which can be turned on/off or adjusted to suit various riders and riding conditions. For details...

Page 18

– 15 – scs : slide control system the slide control system controls engine power output when a sideward slide is detected in the rear wheel. It adjusts output to an optimum level based on data from the imu, thus helping the rider focus on riding without distraction. This system supports the tcs to c...

Page 19

– 16 – about the front and rear wheel speed sensor do not remove the speed sensors installed at the front and rear wheels because they are used for regulating yrc controls. • if you change the front and rear wheels to non-standard parts, manufacture and attach a rotor and sensor referring to the dia...

Page 20

– 17 – 4. Headlightharnessset(2cr-f4350-70) parts list no. Part no. Part name q'ty remarks 1 2cr-84359-70 cord, head light 1 * 2 1st-81950-00 relay assy. 2 * 3 5gf-83976-00 sw., handle 1 2 light on/off sw. Emergency sw. This set is used in endurance races in combination with the kit harness for turn...

Page 21

– 18 – 5. Repairset(2cr-28130-70,2ks-28130-70) select the part set corresponding to your model. Parts list 2cr-28130-70 no. Part no. Part name q'ty remarks * 1 2cr-83500-00 meter assy. 1 * 2 2cr-83963-00 switch handle 3 1 * 3 2cr-83969-00 switch handle 5 1 * 4 2cr-85970-00 fr. Wheel sensor 1 * 5 2cr...

Page 22

– 19 – 6. Ccucomp.(2ks-85800-70) the ccu (communication control unit) facilitates checking or settings of the vehicle information, and enhances rider's relationship with the vehicle. The ccu comp. Consists of the ccu assy. And gps unit. Download the application onto the tablet before use. The ccu of...

Page 23: 123

– 20 – preparation • install the units to the vehicle. Tip the gray and black cable is for ain-1 (analog ch1), and the purple and black cable is for ain-2 (analog ch2). Tip since the eight-digit number (s/n:) on the ccu unit will be used as the password for wireless lan connection between the tablet...

Page 24

– 21 – operations on the tablet application to be used network to be connected before riding draw a circuit record line on the map. (see fig. 1.) ccuconfig (y-trac for ios version) internet transfer the record line to the ccu. Ccuconfig (y-trac for ios version) ccu set the logging mode of the ccu to...

Page 25

– 22 – tip when viewing logging data, analog ch is not displayed by y-trac default setting. To display it, tap graph setting in the graph option mode. On the screen, tap ain-1 or ain-2 to display the arbitrary ch. In the analog display mode, the voltage is indicated by level (0 to 5) by default. The...

Page 26: 123

– 23 – other usages meter setting to indicate ccu's detection of line passing on the meter, enable the stop watch function on the meter (blink ":" (column) and "." (period) in area 2). Mode- a pwr 1 tcs 3 scs 2 km/h 123 odo km 7890 gear n lap 03 latest 40 03 06 × 1000 r/min a-2 qs lif gps 12:00 aber...

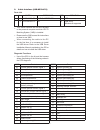

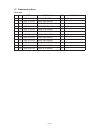

Page 27: 2-2Installingengineparts

– 24 – 2-2installingengineparts 7. Maintenanceset(2cr-maint-71) parts list no. Part no. Part name q'ty remarks * 1 2cr-11181-00 gasket, cylinder head 1 3 t=0.20 mm (std) * 2 2cr-11351-00 gasket, cylinder 1 3 t=0.20 mm (std) * 3 2cr-11603-10 piston ring set 12 * 4 2cr-1165a-00 bolt, connecting rod sp...

Page 28

– 25 – 8. Sparkplugset(14b-r465b-70) parts list no. Part no. Part name q'ty remarks 1 14b-1119c-70 plug, spark 4 ngk r0465b-10 the spark creating portion of this spark plug is of a semi-surface discharge type of shape. Tip since these spark plugs have a copper gasket, caution is needed during instal...

Page 29

– 26 – 9. Pistonset(2cr-116a0-71) parts list no. Part no. Part name q'ty remarks * 1 2cr-11631-10 piston 4 * 2 2cr-11603-10 piston ring set 4 * 3 2cr-11633-00 pin, piston 4 * 4 93450-18169 circlip 8 this set consists of a combination of four genuine pistons so that the weight difference of each item...

Page 30

– 27 – model piston set connecting rod set crankshaft 2015 2cr-116a0-70 2cr-1165b-70 2cr-11400-70 2016 2cr-116a0-71 2cr-11400-71 about compatibility between the piston set, connecting rod set and crankshaft (by model year) piston set: the piston and piston ring of the 2016 model is different from th...

Page 31

– 28 – 12. High-liftcamshafts,camsprocket high-lift camshafts parts list no. Part no. Part name q'ty remarks 1 2cr-12170-70 shaft, cam 1 1 int 2 2cr-12180-70 shaft, cam 2 1 ext thiscamshafthasacamprofileetc.Changed from the std one. No. Part no. Part name q'ty remarks 3 2cr-12176-70 sprocket, cam 1 ...

Page 32

– 29 – notice whenfittingthecamshaft,usetheslotted holes of the cam sprockets and always set the timing to match. If otherwise, no intended performance can be expected and more over, the engine may be damaged. Tip install the cam sprocket as the scratch line and 2cr mark face the outside of the engi...

Page 33

– 30 – 13. Valvespringset(2cr-a2110-70) parts list no. Part no. Part name q'ty remarks 1 2cr-12130-70 sprg' assy. 1 8 i.D.Color: blue (int) 2 2cr-12140-70 sprg' assy. 2 8 i.D.Color: red (ext) this valve spring is used when the camshaft is mounted from the kit. This set consists of a valve spring and...

Page 34

– 31 – 14. Airfunnelset(2cr-1440b-70) parts list installation 1. Assembling the primary funnel secure the primary funnel 1 and 2 to the throttle body with the supplied button head bolts. At this time, install the std lever 1 and 2andfixthem. 2. Assembling the secondary funnel install the secondary f...

Page 35

– 32 – 15. Ais-plugset(2cr-a4890-70) this plug set is used when the ais (air induction system), an exhaust gas purifying system, is removed. Parts list no. Part no. Part name q'ty remarks 1 5sl-1482l-70 plate, 2 2 2 2cr-11159-70 plug, blind 4 3 90336-10020 plug, taper 1 installation 1. Remove the ho...

Page 36

– 33 – 16. Screwcapset(2cr-15171-70) this set is used for repairing the aluminum bolts for assembling each crank case cover. Parts list no. Part no. Part name q'ty remarks 1 90109-06300 bolt 8 acm m6×25 al 2 90109-06301 bolt 10 cluch m6×30 al 3 90109-06299 bolt 5 pick up m6×20 al 4 90109-06300 bolt ...

Page 37

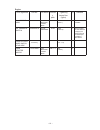

– 34 – 17. Transmissiongear parts list no. Part no. Part name q'ty remarks 1 2cr-17401-70 main axle assy. 1 2 2cr-17121-70 gear, 2nd pinion 1 3 2cr-17131-70 gear, 3rd pinion 1 4 2cr-17151-70 gear, 5th pinion 1 5 2cr-17161-70 gear, 6th pinion 1 * 6 2cr-17402-00 drive, axle assy. 1 7 2cr-17211-70 gear...

Page 38

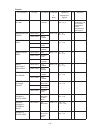

– 35 – notice thissetcontainsmodifiedgearratiosand docks compared with the std gearbox. Kit gears cannot use combine standard gear. Gear ratio std kit 1st 39/15 (2.600) 39/16 (2.438) 2nd 37/17 (2.176) 35/17 (2.059) 3rd 35/19 (1.842) 34/19 (1.789) 4th 30/19 (1.579) 33/21 (1.571) 5th 29/21 (1.381) 32/...

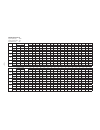

Page 39

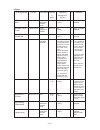

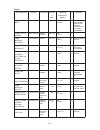

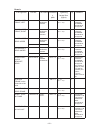

– 3 6 – yzf-r1 speed list engine speed (rpm) 13900 primary reduction ratio 1.63 tire diameter (mm) 642 gear plan the number of teeth ratio 16 16 16 15 16 15 16 15 16 14 15 16 14 15 16 14 15 16 p w 38 39 40 38 41 39 42 40 43 38 41 44 39 42 45 40 43 46 1st std 15 39 2.60 166.6 162.3 158.3 156.2 154.4 ...

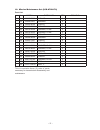

Page 40

– 37 – 18. Missionmaintenanceset(2cr-a7000-70) parts list no. Part no. Part name q'ty remarks * 21 90387-28003 collar 3 * 22 90209-25011 washer 6 * 23 93440-28184 circlip 3 * 24 90387-25023 collar 3 * 25 90214-25004 washer, claw 3 * 26 90214-25003 washer, claw 3 * 27 90387-31003 collar 3 * 28 90209-...

Page 41

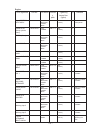

– 38 – 36 38 33 29 29 34 21 22 22 24 23 23 35 25 26 37 28 30 32 31 30 28 28 29 27.

Page 42

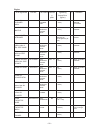

– 39 – transmission assembly m1 m1 m1 m2 m2 m2 m1 m2 m3 m3 m3 m3 a b b b b b c rotate washer so that its teeth meet axle- spline teeth on the axle, and then lock with washer,s claw. Assemble washer with putting together their matching mark. Apply molybdenum oil to inside of diameter. After assembly,...

Page 43

– 40 – 19. Drivesprockets parts list no. Part no. Part name q'ty remarks 1 2cr-17460-74 sprocket, drive 1 14t, 520size 2 2cr-17460-75 sprocket, drive 1 15t, 520size 3 2cr-17460-76 sprocket, drive 1 16t, 520size this sprocket is weight-saved by changing the chain size to 520 in relation to the std on...

Page 44

– 41 – 20. Sprocketnutset(2cr-a7463-70) parts list no. Part no. Part name q'ty remarks * 1 90179-22018 nut 3 * 2 90208-22002 washer, conical sprg. 3 the “out” mark must face outward apply swage after tightening a nut.

Page 45

– 42 – 21. Strainercoverset(2cr-13400-70) parts list no. Part no. Part name q'ty remarks 1 2cr-13410-70 strainer hsg. Assy. 1 2 2cr-13576-70 spacer 1 * 3 93210-22m93 o-ring 2 2 attachment, grease outer surface * 4 92017-06014 bolt,button head 2 2 attachment * 5 90110-06172 bolt,hex. Socket 2 1 attac...

Page 46

– 43 – installation 1. Put 8 o-ring at 7 pipe,oil 1, and connect with 6 pipe,oil 2, then attach 6 pipe,oil 2 to the engine by using 8 o-ring and 9 bolt,hex. Socket, and attach 7 pipe,oil 1 to the engine by using 10 bolt,hex. Socket. Attach 2 spacer to the engine by using 3 o-ring and 4 bolt,button h...

Page 47

– 44 – 3. Attach 1 strainer hsg. Assy. To the engine by using 5 bolt,hex. Socket and 19 gasket,strainer. 1 4. Attach 20 baffle,plate to 15 pan,oil by using 21 bolt. 21 21 21 620 lt 620 20 15 5. Attach 15 pan,oil to the engine by using 16 bolt,button head. 15 6. Attach 17 plug,straight screw and 18 g...

Page 48

– 45 – recommended oil level after engine warm-up (water temperature of 75 to 80 degrees), while using the racing (rear) stand, check whether the oil level is in the range of the upper limit of the oil pan upper window (at the right side of vehicle) and the lower limit of the engine crank case oil w...

Page 49: 2-3Installingchassisparts

– 46 – no. Part no. Part name q'ty remarks 1 2cr-22222-a0 sprg., rear shock 1 83 n/mm identifying stamp: 159.5-56-83 2 2cr-22222-70 sprg., rear shock 1 93 n/mm identifying stamp: 159.5-56-93 3 2cr-22222-75 sprg., rear shock 1 98 n/mm identifying stamp: 159.5-56-98 4 2cr-22222-80 sprg., rear shock 1 ...

Page 50

– 47 – 23. Springfrontfork parts list no. Part no. Part name q'ty remarks 1 2cr-23141-a0 sprg., front fork 1 8.5 n/mm identifying slits 1-1 2 2cr-23141-70 sprg., front fork 1 9.0 n/mm identifying slits 1 3 2cr-23141-75 sprg., front fork 1 9.5 n/mm identifying slits 2 4 2cr-23141-80 sprg., front fork...

Page 51

– 48 – references front and rear load changes and front and rear suspension movement in different scenarios. Accelerating . Load change the wider the throttle is opened, the more the load is concentrated on the rear. . Front fork reaches nearly maximum extended stroke. . Rear cushion up to 20 to 30m...

Page 52

– 49 – 24. Seatcushion(13s-24713-70) parts list no. Part no. Part name q'ty remarks 1 13s-24713-70 cushion seat 1 anti slip seat. Cut to any size for use..

Page 53

– 50 – 25. Frontsparewheelass’y(2cr-25100-70) parts list no. Part no. Part name q'ty remarks 1 2cr-25160-00 cast wheel assy. 1 * 2 93900-00030 valve, rim 1 * 3 1sd-2517g-00 rotor, sensor 1 * 4 2cr-2514a-00 ring, wheel 1 1 * 5 90149-05037 screw 5 * 6 93210-47440 o-ring 1 *this kit does not include a ...

Page 54

– 51 – 26. Rearsparewheelass’y(2cr-25300-70) parts list no. Part no. Part name q'ty remarks 1 2cr-25370-00 cast wheel assy. 1 2 2cr-25840-00 disk brake assy. 1 * 3 90111-08085 bolt, hex. Socket button 5 * 4 93900-00030 valve, rim 1 *this kit does not include a tire. This part is the std wheel, beari...

Page 55

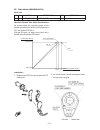

– 52 – 27. Tubeguide(2cr-26243-70) parts list no. Part no. Part name q'ty remarks 1 2cr-26243-70 tube, guide 1 aboutthethrottletubeguidespecifications as shown below, the operating angle of the throttle grip when the throttle is fully opened is 57.5° as against std 64.4°. (except this part, all othe...

Page 56: Tighteningtorquelist

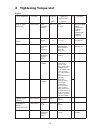

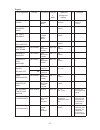

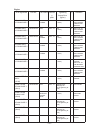

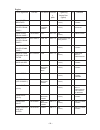

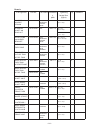

– 53 – 3 tighteningtorquelist engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks plug for sand drain hole 90340-18004 plug, straight screw m18 × 1.5 25 ± 2 (2.5 ± 0.2) 2 apply locking agent (locktite® to both screw thread and tapered portion. Ins...

Page 57

– 54 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks head x joint, assy 90110-06168 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0.2) 6 apply to screw rocking rocker axis plug 90340-12013 plug, straight screw m12 x 1.0 10±2 (1.0±0.2) 3 apply...

Page 58

– 55 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks install thermo- stat assy. 90110-06163 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0.2) 2 the rear of the head cylinder install pipe 1 (body cylinder, case) 90105-06127 bolt, flange m6 x ...

Page 59

– 56 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks install oil cleaner assy 5gh-13440-50 oil cleaner assy m20 x 1.5 17±2 (1.7±0.2) 1 apply grease to o-ring. Install oil pan baffle 90110-06218 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0....

Page 60

– 57 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks upper cover 98907-05020 screw, binding head m5 x 0.8 2.0±0.5 (0.2±0.05) 10 (target value of 2.0 n•m) nut, ring x cylinder head 90179-08442 nut m8 x 1.25 20±2 (2.0±0.2) 8 ex. Pipe x chamber...

Page 61

– 58 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks crankcase 1 x crankcase 2 95812-08060 bolt, flange m8 x 1.25 24±2 (2.4±0.2) 2 apply oil to both screw thread and bearing. Crankcase 1 x crankcase 2 90109-06100 bolt m6 x 1.0 10±2 (1.0±0.2)...

Page 62

– 59 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks install plate, breather 90149-06158 screw m6 x 1.0 10±2 (1.0±0.2) 4 apply to screw rocking install plug to cover crank case 1 90340-27003 plug, straight screw m27 x 1.5 15±2 (1.5±0.2) 1 fo...

Page 63

– 60 – engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks install clutch boss 90179-20007 nut m20 x 1.0 125±5 (12.5±0.5) 1 apply oil to both screw thread and bearing. 1 point swag- ing after tightening install clutch spring 2cr-16337-00 screw, sp...

Page 64

– 61 – to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks install pickup assy 90110-05034 bolt, hexagon socket head m5 x 0.8 6±1 (0.6±0.1) 2 apply to screw rocking oil pressure switch 1ws-82504-00 sw. Oil pressure pt1/8 12.5±2 (1.25±0.2) 1 when mended, ...

Page 65

– 62 – chassis to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks e/g bracket, front, left 90110-12007 bolt, hexagon socket m12 x 1.25 64 – 76 (6.4 – 7.6) 1 procedure to install the engine. For details, see page 69. E/g bracket, front, right 90111-12003...

Page 66

– 63 – chassis to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks shaft, pivot & u nut 90185-20008 nut, self locking m20 x 1.5 80 – 130 (8.0 – 13.0) 1 procedure to install the pivot shaft peripheral parts. For details, see page 70. Arm relay and frame 9...

Page 67

– 64 – chassis to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks handle and handle, crown 91380-06025 bolt, hexagon socket head m6 x 1.0 5 – 8 (0.5 – 0.8) 2 steering shaft and ring nut 90179-30691 nut m30 x 1.0 40 – 64 (4.0 – 6.4) 1 12 – 15 (1.2 – 1.5)...

Page 68

– 65 – for reference tightening torque n•m m5 × 0.8 4.5 – 7.0 m6 × 1.0 7.5 – 12 m8 × 1.25 18 – 28 m10 × 1.25 37 – 58 m12 × 1.25 68 – 108 m14 × 1.5 105 – 167.

Page 69

– 66 – tightening the cylinder head 1. Inthefollowingorder(1→10),applyinitial tightening of 10 n•m (1.0 kgf•m). 2. In the following order (1→10), apply additional tightening of 25 n•m (2.5 kgf•m). 3. In the following order (1→10), apply additional tightening of 45 n•m (4.5 kgf•m). 4. Inthefollowingo...

Page 70

– 67 – installing the crankcase 1. Tighten the bolts in the tightening sequence of 1 to 10 to 20 n•m (2.0 kg•m). 2. After loosening the bolts once in the tightening sequence of 1 to 10, retighten them one by one to 15 n•m (1.5 kg•m). (note: do not loosen all bolts at once. Repeat loosening and tight...

Page 71

– 68 – procedure to tighten the aluminum bolts 1. In the following order, tighten the bolt at 6n•m (0.6kgf•m). 2. In the following order, loosen each bolt, tighten at 3 n•m (0.3 kgf•m), and apply snap and angle tightening at rotating angle of 90°. (note: do not loosen all bolts at once. Repeat loose...

Page 72

– 69 – procedure to install the engine (unchangeable) 1. Attach the two engine adjusting bolts 1 to the frame comp. Temporarily. 2. Fit the engine installation position to the frame comp and attach the bolts 2 and 3 temporarily. 3. Attach the bolt 4 temporarily. 4. Attach the engine mount boss 5 and...

Page 73

– 70 – procedure to install the pivot shaft peripheral parts 1. Tighten the pivot shaft 1 at specified torque. 2. Tightenthenut2atspecifiedtorque. 3. Tighten the nut 3 (self-rocking) at specifiedtorque. Be sure to secure the pivot shaft 1 so that it is not co-rotated. Tip for information about tight...

Page 74

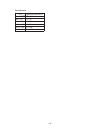

– 7 1 – 4 headlightcordwiringdiagram.

Page 75

– 72 – 5 yzf-r1wiringdiagram.

Page 77

Published by yamaha motor engineering co., ltd.