- DL manuals

- Yamaha

- Toy

- YZF-R1

- Service Manual

Yamaha YZF-R1 Service Manual

Summary of YZF-R1

Page 2

Introduction x this manual is intended for persons with knowledge and experience of motorcycles. Please refer to the yzf-r1 service manual, which shall be published from yamaha motor co. Ltd., for information on part assembly and maintenance. X the design of the yzf-r1 racing kit is based on yzf-r1,...

Page 3

Contents 1 engine specifications................................................................................... 1 2 kit parts ......................................................................................................... 2 2-1 installing engine parts......................................

Page 4

3 tightening torque list ............................................................................... 73 4 headlight cord wiring diagram................................................................. 86 5 yzf-r1 wiring diagram........................................................................

Page 5

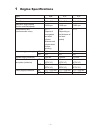

– 1 – 1 engine specifications spec sbk stk std displacement 998 cm³ 998 cm³ 998 cm³ bore/stroke 78.0 x 52.2 mm 78.0 x 52.5 mm 78.0 x 52.2 mm maximum engine speed (limiter controlled speed) 13800 rpm 13800 rpm 13800 rpm compression ratio (recommended value) 13.7:1 (depend of head-gasket and head cyli...

Page 6

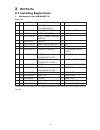

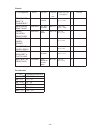

– 2 – 2 kit parts 2-1 installing engine parts 1. Maintenance set (14b-maint-72) these sets of parts necessary for engine disassembly and maintenance are provided in three (3) sets. Parts list no. Part no. Part name q’ty remarks ° 1 14b-11181-70 gasket, cylinder head 1 3 t=0.30 mm * 2 14b-11351-00 ga...

Page 7

– 3 – 2. Spark plug set (14b-r465b-70) the spark creating portion of this spark plug is of a semi-surface discharge type of shape. Tip since these spark plugs have a copper gasket, caution is needed during installation on the following points. 1. The tightening torque is 12 – 15 n•m (1.2 – 1.5 kgf•m...

Page 8

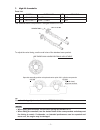

– 4 – 3. Head-gasket, cylinder gasket these parts are used to adjust the squish height and compression ratio. They should be installed in the direction, which enables the punched alpha-numeral “14b” is visible. The standard head cylinder gasket thickness is 0.40 mm and the cylinder gasket thickness ...

Page 9

– 5 – measuring the volume of the cylinder head combustion chamber tip to obtain the highest performance for race use, the four cylinders should be uniform. If you modify the head cylinder, always measure the combustion chamber volume and do the work based on the measured value. Measure the volume o...

Page 10

– 6 – 4. Piston set (14b-116a0-70) select four pistons so that the difference in their weights does not exceed 0.5g. 5. Connecting rod set (14b-1165b-70) select four connecting rod assemblies so that the difference in their weights does not exceed 2g and combine them so that the small end weights ar...

Page 11

– 7 – 7. High-lift camshafts this camshaft has a cam profile etc. Changed from the std one. To adjust the valve timing, use the oval holes of the standard cam sprocket. Tip for valve timing adjustment, refer to the kit tool manual. Notice x when using this camshaft, use the valve spring set 14b-a211...

Page 12

– 8 – 8. Valve spring set (14b-a2110-72) this valve spring is used when the camshaft is mounted from the kit. Notice when using this valve spring, use the camshafts 14b-12170-71, and 14b-12180-71. The camshaft, valve spring and ecu in this set can only be used in the following combinations. Parts li...

Page 13

– 9 – 9. Air funnel set a (mgc-021008-10) installation 1. Installing the plate secure the plate onto the throttle body. As shown, secure the plate only at two positions below, using the supplied screws (25 mm long). 2. Installing the supports install the supports onto the levers. Make sure to use th...

Page 14

– 10 – 3. Installing the lever assembly secure the lever assembly onto the plates. Using the supplied screws (30 mm long), secure the assembly at the locations as shown. 4. Installing the primary funnels secure the primary funnel by screwing it into the plate. Tip x for installation of the plate and...

Page 15

– 11 – 6. Installing the shaft assembly install the shaft assembly that is shorter than the std. Start by clipping the ball joint on the electric motor side, then clip the other side of the rod to the clip of the lever assembly. Motor side clip ball joint lever side.

Page 16

– 12 – 10. Air funnel set b (mgc-021008-20) installation 1. Installing the primary funnels screw on the primary funnels on the throttle body. Put only the 4 lower screws like on the photo. Use the short screws (30 mm). 2. Installing the supports install the supports onto the levers. Don’t forget to ...

Page 17

– 13 – 3. Installing the lever assembly put the screws in the holes of the supports then take the assembly previously mounted and place them on the pins fitted in the primary funnel. (torque 10 n•m) 4. Installing the std connecting rod start by clipping the ball joint on the electric motor side, the...

Page 18

– 14 – 6. Installing the secondary funnel install the secondary funnel onto the lever assembly. Clip the secondary funnel on the 2 shafts and make sure every clips are correctly linked. Ycci system control you can use the ycci system as the kit funnel. You can control the operation timing by using t...

Page 19

– 15 – 11.Throttle body clamp set (14b-1351a-70) this part is used to enhance maintenance performance of the throttle body. Before using it, cut off the protrusion for positioning bands at the cabjoint. The part has a collar to prevent over-tightening. In normal cases, the part will not be tightened...

Page 20

– 16 – 12. Ais-plug set (5vy-a4890-70) this plug set is used when the ais (air induction system), an exhaust gas purifying system, is removed. Installation 1. Remove the hose attached to the cylinder head cover and the air cut-off valve accompanying the hose. 2. Remove the cap fitted to the hose, re...

Page 21

– 17 – std kit 3 2 1 1.

Page 22

– 18 – 13. Clutch spring set (4b1-a6330-70) the clutch spring should have a bigger mounting load than standard. Parts list no. Part no. Part name q’ty remarks 1 4b1-16334-70 spring, clutch 6 1.

Page 23

– 19 – 14. Slipper clutch setting set (4c8-a6377-70) installing this part makes it possible to adjust the engine braking effect. Parts list no. Part no. Part name q’ty remarks ° 1 4c8-16377-70 nut, lock 1 ° 2 4b1-16391-70 shim 3 c a 2 1 b 52.8-53.4mm.

Page 24

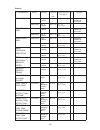

– 20 – (setting of back torque limiter of clutch). A clutch with a back torque limiter mechanism is installed in the yzf-r1 engines. The operation of the back torque limiter can be adjusted through adjusting: the number of shims (set up for the kit); the number of springs; the whole thickness of the...

Page 25

– 21 – as installed in operation stroke load 3 a springs, 3 shims 3 a springs, 2 shims 3 a springs, 1 shim 3 a springs, 0 shim 2 a springs, 3 shims.

Page 26

– 22 – 15. Transmission gear parts list no. Part no. Part name q'ty remarks 1 14b-17401-70-a main axle assy. 1 ab 1 14b-17401-80-c main axle assy. 1 c * 2 14b-15163-00 hsg., bearing 1 * 3 93306-20652 brg. 1 4 14b-17121-70-a gear, 2nd pinion 1 a 4 14b-17121-80-b gear, 2nd pinion 1 bc 5 14b-17131-aa g...

Page 27

– 23 – this transmission gear is set at a closer ratio than the std gear, making it possible to select a gear adapted to the course. Select the gear after referring to the speed table and the ratio table. 17 14b-17261-70-a gear, 6th wheel 1 a 17 14b-17261-80-b gear, 6th wheel 1 bc parts list no. Par...

Page 28

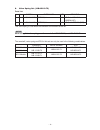

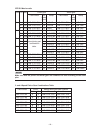

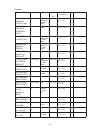

– 24 – notice this set contains modified gear ratios and docks compared with the std gearbox. Kit gears cannot use combine standard gear. Gear ratio std a b c 1st 38/15 (2.533) 34/14 (2.429) 33/14 (2.357) 37/16 (2.313) 2nd 33/16 (2.063) 32/15 (2.133) 32/16 (2.000) 31/16 (1.938) 3rd 37/21 (1.762) 31/...

Page 29

– 25 – yzf-r1 mission ratio notice make sure that the pinion and wheel gear are combined for use according to the chart plan. 3- and 4-speed pinion gear combinations table gearplan ratio pinion gear wheel gear part number the number of teeth stamp part number the number of teeth stamp 1st a 2.429 14...

Page 30

– 26 – yzf-r1 speed list engine sp eed (rpm) 13900 tire radius (mm) 311 perimeter (m) 1.954 primary redu ction ra tio 43 65 1.512 x values in the sp eed table may var y slightly according to tire manufacture r and size. X select after referrin g to the valu e in th e spe ed table. Gear plan the nu m...

Page 31

– 27 – 16. Mission maintenance set (14b-a7000-70) this kit contains three (3) sets of parts necessary for transmission disassembly and maintenance. Parts list no. Part no. Part name q'ty remarks * 21 90387-28003 collar 3 * 22 90209-25011 washer 6 * 23 93440-28184 circlip 10 * 24 90387-25023 collar 3...

Page 32

– 28 – 36 38 33 29 29 34 21 22 22 24 23 23 35 25 26 37 28 30 32 31 30 28 28 29 27.

Page 33

– 29 – transmission assembly m1 m1 m1 m2 m2 m2 m1 m2 m3 m3 m3 m3 a b b b b b c rotate washer so that its teeth meet axle- spline teeth on the axle, and then lock with washer , s claw. Assemble washer with putting together their matching mark. Apply molybdenum oil to inside of diameter. After assembl...

Page 34

– 30 – 17. Drive sprockets this sprocket is weight-saved by changing the chain size to 520 in relation to the std one. Notice when using this drive sprocket, use the sprocket nut of the kit. Parts list no. Part no. Part name q’ty remarks 1 14b-17460-74 sprocket, drive 1 14t, 520size 2 4xv-17460-75 s...

Page 35

– 31 – 18. Sprocket nut set (4c8-a7463-70) this sprocket nut uses a bending type of lock washer instead of the std caulking type. Notice when using this sprocket nut, use the drive sprocket of the kit. Parts list no. Part no. Part name q’ty remarks 1 4c8-17463-70 nut 1 * 2 90215-30233 washer, lock 1.

Page 36

– 32 – 2-2 installing chassis parts 19. Oil catcher tank set (14b-c1707-70) the oil catcher tank is available to meet the racing regulations. The capacity of this tank is 550cc. Installation 1. Remove the coolant reservoir from the chassis. 2. Remove from the chassis the breather hose that is connec...

Page 37

– 33 – 1-n-2-3-4-5-6 made in japan 8 6 5 7 crankcase crankcase 3 2 2 2 4 1 e/g.

Page 38

– 34 – 20. Shock absorber rear (14b-22210-70) rear suspension performance adjustment method low-speed compression damping, high-speed compression damping, rebound damping and preload can be adjusted. Preload adjustment method turn the adjustor clockwise to increase the preload and anticlockwise to r...

Page 39

– 35 – rebound damping adjustment method turn clockwise to increase the damping force and ޓ anticlockwise to reduce the damping force. The adjustment range is between 3 to 20 steps ޓ back from the lightly tightened adjustor position. Shipping position: 15 steps back from the tightened adjustor posit...

Page 40

– 36 – performance and purpose of kit suspension (diff erences compared with st andard suspension on commercially available machines) *s pring load: depends on the stroke. Damping force: depends on the stroke speed. Spring characteristics commercially available machine sp ecs purpose to increase com...

Page 41

– 37 – 21. Spring rear shock x these springs can be used with the standard or kit shock absorbers. X there is a stamp on the side of the springs for rate identification. X the stamp number indicates the length, diameter and rate. X for spring replacement, see the 14b std. Service manual. X the sprin...

Page 42

– 38 – 22. Machine height adjustment shim set (14b-c2127-70) use a 1 mm or 2 mm shim according to the settings. You can also use two shims together. Parts list no. Part no. Part name q'ty remarks 1 14b-22127-70 shim 1 t=1.0 mm 2 14b-22127-80 shim 1 t=2.0 mm 3 90185-16002 nut, self-locking 1 4 90201-...

Page 43

– 39 – 23. Front fork assy front fork performance adjustment method designed to develop damping force independent of each other, the left leg develops the compression damping force and the right one the rebound damping force. Adjustment is possible in preload as well as in compression and rebound da...

Page 44

– 40 – damping adjustment method turn clockwise to increase the damping force and anticlockwise to reduce the damping force. The adjustment range is: rebound : 1 to 25 steps back from the adjustor’s clockwise lightly tightened position. Compression : 1 to 25 steps back from the adjustor’s clockwise ...

Page 45

– 41 – performance and purpose of kit suspension (diff erences compared with st andard suspension on commercially available machines) *s pring load: depends on the stroke. Spring characteristics commercially available machine sp ecs purpose to increase comfort when rid ing in urban areas while preve...

Page 46

– 42 – *damping force: depends on the stroke speed. Damping force characteristics commercially available machine sp ecs purpose to maintain comfort when ridi ng in urban areas and improve road-holding properties when banking into bends. Perf ormance/ characteristics s et the lowest possible damping ...

Page 47

– 43 – 24. Spring front fork x there are slits at the ends of the spring for rate identification. X the number of slits indicates the rate as shown above. X when using an optional spring for the std fork, replace the supplied preload tube with the set. Notice when using an optional spring for the ki...

Page 48

– 44 – front fork spring replacement method 1. Turn the damping adjustor and preload adjustor anticlockwise to set to the weakest position. 2. After fixing the axle bracket in a vice, turn the fork bolt anticlockwise to lower the outer tube until the dust seal touches the upper surface of the axle b...

Page 49

– 45 – 5. Remove the push rod and fit the rod ( special tools ) to the piston rod. 6. Grip the rod ( special tools ) firmly and remove the spanner ( special tools ). Notice be very careful to apply downward pressure on the rod ( special tools ) when you remove the spanner ( special tools ). 7. Remov...

Page 50

– 46 – 8. Remove the washer, special nut and spring guide and replace the spring. Notice be very careful to apply downward pressure on the rod ( special tools ) when you remove the spanner ( special tools ). 9. Press the rod downwards before adjusting the oil level. X oil level in shipping state: wi...

Page 51

– 47 – references front and rear load changes and front and rear suspension movement in different scenarios. Accelerating . Load change the wider the throttle is opened, the more the load is concentrated on the rear. . Front fork reaches nearly maximum extended stroke. . Rear cushion up to 20 to 30m...

Page 52

– 48 – 25. Seat cushion (13s-24713-70) anti slip seat. Cut to any size for use. Parts list no. Part no. Part name q’ty remarks 1 13s-24713-70 cushion seat 1.

Page 53

– 49 – 26. Front spare wheel ass’y (4c8-25100-70) *this kit does not include a tire. This part is an assembly of bearings, spacers and an air valve in a std wheel. Parts list no. Part no. Part name q’ty remarks 1 4c8-25160-00 cast wheel assy. 1 mat black * 2 93900-00030 valve, rim 1.

Page 54

– 50 – 27. Rear spare wheel ass’y (4c8-25300-70) *this kit does not include a tire. This part is an assembly of bearings, spacers and an air valve in a std wheel. Parts list no. Part no. Part name q’ty remarks 1 4c8-25370-00 wheel,cast 1 mat black * 2 93900-00030 valve, rim 1.

Page 55

– 51 – 28. Throttle set (14b-c6300-70) in this throttle set the throttle grip can be removed and maintained by itself. Parts list no. Part no. Part name q’ty remarks ° 1 2c0-26281-70 cap, grip upper 1 * 2 5fl-26282-00 cap, grip under 1 ° 3 5sl-26243-71 tube, guide 1 linear type ° 4 2c0-26391-70 clip...

Page 56

– 52 – pull side (black) air filter side engine side pull side (black) pull side (black) release side (white) release side (white) release side (white) throttle body 12 14 13 8 9 10 11 1 3 2 6 5 7 4 fwd machining off the boss. Scrap away cap, grip upper of the kit as shown above.

Page 57

– 53 – 29. Throttle set (14b-c6300-80) in this throttle set the working angle of the throttle grip turning is made smaller for quicker response to the throttle openning. Parts list no. Part no. Part name q'ty remarks ° 1 2c0-26281-70 cap, grip upper 1 * 2 5fl-26282-00 cap, grip under 1 ° 3 5sl-26243...

Page 58

– 54 – 8 9 1 3 2 6 5 7 4 pull side (black) pull side (black) release side (white) release side (white) pull side (black) air filtre side engine side release side (white) fwd machining off the boss. Scrap away cap, grip upper of the kit as shown above throttle body.

Page 59

– 55 – 30. Tube guide (5vy-26243-80) about the throttle tube guide specifications as shown below, the operating angle of the throttle grip up to when the throttle body opening is 25% is the same as std, and the operating angle of the throttle grip when the throttle is fully opened is 58°. According ...

Page 60

– 56 – 2-3 installing electrical parts 31. Ecu set (14b-8591a-72) x use of this set and a wire harness included in the kit enables regulation (or setting) of fuel injection and ignition timing, etc. X for details as to how to regulate (or set) fuel injection and ignition timings, etc., refer to the ...

Page 61

– 57 – 32. Cable interface (13s-8533a-70) x this cable connects the kit wire harness to the personal computer on which yec fi matching system (yms) is installed. X please see the yms manual for instructions on how to use yms. X when connecting the cable to the pc for the first time, it is necessary ...

Page 62

– 58 – diagnosis functions x use of the ecu in the kit and the harness allows functioning of the following codes in the std diagnosis. * yms-monitor: yec fi matching system also allows functioning of the code shown below. Code contents *yms-monitor 01 throttle sensor tps 1(deg) 02 atmospheric pressu...

Page 63

– 59 – self-diagnosis functions x the ecu and harness in the kit provide the functions for the following codes of standard self-diagnosis: code description 00 all functions normally. 11 cam angle sensor malfunctions. 12 crank angle sensor malfunctions. 13 intake pressure sensor malfunctions (open ci...

Page 64

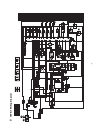

– 60 – 33. Wire harness set (14b-f2590-70) this wire harness is weight-saved by doing away with connecting wires for lights. Notice x remove the coupler of the main switch before starting assembling work. X do not remove the ac generator but leave it to function. Use on the battery alone will make t...

Page 65

– 61 – installing wire harness: 1. Remove the std wire harness from the chassis. 2. Install the wire harness from the kit by reference to the service manual. 3. Pass the wire harness through the hole in the cable holder side and secure it with a clamp at the location indicated. Align the clamping po...

Page 66

– 62 – notice when the oil catcher tank is in use, change the direction of the hose clip so it won't touch the wire harness. Wire harness.

Page 67

– 63 – notice the wire from the acm is designed to be so long that for routing it, enough care should be taken not to allow it to hang out of the chassis or to interfere with other parts. To acm rectifier/regulator to wire harness ecu wire harness.

Page 68

– 64 – installing ecu: 1. Cut the shaded area off the battery box (to provide an installation area for fixing for brkt5 seat). 2. Install brkt5 with bolt and washer at the location where the std mudguard was installed. 3. Install brkt4 to brkt5 with bolt , collar , and grommet . 4. Install plug to b...

Page 69

– 65 – installing rectifier/regulator: 1. Remove from the chassis the std rectifier/regulator that is installed on the right side of the radiator. 2. Install the rectifier/regulator to the catcher tank from the kit using the std chassis bolts. 3. In case the oil catcher tank is not used from the kit...

Page 70

– 66 – x map select switches map 1 and map 2 of the yms “comp. Fuel.” notice when switching to map 1 or map 2 using “map select” while riding, check that proper riding is possible even when using either map. X the switches (2 types) supplied in this set enable the map select and pit road limiter to ...

Page 71

– 67 – x the switch installed to the std machine may be used as is. (see diagram 3.) x the shifter switch function can be used by combining the harness and kit ecu. To use the std switch (left side) to function as the shifter switch, connect the wire sub- lead that was packaged with this set to the ...

Page 72

– 68 – notice do not connect the coupler for resistor (black, 2-prong) and the coupler for power ޓ (white, 2-prong). Connecting them may cause a malfunction. (see diagram 6.) x this harness has a coupler that connects to the 2d made data logger. (see diagram 7.) for details of the specifications of ...

Page 73

– 69 – x this harness comes with a coupler (black 2-pole, plug) for use with a quick shifter. (connection diagram e/g stp sw) (diagram 8) you can use any quick shifter product. 86 connector for quick shifter connector for steering damper (diagram 8).

Page 74

– 70 – 34. Headlight harness set (14b-f4350-71) this set is used in endurance races in combination with the kit harness for turning on the std headlights and taillights. It assumes that the standard headlights and taillights are used. When using std headlights, you can use the coupler of either head...

Page 75

– 71 –.

Page 76

– 72 – 35. Acm set (14b-f1400-70) this acm is designed to have less inertial mass and friction by making it into an inner rotor type. Tip regarding assembly 1. Remove grease from the taper surfaces of both rotor and crank before assembling them. 2. Apply engine oil on the thread and flange of mounti...

Page 77

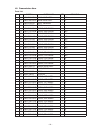

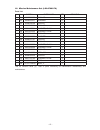

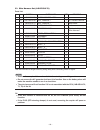

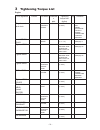

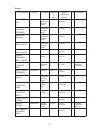

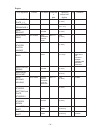

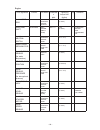

– 73 – 3 tightening torque list engine to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks plug for sand drain hole 90340-18002 plug, straight screw m18 x 1.5 42±4 (4.3±0.4) 3 apply lock- ing agent (locktite® to both screw thread and tapered portion. Ins...

Page 78

– 74 – con rod 5vy-11654-01 bolt, con-rod big end m8 x 0.75 turn of nut method: retighten to snug torque of 19.6 (2.0) • angle of 150 ± 5°. 8 apply molybde- num disulfide oil 5vy-1165a-01 (long bolt) 8 acm rotor 90105-126a8 bolt, flange m12 x 1.25 70±5 (7.0±0.5) 1 for details, see page 72. Sprocket,...

Page 79

– 75 – install pipe, oil 1 90110-06182 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0.2) 2 install housing, strainer 90110-06173 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0.2) 3 install pipe holder 90110-06182 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0.2) 2 install oil delivery pipe 1 90110-0...

Page 80

– 76 – ex. Pipe (diffuser) x muffler 95814-08035 bolt, flange m8 x 1.25 20±2 (2.0±0.2) 2 install ex. Pipe assy 95812-08040 bolt, flange m8 x 1.25 20±2 (2.0±0.2) 1 install wire pulley double nut 14b-1133e- 14b-1133f- wire, pulley,1 wire, pulley,2 m6 x 1.0 5 – 7 (0.5 – 0.7) 2 catalyst converter x brac...

Page 81

– 77 – implant in crankcase 1 90116-10051 bolt, stud m10 x 1.25 8 targeted at 6 – 9 (0.8 targeted at 0.6-0.9) 10 apply oil to both screw thread and bearing surface. Control torque. Crankcase 1 x crankcase 2 90119-09010 bolt, hexagon with washer m9 x 1.25 for details, see page 85. 10 apply oil to bot...

Page 82

– 78 – install cover, crank 2 90110-06323 bolt m6 x 1.0 12±2 (1.2±0.2) 8 clutch cover install cover, crank 2 90110-06324 bolt m6 x 1.0 12±2 (1.2±0.2) 1 clutch cover install cover1 90110-06331 bolt m6 x 1.0 12±2 (1.2±0.2) 5 cam chain cover install cover1 90110-06323 bolt m6 x 1.0 12±2 (1.2±0.2) 1 cam...

Page 83

– 79 – install baffle plate 1 -3 90149-06082 screw m6 x 1.0 10±2 (1.0±0.2) 10 install cover, crankcase 3 90149-06152 screw m6 x 1.0 6 – 8 (0.6 – 0.8) 4 install bracket 90105-06181 bolt, flange m6 x 1.0 10±2 (1.0±0.2) 1 install idler gear 90110-06223 bolt, hexagon socket head m6 x 1.0 10±2 (1.0±0.2) ...

Page 84

– 80 – install joint rod 90111-06019 bolt, hexagon socket button m6 x 1.0 10±2 (1.0±0.2) 1 install arm, shift 95022-06020 bolt, flange (small head) m6 x 1.0 10±2 (1.0±0.2) 1 check ser- ration for tightening up install neutral switch 90110-05067 bolt, hexagon socket head m5 x 0.8 3 – 5 (0.3 – 0.5) 2 ...

Page 85

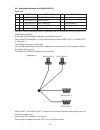

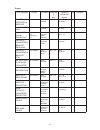

– 81 – chassis to be tightened part no. Part name thread dia. X pitch tightening torque n•m (kgf•m) q’ty remarks handle, crown & outer tube 91314-08030 bolt, hexagon socket head m8 x 1.25 23 – 28 (2.3 – 2.8) 2 handle, crown & steering shaft 90170-28419 nut, hex- agon m28 x 1.0 100 – 125 (10.2 – 12.7...

Page 86

– 82 – arm & frame 90105-10150 bolt, flange m10 x 1.25 — 1 screw in from the left side. 95602-10200 nut, u flange m10 x 1.25 31 – 49 (3.2 – 5.0) 1 arm, relay & arm 90105-10017 bolt, flange m10 x 1.25 — 1 screw in from the left side. 95602-10200 nut, u flange m10 x 1.25 31 – 49 (3.2 – 5.0) 1 arm & re...

Page 87

– 83 – front wheel shaft & flange bolt 90105-14002 bolt, flange m14 x 1.5 70 – 111 (7.1 – 11.3) 1 rear wheel shaft & nut 90185-24007 nut, self locking m24 x 1.5 120 – 180 (12.2 – 18.4) 1 front caliper & front fork 90105-10397 bolt, union m10 x 1.25 30 – 40 (3.1 – 4.1) 4 disc brake & wheel (front) 90...

Page 88

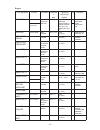

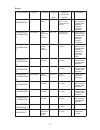

– 84 – tightening the cylinder head tightening the cylinder head (turn-of-nut method) 1. Tighten the bolts in the sequence 1 to 10 to a torque of 40 n•m (4.0 kgf•m). 2. In the sequence 1 to 7, loosen each nut then retighten it to a torque of 22 n•m (2.2 kgf•m) before finally tightening it another 90...

Page 89

– 85 – installing the crankcase tightening the bolts 1. Tighten the bolts in the tightening sequence of 1 to 10 to 29.4 n•m (3.0 kg•m). 2. After loosening the bolts once in the tightening sequence of 1 to 10, retighten them one by one to 17.6 n•m (1.8 kg•m). 3. Retighten the bolts in the tightening ...

Page 90

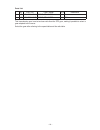

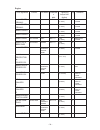

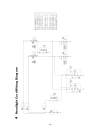

– 86 – 4 headlight cord wiring diagram.

Page 91

– 87 – 5 yzf-r1 wiring diagram.

Page 92

Published by yamaha motor engineering co., ltd.