- DL manuals

- WAGNER

- Paint Sprayer

- Plast Coat 25

- Operating Manual

WAGNER Plast Coat 25 Operating Manual

Summary of Plast Coat 25

Page 1

Plast coat pc 25 pc 35 0348 870 03 / 2010 betriebsanleitung p. 2 operating manual p. 24 mode d’emploi p. 48 gebruiksaanwijzing p. 72.

Page 2: Plast Coat 25 · 35

26 plast coat 25 · 35 warning! Suction pumps develop high spraying pressures. Attention − danger of injury! 1 never reach into the spray jet with your fingers or hand! Never aim the spray lance at yourself or other persons! The materials sprayed cause chemical burns or irritations! Protect your skin...

Page 3: Plast Coat 25 · 35

27 plast coat 25 · 35 gb contents 1 safety requirements _____________________ 28 2 introduction to working with the mortar spraying machines plastcoat 25 and 35 __ 29 2.1 operationofthemortarsprayingmachines plastcoat 25 and 35 __________________________ 29 2.2 what materials can be sprayed? _______...

Page 4: Plast Coat 25 · 35

28 plast coat 25 · 35 gb 1 safety requirements all local safety regulations in force must be observed. For safe operation of the mortar spraying machines, always comply with the following specific instructions: 1. Use of the mortar spraying machines the mortar spraying machines plastcoat 25 and 35 a...

Page 5: Plast Coat 25 · 35

29 plast coat 25 · 35 gb 2.1 operation of the mortar spraying machines plastcoat 25 and 35 the coating materials are supplied to the machine by means of the receptacle. The spiral conveyor feeds the coating mate- rial into an eccentric screw pump. This pump generates the pressure required for the tr...

Page 6: Plast Coat 25 · 35

30 plast coat 25 · 35 gb 4 equipment overview – mortar spraying machines plastcoat 25 and 35 1 control unit 2 receptacle 3 screw conveyor 4 pump jacket – pump screw 5 pressure gauge 6 outletunit 7 compressed air connection 8 mortar hose, assy. 9 texture nozzle 10 spray lance with automatic control 1...

Page 7: Plast Coat 25 · 35

31 plast coat 25 · 35 gb 4.1 control unit 1 master switch 0–1 2 indicator lamp 3 feed rate regulator 0–10 4 changeover switch 5 mains cable 6 connection for remote control 2 5 3 4 1 6 the mortar spraying machine can be switched on using the master switch (1, fig. 3). The indicator lamp (2) shows tha...

Page 8: Plast Coat 25 · 35

32 plast coat 25 · 35 gb accessories for the receptacle 4.3.1 sliding cover prevents contamination getting into the coating material. Ex- tends the hardening time of the coating material, particularly with direct sunlight. 4.3.2 sack mangle for using coating material in sacks, a sack mangle can be p...

Page 9: Plast Coat 25 · 35

33 plast coat 25 · 35 gb 4.6 spray lance with automatic control (fig. 8) 1 material connection 2 switch sleeve, switching the mortar spraying machine on and off using remote control 3 texture nozzle 4 air tap 5 material tap 6 remote control connection 7 atomization air connection 1 7 5 4 2 3 6 4.7 s...

Page 10: Plast Coat 25 · 35

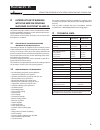

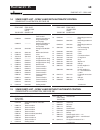

34 plast coat 25 · 35 gb accessoires illustration, see page 99/100. Coating materials equipment table 6 coating materials equipment table plastcoat 25 and plastcoat 35 synthetic resin based systems kh- coa ting plast er/c oncr et e c on tac t kh-base plastic/quar z plastic w ood chip pain t foam mor...

Page 11: Plast Coat 25 · 35

35 plast coat 25 · 35 gb onlyuseothercoatingmaterialsafterconsultingwagnerapplicationtechnologydepartment. Coating materials equipment table mineral plaster systems wdvs adhesiv e/filler reinf or cing fibr e filler gr oo ve plast er up t o g 5 ligh t first c oa t plast er ligh t t ex tur e plast er ...

Page 12: Plast Coat 25 · 35

36 plast coat 25 · 35 gb 7 placing into operation installation location position mortar spraying machine in a level position to pre- vent it from sliding away. Connecting mortar hose • checkthattheoutletunit(1,fig.11)isseatedfirmly.Ifneces- sary tighten star grips (2) by hand. • connectmortarhose(3)...

Page 13: Plast Coat 25 · 35

37 plast coat 25 · 35 gb placing into operation preparing the mortar spraying machine only work with the safety grill inserted! Recommended lubricant for the mortar hose water is not a satisfactory lubricant. Danger of blockages! Synthetic resin products –> synthetic resin dispersion pcc systems –> ...

Page 14: Plast Coat 25 · 35

38 plast coat 25 · 35 gb spray lance without automatic control • openmaterialtap(3,fig.16). • turnondevicewithremotecontrolswitch(1,fig.16). • coatingmaterialwillbepumpedintothemortarhose. • pumpsyntheticresindispersionorcellulosepastefromthe mortar hose into a bucket. • assoonascoatingmaterialstart...

Page 15: Plast Coat 25 · 35

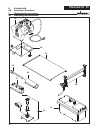

39 plast coat 25 · 35 gb 9 fitting accessories 9.1 compressor v 400 suction volume 360 l/min • attachcompressorholder(item1,fig.17)andsecurewith star grip (2). • placecompressorontoholder.Slideretainingplate(3)over the compressor base. • securethecompressorwithstargrips(4). Technical data roller len...

Page 16: Plast Coat 25 · 35

40 plast coat 25 · 35 gb using coating materials in sacks • pullslidingcoverbackabout15cm. • placesackontheslidingcoverinsuchawaythatthetop faces the front end of the sliding cover. • cutsackopen. • allowthecoatingmaterialtoflowintothereceptacle. • move sack mangle forwards over the sack by turning ...

Page 17: Plast Coat 25 · 35

41 plast coat 25 · 35 gb 10.2 cleaning device and changing pump jacket never remove the safety grill for any clea- ning work! Disassembly • lubricatepump. Turn changeover switch to (backwards). Spray pump antiseize or a little dishwashing liquid into the outlet unit (2, fig. 22) or place a little di...

Page 18: Plast Coat 25 · 35

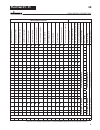

42 plast coat 25 · 35 gb fault possible cause remedy motar spraying machine does not start the mortar spraying machine has been overloaded. Set master switch and changeover switch to „0“. Turn mortar spraying machine back on after about 10 sec. Caution: set changeover switch to „0“ before turning on...

Page 19: Plast Coat 25 · 35

43 plast coat 25 · 35 gb fault possible cause remedy motar spraying machine does not start the mortar spraying machine has been overloaded. Set master switch and changeover switch to „0“. Turn mortar spraying machine back on after about 10 sec. Caution: set changeover switch to „0“ before turning on...

Page 20: Plast Coat 25 · 35

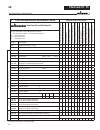

44 plast coat 25 · 35 gb ite m par t no . Plastc oa t 25 par t no . Plastc oa t 35 d esig na tion 1 0348 363 0348 363 m ot or cable 2 9982 820 9982 820 cable scr ew c onnec tion 3 9982 823 9982 823 adapt er 4 0348 230 ------------- ------------- 0348 231 tr ansmission mot or 230 v~, 50 h z tr ansmis...

Page 21: Plast Coat 25 · 35

45 plast coat 25 · 35 gb 14 spare parts list – spray lance with automatic control (sparepartsillustration,seepage98) item part no. Spray lance 100 mm long part no. Spray lance (ceiling spray lance) 800 mm lang designation 0348 241 0348 960 spray lance with auto- matic control 0348 904 0348 904 exten...

Page 22: Plast Coat 25 · 35

46 plast coat 25 · 35 gb 16 spare parts list – compressor v 400 item part no. Designation 1 0342 231 compressor v 400, 230 v~, 50 hz suction volume 360 l/min 2 9992 823 rapid action coupling 3 0348 452 retaining plate 4 0348 442 compressor holder 5 9990 373 star grip m 8 6 0348 957 compressor holder...

Page 23: Plast Coat 25 · 35

47 plast coat 25 · 35 gb 17 spare parts list – container suction system item part no. Designation 1 0348 907 container suction system 2 9971 529 seal 3 0342 205 suction hose 4 0097 085 coupling 5 0348 361 connecting plate 6 0348 947 connecting bridge 7 0097 105 coupling 2 2 4 5 3 2 2 7 7 2 6 1 spare...

Page 24: Plast Coat 25 · 35

48 plast coat 25 · 35 gb 18 accessories plastcoat 25 and 35 (accessoriesillustration,seepage99/100) item part no. Designation 1 0268 779 texture nozzle 4 0348 915 texture nozzle 5 0268 780 texture nozzle 6 0348 916 texture nozzle 7 0268 781 texture nozzle 8 (standard) 0348 917 texture nozzle 9 0268 ...

Page 25: Plast Coat 25 · 35

49 plast coat 25 · 35 gb.

Page 26: Plast Coat 25 · 35

97 plast coat 25 · 35 1 51 52 23 22 24 6 40 38 42 43 41 36 50 44 45 3 1 2 4 9 11 14 7 17 18 15 12 19 26 27 6 31 15 32 33 35 30 6 10 30 30 37 49 46 53 47 16 16 48 6 25 39 5 34 2 6 21 d ersatzteilbild gb spare parts illustration f eclaté nl afbeelding onderdelen.

Page 27: Plast Coat 25 · 35

98 plast coat 25 · 35 d ersatzteilbild spritzlanze mit automatik gb spare parts illustration – spray lance with automatic control f eclaté lance de projection avec commande autom. Nl afbeelding onderdelen spuitlans met automaat 14 7 1 8 9 4 21 19 20 22 2 3 5 4 6 10 11 12 15 13 11 17 18 16 d ersatzte...

Page 28: Plast Coat 25 · 35

99 plast coat 25 · 35 16 21 1 2 3 4 5 7 15 20 6 19 24 10 17 13 22 11 8 12 9 18 17 23 14 14 14 d zubehörbild gb accessories illustration f illustration des accessoires nl afbeelding met toebehoren.

Page 29: Plast Coat 25 · 35

100 plast coat 25 · 35 34 33 29 30 31 26 25 35 32 d zubehörbild gb accessories illustration f illustration des accessoires nl afbeelding met toebehoren.

Page 30: Plast Coat 25 · 35

103 plast coat 25 · 35 gb testing of the unit for safety reasons, we would recommend having the device checked by an expert as required but at least every 12 months to ensure that it can continue to operate safely. In the case of unused devices, the check can be postponed until they are next started...

Page 31: Plast Coat 25 · 35

104 plast coat 25 · 35 gb 3. Handling if defects can be seen in the materials, processing or perform- ance of the device during the guarantee period, guarantee claims must be made immediately, or at the latest within a period of 2 weeks. The authorised specialist shop that delivered the device is en...

Page 32: Plast Coat 25 · 35

109 plast coat 25 · 35.