Xerox 6100BD - Phaser Color Laser Printer Manual

DocuTech 61xx Production Publisher Family

701P48388

February 19, 2008

Operator HandyBook

The purpose of this HandyBook is to provide a quick reference for the operator. It does not

replace the Operator Guide or other Xerox supplied reference materials.

More information is available at www.Xerox.com. The Operator Guide is available for download

as well.

Summary of 6100BD - Phaser Color Laser Printer

Page 1

Docutech 61xx production publisher family 701p48388 february 19, 2008 operator handybook the purpose of this handybook is to provide a quick reference for the operator. It does not replace the operator guide or other xerox supplied reference materials. More information is available at www.Xerox.Com....

Page 2

Prepared by: xerox corporation bgo/psg/pdu/cost productivity 800 phillips road, 207-02z webster, new york 14580 usa © 2008 xerox corporation. All rights reserved. Xerox® and the sphere of connectivity design are trademarks of xerox corporation in the us and/or other countries. Changes are periodical...

Page 3: Table of Contents

Dt6180 handybook table of contents table of contents...................................................................... 3 1. System hardware ................................................................. 7 processor components ......................................................................

Page 4

Dt6180 handybook clean the bindexer sensors (q1205, q1206, q1207)............................................................... 74 clean the bins exit sensors (q1222)......................................................................................... 75 clean the front stack (q1227), rear stac...

Page 5

Dt6180 handybook 8. Disable stock size checking............................................................................................... 149 9. Display all active machine faults ........................................................................................ 150 10. Enable and bring on...

Page 6

System hardware dt6180 handybook 6.

Page 7: System

System hardware dt6180 handybook 7 1. System hardware.

Page 8

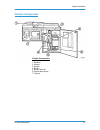

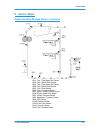

System hardware dt6180 handybook 8 processor components processor components 1. Paper trays 2. Electrical module 3. Dry ink cartridge 4. Photoreceptor, located behind a panel 5. Laser, located behind a panel 6. Fuser agent reservoir 7. Inverter 8. Decurler lever 9. Dry ink waste container.

Page 9

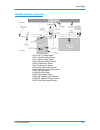

System hardware dt6180 handybook 9 interposer components interposer components 1. Upper entrance transport 2. Upper vertical transport 3. Upper turn transport 4. Tray 4 5. Upper exit transport 6. Tray 5 7. Lower entrance transport 8. Lower turn transport 9. Lower exit transport 10.Lower vertical tra...

Page 10

System hardware dt6180 handybook 10 finisher components finisher components: 1. Bindexer 2. Stitcher 3. Stacker 4. Binder 5. Binder tape reel 6. Stitcher wire spools 7. Top tray.

Page 11

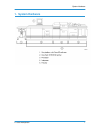

System hardware dt6180 handybook 11 paper path areas the numbers in figure 4-6 identify the following paper path are as follows: • areas 1 to 4 - the stock leaves a paper tray and is fed to the photoreceptor. • areas 5 to 10 - the system prints an image on one side of the stock. If the job requires ...

Page 12

Paper trays & loading media dt6180 handybook 12.

Page 13

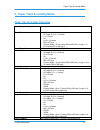

Paper trays & loading media dt6180 handybook 13 2. Paper trays & loading media paper tray & finisher capacities stock weight (all trays) substance 16 to 110 (60 to 200 g/m2) tray 1 stock sizes • us letter (8 1/2 x 11 inches) • us legal (8 1/2 x 14 inches) • 9 x 11 inches • a4 • 8 1/2 x 13 inches • 2...

Page 14

Paper trays & loading media dt6180 handybook 14 tray 5 stock sizes • us letter (8 1/2 x 11 inches) • us legal (8 1/2 x 14 inches) • us ledger (17 x 11 inches) • 9 x 11 inches • a3 • a4 • 8 1/2 x 13 inches • 223 x 297 mm • iso b4 • jis b4 • custom (width = 8 to 17 inches (203 to 432 mm), length = 10 ...

Page 15

Paper trays & loading media dt6180 handybook 15 than substance 20 (75 g/m2) is being run, the capacity of the top tray is reduced. 500 sheets of substance 20 (75 g/m2) is equal to approximately: 415 sheets of substance 24 (90 g/m2) 310 sheets of substance 32 (120 g/m2) 225 sheets of substance 110 (2...

Page 16

Paper trays & loading media dt6180 handybook 16 adding paper to tray 1 or 2 the following steps must be performed to add paper to tray 1 or 2. 1. Press the tray unlock button on the front of the tray. Wait for the red "please wait" light to go off. 2. When the green "ready to open" light comes on, p...

Page 17

Paper trays & loading media dt6180 handybook 17 move the rear guide forward until it touches the edge of the stack. Lower the feed belt. Close the tray slowly, but firmly, until it latches..

Page 18

Paper trays & loading media dt6180 handybook 18 adding paper to trays 3, 4, or 5 1. Press the tray unlock button on the front of the tray. Wait for the red "please wait" light to go off. Note: if the tray is not pulled out all of the way, the tray elevator will not go down as paper is added. 2. When...

Page 19

Paper trays & loading media dt6180 handybook 19 loading transparencies the following are the different types and usage of transparencies for paper trays 1, 2 and 3. • transparencies with a 13 mm (0.5 inch) white stripe should be loaded with the white stripe to the right if you are using paper trays ...

Page 20

Paper trays & loading media dt6180 handybook 20 adding inserts for docusp 4.X and above: creating inserts differs from slip sheets in that they separate pages of a job while slip sheets separate one job from another. Inserts may also be pre-printed stock or forms. Note: inserts may not be programmed...

Page 21

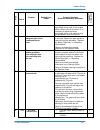

Paper trays & loading media dt6180 handybook 21 satisfaction guides satisfaction guide for paper trays 1 and 2 stock reliable feeds may be expected less reliable feeds may be expected suggested alternatives size 8 x 10 inches to 9 x 14 inches (203 x 254 mm to 229 x 356 mm) stock smaller than 8 x 10 ...

Page 22

Paper trays & loading media dt6180 handybook 22 satisfaction guide for paper tray 3 stock reliable feeds may be expected less reliable feeds may be expected suggested alternatives size 8 x 10 inches to 17 x 11 inches (203 x 254 mm to 432 x 279 mm) smaller or larger sizes cannot be used. Weight subst...

Page 23

Paper trays & loading media dt6180 handybook 23 satisfaction guide for paper tray 4 stock reliable feeds may be expected less reliable feeds may be expected suggested alternatives size 8 x 10 inches to 17 x 11 inches (203 x 254 mm to 432 x 279 mm) smaller or larger sizes cannot be used. Weight subst...

Page 24

Paper trays & loading media dt6180 handybook 24 satisfaction guide for 2-sided printing stock reliable feeds may be expected less reliable feeds may be expected suggested alternatives size 8 x 10 inches to 17 x 11 inches (203 x 254 mm to 432 x 279 mm) 17 x 11 inch (432 x 279 mm) paper can only be se...

Page 25

Paper trays & loading media dt6180 handybook 25 stock type instructions for use holes to the left. Do not bind or run 2-sided prints. • never-tear do not bind or run 2-sided prints. • 3 hole drilled, edge reinforced, 4024 dp paper do not stitch or bind. Do not run with tabs. Tabs can be inserted off...

Page 26

Paper trays & loading media dt6180 handybook 26 stock type instructions for use load the paper into trays 1 and 2; side 1 up with the top edge to the front of the tray. Do not use freshly preprinted paper in trays 1 and 2. • textured paper heavily textured paper may produce prints with a ragged char...

Page 27

Recommended shift preventative maintenance plan dt6180 handybook 27 3. Recommended shift preventative maintenance plan regular operator maintenance of your equipment is likely to improve overall performance. The maintenance could be done at the beginning or end of the shift, which ever is decided up...

Page 28

Recommended shift preventative maintenance plan dt6180 handybook 28 2. Shut down, then start up the system, then power on the printer warning: powering off the system, and thus the printer will result in the loss of all jobs in the print queue. Under normal operating conditions, use the docusp contr...

Page 29: Replacing

Replacing consumables dt6180 handybook 29 4. Replacing consumables add fuser agent note: you should add fuser agent as soon as possible after the message is displayed. If fuser agent is not added the machine will stop running after approximately 5,000 prints and will not run until fuser agent is add...

Page 30

Replacing consumables dt6180 handybook 30 7. Open a new box of fuser agent and remove the bottle. Caution: make sure you use the fuser agent specific to the machine model you are using. Fuser agent for the machine model docutech 90 is not compatible with the docutech 135. 8. Remove the cap from the ...

Page 31

Replacing consumables dt6180 handybook 31 replace stitcher a wire note: you will need wire cutters to perform this procedure. Wire cutters can be found next to stitcher spool b. 1. Open the finisher doors. 2. Raise the stitcher panel. The stitcher panel is a black plate about 228 mm (9 inches) squar...

Page 32

Replacing consumables dt6180 handybook 32 8. Use the wire cutters to pull the remaining wire out of the plastic tubing. 9. Place the stitcher plug in the measuring bracket. The measuring bracket is a black metal plate about 25 mm (1 inch) in length, with a hole in it that the stitcher plug fits into...

Page 33

Replacing consumables dt6180 handybook 33 > 21. Re-insert the plug into the stitcher head. The plug will snap itself into place if installed correctly. 22. Push the green stitcher head release handle down and back. 23. Lower the stitcher panel. 24. Close the finisher doors..

Page 34

Replacing consumables dt6180 handybook 34 replace the binder tape reel 1. Open the finisher doors. 2. Grasp the green handle on the binder assembly and pull the drawer out until it stops. The green handle is to the right of paper tray 3. Warning: all areas of the binder assembly, including the binde...

Page 35

Replacing consumables dt6180 handybook 35 6. Remove the tape reel. 7. Slide the new tape reel onto the tape reel drive. Make sure that the larger hole in the center of the tape reel faces the tape reel drive. 8. If necessary, rotate the tape reel slightly until it clicks into position. 9. Move the r...

Page 36

Replacing consumables dt6180 handybook 36 note: if a problem occurs when you are trying to turn the green knob, close the finisher doors. The screen will display a 'please wait - finisher reset in progress' message. Wait until a 'ready' message is displayed, then open the finisher doors and try feed...

Page 37

Replacing consumables dt6180 handybook 37 replace the toner (dry ink) bottle caution: do not use warm water or cleaning solvents to remove toner from your skin or clothing. This will set the toner and make it difficult to remove. If toner gets on your skin or clothing, use a brush to remove the tone...

Page 38

Replacing consumables dt6180 handybook 38 seal that is attached to the bottle. 7. Shake the new bottle several times to loosen the toner. 8. Insert the bottle into the receptacle. 9. Rotate the green handle down, to the latched position. 10. Push the new bottle all the way into the machine. 11. Hold...

Page 39

Replacing consumables dt6180 handybook 39 caution: to prevent a toner spill, do not tip or tilt the waste container. 5. Remove the cap from the top of the full toner waste container. 6. Place the cap over the opening on the end of the full toner waste container. 7. Remove the new toner waste contain...

Page 40

Replacing consumables dt6180 handybook 40 order supplies, consumables, and parts dt135/6100/6115/6135/6155/6180 supplies/consumables/parts equipment supplies dry ink waste container - 502s67618 please call the parts desk 1-800-828-5881 toner - 6r206 binder tape/reel - 8r1174 (32 k) binder tape/reel ...

Page 41: Machine

Machine maintenance dt6180 handybook 41 5. Machine maintenance adjusting for paper curl measure 5 sheets - 8½x 11, short edge.

Page 42

Machine maintenance dt6180 handybook 42 5 sheets, short edge measure paper curl.

Page 43

Machine maintenance dt6180 handybook 43 adjusting for paper curl - adjusting the decurler lever 1. Open the right door of the processor. 2. Locate the decurler lever in area 7 of the paper path, as shown below. 3. If the print curl is +2 or more, move the green decurler lever to the right. 4. If the...

Page 44

Machine maintenance dt6180 handybook 44 adjusting the heavy paper levers adjust the heavy paper levers to prevent skewing from heavy weight or long paper. 1. Open the right door of the processor. 2. Open the left door of the processor. 3. Locate the black heavy paper levers behind area 4 and area 2....

Page 45

Machine maintenance dt6180 handybook 45 5. Run the print job. 6. When the print job has been completed, lower the heavy paper lever. A. Pull the silver latch release toward you. B. Lower the left and right black levers to the horizontal position, as shown below. Lowering the levers 8. Close the proc...

Page 46

Machine maintenance dt6180 handybook 46 adjust the binder tape registration note: adjusting the top edge of the binder tape changes the positioning of the tape. Adjusting the bottom of the binder tape changes the length of the tape. To adjust the binder tape registration: 1. Make sure that the tape ...

Page 47

Machine maintenance dt6180 handybook 47 book. 7. Close the finisher doors. 8. Run a test job to inspect your adjustment. 9. If necessary, perform the procedure again as needed. Enable a paper tray for clean up if you are using docusp software version 3.X and above: 1. From the docusp for docutech 20...

Page 48

Machine maintenance dt6180 handybook 48 enable or disable the stacker note: before you begin, you must be logged on as a system administrator or trusted user. To enable or disable the stacker using docusp software version 3.X: 1. Select [printer manager] on the docusp for docutech 2000 series for 61...

Page 49

Machine maintenance dt6180 handybook 49 modify the bindexer capacity number if you are using software version 3.X and above: 1. From the docusp for docutech 2000 series 61xx window, select [printer manager]. The printer manager window will be displayed. 2. Select the [stacking] tab. 3. Select the [s...

Page 50

Machine maintenance dt6180 handybook 50 stop a job from printing at the printer note: you must logon as a system administrator or trusted user to perform this task. To stop a job at the printer using docusp software version 3.X or above: 1. In the docusp for docutech 2000 series for 61xx window, sel...

Page 51: Problem

Problem solving dt6180 handybook 51 6. Problem solving potential solutions for common problems are available using the either of 2 methods: 1. If you know the fault code: a. Look up fault code in the table, “common fault codes & case”, find case number (page 50 - page 52). B. Look up case number in ...

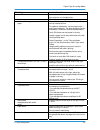

Page 52

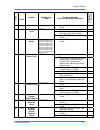

Problem solving dt6180 handybook 52 common fault codes & case look-up case number in table “problem listing and solutions, listed by case number”, following fault code table, for solutions. Fault code case descp case c16-351 communication failure faults 10971 c16-352 communication failure faults 109...

Page 53

Problem solving dt6180 handybook 53 fault code case descp case p03-364 printer run faults 2823 p03-370 printer run faults 2823 p03-371 printer run faults 2823 p03-373 printer run faults 2823 p03-374 printer run faults 2823 p03-375 printer run faults 2823 p03-378 printer run faults 2823 p04-201 timin...

Page 54

Problem solving dt6180 handybook 54 fault code case descp case p12-108 post inverter sensor faults 3304 p12-111 post inverter sensor faults 3304 p12-112 output transport sensor faults 10984 p12-115 output transport sensor faults 10984 p12-116 trail edge bindexer entrance fault 3336 p12-122 bindexer ...

Page 55

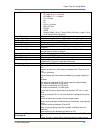

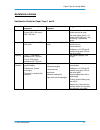

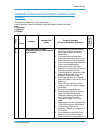

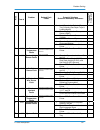

Problem solving dt6180 handybook 55 problem listing and solutions, listed by case number first group of problems don’t have case number look-up solutions, listed in alphabetical order immediately following this table. Area p=processor i=interposer f=finisher area case # problem related fault codes p...

Page 56

Problem solving dt6180 handybook 56 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? The green dot inside the tray. • fan the stock at all four corners. Change it if it has uneven edges or if it was not drilled...

Page 57

Problem solving dt6180 handybook 57 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? This guide. 3. If the processor has a ground fault protector, determine whether the protector has shut off the power. If the ...

Page 58

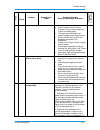

Problem solving dt6180 handybook 58 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? If an adjustment is made to the binder tape length during a job, it will not take effect until the next job is printed. If it...

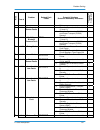

Page 59

Problem solving dt6180 handybook 59 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? 3. Power off, then power on the printer y 1. Release the camming motor brake y 2. Clear the entire paper path from the paper ...

Page 60

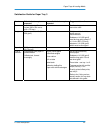

Problem solving dt6180 handybook 60 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? Printer 1. Clear the paper jam in areas 8, 11, 12, and 13 y p 3304 post inverter sensor faults p12-108 p12-111 2. Clean the p...

Page 61

Problem solving dt6180 handybook 61 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? 13, 14, and 15 b faults 2. Clean the bin b bindexer sensor (q1206) y 1. Power off, then power on the printer y p 3792 arc det...

Page 62

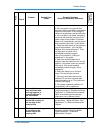

Problem solving dt6180 handybook 62 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? 2. Load paper in the selected paper tray correctly (see paper trays & loading media) y 3. Clean the registration transport se...

Page 63

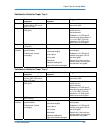

Problem solving dt6180 handybook 63 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? 1. Modify the lighter / darker setting (see machine maintenance) y 2. Power off, then power on the printer y 3. If you have a...

Page 64

Problem solving dt6180 handybook 64 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? On one job 1. Modify the lighter / darker setting (see machine maintenance) y 2. If the job is sent from a digipath, clean th...

Page 65

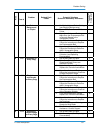

Problem solving dt6180 handybook 65 area case # problem related fault codes potential solutions /solutions ranked by relevance: detail so luti ons follo wi ng problem tab le? 4. Clean the fuser (q1010) and prefuser sensors (q1009) y 5. If paper is jammed in the fuser, release the camming motor brake...

Page 66

Solutions in alphabetical order dt6180 handybook 66 solutions in alphabetical order clean finisher entrance sensor (q1201) .................................................................................. 68 clean the bin a bindexer sensor (q1205).......................................................

Page 67

Solutions in alphabetical order dt6180 handybook 67 use a new ream of paper ...................................................................................................... 139.

Page 68

Solutions in alphabetical order dt6180 handybook 68 clean finisher entrance sensor (q1201) note: the finisher entrance sensor (q1201) is to the right of area 8 along the top paper path. 1. Fold a sheet of a4 or 8.5 x 11 inch paper twice to make a 51 mm (2 inch) wide strip. This will be used to clear...

Page 69

Solutions in alphabetical order dt6180 handybook 69 area h: 8. Open the finisher top cover. 9. Open the finisher front doors. Follow the instructions on the labels for 11, 12, and 13 to clear all sheets. Area 11:.

Page 70

Solutions in alphabetical order dt6180 handybook 70 area 12: area 13:.

Page 71

Solutions in alphabetical order dt6180 handybook 71 10. Close all covers and doors. Clean the bin a bindexer sensor (q1205) 1. Open the left finisher door. The handle is above paper tray 3. 2. Open the bindexer door. The door is located above the paper tray 3 area. You should see a light green trian...

Page 72

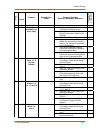

Solutions in alphabetical order dt6180 handybook 72 5. Close and latch the bindexer door. 6. Close the left finisher door. Clean the bin b bindexer sensor (q1206) 1. Open the left finisher door. The handle is above paper tray 3. 2. Open the bindexer door. The door is located above the paper tray 3 a...

Page 73

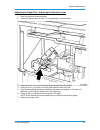

Solutions in alphabetical order dt6180 handybook 73 clean the binder tape guide sensor (q1213) warning: do not touch the heated areas of the binder. The top of the binder is approximately 425° f / 218° c. If the binder has been in a 'ready' condition, allow it to cool for at least one hour before co...

Page 74

Solutions in alphabetical order dt6180 handybook 74 between the two parts of the sensor to clear any obstructions. 7. Push the binder drawer into the machine until it latches. 8. Close the finisher doors. Clean the bindexer sensors (q1205, q1206, q1207) 1. Open the left finisher door using the handl...

Page 75

Solutions in alphabetical order dt6180 handybook 75 4. Fold a piece of a4 (8.5 x 11 inch) paper. Brush the folded piece of paper across each of these openings to make sure the sensors are clear of any obstructions. 5. Close and latch the bindexer door. 6. Close the finisher door. Clean the bins exit...

Page 76

Solutions in alphabetical order dt6180 handybook 76 warning: you may have to hold the bypass transport in the raised position if it lowers into the original position. 3. Stand directly in front of finisher, just to the right of paper tray 3. 4. Look between the brown cover on your left, with the sti...

Page 77

Solutions in alphabetical order dt6180 handybook 77 clean the front stack (q1227), rear stack height (q1218), and set path (q1221) sensors the q1227, q1218, q1221 sensors are on the stacker tray. Note: q1218 is a dual sensor containing q1218 and q1227. 1. Fold a piece of a4 (216 mm x 279 mm / 8.3 x ...

Page 78

Solutions in alphabetical order dt6180 handybook 78 5. On the upper right side of the opening, locate the label for area 19. 6. About 76 mm (3 inches) down from the label and all the way to the right of the opening you should see three wires (red, orange and brown) leading to a black plastic block m...

Page 79

Solutions in alphabetical order dt6180 handybook 79 get caught. 11. To the left of the ground strap attachment bolt, about 178 mm (7 inches) closer to the floor, you should see a red, orange, and brown wire leading to a black plastic block mounted on a metal bracket. The plastic block, with small wh...

Page 80

Solutions in alphabetical order dt6180 handybook 80 16. Look 76 mm (3 inches) directly above the sensor for orange and white wires. These wires are attached to the detector which faces straight down. 17. Brush a folded sheet of paper across the sensor. 18. Close the finisher front doors. If present,...

Page 81

Solutions in alphabetical order dt6180 handybook 81 5. Use a cotton swab to clean this mirror and the small plastic sensor to the right of the mirror. Make sure you do not touch the hot surfaces in this area. Cleaning the q1009 sensor: 6. To the left of paper tray 1, at the back of the fuser module,...

Page 82

Solutions in alphabetical order dt6180 handybook 82 clean the post inverter (q1202) and output transport (q1203) sensors note: the q1202 and q1203 sensors are in area 12. 1. Fold a sheet of 216 mm x 279 mm (8.5 x 11 inch) or a4 (210 mm x 297 mm / 8.3 x 11.7 inch) paper twice to make a 51 mm (2 inch)...

Page 83

Solutions in alphabetical order dt6180 handybook 83 to clean the q1203 sensor: 6. Place the short edge of the folded paper above the white rollers on the left side of the top tray feeder, as near to the front of the machine as the feeder will let you. Push the paper edge under the curved metal lip, ...

Page 84

Solutions in alphabetical order dt6180 handybook 84 clean the pre-fuser sensor (q1009) caution: the surrounding area of the machine around the sensor can be extremely hot! To clean the q1009 sensor: 1. Open the right and left processor doors. 2. To the left of paper tray 1, at the back of the fuser ...

Page 85

Solutions in alphabetical order dt6180 handybook 85 6. Clean the sensor with a small amount of lens and mirror cleaner on a soft, lint-free cloth. 7. Push the fuser module firmly back into the machine. 8. Close the processor doors. Clean the registration transport sensor (q861) the q861 sensor is lo...

Page 86

Solutions in alphabetical order dt6180 handybook 86 6. Lower the green handle by squeezing the front and rear plates of the handle together to release the handle. 7. Close the processor door. Clean the set path sensor (q1221) note: the q1221 sensor is on the stacker tray. To locate the q1221 sensor ...

Page 87

Solutions in alphabetical order dt6180 handybook 87 3. If present, the bypass transport must be raised to gain access to the sensors. Warning: you may have to hold the bypass transport in the raised position if it lowers into the original position. 4. Stand in front of the stacker drawer. Along the ...

Page 88

Solutions in alphabetical order dt6180 handybook 88 to locate the q1221 sensor: 8. Using the q1218 sensor as a reference point, look about 38 mm (1 1/2 inch) closer to the front of the machine. You should see the round sensor for q1221 pointing straight up. 9. Put your finger on the sensor and move ...

Page 89

Solutions in alphabetical order dt6180 handybook 89 clean the tape binder area clean the binder tape area: note: it is highly recommended that the binder be cleaned before the binder warm-up cycle begins or before powering on the machine. 1. Open the finisher doors. Warning: all areas of the binder ...

Page 90

Solutions in alphabetical order dt6180 handybook 90 4. If binder tape is in the area of the cleaner, pull the reel slightly away from the tape to avoid tape damage. 5. Lift up on the cleaner and push down against the single end tab. Move the cleaner back and forth until the end tab breaks. 6. Contin...

Page 91

Solutions in alphabetical order dt6180 handybook 91 cleaning the calipers: 12. Using the binder platen cleaner, clean the binder caliper surface until all the glue is removed. Closing the binder: 13. Push in the binder drawer until it stops. 14. Close the finisher doors. 15. Place the platen cleaner...

Page 92

Solutions in alphabetical order dt6180 handybook 92 3. Grasp the handle and rotate it to the right. 4. Remove any paper in this area. 5. Rotate the handle to the left, to the latched position. If the handle does not stay in position when released, it is not latched properly. 6. Locate the green hand...

Page 93

Solutions in alphabetical order dt6180 handybook 93 7. Grasp the handle and rotate it to the left. 8. Remove any paper in this area. 9. Rotate the handle to the right, to the latched position. If the handle does not stay in position when released, it is not latched properly. 10. Close the finisher d...

Page 94

Solutions in alphabetical order dt6180 handybook 94 7. Grasp the handle, push down on the top of the handle with your thumb, and then pull the baffle open toward the right. 8. Remove any paper under the baffle. 9. Close the baffle. 10. Close the finisher top cover. Clear paper jams in areas 11, 12, ...

Page 95

Solutions in alphabetical order dt6180 handybook 95 3. Grasp the handle and rotate it to the right. 4. Remove any paper in this area. 5. Rotate the handle to the left, to the latched position. If the handle does not stay in position when released, it is not latched properly. 6. Close the finisher do...

Page 96

Solutions in alphabetical order dt6180 handybook 96 9. Grasp the green handle and rotate it to the left to open the baffle. 10. Remove any paper under the baffle. 11. Close the baffle. 12. Locate the green handle on the right side of the mechanical assembly. This is area 13..

Page 97

Solutions in alphabetical order dt6180 handybook 97 13. Grasp the handle, push down on the top of the handle with your thumb, and then pull the baffle open toward the right. 14. Remove any paper under the baffle. 15. Close the baffle. 16. Close the finisher top cover. Clear paper jams in areas 13, 1...

Page 98

Solutions in alphabetical order dt6180 handybook 98 4. Remove any paper under the baffle. 5. Close the baffle. 6. If present, lower the bypass transport. Close the finisher top cover. To clear area 14: 7. Open the left finisher door using the handle above paper tray 3. 8. Locate the green handle beh...

Page 99

Solutions in alphabetical order dt6180 handybook 99 9. Remove any paper in this area. 10. Rotate the handle to the right until the handle latches into position. If the handle does not stay in position when released, it is not latched properly. To clear area 15: 11. Open the left finisher door using ...

Page 100

Solutions in alphabetical order dt6180 handybook 100 13. Remove any paper in the three bins behind the door. 14. Close the bindexer door. 15. Close the finisher door. Clear paper jams in areas 17 and 18 note: even if paper is not visible, go through the sequence to clear the paper jam. Carefully ins...

Page 101

Solutions in alphabetical order dt6180 handybook 101 same size as the top cover. If so, there is a handle to raise the transport with. The handle is a black rod with a silver spring on each side and is located on the very front of the transport. 4. Lift the transport and manually hold it in place wh...

Page 102

Solutions in alphabetical order dt6180 handybook 102 9. Locate the handle on the left side of the binder and pull it up quickly to snip off the tape that you advanced. Press the green handle down. 10. Push the binder into the finisher until it latches. 11. Close the finisher doors. 12. Close the fin...

Page 103

Solutions in alphabetical order dt6180 handybook 103 note: you can select [close] to close the printer fault window without clearing the fault. However, the fault will remain until it is reset through the printer fault clearance window. 5. Select [redisplay] on the printer faults window to update an...

Page 104

Solutions in alphabetical order dt6180 handybook 104 2. Locate the green handle in the top left corner with an arrow pointing to the right. This is area 11. 3. Grasp the handle and rotate it to the right. 4. Remove any paper in this area. 5. Rotate the handle to the left, to the latched position. If...

Page 105

Solutions in alphabetical order dt6180 handybook 105 7. Grasp the handle and rotate it to the left. 8. Remove any paper in this area. 9. Rotate the handle to the right, to the latched position. If the handle does not stay in position when released, it is not latched properly. To clear areas 17 and 1...

Page 106

Solutions in alphabetical order dt6180 handybook 106 note: area 17 is immediately under the finisher top cover, or silver transport area, if so equipped. Area 18 is immediately below area 17. Clearing all paper under the cover or transport area will clear both areas. 14. Open and pull out the binder...

Page 107

Solutions in alphabetical order dt6180 handybook 107 17. Locate the handle on the left side of the binder and pull it up quickly to snip off the tape that you advanced. Press the green handle down. 18. Push the binder into the finisher until it latches. 19. Close the finisher top cover. 20. Close th...

Page 108

Solutions in alphabetical order dt6180 handybook 108 3. Grasp the green handle and rotate it to the left to open the baffle. 4. Remove any paper under the baffle. 5. Close the baffle. 6. Locate the green handle on the right side of the mechanical assembly. This is area 13..

Page 109

Solutions in alphabetical order dt6180 handybook 109 7. Grasp the handle, push down on the top of the handle with your thumb, and then pull the baffle open toward the right. 8. Remove any paper under the baffle. 9. Close the baffle. 10. Close the finisher top cover. To clear area 14: 1. Open the lef...

Page 110

Solutions in alphabetical order dt6180 handybook 110 3. Remove any paper in this area. 4. Rotate the handle to the right until the handle latches into position. If the handle does not stay in position when released, it is not latched properly. To clear area 15: 1. On the right side of the finisher a...

Page 111

Solutions in alphabetical order dt6180 handybook 111 clear the paper jam in areas 3 and 4 note: even if paper is not visible, go through the sequence to clear the paper jam. Carefully inspect the rollers for any debris or torn pieces of paper. When clearing misfeeds, make sure a full sheet of paper ...

Page 112

Solutions in alphabetical order dt6180 handybook 112 clear the paper jam in areas 5 and 6 to clear area 5: 1. Open the processor doors using the handle above paper tray 1. 2. To the left of paper tray 2 is a green handle with an arrow on it. Rotate the handle to the right, and hold it in this positi...

Page 113

Solutions in alphabetical order dt6180 handybook 113 clear the paper jam in areas 7, 6, and 5 clear jams in order from areas 7, 6, and then area 5. 1. Open the processor doors using the handle above paper tray 1. To clear area 7: 2. Just below the top of the machine, behind the left processor door, ...

Page 114

Solutions in alphabetical order dt6180 handybook 114 7. Push the fuser assembly into the machine until it stops. To clear area 5: 8. To the left of paper tray 2 is a green handle with an arrow on it. Rotate the handle to the right, and hold it in this position. 9. Remove all paper from the area to t...

Page 115

Solutions in alphabetical order dt6180 handybook 115 clear the paper jam in areas 8 and 9 note: even if paper is not visible, go through the sequence to clear the paper jam. Carefully inspect the rollers for any debris or torn pieces of paper. When clearing misfeeds, make sure a full sheet of paper ...

Page 116

Solutions in alphabetical order dt6180 handybook 116 7. Turn the green knob (located to the right of the lever) in the direction of the arrow on the knob. This will move any jammed sheets of paper further along the paper path to where the sheets are more accessible and easier to remove. 8. If paper ...

Page 117

Solutions in alphabetical order dt6180 handybook 117 6. Grasp the handle and rotate it to the right. 7. Remove any paper in this area. 8. Rotate the handle to the left, to the latched position. If the handle does not stay in position when released, it is not latched properly. 9. Close the finisher d...

Page 118

Solutions in alphabetical order dt6180 handybook 118 12. Grasp the green handle and rotate it to the left to open the baffle. 13. Remove any paper under the baffle. 14. Close the baffle. 15. Locate the green handle on the right side of the mechanical assembly. This is area 13..

Page 119

Solutions in alphabetical order dt6180 handybook 119 16. Grasp the handle, push down on the top of the handle with your thumb, and then pull the baffle open toward the right. 17. Remove any paper under the baffle. 18. Close the baffle. 19. Close the finisher top cover. Clear the paper jams in areas ...

Page 120

Solutions in alphabetical order dt6180 handybook 120 5. Close the bindexer door. To clear area 17: 6. Open the finisher top cover by lifting the handle to release the cover. Push the cover open all the way. 7. Under the finisher top cover, locate the large silver colored transport. On the very front...

Page 121

Solutions in alphabetical order dt6180 handybook 121 clear the paper jams in areas 17 and 19 to clear areas 17 and 19: 1. Open the finisher top cover by lifting the handle to release the cover. Push the cover open all the way. 2. Open the finisher doors. 3. Some machines will have a large silver col...

Page 122

Solutions in alphabetical order dt6180 handybook 122 6. Clear sheets from area 19. 7. Close the finisher doors. 8. Close the finisher top cover..

Page 123

Solutions in alphabetical order dt6180 handybook 123 clear the paper jams in areas 7, 6, 5, 4, and 2 note: these areas should be cleared in the order given; from areas 7, 6, 5, 4, and then area 2. To clear area 7: 1. Open the processor doors. 2. Just below the top of the machine, behind the left pro...

Page 124

Solutions in alphabetical order dt6180 handybook 124 7. Push the fuser module into the machine until it stops. To clear area 5: 8. To the left of paper tray 2 is a green handle with an arrow on it. Rotate the handle to the right, and hold it in this position. 9. Remove all paper from the area to the...

Page 125

Solutions in alphabetical order dt6180 handybook 125 19. Lower the green handle back into position. Note: even if paper is not visible, go through the sequence to clear the paper jam. Carefully inspect the rollers for any debris or torn pieces of paper. When clearing misfeeds, make sure a full sheet...

Page 126

Solutions in alphabetical order dt6180 handybook 126 10. Insert the plug into the slot on the measuring bracket. The measuring bracket is a black metal piece on the right side of a very large gray metal block. 11. Feed the wire until the wire touches the back of the measuring bracket. 12. Insert the...

Page 127

Solutions in alphabetical order dt6180 handybook 127 fan the paper, turn the paper over, and reload 1. Open the paper tray you are using. 2. Remove the paper from the tray and lay it on a flat surface. 3. Place the palm of your hand on the centre of the stack of paper to hold it firmly. 4. Place the...

Page 128

Solutions in alphabetical order dt6180 handybook 128 5. Push the fuser drawer all the way into the machine until it latches in place. Make sure the drawer is latched before closing the processor doors. 6. Close the processor doors. If printing to the edges of the paper stock, set lead edge screening...

Page 129

Solutions in alphabetical order dt6180 handybook 129 4. Select [ok]. If the job is sent from a digipath, clean the document glass on the digipath clean the document glass often to make sure that scanning is of the best possible quality. Keeping the document glass clean will result in fewer misfeeds ...

Page 130

Solutions in alphabetical order dt6180 handybook 130 open and close the area 3 and 4 baffles securely the baffles are metal plates or wireforms of the paper path that guide the paper through the machine. Some baffles can be opened while clearing a paper jam and not closed properly; causing further p...

Page 131

Solutions in alphabetical order dt6180 handybook 131 open and close the area 9 baffle securely the baffles are metal plates or wireforms of the paper path that guide the paper through the machine. Some baffles can be opened while clearing a paper jam and not closed properly; causing further paper ja...

Page 132

Solutions in alphabetical order dt6180 handybook 132 perform an immediate shutdown at the docusp note: before you begin, you must be logged on as a system administrator or trusted user. If jobs are currently printing or waiting to print, you will need to place them on hold. 1. If you are using docus...

Page 133

Solutions in alphabetical order dt6180 handybook 133 doors. 5. There are three circuit breakers below the gauge; cb101, cb102, and cb103. Push up on each breaker handle to reset it. 6. Close the electrical module door. 7. Power on using the main power button. 8. Close the processor door. Power off, ...

Page 134

Solutions in alphabetical order dt6180 handybook 134 push down on the stacker safety door note: if the stacker safety door is stuck in the up position then you will need to open the finisher top cover before you open the front doors. 1. Open the finisher doors, by lifting up on the handle on the lef...

Page 135

Solutions in alphabetical order dt6180 handybook 135 read the meter you must be logged in as trusted user or system administrator to read the meter. See the related items below for additional information. To read the meter using docusp software version 3.X, 4.X, or 5.X: 1. In the docusp for docutech...

Page 136

Solutions in alphabetical order dt6180 handybook 136 4. Facing the machine, locate the camming motor on the back left side of the fuser drawer. 5. Reach under the camming motor and locate the camming motor brake release on the bottom of the camming motor. The brake looks like a silver / gray square ...

Page 137

Solutions in alphabetical order dt6180 handybook 137 remove paper from interposer areas b1 and b2 to clear area b1: 1. Open the interposer front doors. 2. Pull up and to the left on the green handle labeled 'b1'. The handle is located in the lower-middle area of the interposer. 3. Clear all paper an...

Page 138

Solutions in alphabetical order dt6180 handybook 138 reset the white power switch 1. Open the processor doors. 2. Locate paper tray 1. 3. The white power switch is above and to the right of the paper tray. The switch is marked with the number 0 on the bottom and the number 1 on the top. 4. Make sure...

Page 139

Solutions in alphabetical order dt6180 handybook 139 tap on the toner (dry ink) cartridge to loosen the toner 1. Open the left processor door. 2. Carefully, pull the toner cartridge out of the machine until it stops. 3. Tap on the side of the cartridge several times to loosen the toner. 4. Push the ...

Page 140

Perform printer functions dt6180 handybook 140

Page 141

Perform printer functions dt6180 handybook 141 7. Perform printer functions these printer functions detail instructions are all available at www.Support.Xerox.Com . 1-10 are included in this book. 1. How to add a font to the docusp controller 2. How to allow main, aux, auto, and unspecified to be us...

Page 142

Perform printer functions dt6180 handybook 142 1. Add a font to the docusp controller additional fonts can be loaded onto the controller from diskette, cd, or a unix directory. If the source is a unix directory, the directory must be on a mounted file system accessible at the controller. Fonts loade...

Page 143

Perform printer functions dt6180 handybook 143 2. Allow main, aux, auto, or unspecified to be used as stock names note: when main, aux, auto, or unspecified is used as stock name, the docusp displays an error message 'main, aux, auto, or unspecified is an invalid stock name, stock name must contain ...

Page 144

Perform printer functions dt6180 handybook 144 3. Backup vipp files before an upgrade the vipp system files are any directories and/or files located under /usr/xgf. The working vipp files are, by default, located under /usr/xgfc. However, mappings can be made to other locations, so check the /usr/xg...

Page 145

Perform printer functions dt6180 handybook 145 4. Check the systems queue output location and finishing selections note: before you begin you must be logged on as an administrator. See the related items below for additional information. If you are using docusp version 3.X: 1. From the docusp print s...

Page 146

Perform printer functions dt6180 handybook 146 5. Clear the faulted job to select reset from the fault frame on docusp software version 3.X: 1. From the docusp for docutech 2000 series 61xx (or your printer model) window, select the fault from the fault list that you want to reset. The fault list is...

Page 147

Perform printer functions dt6180 handybook 147 6. Create a new queue note: you must be logged in as system administrator or trusted user to perform this task. To create a queue using docusp software version 3.X or above: 1. From the docusp for docutech 2000 series 61xx (or your printer model) window...

Page 148

Perform printer functions dt6180 handybook 148 7. Delete a job in job manager to delete a job in job manager using docusp software version 3.X: 1. From the docusp for docutech 2000 series 61xx window, select [system], then select [logon] from the toolbar menu. 2. Select [administrator] from the pull...

Page 149

Perform printer functions dt6180 handybook 149 8. Disable stock size checking note: you must be logged in as system administrator to perform this task. To disable stock size checking using docutech software version 3.X: 1. From the docusp for docutech 2000 series 61xx window, select [printer manager...

Page 150

Perform printer functions dt6180 handybook 150 9. Display all active machine faults to find a list of the most recent faults using docusp software version 3.X and above: 1. From the docusp for docutech 2000 series for 61xx window, select [system] from the toolbar. A menu will be displayed. 2. Select...

Page 151

Perform printer functions dt6180 handybook 151 10. Enable and bring on-line an external finisher note: examples of external finishers include the signature booklet maker (sbm), signature booklet maker ii (sbmii), borg, high capacity stacker (hcs), and document booklet systems (dbs). Before you begin...

Page 152

Perform printer functions dt6180 handybook 152 external finishers. Note: only one external finisher can be active at a time. 4. If there are no finishers enabled and on-line, continue with steps 5-9. If there is a finisher enabled (denoted by a check mark in the enable column to the right of the fin...

Page 153: Programming

Programming features dt6180 handybook 153 8. Programming features add binding to a job note: you must be logged in as system administrator or trusted user to perform this task. To add binding to a job in the job queue using docusp software version 3.X: 1. From the docusp for docutech 2000 series 61x...

Page 154

Programming features dt6180 handybook 154 enable offset stacking note: before you begin you must be logged on as a system administrator or trusted user. To enable offset stacking using docusp software version 3.X or above: 1. From the docusp for docutech 2000 series for 61xx window, select [printer ...

Page 155

Programming features dt6180 handybook 155 export the accounting log 1. From the docusp display screen, logon as the trusted user or system administrator. See the related items below for additional information. 2. Click on [administration] from the toolbar, then click [accounting]. The accounting win...

Page 156

Programming features dt6180 handybook 156 program image shift for a job to program image shift for a job with docusp software version 3.X: 1. From the docusp for docusp 2000 series 61xx window, select [job manager]. The job manager window is displayed. 2. Click to select the job. The job will be hig...

Page 157

Programming features dt6180 handybook 157 program tabs note: jobs must be in a held or pending status to perform this function. Docusp 3.X if you are using docusp software version 3.X or above: 1. In the docusp for docutech 2000 series 61xx window, select [job manager]. 2. Right-click the desired jo...

Page 158

Programming features dt6180 handybook 158 program the pcl paper stock sequences to pull from a specific paper tray at the printer this programming process is intended for the experienced user. If tray calls are not working as intended, check the pcl dump of the file to make sure the expected escape ...

Page 159

Programming features dt6180 handybook 159 • tray 1 - 8.5x11, red, plain • tray 2 - 8.5x11, blue, plain • tray 3 - 8.5x11, white, plain 2. Program the pcl paper source settings in the queue manager: • standard &l1h = red, plain • lower &l4h = blue, plain • large capacity &l5h = white, plain as you ca...

Page 160

Programming features dt6180 handybook 160 18. Select [close]. 19. Select [ok]. Docusp 2.X program the paper tray settings in the printer manager: 1. In the docusp print services window, select printer manager. The printer manager window will be displayed. 2. Click to select [tray 1] to highlight it....

Page 161

Programming features dt6180 handybook 161 uncheck the job ticket in job forwarding the docusp version 3.61.19 release introduces the ability to forward a job without a job ticket attached. The ability to include or exclude the job ticket adds new flexibility when job forwarding from and to other non...

Page 162

Programming features dt6180 handybook 162 setup job forwarding for printer to printer in docusp the ability to forward a job from one docusp printer to a second docusp printer is an added feature of docusp version 3.6. Job forwarding allows the trusted user or administrator to select any active job ...

Page 163

Programming features dt6180 handybook 163 gettiff macro jobs that reference postscript or tiff files. Jobs requiring file referencing can be forwarded using common mount points between the docusp controllers where the referenced files are stored. • the name and ip address of the receiving docusp con...

Page 164

Sensor maps dt6180 handybook 164.

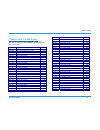

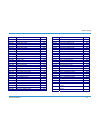

Page 165: 9. Sensor Maps

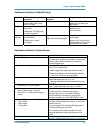

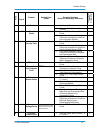

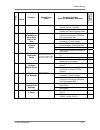

Sensor maps dt6180 handybook 165 9. Sensor maps paper handling module sensor locations q811 tray 1 take away roll sensor q812 tray 1 stack relief sensor q821 tray 2 take away roll sensor q822 tray 2 stack relief sensor q831 tray 3 feed sensor q832 tray 3 transport sensor q841 duplex inverter positio...

Page 166

Sensor maps dt6180 handybook 166 inverter sensor locations q1201 finisher entrance sensor q1202 post inverter sensor q1203 top transport output sensor q1204 top tray empty q1205 bin a entrance sensor q1206 bin b entrance sensor q1207 bin c entrance sensor q1222 bins exit sensor.

Page 167

Sensor maps dt6180 handybook 167 finisher sensor locations q1210 set in tilt bed sensor q1211 flapper position sensor q1213 tape in guide sensor q1215 stitcher position encoder q1216 catch wire a sensor q1217 catch wire b sensor q1218 rear stack height sensor q1219 stacker drawer empty sensor q1221 ...

Page 168

Sensor maps dt6180 handybook 168 interposer sensor locations q1422 top transport entrance sensor q1423 top transport exit sensor q1424 lower transport turn jam sensor q1425 lower transport exit jam sensor q1426 loop jam sensor.