- DL manuals

- Xerox

- Software

- Synergix 8830

- Service Manual

Xerox Synergix 8830 Service Manual

Summary of Synergix 8830

Page 1

The document company xerox xerox 8830 printer service manual 701p12720 january 1998 caution certain components in the 8830 are susceptible to damage from electrostatic discharge. Observe ali esd procedures in order to avoid component damage.

Page 3

Page rev title 1/98 ii 1/98 iii 1/98 iv 1/98 v 1/98 vi 1/98 vii 1/98 viii 1/98 1-1 1/98 1-2 1/98 1-3 1/98 1-4 1/98 1-5 1/98 1-6 1/98 1-7 1/98 1-8 1/98 1-9 1/98 1-10 1/98 1-11 1/98 1-12 1/98 1-13 1/98 1-14 1/98 1-15 1/98 1-16 1/98 1-17 1/98 1-18 1/98 1-19 1/98 1-20 1/98 1-21 1/98 1-22 1/98 1-23 1/98 ...

Page 4

Revision control list (contd) 6-1 6-2 6-3 6-4 6-5 6-6 6-7 6-8 6-9 6-10 6-11 6-12 6-13 6-14 6-1s 6-18 6-17 6-18 6-19 6-20 6-21 6-22 6-23 6-24 6-25 6-26 6-27 6-28 6-29 6-30 6-31 6-32 6-33 6-34 6-35 6-36 6-37 6-38 6-39 6-40 6-41 6-42 6-43 6-44 6-45 6-46 6-47 6-48 6-49 1/98 1/98 1/98 1/98 1/98 1/98 .1/9...

Page 5

Title page introduction vi about this manual vi organization vi how to use this manual vii section 1 service call procedures 1 -1 section 2 repair analysis procedures 2-1 section 3 print quality raps 2-1 section 4 repairs and adjustments 4-1 section 5 parts lists 5-1 section 6 general procedures 6-1...

Page 6

About this manual initial actions/ system checks final action this manual is part of a documentation system that includes the training. This manual contains repair analysis procedures (raps), repair procedures, adjustment procedures, parts list, diagnostic procedures, installation procedures, wiring...

Page 7

Section 6. - general procedures this section contains diagnostic procedures, installation procedures, and general information, which includes product specifications for the 8830. Section 7. - wiring data this section contains plug/ jack location index, plug/ jack location drawings, and the bsds. Sec...

Page 8

1/98 introduction viii 8830

Page 9

1. Service call procedures section contents title page introduction 1-2 call flow diagram 1-3 initial actions / system checks 1-4 print defect isolation procedure 1-5 workstation checkout procedure ...1-6 status code entry chart 1-7 message display entry chart 1 -18 maintenance procedures 1-19 syste...

Page 10

Introduction the service call procedures are designed to assist the service representative to identify printer faults, perform the necessary corrective action and perform the correct maintenance procedures. The service call procedures are designed to be used with the 8830 service manual and is the e...

Page 11

Call flow diagram 8830 1/98 1-3 call flow diagram.

Page 12

Initial actions / system checks initial actions / system checks 1/98 1-4 8830 1. Ask the operator to describe the problem. 2. Ask the operator to halt all print jobs and stop controller. 3. Check the log book. 4. Check the recent fault log for trends: a. With a controller - print out the configurati...

Page 13

Print defect isolation procedure 8830 1/98 1-5 print defect isolation procedure.

Page 14

Workstation checkout procedure workstation checkout procedure 1/98 1-6 8830

Page 15

Status code entry chart status code c1-01 c2-01 c3-01 c1-04 c2-04 c3-04 c1-05 c2-05 c3-05 description position sensor error the roll 1, 2, or 3 position sensor did not actuate or deactuate. Media registration sensor error the media sensor did not actuate or deactuate when feeding from roil 1, 2, or ...

Page 16

Status code entry chart (cont.) status code c3-06 c3-07 c1-09 c2-09 c3-09 c1-19 c2-19 c3-19 c1-29 c2-29 c3-29 c1-39 c2-39 c3-39 description roll 2 position sensor error media was not detected at the roll 2 position sensor when feeding from roll 3. Roll 1 position sensor error media was not detected ...

Page 17

Status code entry chart (cont.) status code c1-59 c2-59 c3-59 c4-24 c4-34 c4-49 e2-01 e2-09 description this is a firmware problem this is a firmware problem. Press power off (0) then power on (1). If problem persists, replace the firmware. Registration sensor error the cut sheet does not reach the ...

Page 18

Status code entry chart (cont.) status code e2-11 e4-01 e4-02 e4-03 e4-04 e4-09 e4-11 description registration sensor error the media registration sensor was detected to be actuated when the machine powered up. Media exit sensor error the media trail edge jammed in the media exit sensor area. Media ...

Page 19

Status code entry chart (cont.) status code e4-12 e4-13 e4-14 e5-03 e5-04 e5-05 e5-06 description sheet feed sensor error the sheet feed sensor was detected to be actuated when the machine powered up. This requires the media exit area to be opened, and to be removed. Stripper finger jam switch error...

Page 20

Status code entry chart (cont.) status code e6-00 e6-01 e7-01 e7-02 e9-xx fx-xx description front door interlock switch error the c button was pressed while a print was being made in the roll feed mode. An operator induced soft shutdown results in a complete print being made. The left side door must...

Page 21

Status code entry chart (cont.) status code j1-01 j2-02 ll-00 ll-02 ll-05 ll-06 ll-07 ll-10 description toner sensor error out of toner. Cartridge home sensor error toner cartridge could not find the home position. Communication error applies only to printers with a bit mapped user interface (fx). C...

Page 22

Status code entry chart (cont.) status code ll-11 ll-12 ll-21 ll-22 ll-30 ll-41 description communications error failed communications between the driver pwb (a2) and the main pwb (a3). Photoreceptor motor stall fault hvps charge error the charge scorotron fault signal was active for 1.5 seconds. Tr...

Page 23

Status code entry chart (cont.) status code ll-42 ll-43 ll-44 ll-45 ll-4f ll-50 description fuser temperature error the fuser roll temperature is greater than the maximum allowable temperature for more than thirty seconds. Maximum temperature is currently 348° f (176° c). Fuser temperature error fus...

Page 24

Status code entry chart (cont.) status code ll-51 ll-52 ll-53 ll-54 ll-55 ll-56 ll-57 ll-58 description power on self test fault the internal ram failed post. Power on self test fault or main pwb installed without control eproms the external ram failed post. Power on self test fault iot firmware che...

Page 25

Status code entry chart (cont.) status code ll-60 ll-61 ll-89 ll-90 ll-91 u1-01 description power on self test nvm checksum fault record the existing nvm values. Run diagnostic [0360] to reset nvm to the default values. Manually restore the required nvm values. Power on self test revision level faul...

Page 26

Message display entry chart message displayed printer is warming up (continuously displayed) adjusting the print quality (continuously displayed) please close the media drawer x (refer to note) please close the cut sheet feed shelf please close the front door please close the top door please close t...

Page 27

Maintenance procedures image module 1/98 1-19 maintenance procedures interval normal call normal call normal call as required task check, clean, or repair spacing wheels as required. Check and clean, if required, the scorotron. Clean the image bar. Repair or replace the scorotron/grid. Reason contam...

Page 28

Xerographic module interval normal call normal call normal call normal call normal call task clean the xerographic module. Clean the erase lamp. Inspect the photoreceptor for damage. Inspect components for vellum contamination. Inspect all seals for damage. Inspect the cleaner blade for damage. Chec...

Page 29

Xerographic module (cont.) note 1: ensure that the vacuum does not contact the edge of the cleaner blade that touches the surface of the photoreceptor drum. Note 2: where possible, dust the drum and the cleaning blade with zinc stearate away from the xerographic module to prevent the charge scorotro...

Page 30

Media transport interval normal call normal call normal gall normal call 25k ft 7km task clean the lower paper transports, turnaround baffle, paper feed rolls. Clean the under side of the transport. Clean the transfer corotron empty the condensation reclaim bottle. Repair or replace the transfer cor...

Page 31

Developer module 8830 1/98 1-23 maintenance procedures interval normal call normal call norma! Call normal call normal call 30k ft. 9km task brush the developer from the developer seal and lower edge of the developer housing back into the developer mag roll and then clean the seal. Check that the de...

Page 32

Covers interval normal call cutter interval normal call normal call task clean the covers. Task check the cam for lubrication. Clean the cutter. Media drawers interval normal call task clean the media drawer. Reason customer satisfaction. Reason to ensure the correct cutter operation. The cutter wil...

Page 33

System checkout/ final action enter diagnostic mode and make three (3) prints of internal test pattern from the controller (if present), if a controller is not present, print [0955-5] from the iot. Prints are delivered to the exit tray. Y n i refer to initial action / system checks to i begin your r...

Page 34

Notes: 1/98 1.26 8830

Page 35

Section contents title page status indicators raps c1.04, c2.04, c3.04 rap 2-2 ll41, ll.45 fuser warmup fault rap 2-3 ll.42 thermal control rap 2-5 ll.43 fuser overtemperature rap 2-6 ll.44 fuser too hot rap 2-7 ll 60/61 nvm fault rap 2-8 ll90 overtoned fault rap 2-9 ll91 undertoned fault rap 2-11 o...

Page 36

C1.04,c2.04,and c3.04 note: roll x means roll 1,2, or 3. The media drive motor (mot1, bsd 7.1) was trying to feed the roll x media forward to the registration position but the media registration sensor (a21q1, bsd 8.1) failed to sense the media. Initial actions • check the media roil (in the drawer ...

Page 37

Ll.41, ll.45 fuser warmup fault rap note: refer to bsd 10.1 while using this rap. This rap is used when the fuser does not warm up when the control logic attempts to increase the heat. Ll.41 is displayed when the fuser heat does not increase to 110° f (43° c) within one minute. Ll.45 is displayed wh...

Page 39

Ll.42. Thermal control rap note: refer to bsd 10.1 while using this rap. This rap is used to locate certain problems in the thermal control circuitry in the fuser area. Warning dangerous voltage initial actions switch off, then switch on the printer. If the problem still exists, perform the procedur...

Page 40: A D

Ll.43 fuser overtemperature rap note: refer to bsd 10.1 while using this rap. Warning dangerous voltage ll.43 is displayed when the logic detects that there is a problem with the fuser temperature and an overtemperature condition has caused the thermal fuse, a23f1, to open. Initial actions • ensure ...

Page 41

Ll.44 fuser too hot rap note: refer to bsd 10.1 while using this rap. Warning dangerous voltage ll.44 is displayed when the fuser temper- ature exceeds 420° f (216° c), the maximum allowed temperature. The status code may also be displayed if the temperature limit thermistor, a23rt2, has a malfuncti...

Page 42

Ll60/ll61 nvm fault rap this rap is used for nvm (non-volatile memory) problems that are indicated by a status code or a message display. The control panel displays the message nvm fault call for assistance. Ll60 or ll61 may also be displayed. The problem may be caused when the nvm data are corrupte...

Page 43

Ll.90 overtoiled fault rap note: refer to bsd 9.7 while using this rap. The status code ll.90 is displayed when the logic detects that the toner concentration is significantly greater than the control point value. The toner control system is designed to maintain the toner concentration within an acc...

Page 44

Enter the code [9-21-4] in order to switch on the main drive motor and the toner sensor circuit. Connect the (+) meter lead to the toner sensor a22q1p1-2 and the (-) meter lead to a22q1p1-4. There is +15 vdc present. Y n check for an open or short circuit to ground in the wires connected to a22q1p1-...

Page 45

Ll.91 undertoned fault rap note: rap. Refer to bsd 9.7 while using this the status code ll.91 is displayed when the logic detects that the toner concentration is significantly less than the control point value. The toner control system is designed to maintain the toner concentration within an accept...

Page 46

A use the last print to check the image density. The image density of the 1.0 solid square in the center of the test pattern [0955-5] is equal to or (ess than the 1.20 density square on the output reference sir 495.1. Y n perform the tone-up procedure [09-06]. If the printer does not tone-up, perfor...

Page 47

0f1 control panel rap note: refer to bsd 2.1 while using this rap, unless otherwise directed this rap is used when the control panel does not operate, or when the control panel operates incorrectly. Initial actions • make sure that ac power is applied to the machine. • ensure that the 26-conductor r...

Page 48

Of2 power on self test (post) rap note: refer to bsd 1.2 and bsd 2.1 while using this rap. This rap is used when the logic detects a fault during the power on self-test (post). The printer does not initialize and the control panel displays a 1,2, 3, 4, 5, 6, or 7. Initial actions • ensure that the e...

Page 49

Clutch rap initial actions • this procedure can be used to check any clutch procedure enter diagnostics (general procedures). Enter code [xxxx] to test the clutch (refer to appropriate bsd for the specific code). Actuate the clutch. The clutch energizes. Y n deactuate the clutch. There is +26 vdc at...

Page 50

Sensor rap initial actions • this procedure can be used to check any sensor. • ensure that the sensor is not blocked. • clean the sensor surfaces before using this procedure. Procedure enter diagnostics (general procedures). Enter code [xxxx] to test the sensor (refer to appropriate bsd for the spec...

Page 51

Switch rap initial actions • this procedure can be used to check any switch. Procedure enter diagnostics (general procedures). Enter code [xxxx] to test the switch (refer to appropriate bsd for the specific code). Actuate the switch the switch toggles from h to l or from l to h. Y n the message disp...

Page 52

Notes: 1/98 2-18 8830

Page 53: 3. Print Quality

3. Print quality section contents title page print quality initialization procedure 3-2 print defects 3-3 print quality definitions 3-3 print quality general diagnostics 3-4 print quality specifications 3-5 damaged media 3-7 media handling problems 3-8 pq 1 background 3-9 pq 2 bands 3-10 pq 3 bands ...

Page 54

Print quality initialization procedure prior to any print quality troubleshooting, validate the problem is in the iot by entering [9-55]. Select test pattern 5. Examine the test print for defects. If defects appear, complete the following checklist. If the defects are still present after completing ...

Page 55

Print defects print quality refers to the entire print. Defects can occur anywhere on the print. These defects could be damaged media or print quality defects. Always eliminate problems that cause the damaged media before attempting to fix print quality problems. Some damaged media problems could ca...

Page 56

Media handling this is the process of transporting the media from the supply area through the xerographic and the fusing subsystems. Resolution the uniformity or clarity of fine tine detail. Residual image this is an image thai is repeated onto the same print or consecutive prints. The image can eit...

Page 57

Print quality specifications test patterns there are nine internal test patterns that can be run from diagnostic mode [9-55]. (refer to section 6. For details) test pattern 1 is used while adjusting lead edge, trail edge and side edge erase. Test pattern 2 is used to produce horizontal black and whi...

Page 58

Lead edge registration (a) this is the degree to which the lead edge of a print image is within a specified distance from the lead edge of the media. Use a wide roll of media and run 4 prints of test pattern [9-55-7] and use the fourth print. Measure the distance from the lead edge of the media to t...

Page 59

Damaged media defect 1. Crease marks a thin irregular line on the media caused by stressing the media. 2. Dog ears this is a comer of the lead edge of the print that has been bent back. 3. Frayed side edge this is damage to the sides of the print. 4. Wrinkle this is damage that is probably caused by...

Page 60

Media handling problems introduction experience has shown that many media transportation problems have more than one cause and must be handled using a systematic approach. Media transportation problems appear as one of the following symptoms: • pre-fuser jams • print quality defects • physical disto...

Page 61

Pq1 background symptom / check contamination of the blank area by toner particles on the print probable cause 1. An incorrect electrostatic value 2. Developer bias incorrect. 3. Toner concentration too high. 4. Erase lamp operation. 5. Contaminated charge scorotron 6. Defective cleaner blade 7. Web ...

Page 62

Pq2 bands symptom/ checks bands are 1 mm or more wide and are in the media feed direction. High density bands are called black lines. Probable cause 1. Contaminated charge scorotron 2. Defective cleaner blade 3. Contaminated magnetic roll. 4. Incorrect electrostatic value. 5. Toner cloud from the de...

Page 63

Pq3 bands symptom/ check bands are 1 mm or more and are perpendicular to the media feed direction. High density bands are called black lines. Probable cause 1. Defective or intermittent charge scorotron. 2. Defective transfer / detack corotron. 3. Poor cleaning 4. Defective or contaminated drum. Cor...

Page 64

Pq4 black lines symptom/check black lines appear in the direction of media feed. Probable cause 1. Developer bias and transfer corotron voltage set incorrectly 2. Contaminated, damaged or disconnected charge scorotron 3. Poor cleaning 4. The surface of the heat roll is damaged. 5. The drum surface i...

Page 65

Pq5 black prints symptom/ check the print is totally black with no image. Probable cause 1. Defective charge scorotron 2. Charge control circuit/ defective harness corrective action 1. Clean or replace the screen/pins (rep 9.8). 2. Perform gp1 hvps checkout procedure. 8830 1/98 3-13 pq4 black lines.

Page 66

Pq6 blank prints / partial image symptom/ check no image or a partial image is produced when making a print. Probable cause 1. Developer housing 2. Transfer corotron 3. Defective hvps 4. Image module leds inoperative 5. No drum drive / defective drum. Corrective action 1 a. Ensure that the developer...

Page 67

Pq7 blurred image symptom/ check the image is not clear or sharp. Probable cause 1. Defective/contaminated image module. 2. Contamination on transfer/ detack corotron 3. Defective drive gear 4. Defective registration roller 5. Media transport 6. Defective buckle control corrective action 1a. Ensure ...

Page 68

Pq8 deletions (bands) symptom/check deletion bands or very low image density in the print feed direction. Probable cause 1. Damp media 2. Corotrons 3. Defective hvps 4. Developer housing 5. Defective or contaminated led image bar. 6. Contaminated erase lamp. 7. Media transport 8. Heat roll 9. Defect...

Page 69

Pq 9 deletions (bands) symptom/ check deletion bands or very low image density perpendicular to the print feed direction. Probable cause 1. Damp media 2. Incorrect corotron operation. 4. Defective drum or no drum drive. 5. Magnetic roll 6. Image module roller not contacting drum 7. Media transport- ...

Page 70

Pq 10 deletions (in solid and halftone areas) symptom/check bands of deletion in the solid or halftone areas in the print feed direction. Probable cause 1. Damp media 2. Exposure 3. Incorrect corotron operation 4. Magnetic roll 5. The surface of the heat roll is damaged. 6. Media transport. Correcti...

Page 71

Pq 11 deletions (spots) symptom/ check localized areas of deletion in the solid or halftone areas in the print feed direction. Probable cause 1. Damp media 2. T/dt corotrons 3. Developer housing 4. Insufficient toner resulting in developer bead carryover. 5. The surface of the heat roll is damaged. ...

Page 72

Pq12 finger marks symptom/ check toner marks on the lead edge or trail edge of the print. Probable cause 1. Defective or dirty transfer/detack corotron 2. Cleaner seal 3. Web oiler 4. Turnaround baffle 5. Heat roll 6. Fabric guide corrective action 1a. Clean or replace the corotron wire (pl 9.4). 1b...

Page 73

Pq13 light image symptom/ check image area of a print has low density. Probable cause 1. Damp media 2. Incorrect image module led duty cycle 3. Incorrect corotron operation 4. Incorrect image density adjustment 5. Defective drum ground. 6. Defective drum. 7. Media transport 8. Developer housing corr...

Page 74

Pq14 misregistration symptom/ check the registration of the image on the prints is incorrect from top to bottom or side to side. Probable cause 1. Incorrect registration adjustment 2. Damaged or worn components in the media feeding area 3. Defective registration sensor 4. Incorrect registration roll...

Page 75

Pq15 residual image symptom/ check this is an image that is repeated on the same print or consecutive prints. The image can either be a ghosting of the original image or a toner image. The repeated image is usually spaced 10.38 inches (265 mm) from the original image. Perform panic stop / image on d...

Page 76

Pq16 skewed image symptom/ check the image is skewed to one side on the print because the media is skewed. Probable cause 1. Media is not loaded correctly. 2. Media transport. 3. Defective or contaminated rollers in the media feed area 4. Incorrect registration roller nip 5. Obstruction in media pat...

Page 77

Pq17 smears symptom/ check areas of the image on the print are blurred. This occurs at the image transfer area and is caused by a difference of speed between the drum and the media. Location of smear 20 - 25 mm from the lead edge of the print 40 - 50 mm from the lead edge of the print 106 - 126 mm f...

Page 78

Pq17a smudge symptom/ check a smudge is a displacement of the toner image on the drum or the media. Perform gp2, image on drum to determine if the smudge occurs on the media or the drum. Vellum smudge is a special defect that exhibits marginal fusing fix. Toner can chip off of the media and horizont...

Page 79

Pq18 spots symptom/ check circular black spots on the print. Perform panic stop/image on drum procedure (section 6), and examine the drum for the defect. Repetitive spots repetitive spots random spots random spots random spots probable cause 1. Defective, damaged or contaminated drum 2. Contaminated...

Page 80

Pq19 uneven density symptom/check density and line thickness vary across the print. Probable cause 1. Incorrect corotron operation 2. Contaminated led image bar 3. Machine level 4. Developer mag brush not contacting the drum evenly. 5. Defective drum corrective action 1. Perform gp1, hvps checkout p...

Page 81

Pq 20 unfused prints symptom/ check characters and image are easily rubbed off a print. Probable cause 1. Damp media 2. Incorrect fuser temperature 3. Incorrect fuser pressure 4. Defective heat roll 5. Fabric guide. Corrective action 1a. Refer to bsds 7.1 and 7.3 to check for correct operation of th...

Page 82

Pq21 wrinkle symptom/ check this is damage that is probably caused by the fuser subsystem. This is a severe case of creases that runs in the direction of media travel. Probable cause 1. Damp media 2. Damaged or contaminated pinch rolls 3. Damaged or contaminated heat roll 4. Incorrect fuser contact ...

Page 83

Pq22 offsetting symptom/ check offsetting is the result of toner adhering to the fuser heat roll and transferring to subsequent prints. Probable cause 1. There is insufficient fuser oil on the heat roll. 2. The fuser temperature is out of specification. 3. The fabric guide is not contacting the fuse...

Page 84

Notes: 1/98 3-32 8 8 3 0

Page 85: 4. Repair / Adjustment

Section contents run control rep 3.1 main pwb 4-3 rep 3.2 high voltage power supply. 4-4 media roll feed rep 7.1 media supply drawer 4-5 rep 7.2 rewind gear and rewind internal gear 4-6 rep 7.3 roll feed pinch rolls 4-7 rep 7.4 roll feed drive rolls 4-8 rep 7.5 feed clutch 4-9 rep 7.6 rewind clutch ...

Page 86

Notes: 1/98 4.2 8830

Page 87

Rep 3.1 main pwb parts list on pl 1.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove the lower right side cover. 2. (figure 1): remove the main pwb. Note: if the printer is not equipped with a second language, there will be only two eproms (control and languag...

Page 88

Rep 3.2 high voltage power supply parts list on pl 1.3 warning switch off the main power switch. •disconnect the power cord. R e m o v a l 1. Loosen the screws and open the rear door. 2. (figure 1): remove the high voltage power supply. Replacement . 1. If a new high voltage power supply is being in...

Page 89

Rep 7.1 media supply drawer parts list on pl 7.1 warning switch off the main power switch. Disconnect the power cord. Note: all three roll supply drawer assemblies are removed the same way. Removal 1. Open the media supply drawer that is to be removed. 2. (figure 1): remove the cover. 3. (figure 2):...

Page 90

Rep 7.2 rewind gear and rewind internal gear parts list on pl 7.3 warning switch off the main power switch. Disconnect the power cord. Note: all three rewind gears and rewind internal gear assemblies are removed the same way. Removal 1. Pull out the media supply drawer. 2. Remove the roll of media. ...

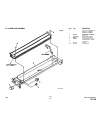

Page 91

Rep 7.3 roll feed pinch rolls parts list on pl 7.5 warning switch off the main power switch. Disconnect the power cord. Note: all three roll feed pinch roll assemblies are removed the same way. Removal 1. Open the media supply drawer and remove the media roll. 2. (figure 1): remove the roll feed pin...

Page 92

Rep 7.4 roll feed drive rolls parts list on pl 7.1 warning switch off the main power switch. Disconnect the power cord. Note: all three roll feed drive roll assemblies are removed the same way. Removal 1. Remove the appropriate media supply drawer (rep 7.1). 2. Remove the feed clutch (rep 7.5). 3. R...

Page 93

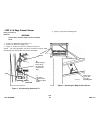

Rep 7.5 feed clutch parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. (figure 1): remove the feed clutch. 6 disconnect the connector 2 move the motor bracket to relieve the tension on the chain remove the...

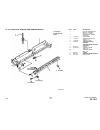

Page 94

Rep 7.6 rewind clutch parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. (figure 1): remove the rewind clutch. 3 remove the chain 2 move the motor bracket to relieve the tension on the chain r loosen the s...

Page 95

Rep 7.7 motion sensor parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Remove the rewind clutch (rep 7.6). 3. (figure 1): remove the motion sensor. Replacement 1. Reinstall the motion sensor and the rewi...

Page 96

Rep 7.9 roll drive motor parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. (figure 1): remove the roll drive motor assembly. 3. (figure 2): remove the bracket from the roll drive motor. Remove the roll dr...

Page 97

Rep 7.10a lower media roll heater parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. (figure 1): remove the lower media roll heater. Remove the lower media roll heater figure 1. Removing the lower media ro...

Page 98

Rep 7.10b upper media roll heater parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove media supply drawer 1 (rep 7.1). Caution be sure to support the media roll heater/guard with your hand white removing the mounting screws in the next step. 2....

Page 99

Rep 7.11 encoder disk parts list on pl 7.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Remove the rewind clutch (rep 7.6). 3. (figure 1): remove the encoder disk. Replacement 1. Reinstall the motion sensor and the rewin...

Page 100

Notes: 1/98 4-16 8 8 3 0

Page 101

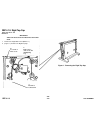

Rep 8.1 media transport assembly parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Latch the xerographic module at the servic...

Page 102

5. (figure 3): remove the media transport assembly. 1 disconnect the latch arms from the transport (both sides) 5 ensure that the moisture collection tube is out of the hole in the frame remove the media transport assembly loosen the screw and rotate the bracket downward pull the pin and hold it out...

Page 103

Replacement 1. If a new media transport assembly is being installed, perform the media transport to drum spacing (adj 8.4). 2. Open the cutter drawer. 3. (figure 4): reinstall the media transport assembly. Reconnect the corotron leads and connector a21p1 route the drain hose and reconnect it rotate ...

Page 104

Rep 8.2 media exit switch parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. R e m o v a l 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. Remove the fabric guide (rep 8.9). 4. (figure 1): ...

Page 105

Rep 8.3 buckle switch parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. Remove the fabric guide (rep 8.9). 4. Remove the pressure pl...

Page 106

Rep 8.4 cut sheet media feed clutch parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. (figure 1): remove the cut sheet media feed cl...

Page 107

Rep 8.5 pressure plates parts list on pl 10.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. R e m o v a l 1. Latch the xerographic module at the service ...

Page 108

Replacement caution be careful not to damage the sheet media switch actuator while reinstalling the lower pressure plate. 1. (figure 2): reinstall the lower pressure plate. Reinstall the lower pressure plate r2443 figure 2. Reinstalling the lower pressure plate caution be sure to push the buckle swi...

Page 109

Rep 8.6 sheet drive roll parts list on pl 8.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Latch the xerographic module at the service positi...

Page 110

Rep 8.7 sheet pinch rolls parts list on pl 8.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Latch the xerographic module at the service posit...

Page 111

Rep 8.8 media registration sensor parts list on pl 8.2 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Latch the xerographic module at the servi...

Page 112

Notes: 1/98 4-28 8830

Page 113

Rep 8.9 fabric guide parts list on pl 10.3 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Lower the media transport cover. 2. (figure 1): caref...

Page 114

Replacement 1. (figure 2): reinstall the fabric guide. Ensure that the edge of the handle is inside the edge of the frame figure 2. Reinstalling the fabric guide rep 8.9 1/98 4-30 8830

Page 115

Rep 8.10 media transport drive motor parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position (rep 9.2). Remove the media transport assembly (rep 8.1). Remove the fabric guide (rep 8.9). Remove the press...

Page 116

Rep 8.11 sheet feed switch parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. Remove the fabric guide (rep 8.9). 4. Remove the pressu...

Page 117

Rep 8.12 registration pinch rolls parts list on pl 8.2 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Latch the xerographic module at the servi...

Page 118

4. (figure 2): remove the registration pinch rolls. 4 remove the two retainers (one each end) 1 remove the two e-rings (one each end) 5 remove the two rolls (one each end) remove the registration pinch roll assembly remove the two bearings (one each end) figure 2. Removing the registration pinch rol...

Page 119

Replacement 1. Reinstall the rolls and retainers onto the shaft. 2. (figure 3): reinstall the registration pinch roll assembly. Slot reinstall the two e-rings (one each end) bend the spring and reinstall the springs into the slots on the frame (4) reinstall the two bearings (one each end) reinstall ...

Page 120

3. (figure 4): reinstall the springs, 4. Complete the reassembly of the printer and perform the following; a. Fuser temperature (nvm) (adj 10.1) b. Vertical magnification (adj 8.1) c. Lead edge registration (adj 8.2) d. Cut length (adj 8.3) 6 reinstall the two springs (one each end) rotate the screw...

Page 121

Rep 8.13 media feed drive belt parts list on pl 8.1 warning switch off the main power switch. Disconnect the power cord. R e m o v a l 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. Remove the fabric guide (rep 8.9). 4. Remove ...

Page 122

Rep 8.15 cutter home sensor parts list on pl 7.8 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. R e m o v a l 1. Open the cutter drawer. 2. (figure 1): re...

Page 123

Rep 8.16 exit roll parts list on pl 8.4 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. Remove the media exit switch (rep 8.2). 4. (figure 1): remove t...

Page 124

Rep 8.17 registration drive roll parts list on pl 8.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Latch the xerographic module at the service position (rep 9.2). 2. Remove the media transport assembly (rep 8.1). 3. Remove the fabric guide (rep 8.9). 4. Remove the ...

Page 125

8. (figure 2): remove the baffle. 9. Remove the registration drive roll by pushing the beatings out of the frame and moving the roll as required for removal. 2 remove the two screws (one each end) remove the two springs (one each end) rotate the screw until it is free of the slot remove (he baffle 6...

Page 126

Notes: 1/98 4.42 8830

Page 127

Rep 9.1 xerographic module parts list on pl 9.1,10.1 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Raise and latch the top cover. 3. Lift and rotate the image module to the service position. 4. Lower the media transport c...

Page 128

6. Remove the web oiler assembly (rep 10.7). Note: in the following steps, "left" and "right" describe machine locations as observed when you are facing the xerographic module at the left side of the printer. 7. (figure 2): install the handles onto the left and right side of the xerographic module. ...

Page 129

9. (figure 4); move the bearing out of the xerographic module frame (left side). 2 lift the drum assembly and move the bearing to the right drum assembly carefully lower the drum assembly 1 disconnect the retaining clip that holds the bearing and rotate the clip out of the way figure 4. Moving the b...

Page 130

Rep 9.2 drum assembly parts list on pl 9.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Raise and latch the top cover. 3. Lift and rotate the image module to the service position. 4. Lower the media transport cover. Note...

Page 131

Note: the latches that secure the xerographic module to the printer frame are spring-loaded and will automatically engage the holes. The latches have a 1/4 turn lockout feature that may be used to prevent actuation during reinstallation of the xerographic module. When performing the following step, ...

Page 132

Note: in the following steps, "left" and "right" describe machine locations as observed when you are facing the xerographic module at the left side of the printer. 7. (figure 3): move the bearing out of the xerographic module frame (left side). Lift the drum assembly and move the bearing to the righ...

Page 133

Rep 9.3 drum parts list on pl 9.2 warning switch off the main power switch. Disconnect the power cord. Removal note: when the drum is replaced, install a cleaner blade kit (rep 9.4). 1. Remove the drum assembly (rep 9.2). 2. (figure 1): carefully place the drum assembly, gear box down, in a safe pla...

Page 134

Rep 9.4 cleaner blade kit parts list on pl 9.5a note: these are the instructions to install the cleaner blade kit. The kit contains the following items: • right-hand seal (57 mm wide) • left-hand seal (41 mm wide) • cleaner blade • photoreceptor seal • blade retainer (3) warning switch off the main ...

Page 135

Replacement 1. (figure 2): replace the photoreceptor seal. A. Carefully fold the photoreceptor seal along the perforations. B. Slide the photoreceptor seal into the channel, smaller side up, so that the edge of the photoreceptor seal forms a seal with the inside lip of the channel. C. Using a soft, ...

Page 136

5. (figure 3): complete the installation of the remaining two blade retainers, positioning them, one at a time, to the left of the first one. 6. Replace the left-hand seal. A. Insert the red stripe end of the left-hand seal underneath the folded photoreceptor seal. B. Install the seal fuzzy side up....

Page 137

Rep 9.5 developer module parts list on pl 9.8 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal caution before removing the developer module, ensure ...

Page 138

Caution ensure that the clamp will not cause interference when the developer module is removed. 6. (figure 2): remove the developer module. 1 move the lock into the groove on the gear while performing step 2 move the gear to disengage press tab and swing down clamp bar (one each end) figure 2. Remov...

Page 139

Replacement 1. (figure 3): reinstall the developer module. Caution ensure that the developer module is fully reinstalled in the brackets. Caution ensure that the gear is free to engage the developer module drive gears. Move the lock out of the groove on the gear while performing step 5 move the gear...

Page 140

Note: to ensure that the toner cartridge is correctly engaged in the drive plate, rotate the cartridge in both directions. 2. (figure 4): reinstall the toner cartridge. 3. If new developer material has been installed, perform the toner sensor calibration code [09216], slide the top shield closed par...

Page 141

Rep 9.6 cartridge drive motor parts list on pl 9.10 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Remove the developer module (rep 9.5). 2. (f...

Page 142

Rep 9.7 developer material parts list (refer to other tools and supplies, machine consumables, section 6.) warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. ...

Page 143

Note: rotate the developer module away from the magnetic roll in the following step. 4. (figure 2): dump the developer material. Magnetic roll rotate the developer module r1780c figure 2. Dumping the developer material 8830 1/98 4-59 rep 9.7.

Page 144

Caution do not rotate the auger gears individually more than the slight amount required for removal or to mesh the teeth during reinstallation. If the factory setting of the augers is changed during the procedure, perform the adjustment procedure, augers (adj 9.6). 5. (figure 3): remove the air pres...

Page 145

Replacement note: pour the developer material evenly over the full length of the augers. 1. (figure 4): install the developer material and record the batch number in the machine log. Note: the gears must be reinstalled with the flanges as shown to ensure that all the gears are secured. 2. (figure 5)...

Page 146

3. (figure 6): reinstall the sump shield in the developer module. 4. (figure 7): reinstall the top shield, taking care not to overtighten the screws. Reinstall the sump shield reinstall the sump shield under the edges on the housing tighten the screws (2) reinstall the screws (2) reinstall the top s...

Page 147

Note: to ensure that the toner cartridge is correctly engaged in the drive plate, rotate the cartridge in both directions. 6. (figure 8): reinstall the toner cartridge. 7. If new developer material has been installed, perform toner sensor calibration code [09216]. 8. Perform the electrostatic series...

Page 148

Rep 9.8 scorotron pin kit parts list on pl 9.3 note: these are the instructions to install the scorotron pin kit. The kit contains the following items: • pin array • torsion spring (2) • container warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and o...

Page 149

5. (figure 2): remove the grid channel. Remove the grid channel replacement 1. Install the torsion springs from the repair kit. Caution be careful not to damage the tips of the new pin array. Bent tips can cause print quality problems. 2. Install the pin array from the repair kit into the end blocks...

Page 150

Rep 9.9 transfer/detack corotron parts list on pl 9.4 warning switch off the main power switch. Disconnect the •power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Loosen the screws and open the rear cover...

Page 151

Rep 9.11 toner sensor parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Remove the developer module (rep 9.5). Caution the de...

Page 152

Rep 9.12 toner cartridge home sensor parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Remove the developer module (rep 9,5)....

Page 153

Replacement 1. Reinstall the toner cartridge home sensor. 2. Perform the toner cartridge home sensor adjustment (adj 9.5). 1 reinstall the cartridge drive plate with the sea] up caution to avoid damage to the drive plate seal, always rotate the drive plate in the direction shown in figure 3. 3. (fig...

Page 154

Rep 9.13 sump shield parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Remove the developer module (rep 9.5). 2. (figure 1): ...

Page 155

Replacement caution ensure that the full length of the edge of the sump shield is under the edge of the housing. 1. (figure 2): reinstall the sump shield in the developer module. Reinstall the sump shield under the edges on the housing reinstall the sump shield figure 2. Reinstalling the sump shield...

Page 156

Rep 9.14 cartridge drive plate parts list on pl 9.9 warning switch off the main power switch. Disconnect the power cord. .Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Remove the developer module (rep 9.5). 2. (...

Page 157

Replacement 1. (figure 2): reinstall the cartridge drive plate. Caution to avoid damage to the drive plate seal, always rotate the drive plate in the direction shown in figure 2. 1 reinstall the cartridge drive plate with the seal up reinstall the gear reinstall the screws (2) and the ground wire 2....

Page 158

Rep 9.17 photoreceptor seal parts list on pl 9.5b warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove the drum assembly (rep 9.2). 2. (figure 1): remove the right-hand seal, the left-hand seal (not shown), and the photoreceptor seal. 3. Thoroughly clean the photore...

Page 159

Rep 9.18 air pressure tubes parts list on pl 9.9, 9.10 warning switch off the main power switch. Disconnect the power cord. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly. Removal 1. Remove the developer module (rep 9.5). Ca...

Page 160

Replacement caution do not rotate the auger gears individually more than the slight amount required for removal or to mesh the teeth during reinstallation. If the factory setting of the augers is changed during the procedure, perform the adjustment procedure, augers (adj 9,6). Note: the gears must b...

Page 161

Rep 9.19 roller kit parts list on pl 9.3 note: these are the instructions to install roller kit 600k58740. The kit contains the following items: • rollers (2) • pins (2) warning switch off the main power switch. Disconnect the power cord. R e m o v a l 1. Raise and secure the top cover. 2. Open the ...

Page 162

Rep 9.20 image module parts list on pl 9.3 note: these are the instructions to install the image module assembly kit 600k58760. The kit contains the following: • image module assembly warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove the developer module (rep 9.5...

Page 163

8. Open the cutter drawer. 9. (figure 3): disconnect the video cable connector j307a from the main pwb and push the connector through the hole in the frame. Disconnect j307a push the cable remove the cable from through the hole the clamps figure 3. Disconnecting the video cable 10. (figure 4): relea...

Page 164

12. (figure 6): continue to pull the video cable through the hole after releasing it from the cable guides. 13. (figure 7): disconnect a5p2 from the low voltage power supply and release the harness from the cable clamps. 14. (figure 8): disconnect the ground wire and release the harness from the cab...

Page 165

Note: observe the way that the spring rests on the frame, underneath the cable clamp. This is how the reassembled parts must fit. 15. (figure 9): complete the removal preparation on the front area of the image module assembly. Remove the screw and the cable clamp spring 1 remove the bolt from the en...

Page 166

16. (figure 10): continue to pull the video cable through the hole after releasing it from the cable guides. 17. Lift out the image module assembly / pivot bar combination. Replacement 1. Reverse the removal steps for replacement of the image module assembly. 2. Perform electrostatic series (adj 9.2...

Page 167

Rep 10.1 heat rod parts list on pl 10.2 warning switch off the main power switch. Disconnect the power cord. Allow the fuser assembly to cool before the procedure is performed. Removal 1. Remove the stripper finger assembly. 2. Perform the xerographic module procedure (rep 9.1) through step 11. This...

Page 168

(figure 2): disconnect the heat rod and remove the bracket (left side). Bracket remove the screws (2) and the bracket caution wear gloves or wrap a sheet of paper around the heat rod when handling the heat rod. Do not touch the glass section of the heat rod oil from fingers can cause damage to the h...

Page 169

Replacement caution wear gloves or wrap a sheet of paper around the heat rod when handling the heat rod. Do not touch the glass section of the heat rod. Oil from fingers can cause damage to the heat rod. .1. (figure 4): reinstall the heat rod. Note: do not remove the connectors from the wires on the...

Page 170

2. (figure 5): reinstall the bracket (left side). 2 reinstall the screws and the bracket connect the connector figure 5. Reinstalling the bracket (left side) 3. (figure 6): reinstall the grommet and the bracket (right side). 4. Ensure that the thermistor pad is clean. Reinstall the bracket on to the...

Page 171

Rep 10.2 heat roll parts list on pl 10.2 warning switch off the main power switch. Disconnect the power cord. Allow the fuser assembly to cool before the procedure is performed. Note: the art used for this procedure was developed for previous products and may not match the 8830 configuration exactly...

Page 172

Rep 10.3 fuser triac parts list on pl 1.2 warning switch off the main power switch. Disconnect the power cord. Removal 1. Remove the two right side covers. 2. (figure 1): remove the fuser triac. Remove the fuser triac replacement 1. Cover the entire surface where the fuser triac mounts to the frame ...

Page 173

Rep 10.7 web oiler assembly parts list on pl 9.6 warning switch off the main power switch. Disconnect the power cord. Removal 1. Loosen the screws and open the rear door. 2. Raise and latch the top cover. 3. Ensure that there is a clean, flat surface on which to place the web oiler assembly after it...

Page 174

Rep 10.8 stripper fingers parts list on pl 10.4 warning switch off the main power switch. Disconnect the power cord. Allow the fuser assembly to cool before the procedure is performed. Removal 1. Remove the s tripper finger assembly. 2. (figure 1): remove the stripper fingers. Stripper finger 1 remo...

Page 175

Rep 10.9 web oiler parts list on pl 9.7 warning switch off the main power switch. Disconnect the power cord. Warning wear protective gloves when handling parts with silicon oil on them. Do not allow silicon oil to contact your eyes. Silicon oil can cause severe eye irritation. Wash your hands immedi...

Page 176

Replacement 1. (figure 3): reinstall the supply roll. L mount the opposite end of (he supply roll onto the lh side plate rh side plate. Supply roll pull the knob and lock on the the supply roll figure 3. Reinstalling the supply roll 2. (figure 4): reinstall the takeup roll. 3. After reinstallation o...

Page 177

Adj 3.2 country configuration purpose the purpose is to set the line service (input power) and billing type (billing meter) configurations according to the customer's requirements. Adjustment 1. Enter diagnostics. 2. Enter code [0261]. 3. (table 1): set the line service configuration using the previ...

Page 178

Adj 8.1 vertical magnification purpose the purpose is to calibrate the printer to produce the correct length images for each media type. Prerequisite 1. Check the fuser temperature (nvm) (adj 10.1). Check 1. Enter diagnostics. 2. Enter code [0955] and make one 1200 mm print of test pattern #7. 3. Al...

Page 179

Adj 8.2 lead edge registration purpose the purpose is to adjust the print media to the image on the drum for lead edge registration within specification. Prerequisite 1. Check the following: a. Fuser temperature (nvm) (adj 10.1) b. Vertical magnification (adj 8.1) c h e c k 1. Enter diagnostics. 2. ...

Page 180

Adj 8.3 cut length purpose the purpose is to calibrate the printer to produce the correct length prints for each media type. Prerequisite 1. Check the following: a. Fuser temperature (nvm) (adj 10.1) b. Vertical magnification (adj 8.1) c. Lead edge registration (adj 8.2) adjustment 1. Enter diagnost...

Page 181

Adj 8.4 media transport purpose the purpose is to set the correct spacing between the media transport and the drum when a new media transport is installed. The correct spacing is obtained by adjusting the position of the lower turnaround •baffle. Note: the art used for this procedure was developed f...

Page 182

Adjustment warning switch off the main power switch. Disconnect the power cord. 1. Remove the transfer / detack corotron (rep 9.9). 2. Remove the developer module (rep 9.5). 3. Remove the white toner shield. 4. (figure 2): position the lower turnaround baffle. 5. Close the media transport cover. Pus...

Page 183

Note: the position of the lower turnaround baffle determines the position of the upper turnaround baffle, when the position of the lower turnaround baffle is correctly set, the upper turnaround baffle is correctly positioned, 6. Cut two strips of 0.030 inch (coral) shimstock 0.75 inches (20 mm) wide...

Page 184

Notes: 1/98 4-100 8830

Page 185

Adj 9.2 electrostatic series purpose the purpose is to set the drum voltages to obtain good print quality as specified in section 3 of this service manual. On iots with tag 23, it is necessary to establish the correct average light •output (alo) of the led bar in order to set the voltages. Adjustmen...

Page 186

11. Position the electrometer probe to measure the voltage on the drum. A. Install the probe wing onto the electrometer probe. Ensure that the window of the wing is centered over the window of the probe. B. (figure 2): remove the plug from the side of the image module. C. Slide the electrometer prob...

Page 187

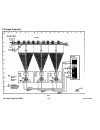

Bar# 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 value .75 .77 .68 .74 .80 .75 .74 .75 .79 .61 .65 .58 .71 .62 .69 .70 .70 .74 .71 .79 .67 .92 .76 .83 .79 1.05 1.05 1.05 1.10 1.13 1.02 .97 1.03 1.00 1,01 1.06 .95 bar# 39 40 41 42 43 44 45 46 ...

Page 188

Bar# 281 282 283 284 285 286 287 288 289 290 291 292 293 294 295 296 297 298 299 300 301 302 303 304 305 306 307 308 309 310 311 312 313 314 315 316 317 318 value .89 .89 .90 .66 .71 .76 .81 .81 .93 .60 .63 .64 .69 .66 .71 .85 .82 .86 .81 .92 1.01 .58 .60 .67 .72 .62 .83 .63 .64 .78 .67 .76 .80 .58 ...

Page 189

Adj 9.3 image density purpose the purpose is to set the toner concentration to obtain good print quality as specified in section 3 of this service manual. Note: electrostatic series adj 9.2 must be performed before the image density is adjusted. Check 1. Enter diagnostics. 2. Enter code [0955] and m...

Page 190

Adj 9.5 toner cartridge home sensor purpose the purpose is to set the toner cartridge home sensor to the correct distance from the magnet on the toner cartridge. Warning switch off the main power switch. Disconnect the power cord. Check 1. Remove the developer module (rep 9.5). 2. Remove the cartrid...

Page 191

8830 1/98 4-109 adj 10.2.

Page 192

Adj 10.1 1/98 4-108 8830

Page 193

Notes: 1/98 8830 4-111.

Page 194

1/98 4-112 8830

Page 195

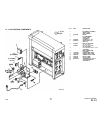

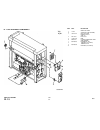

5. Parts list section title introduction parts list electrical components pl 1.1 electrical control components/dc power generation pl 1.2 ac electrical components pl 1.3 dc electrical components pl 1.4 control console media roll peed pl 7.1 roll supply feed assembly pl 7.2 roll supply drives pl 7.3 ...

Page 196

Overview the paris list section identifies all part numbers and the cor- responding location of all spared subsystem components. Organization parts lists each item number in the part number listing corresponds to an item number in the related illustration. All the parts in a given subsystem of the m...

Page 197

S y m b o l o g y a tag number within a circle having a shaded bar and pointing to a tag number within a circle with no apex shows that the entire an item number shows that the configuration of the part shown is drawing has been changed by the tag number within the circle a tag number within a circl...

Page 198

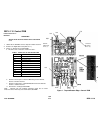

Pl 1.1 electrical control components/dc power gen- eration item 1 2 3 4 5 6 7 . 8 9 part 105k15862 160k33322 600k59935 600k59955 .. .. .. 537k51150 537k51160 162k29730 160k30285 description dc low voltage power supply driver pwb (a2) circuit assembly kit (naco) (tag 4, 16,17) circuit assembly kit (e...

Page 199

Pl 1.2 ac electrical components 1 {2-12 13 {14 11 (2 places) (2 places) (k1, k3) item 1 2 3 4 5 6 . 7 8 9 - 10 11 12 13 14 part 142k1540 — 109e1040 707w1652 103e2721 103e2731 - - 117k22761 117k27550 10be1762 120e2160 120e2150 600k60610 description ac module assembly (60hz) (50hz) (not spared) filter...

Page 200

Pl 1.3 dc electrical components item 1 2 3 4 5 6 7 8 9 10 part 111k21 105k13541 54k12300 127e11240 92e36450 600k60900 600k60890 description media counter standoff (not spared) high voltage power supply (rep 3.2) fan duct fan charge corotron label (red arrow) diagnostic kit harness (p/o item 7) loopb...

Page 201

Pl 1.4 control console 0000004a-rn0 item part 1 101k260b2 2 96e78251 description control console control console label 8830 2/97 5-7 parts list section pl 1.4.

Page 202

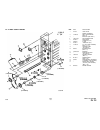

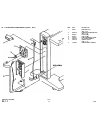

Pl 7.1 roll supply feed assembly 6{7, 8 (3 places) (6 places) 3 (3 places) (exploded on pl7.3, item 1 pl7.4, item 1 pl7.5, item 1 pl7.6. Item 1) em 1 2 3 4 5 6 7 8 part 130k51801 130e2271 50k19612 10k1351 22k2s930 .. 126k7330 description position sensor drawer interlock switch roll supply drawer ass...

Page 203

Pl 7.2 roll supply drives 1 {2,3,5 15 {7-14 18 11 (3 places) (3 places) 1 2 (3 places) 11 (3 places) 10 (3 places) (cl1,3,5) (3 places) item part description 1 7k7561 roll drive motor assembly 2 127k4293 roll drive motor (rep 7.9) 3 -- bracket (p/o item 1) 4 140k15953 drive motor pwb 5 7e16410 main ...

Page 204

Pl 7.3 roll supply drawer components (part 1 of 4) 3 1(2-11 (2 places) item 1 2 3 4 5 6 7 8 . 9 10 11 part -- 22e11540 7e14650 29e14760 — . . 3e17610 9e27340 7e14600 description part of roll supply drawer assembly (ref: pl7.1 item 3) support roller rewind internal gear (20t) (rep 7.2) lh support pin...

Page 205

Pl 7.4 roll supply drawer components (part 2 of 4) 1(2-8 item 1 2 3 4 5 6 7 8 part .. 3e17610 9e27340 .. 29e14750 22e11540 description part of roll supply drawer assembly (ref pl7.1 item 3) rh roll lock (p/o item 1) roll lock roll lock spring rh cradle bracket (p/o item 1) rh support pin support rol...

Page 206

Pl 7.5 roll supply drawer components (part 3 of 4) 1(2-16,18 item part (2 places) 18 (2 places) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 17e42s0 68e17221 9e27351 22e10060 9e32790 29e14460 9e27330 29e13701 3k7581 3e39000 48k44880 38k9190 121e7680 48e39380 891e1960 description part of rol...

Page 207

Pl 7.6 roll supply drawer components (part 4 of 4) 1(3-6 item 1 2 3 4 s 6 part -- 52k3580 92e22541 92e36431 92e22560 description part of roll supply drawer assembly (ref: pl7.1 item 3) roll support tube assembly label (push here) label (media lead) drawer frame (p/o item 1) label (pinch arrows) 0000...

Page 208

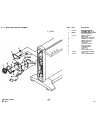

Pl 7.7 media cutter assembly 1 { 2 , 8 i (2 places ) item 1 2 3 4 5 6 7 8 9 part 37k1020 - 3e18781 10k1360 110e2640 •- .. 11e4470 description media cutter assembly media cutter (p/o item 1) bracket (not spared) latch media cutter sude media cutter cover interlock switch (s1) bracket (not spared) cut...

Page 209

Pl 7.8 media cutter components ag item 1 2 3 4 5 6 7 b 9 10 11 12 part .. 38k6601 127k19850 9e27340 3e16521 - 423w57550 130e3250 20e18b30 2be7430 description part of media cutter assembly (ref: pl7.7 item 1) media cutter frame (p/o item 1) media exit guide cutter motor latch spring cutter latch driv...

Page 210

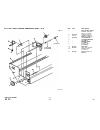

Pl 8.1 media transport assembly 4(1-3,5,9-11 5(6-8 an (exploded on pl8.2, item 1 pl8.3, item 1 pl8.4, item 1 pl9.4, item 1 pl10.3, item 1) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 part 423w72201 20e13353 26e11970 22k49203 .. 20e13603 127k4293 22e11441 20e12353 423w64001 120e216...

Page 211

Pl 8.2 media registration components 6 (3 places) 8 (3 places) 9 (3 places) (3 places) 1(2,11-15 2(3-10 item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 part 130e5990 30k37830 16e6020 22e10531 6e42300 9e32500 9e32480 6k13880 413w31054 15 16e8931 description part of media transport assembly (ref: pl8.1 item 4) ...

Page 212

Pl 8.3 cut sheet feed components 12 1 {2-5,11,12 5 {6-10 (3 places) (3 places) 8 9 (3 puces) 10 (3 places) item 1 2 3 4 5 6 7 8 9 10 11 12 part -- . . 19e14350 6k15681 .. -- 16e6020 22e9390 9e32490 6e23540 .. -- description part of media transport assembly (ref: pl8.1 item 4) media transport frame (...

Page 213

Pl 8.4 media transport components item 1 2 3 4 5 6 7 8 9 10 11 12 13 part 110k8711 — 19e7100 .. 110k3731 .. 49e54980 — 32e10830 - description part of media transport assembly (ref: pl8.1 item 4) buckle switch (upper) (rep 8.4) media exit switch (lower) (rep 8.2) sensor bracket (p/o item 1) transport...

Page 214

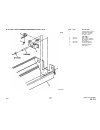

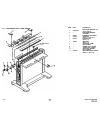

Pl 9.1 xerographic module assembly (exploded on pl9.2, item1 pl9.3, item 1 pl9.5a, item 1 pl9.5b, item 1 pl9.6, item 1) 1 { 2 , 3 item 1 2 3 4 . 5 part 127k17882 sk41s1 126k5992 128k7152 s3e4750 description photoreceptor drive assembly photoreceptor drive (p/o item 1) coupling xerographic module ass...

Page 215

Pl 9.2 photoreceptor 1 {2,3,12,13 3(4,6-11,13 11 {to pl9.5b, item 11) item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 part .. 6k15640 13k380 28e11470 -- -- 230w652 7e1340 30e16161 - 1r535 description part of xerographic module assembly (ref: pl9.1 item 4) xerographic frame (p/o item 1) shaft assembly bearing ...

Page 216

Pl 9.3 image module assembly 1(2,13 2{ 3-5, 9,10 6 ( 7 , 8 11(12 14( 15,18-20 15(16,17 12 22 item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 part 125k2220 26e576s0 62e8051 600k58750 -- -- -- 600k58730 35e41210 60qk58760 600k58740 - — — — 160k30980 21e7680 35e37240 description part of x...

Page 217

Pl 9.4 transfer/detach corotron 1 ( 2 - 4 8 (2 places) x (for location ref: pl8.1, item 4) item 1 2 3 4 5 6 7 8 9 part 19e16080 19e19971 125k25b0 38e6610 38e6620 4e502 600k37740 description part of media transport assembly (ref: pl8.1 item 4) transport frame (p/o item 1) left corotron clamp right co...

Page 218

Pl 9.5a drum cleaning (part 1 op 3) item 1 2 3 4 5 6 7 8 part 600k59060 -- .. .. 101k25780 — description part of xerographic module assembly (ref: pl9.1 item 4) xerographic frame (p/o item 1) cleaning blade kit (rep 9.4) blade seal (p/o item 3) cleaner blade retainer (p/o item 3) cleaner blade (p/o ...

Page 219

Pl 9.5b drum cleaning (part 2 of 3) 1(2-6,9,10 p/o kit ref: pl9.5a, item 3 8{8a item part 1 10, (to pl9.2 , item 11) 8 8a 9 10 2 7e5221 3 23e1620 4 20e4350 5 13e803 6 94k85 7 35k5790 600k8481 description part of xerographic module assembly (ref: pl9.1 item 4) auger gear pulley auger drive belt auger...

Page 220

Pl 9.5c drum cleaning (part 3 of 3) item part 1 35k5950 2 54e6533 3 35k5941 4 93k2420 description toner exit seal toner waste tube waste bracket seal toner bottle 000003ba-rno parts list section pl 9.5c 9/97 6-26 8830

Page 221

Pl 9.6 web oiler assembly 1{2-8 (exploded on pl9.7, item 1) item 1 2 3 4 5 6 7 a part 94k3301 127k21990 7k8920 7k8930 3e39010 3e44550 description part of xerographic module assembly (ref: pl9.1 item 4) web oiler assembly (rep 10.7) web oiler motor oiler drive gear idler gear (40t/18t) xerographic fr...

Page 222

Pl 9.7 web oiler components 1 { 2-10 ( v i e w rotated 180') item 1 2 3 4 5 6 7 a s 10 part 22k49131 22k49380 — 7e42580 - 130k55130 146k461 5e11130 description part of web oiler assembly (ref: pl9.6 item 2) web oiler (rep 10.9} pinch roll take up shaft (p/o item 1) spring (p/o item 1) take up gear w...

Page 223

Pl 9.8 developer module assembly 4 12 (exploded on pl9.9, item 1 pl9.10, item 1) 10 item 1 2 3 4 5 6 7 8 9 10 11 12 13 part 127e10341 35k5900 10e4190 14k4740 14k4730 28e7771 9e41251 7e15351 30k56160 50e12851 30k56150 121k10422 19e21480 description drum/developer drive motor gasket trickle slide deve...

Page 224

Pl 9.9 developer module components (part 1 of 2) 14 item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 part 54e3181 3e19330 - 5k1351 130k30381 2e40470 55k13840 130k53300 19e15551 1e23080 55k13830 35e12210 description part of developer module assembly (ref: pl9.8 item 12} pressure equalizer tube (rep 9.8) c...

Page 225

Pl 9.10 developer module components (part 2 of 2) item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 part -- 7e16330 7e16341 127k22600 120e4750 7e14690 7k5260 7e14700 7e14710 54e3491 35k4581 600k58720 - description part of developer module assembly (ref: pl9.8 item 12) cartridge gear (44t) cartridge drive gea...

Page 226

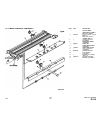

Pl 10.1 xerographic module assembly item part 1 126k5992 126k7152 2 127e10331 3 7e44391 description xerographic module assembly (60hz) (rep 9.1) xerographic module assembly (50hz) (rep 9.1) fuser drive motor drive pulley (28t) 0600028a-rno parts list section pl 10.1 9/97 5-32 8630

Page 227

Pl 10.2 fuser components 1(2-8,10,13,15,17,18,19 16{ 9,11,12 17- 15- 11 item 1 2 3 4 5 6 7 8 - 9 10 11 12 13 14 15 16 17 18 19 part -- 5k3430 5k2613 62e5461 22k40050 126e492 126e821 — 7e42570 115e2231 6e23471 7e42780 16e8080 49e6460 600k45270 120e5440 120e6510 121e1402 description part of xerographi...

Page 228

Pl 10.3 fuser pressure components and moisture col- lection (for location ref: pl8.1 item 4) item 1 2 3 4 s 6 7 8 9 10 11 12 13 14 15 part 23k942 3k9130 9e32490 — - -- 33k2430 33k2040 9e46870 52e7900 420w10201 description part of media transport assembly (ref: pl8.1 item 4) fabric guide (rep 8.9) fa...

Page 229

Pl 10.4 fuser heat control and stripper fingers 1 {2,3,4,5,6 6 {7,8,10,11,12 9 {9a bh 12 (5 places) 9a (10 places) 11 (10 places) item 1 2 3 4 5 6 7 8 9 9a 10 11 12 part -- 130k54730 110e5500 130k54841 30k55720 9e61600 600k35880 — 9e38060 6be38113 38k11070 description part of xerographic module asse...

Page 230

Pl 14.1 transport latching cover and rear door item 1 2 3 4 5 6 7 8 a 10 11 12 13 14 15 16 17 18 part 130e2271 14e20541 48k47700 17k1120 30k55630 121e7680 19e33441 115e1410 -- 96e72590 809e2290 600k59260 — .. 35e41160 29e28060 110k9430 description feed shelf interlock switch (s29) left hinge spacer ...

Page 231

Pl 14.2 front door and right side covers 9 {3,11 em 1 2 3 4 5 6 7 8 9 10 11 part 48k58181 891e9080 48k47710 14e20551 48k47681 48k47692 48k44401 3e18740 110e2640 description front door cover logo plate keeper (p/o item 9) right side, left cover right hinge spacer right side, left lower cover right si...

Page 232

Pl 14.3 developer cover and catch tray item part 73e11800 73e11710 48e51410 description catch tray kit tray support kit rear developer cover (w/tag 6) 0000035b rno parts list section pl 14.3 9/97 5-38 8830 1 2 3.

Page 233

Pl 14.4 top cover and catch tray brackets em 1 2 3 4 5 6 7 a 9 part 48k45052 55e38100 29e23670 35e37240 35e41150 30k57191 30k57830 30k57181 30k57900 description top cover shielding pao pin gasket gasket rh service bracket rh catch tray bracket lh service bracket lh catch tray bracket 0000037b rno 88...

Page 234

Pl 15.1 miscellaneous electrical connectors and fas- teners item part 2. 1 2 3 3a 3b 30 description contact socket (20-26 awg) (to be available at later date) contact pin (20-26 awg) (to be available at later date) wire and connector repair kit (to be available at later date) socket wire (10/kit) co...

Page 235

Item a b c d e f g h j k . L m n p r s t u v w x y z aa ab ac ad ae af aq ah aj ak al am an ap ar as at au av aw ax ay az ba bb bc bd be bf bg bh part 112w11655 112w7455 354w21052 354w21252 153w23352 132w253 156w27555 156w27655 251w10856 354w20852 354w24251 356w2502 251w10455 256w20454 112w27255 351...

Page 236

Part number 1r535 1e23080 2e40470 3k7581 3k9130 3e16521 3e17610 3e17610 3e18740 3e18781 3e19330 3e39000 3e3b010 3e44550 4e502 5k1351 5k2613 5k3430 5k4151 5e6810 5e11130 6k13880 6k15b40 6k15681 6e23471 6e23540 6e42300 7e1340 7e5221 7k5260 7k5760 7k7561 7k8920 7k8930 7e14600 7e14610 7e14650 7e14690 7e...

Page 237

6. General procedures section contents title page title page diagnostics to enter the diagnostic mode 6-2 to exit the diagnostic mode 6-2 input diagnostic test procedure 6-2 input diagnostic test codes 6-3 output diagnostic test procedure 6-4 output diagnostic test codes 6-4 stripper motor commands ...

Page 238

( to diagnostic mode mode is entered by pressing and holding the zero (0) button while switching on the printer. The diagnostic mode may also be entered the control panel by entering the printer menu>,iot diagnostics, and entering the password (6789). When entering the diagnostic mode, the message d...

Page 239

Input diagnostic test codes code [0101] [0102] [0103] [0104] [0105] [0106] [0202] [0211] [0701] [0702] [0707] [0708] component tested front door interlock line voltage sense line frequency sense line voltage high/low cut sheet feed shelf interlock top cover interlock keyboard test message rom test m...

Page 240

Output diagnostic test procedure the output diagnostic test is used verify correct operation of output components. The output diagnostic test allows the operation of the individual or multiple (chaining) output component(s) in order to verify operation. Refer to page 6-6 for instructions on how to e...

Page 241

Code [0925] [0956] [0957] [0966] [1009] component tested toner cartridge (1 revolution) test pattern - additional delay display area coverage of last print made. Erase lamp fuser power relay on stepper motor commands additional information: 1. Codes [0728] and [0731] must be chained with [0704] in o...

Page 242

To enter multiple tests (chaining) the media button is used when entering more than one test. To chain one code to another, perform the following: 1. Enter the desired code for the first test. 2. Press the media button, then enter the additional code(s) for additional tests. To exit from multiple te...

Page 243

Code [0361] [0362] [0363] [0364] [0365] [0391] description watchdog timer test. This code can be used to exit the diagnostic mode diagnostic time-out interval. This code allows the adjustment of the time interval that the printer will stay in the diagnostic mode. The time interval range is 5 to 50 m...

Page 244

Code [0921] (cont'd) [0922] [0926] [0955] description next/previous - pressing these buttons affects the duty cycle value in tests 2 and 3, and changes vhigh in [0921-2], when running tests 2 and 3, pressing the enter button copies the current duty cycle value to nvm. This code disables toner faults...

Page 245

Code [1032] [1033] [1034] [1035] [1036] description specify web oil rate. This is used to adjust the web oil rate from 50% to 200%. (a 100% setting is nominal.) this setting directly impacts the life of the oil web. 50% means that 1/2 as much web is used. Advance oil web. Used to tension the web cor...

Page 246

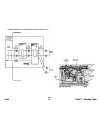

Gp1 hvps checkout the purpose of this checkout procedure is to verify correct operation of the high voltage power supply. Note: use the 26v rtn test point when measuring all voltages. Failure to use this test point can cause incorrect readings. View: rear(top) figure 1. Location of hvps test points ...

Page 247

Gp2 image on drum (panic stop) procedure this procedure allows the isolation of print quality problems by observing the image on the drum before the transfer of the toner to the media, if the defect is visible on the drum before the transfer, the defect is related to the charge, the imaging, or the ...

Page 248

Gp3 drum-maintenance warning when performing this drum maintenance, do the following: • ensure that there is adequate ventilation in the area. • use protective gloves at all times. « do not smoke. • wash your hands when the procedures are completed. Caution these procedures must be completed in the ...

Page 249

Gp4 d r u m cleaning enhancement 1. Remove the drum assembly (rep 9.2). 2. Use the dusting pouch (8r181) to apply a thin layer of zinc stearate over the entire surface of the drum. 3. With a new lint-free cloth (600s4372), wipe the entire surface of the drum, using moderately heavy pressure. Use a b...

Page 250

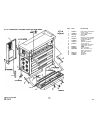

Installation procedure prepare to install the printer caution before installing the printer, check for the correct voltage, polarity, and the grounding of the ac outlet that is provided by the customer. Use the digital multimeter. Incorrect voltage applied to the printer could result in poor perform...

Page 251

Floor space requirements warning this product will produce ozone during operation. The ozone that is produced is dependent on the print volume and is heavier than air. Providing the correct environmental parameters as specified in xerox installation procedures will ensure that concentration levels m...

Page 252

3. 4. 5. 6. 7. 8. Close the media transport cover. Open the media drawers (3) and remove the packaging material from the media tubes. Remove the scorotron from the media drawer and carefully remove the packing material from the scorotron. Lift and rotate the image module to the service position. Ins...

Page 253

14. (figure 8): remove the developer module. 15. (figure 9): remove the sump shield. Ensure that the gear lock is pulled back slide gear to left and lock into position with gear lock remove the top shield loosen rear screws remove front screws r3021k press in and rotate retaining clip to down positi...

Page 254

16. Remove the bottle of developer material from the supply kit. 17. (figure 10): install the developer material evenly along the entire length of the augers. Install the developer material record the batch number of the developer material on the printer log augers 01627b 18. (figure 11): reinstall ...

Page 255

Caution ensure that the developer module is kept close to the printer frame during reinstallation in order to avoid damage to the toner dispenser motor. 20. (figure 13): reinstall the developer module. 21. (figure 14): reinstall the developer module. 22. (figure 15): reinstall the toner cartridge. S...

Page 256

23. (figure 16): complete the toner cartridge installation. Remove the tape 27. (figure 17): prepare to level the printer. Rotate the leveling bolts (located inside the front and rear doors) fully counterclockwise. 2 close the cover 28. (figure 18): check the level of the printer. Note: to ensure th...

Page 257

29. (figure 19): adjust the side-to-side level of the printer. 30. (figure 20): adjust the front-to-rear level of the printer. Rotate the bolts to adjust the level of the printer repeat step 1 at the other end of the printer rotate the bolts equally to adjust the level of the printer 31. Repeat the ...

Page 258

35. Install the second language eprom on the main pwb (if required). 36. Install the catch tray or folder. Refer to section 8 for folder installation instructions. Note: the 8830 printer comes with either a plain cover to attach to the right side of the printer or the 8830 controller. 37. If the pri...

Page 259

10. (figures 21 and 22): record the media counter readings onto the service call report. Record and report any accessory serial numbers (i.E., finisher, controller), figure 21. Media counter location enter the reading from the media counter here access the control panel menu and record the meter a r...

Page 260

Product demonstration caution so hz machines only:. Do not run program 3- 60-3 as this will cause all settings on the printer to be lost. To demonstrate the capabilities of the printer, refer to the user guide. Perform the following procedures to train an operator. A. Getting to know your printer b....

Page 261

Removal procedure purpose the purpose is to repack the 8830 printer and the 8830 controller (if present) for removal by delivery / removal carriers. 8830 printer repack kit kit contents 673k34330 inspect the shipment for the following items: • poly tape • bubble pack • foam pads (2 • cable ties (2) ...

Page 262

15. Raise and latch the top cover. 16. (figure 2): raise the image module to engage the developer module shipping brackets. 17. (figure 3): install the shipping pads. 1 loosen screw slide bracket onto the shaft r3016k 4 repeat steps 1 through 3 on other side figure 2. Engaging the shipping brackets ...

Page 263

8830 1/98 6-29 general tools and supplies (naco) general tools and supplies (naco) supplies description part service manual binder 600p88124 tools description part basic multinational tool kit 600t1835 supplemental tool kit . 600t1837 metric supplemental tool kit 600t1836 digital multimeter 600t2020...

Page 264