- DL manuals

- Vega

- Transmitter

- VEGABAR 82

- Operating Instructions Manual

Vega VEGABAR 82 Operating Instructions Manual

Summary of VEGABAR 82

Page 1

Operating instructions pressure transmitter with ceramic measuring cell vegabar 82 4 … 20 ma document id: 45027.

Page 2: Contents

2 contents vegabar 82 • 4 … 20 ma 45027-en-170522 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ..................................................................

Page 3

3 contents vegabar 82 • 4 … 20 ma 45027-en-170522 8 diagnostics and servicing 8.1 maintenance .................................................................................................................. 51 8.2 cleaning - hygienic connection with compression nut ...................................

Page 4: 1 About This Document

4 1 about this document vegabar 82 • 4 … 20 ma 45027-en-170522 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tionsformaintenance,faultrectification,theexchangeofpartsand the...

Page 5: 2 For Your Safety

5 2 for your safety vegabar 82 • 4 … 20 ma 45027-en-170522 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the requi...

Page 6

6 2 for your safety vegabar 82 • 4 … 20 ma 45027-en-170522 to avoid any danger, the safety approval markings and safety tips on the device must also be observed and their meaning looked up in this operating instructions manual. 2.5 eu conformity thedevicefulfilsthelegalrequirementsoftheapplicableeud...

Page 7

7 2 for your safety vegabar 82 • 4 … 20 ma 45027-en-170522 2.9 environmental instructions protection of the environment is one of our most important duties. That is why we have introduced an environment management system with the goal of continuously improving company environmental pro- tection.Thee...

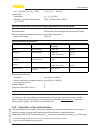

Page 8: 3 Product Description

8 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 3 product description 3.1 configuration thetypelabelcontainsthemostimportantdataforidentificationand use of the instrument: 2 1 13 14 12 10 11 5 3 6 4 7 8 9 fig. 1: layout of the type label (example) 1 instrument type 2 product code 3 fi...

Page 9

9 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 this operating instructions manual applies to the following instrument versions: • hardware from 1.0.0 • software version from 1.3.0 note: youcanfindthehardwareandsoftwareversionoftheinstrumentas follows: • on the type plate of the elect...

Page 10

10 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar 82 is suitable for applications in virtually all industries. It is used for the measurement of the following pressure types. • gauge pressure • absolute pressure • vacuum measured products are gases, vapours and liquids. Dependi...

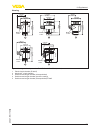

Page 11

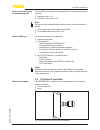

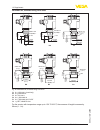

11 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 the recessed installation is particularly suitable for applications with gases, vapours and clear liquids. The measuring cell seal is posi- tioned laterally as well as in addition in front. 1 2 5 6 3 4 fig. 3: recessed installation of t...

Page 12

12 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 1 2 3 4 5 fig. 5: front-flush installation of the measuring cell (example: m30 x 1.5) 1 measuring cell 2 seal for the measuring cell 3 seal for the process fitting 4 process fitting 5 diaphragm thefront-flushinstallationisparticularlysu...

Page 13

13 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 1 2 3 4 5 fig. 7: hygienic installation of the measuring cell (example: hygienic fitting with compression nut) 1 measuring cell 2 form seal for the measuring cell 3 gap-free seal for process fitting 4 process fitting 5 diaphragm thefron...

Page 14

14 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 caution: the vegabar 82 in this version may not be used in oxygen ap- plications. For this purpose, instruments are available in the special version "oil and grease-free for oxygen applications". 3.4 packaging, transport and storage you...

Page 15

15 3 product description vegabar 82 • 4 … 20 ma 45027-en-170522 • pc/notebook with bluetooth usb adapter (windows operating system) youcanfindfurtherinformationintheoperatinginstructions"display and adjustment module plicscom" (document-id 27835). The interface adapter vegaconnect enables the connec...

Page 16: 4 Mounting

16 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 4 mounting 4.1 general instructions make sure before mounting that all parts of the instrument exposed to the process are suitable for the existing process conditions. These are mainly: • active measuring component • processfitting • process seal ...

Page 17

17 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 prior to setup you have to replace these protective caps with ap- proved cable glands or close the openings with suitable blind plugs. Oninstrumentswiththreadedprocessfitting,thehexagonmustbe tightenedwithasuitablewrench.Fortheproperwrenchsizesee ...

Page 18

18 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 caution: donotuseahigh-pressurecleaner.Thefilterelementcouldbedam- aged, which would allow moisture into the housing. Thefollowingparagraphsdescribehowthefilterelementisarranged inthedifferentinstrumentversions. Thefilterelementismountedintotheele...

Page 19

19 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 → turnthemetalringinsuchawaythatthefilterelementpoints downward after installation of the instrument. This provides better protection against buildup. 1 2 fig. 11: position of the filter element - ex-d version 1 rotatable metal ring 2 filter eleme...

Page 20

20 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 thefilterelementismountedintotheelectronicshousing.Ithasthe following functions: • ventilation of the electronics housing • atmospheric pressure compensation (with relative pressure meas- uring ranges) → turnthehousingsothatthefilterelementpointsd...

Page 21

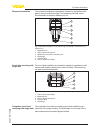

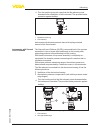

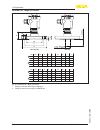

21 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 1 4 3 2 1 2 3 4 fig. 15: measurement setup with process pressure measurement of gases in pipelines 1 vegabar 82 2 blocking valve 3 siphon in u or circular form 4 pipeline a protective accumulation of water is formed through condensation in the pip...

Page 22

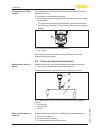

22 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 3 1 2 fig. 16: measurement setup for process pressure measurement of liquids in pipelines 1 vegabar 82 2 blocking valve 3 pipeline 4.4 level measurement keep the following in mind when setting up the measuring system: • mount the instrument below ...

Page 23

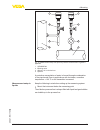

23 4 mounting vegabar 82 • 4 … 20 ma 45027-en-170522 4.5 external housing 1 2 3 4 5 fig. 18: setup process assembly, external housing 1 pipeline 2 process assembly 3 connection cable process assembly - external housing 4 external housing 5 signal cable 1. Mark the holes according to the following dr...

Page 24

24 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried out ...

Page 25

25 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 free openings for the cable glands are therefore covered with red dust protection caps as transport protection. Prior to setup you have to replace these protective caps with ap- proved cable glands or close the openings with suit...

Page 26

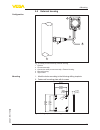

26 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 5. Insert the cable into the sensor through the cable entry fig. 20: connection steps 5 and 6 - single chamber housing 6. Insert the wire ends into the terminals according to the wiring plan information: solidcoresaswellasflexibl...

Page 27

27 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 5.3 ex-d-ia double chamber housing 3 1 2 5 6 7 8 1 2 ( ) (-) + 4...20ma fig. 21: electronics compartment - ex-d-ia double chamber housing 1 internal connection to the terminal compartment 2 for display and adjustment module or in...

Page 28

28 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 1 2 + ( ) (-) 4...20ma 2 3 1 fig. 23: electronics and terminal compartment - single chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 ground terminal for connection of the ...

Page 29

29 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 5.6 external housing with version ip 68 (25 bar) 1 2 3 fig. 25: vegabar 82 in ip 68 version 25 bar with axial cable outlet, external housing 1 transmitter 2 connection cable 3 external housing 1 2 3 5 1 2 ( ) + (-) 6 7 8 4...20ma...

Page 30

30 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 1 2 3 4 6 3 4 1 2 5 fig. 27: connection of the sensor in the housing base 1 yellow 2 white 3 red 4 black 5 shielding 6 breather capillaries 1 2 + ( ) (-) 4...20ma 2 3 1 fig. 28: electronics and terminal compartment - single chamb...

Page 31

31 5 connecting to power supply vegabar 82 • 4 … 20 ma 45027-en-170522 then the actual measured value is outputted to the signal cable. The value takes into account settings that have already been carried out, e.G. Default setting..

Page 32: Module

32 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor andremovedagainatanytime.Youcanchooseanyoneoffourdiffer...

Page 33

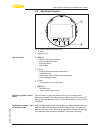

33 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 6.2 adjustment system 1 2 fig. 30: display and adjustment elements 1 lc display 2 adjustment keys • [ok] key: – move to the menu overview – confirmselectedmenu – edit parameter – save value • [->] key: – change...

Page 34

34 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 1 2 4 5 3 fig. 31: display and adjustment elements - with adjustment via magnetic pen 1 lc display 2 magnetic pen 3 adjustment keys 4 bluetooth symbol 5 lid with inspection window when the [+] and [->] keys are...

Page 35

35 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 in this menu item, you can select the national language for further parameterization. With the "[->]" button, you can select the requested language, with "ok"youconfirmtheselectionandmovetothemainmenu. You can ...

Page 36

36 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 diagnosis: information, e.G. On instrument status, pointer, measure- ment reliability, simulation additional adjustments: pin, date/time, reset, copy function info: instrument name, hardware and software versio...

Page 37

37 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 in this menu item, the adjustment units of the instrument are deter- mined. The selection determines the unit displayed in the menu items "min. Adjustment (zero)" and "max. Adjustment (span)". Unit of measureme...

Page 38

38 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 selected process variable correctly, an allocation of the output signal to 0 % and 100 % must be carried out (adjustment). With the application "level", the hydrostatic pressure, e.G. With full and empty vessel...

Page 39

39 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 3. Set the requested mbar value with [+] and store with [ok]. 4. Go with [esc] and [->] to the span adjustment thezeroadjustmentisfinished. Information: the zero adjustment shifts the value of the span adjustme...

Page 40

40 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 2. Edit the percentage value with [ok] and set the cursor to the requested position with [->]. 3. Set the requested percentage value (e.G. 10 %) with [+] and save with [ok]. The cursor jumps now to the pressure...

Page 41

41 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 caution: note the following, if the respective sensor is used as part of an over- fillprotectionsystemaccordingtowhg: if a linearisation curve is selected, the measuring signal is no longer necessarilylineartot...

Page 42

42 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 the following languages are available: • german • english • french • spanish • russian • italian • dutch • portuguese • japanese • chinese • polish • czech • turkish in the delivery status, the vegabar 82 is se...

Page 43

43 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 in case of error, e.G. The error code f017, e.G. The error description "adjustment span too small"andafourdigitfigurearedisplayedfor servicepurposes.Youcanfindtheerrorcodeswithdescription,rea- sonaswellasrectif...

Page 44

44 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 note: without manual deactivation, the sensor terminates the simulation automatically after 60 minutes. In this menu item, you adjust the internal clock of the sensor. There is no adjustment for summer/winter (...

Page 45

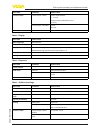

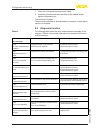

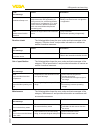

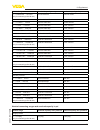

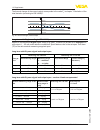

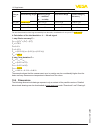

45 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 menu item parameter default value current output current output - mode output characteristics 4 … 20 ma reaction when malfunctions occur ≤3.6ma current output - min./max. 3.8 ma 20.5 ma lock adjustment released...

Page 46

46 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 the instrument settings are copied with this function. The following functions are available: • read from sensor: read data from sensor and save in the display and adjustment module • write to sensor: save data...

Page 47

47 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 in menu item "current output, variable" you specify which measured variable is outputted via the current output. The following selection is possible: • filling height • density • differentialpressure • static p...

Page 48

48 6 set up with the display and adjustment module vegabar 82 • 4 … 20 ma 45027-en-170522 in this menu item, the date of factory calibration of the sensor as well as the date of the last change of sensor parameters are displayed via the display and adjustment module or via the pc. In this menu item,...

Page 49: 7 Setup With Pactware

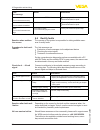

49 7 setup with pactware vegabar 82 • 4 … 20 ma 45027-en-170522 7 setup with pactware 7.1 connect the pc 3 1 2 fig. 33: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 3 sensor 7.2 parameter adjustment for parameter adjustme...

Page 50

50 7 setup with pactware vegabar 82 • 4 … 20 ma 45027-en-170522 fig. 34: example of a dtm view all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assistant...

Page 51

51 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 8 diagnostics and servicing 8.1 maintenance if the device is used properly, no special maintenance is required in normal operation. Insomeapplications,productbuilduponthediaphragmcaninfluence the measuring result. Depending on the...

Page 52

52 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 7. Insertnewo-ringsealfortheprocessfitting 8. Install the process pressure transmitter in the welded socket, tighten compression nut thecleaningisfinished. The pressure transmitter is directly ready for operation, a fresh adjust- ...

Page 53

53 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 code text message reason rectification f264 installation/setup error • inconsistent settings (e.G.: distance, adjustment units with application pro- cess pressure) for selected application • invalidsensorconfiguration(e.G.:appli- ...

Page 54

54 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 code text message reason rectification m502 error in the event memory • hardware error eeprom • exchanging the electronics • send instrument for repair m504 error at a device interface • hardware defect • exchanging the electronic...

Page 55

55 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 sinceweofferthisserviceworldwide,thesupportisprovidedin english. The service itself is free of charge, the only costs involved are the normal call charges. 8.5 exchange process assembly with version ip 68 (25 bar) with version ip ...

Page 56

56 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 3. Loosen the plug connector 4. Mount the new process assembly on the measuring point 5. Plug the connector back in 6. Mount the cable assembly on the process assembly and turn it to the desired position 7. Tightenthefixingscrewwi...

Page 57

57 8 diagnostics and servicing vegabar 82 • 4 … 20 ma 45027-en-170522 • printandfilloutoneformperinstrument • clean the instrument and pack it damage-proof • attach the completed form and, if need be, also a safety data sheet outside on the packaging • please contact the agency serving you to get th...

Page 58: 9 Dismount

58 9 dismount vegabar 82 • 4 … 20 ma 45027-en-170522 9 dismount 9.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" and "con...

Page 59: 10 Supplement

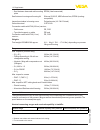

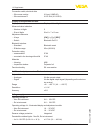

59 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 10 supplement 10.1 technical data note for approved instruments the technical data in the respective safety instructions are valid for approved instruments (e.G. With exapproval).Thesedatacandifferfromthedatalistedherein,forexampleregardingthep...

Page 60

60 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 Ʋ seal between base and wall mounting plate epdm(fixedconnected) seal between housing and housing lid silicone si 850 r, nbr silicone-free, epdm (coating- compatible) inspection window in housing cover polycarbonate (ul-746-c listed) ground ter...

Page 61

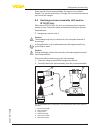

61 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 nominal range overload capacity, max. Pressure overload capacity, min. Pressure 0 … +0.025 bar/0 … +2.5 kpa (only for measuring cell ø 28 mm) +5 bar/+500 kpa -0.05 bar/-5 kpa 0 … +0.1 bar/0 … +10 kpa +15 bar/+1500 kpa -0.2 bar/-20 kpa 0 … +0.4 ...

Page 62

62 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 nominal range overload capacity, max. Pressure overload capacity, min. Pressure 0 … +1.5 psig +225 psig -2.901 psig 0 … +5 psig +375 psig -11.60 psig 0 … +15 psig +525 psig -14.51 psig 0 … +30 psig +600 psig -14.51 psig 0 … +75 psig +975 psig -...

Page 63

63 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 zero/span adjustment: Ʋ zero -20 … +95 % Ʋ span -120 … +120 % Ʋ differencebetweenzeroandspan max. 120 % of the nominal range max. Permissible turn down unlimited (recommended 20 : 1) switch-on phase run-up time approx. ≤5s starting current Ʋ fo...

Page 64

64 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar 82 vegabar 82 - ip 68 (25 bar) dead time ≤25ms ≤50ms rise time (10 … 90 %) ≤55ms ≤150ms step response time (ti: 0 s, 10 … 90 %) ≤80ms ≤200ms damping (63 % of the input variable) 0 … 999 s, adjustable referenceconditionsandinfluencingvar...

Page 65

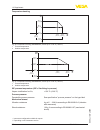

65 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 ( f tbasis fig. 38: basic temperature error f tbasis at td 1 : 1 the basic temperature error in % from the above graphic can increase due to the additional factors, depending on the measuring cell version (factor fmz) and the turn down (factor ...

Page 66

66 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 the thermal change of the current output corresponds to the value f a in chapter "calculation of the total deviation (according to din 16086)". 0,3 % -0,15 % -40°c -20°c 20°c 40°c 60°c 80°c 0,15 % -0,3 % fig. 39: thermal change, current output ...

Page 67

67 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 nominal measuring range in bar/ kpa nominal meas- uring range in psig measuring cell ø 28 mm measuring cell ø 17.5 mm 0 … 10 bar/0 … 1000 kpa 0 … 150 psig 0 … 25 bar/0 … 2500 kpa 0 … 350 psig 0 … 60 bar/0 … 6000 kpa 0 … 900 psig 0 … 100 bar/0 …...

Page 68

68 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 temperature derating 1 2 0 °c (32 °f) -40 °c (-104 °f) 55 °c (131 °f) 80 °c (176 °f) 130 °c (266 °f) 100 °c (212 °f) -40 °c (-104 °f) fig. 40: temperature derating vegabar 82, version up to +130 °c (+266 °f) 1 process temperature 2 ambient temp...

Page 69

69 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 electromechanical data - version ip 66/ip 67 and ip 66/ip 68 (0.2 bar) 9) options of the cable entry Ʋ cable entry m20 x 1.5, ½ npt Ʋ cable gland m20 x 1.5, ½ npt (cable ø see below table) Ʋ blind plug m20 x 1.5; ½ npt Ʋ closing cap ½ npt mater...

Page 70

70 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 connection cable, electrical data Ʋ wire cross-section 0.5 mm² (awg 20) Ʋ wire resistance r ´ 0.037Ω/m(0.012Ω/ft) display and adjustment module display element display with backlight measured value indication Ʋ number of digits 5 Ʋ sizeofdigits...

Page 71

71 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 Ʋ for u n 24 v dc (18 v b ≤1.0v eff (16…400hz) load resistor Ʋ calculation (u b - u min )/0.022 a Ʋ example - non-ex instrument with u b = 24 v dc (24v-9.6v)/0.022a=655Ω potential connections and electrical separating measures in the instrument...

Page 72

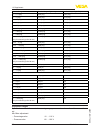

72 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 term stability f stab : f total = f perf + f stab the basic accuracy f perf consistsofthethermalchangeofthezerosignalandtheoutputspanf t as well as the deviation f kl : f perf =√((f t ) 2 + (f kl ) 2 ) thethermalchangeofzerosignalandoutputspanf...

Page 73

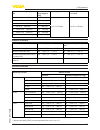

73 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 2. Determination temperature error f t 50 ( f tbasis fig. 42: determination of the basic temperature error for the above example: f tbasis = 0,15 % measuring cell version measuring cell standard, depending on the accuracy class 0.05 %, 0.1 % 0....

Page 74

74 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 time pe- riod measuring cell ø 28 mm measuring cell ø 17.5 mm all measuring ranges measuring range 0 … +0.025 bar (0 … +2.5 kpa) allprocessfittings processfittingg½ (iso 228-1) one year five years ten years tab. 26: determination of the long-te...

Page 75

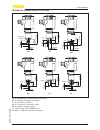

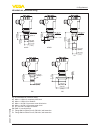

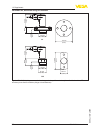

75 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 housing ~ 69 mm (2.72") ø 79 mm (3.11") 112 mm (4.41") m20x1,5/ ½ npt ~ 116 mm (4.57") 116 mm (4.57") m20x1,5 m20x1,5/ ½ npt ~ 69 mm (2.72") ø 79 mm (3.11") 117 mm (4.61") m20x1,5/ ½ npt ~ 59 mm (2.32") ø 80 mm (3.15") 112 mm (4.41") m20x1,5/ ½...

Page 76

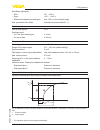

76 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 external housing on ip 68 version 1 2 3 4 5 82 mm (3.23") 80 mm (3.15") 108 mm (4.25") 41,6 mm (1.64") ~ 66 mm (2.60") 59 mm (2.32") 110 mm x 90 mm (4.33" x 3.54") 110 mm x 90 mm (4.33" x 3.54") 51 mm (2.01") 41,6 mm (1.64") fig. 44: vegabar 82...

Page 77

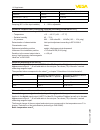

77 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar82,threadedfittingnotfront-flush dd lf du c2 dq di g½ g¼ g½ g¼ sw 27 mm (1.06") g½ 23 mm (0.91 ") 73 mm (2.87 ") 70 mm (2.76 ") 17 mm (0.67 ") 85 mm (3.35 ") 17 mm (0.67 ") 3 mm (0.12" ) 20 mm (0.79 ") 3 mm (0.12 ") 20 mm (0.79 ") 2 mm (...

Page 78

78 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar82,threadedfittingfront-flush n9 c3 22 mm (0.87") 44 mm (1.73") ø 24 mm (0.95") ø 27 mm (1.06") 21 mm (0.83") 45 mm (1.77") ø 18 mm (0.71") sw 36 mm (1.42") g¾ sw 27 mm (1.06") g½ c5 44 mm (1.73") 21 mm (0.83") ø 40 mm (1.58") ø 30 mm (1...

Page 79

79 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar82,hygienicfitting ar aa es fr ez/nb e3 50 mm (1.97") 51 mm (2.01") 51 mm (2.01") ø 78 mm (3.07") ø 92 mm (3.62") ø 92 mm (3.62") ø 84 mm (3.31") ø 48 mm (1.89") sw 46 mm (1.81") 51 mm (2.01") 60 mm (2.36") ø 64 mm (2.52 ") ø 78 mm (3.07...

Page 80

80 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar82,flangeconnection 3.46 " 4.02 " 5.43 " 0.12 " 0.12 " 0.12 " 4xø 0.71 " 4xø 0.71 " 8xø 0.71 " 4.33 " 4.92 " 6.30 " 5.91 " 6.50 " 7.87 " 0.71 " 0.79 " 0.95 " 5” 0.13 " 8xø 0.75 " 6 " 0.94 " 7.5 " dn mm pn d k b a8 40 40 150 18 110 b2 50 ...

Page 81

81 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar82,extensionfitting bs af/ag f9 45,5 mm (1.79") 51 mm (2.01") 6 mm (0.24") m 44 x 1,25 sw 46 mm (1.81") 21 mm (0.83") 52 mm (2.05") ø 27,4 mm (1.08") 29 mm (1.14") 48 mm (1.89") ø 25 mm (0.98") m30x1,5 al/ap sw 32 mm (1.26") ø 29,9 mm (1...

Page 82

82 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar82,extensionfittingforheadbox 43 mm (1.69") ø 48 mm (1.89") 23 mm (0.91") ø 48 mm (1.89") 23 mm (0.91") 50 mm (1.97") 115 mm (4.53") 115 mm (4.53") 84 mm (3.31") 43 mm (1.69") 84 mm (3.31") 50 mm (1.97") cl br fig. 50: vegabar 82, flange...

Page 83

83 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 vegabar 82, connection acc. To iec 61518 63,5 mm (2.50" ) 39 mm (1.54" ) 105 mm (4.13" ) 60 mm (2.36" ) 70 mm (2.76" ) 45 mm (1.77") 75 mm (2.95") 65 mm (2.56") 41 mm (1.63") 7/16 - 20 unf 1/4 - 18 npt 40 mm (1.57") sj sk fig. 51: vegabar 82, c...

Page 84

84 10 supplement vegabar 82 • 4 … 20 ma 45027-en-170522 10.5 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen unter...

Page 85: Index

85 index vegabar 82 • 4 … 20 ma 45027-en-170522 index a adjust date/time 44 adjustment 35, 39, 40 – process pressure 38, 39 – system 33 – unit 37 c change the language 41 check output signal 54 connection cable 24 connection procedure 25 connection technology 25 copy sensor settings 46 current outpu...

Page 86

86 notes vegabar 82 • 4 … 20 ma 45027-en-170522.

Page 87

87 notes vegabar 82 • 4 … 20 ma 45027-en-170522.

Page 88

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 45027-en-170522 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...