- DL manuals

- Vega

- Measuring Instruments

- VEGAPULS 66

- Operating Instructions Manual

Vega VEGAPULS 66 Operating Instructions Manual

Summary of VEGAPULS 66

Page 1

Operating instructions vegapuls 66 standpipe version foundation fieldbus.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 5 2 for your safety 2.1 authorised personnel. . . . . . . . ...

Page 3

6.6 saving the parameter adjustment data . . . . . . . 38 7 setup with pactware™ and other adjustment programs 7.1 connecting the pc . . . . . . . . . . . . . . . . . . . . . 39 7.2 parameter adjustment with pactware™. . . . . . 39 7.3 parameter adjustment with ams™ . . . . . . . . . . 40 7.4 saving...

Page 4

Supplementary operating instructions manuals information: vegapuls 66 is available in many versions and is therefore supplied according to customer order. Depending on the selected version, supplementary operating instructions man- uals also come with the delivery. You will find the supple- mentary o...

Page 5: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained, qualified personnel. The contents of t...

Page 6: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel a...

Page 7

- emission: class b - susceptibility: industrial areas l r & tte directive: i-ets 300-440 expert opinion no. 0043052-01/see, notified body no. 0499 l lvd: en 61010-1: 2002 2.6 fulfilling namur recommendations with regard to interference resistance and interference emission, vegapuls 66 fulfils namur re...

Page 8

L the instrument must be insensitive to interfering emis- sions, also to such that may cause unwanted operating conditions. Vegapuls 66 was tested and meets the limit values for a digital instrument of class b, according to part 15 of the fcc regulations. The limit values are for protection against ...

Page 9

L mount and operate the instrument in such a way that no danger of ignition from electrostatic charges is to be expected. The antenna, the process fitting or the housing (as the case may be depending on instrument version) are made of electrically non-conductive plastic. L make sure that the seal is ...

Page 10

L chapter "disposal" 10 vegapuls 66 standpipe version - foundation fieldbus for your safety 28744 -en -070201.

Page 11: 3 Product Description

3 product description 3.1 configuration the scope of delivery encompasses: l vegapuls 66 radar sensor l documentation - this operating instructions manual - operating instructions manual "indicating and adjust- ment module plicscom" (optional) - supplementary instructions manual "heating for indi- ca...

Page 12

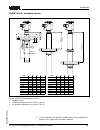

1 2 3 fig. 1: vegapuls 66 in flange version up to 150 °c with plastic housing 1 housing cover with integrated plicscom (optional) 2 housing with electronics 3 process fitting with standpipe antenna 3.2 principle of operation vegapuls 66 is a radar sensor in c-band (emitting frequency approx. 6 ghz) fo...

Page 13

For pressures up to 160 bar (2320 psi) and temperatures up to 400 °c (752 °f), the graphite seal and the ceramic antenna cone are available. The antenna of the radar sensor emits short radar pulses with a duration of approx. 1 ns. These pulses are reflected by the product and received by the antenna ...

Page 14

3.3 operation vegapuls 66 can be adjusted with different adjustment media: l with indicating and adjustment module l with the suitable vega dtm in conjunction with an adjustment software according to the fdt/dtm standard, e.G. Pactware™ and pc l a configuration tool the entered parameters are generall...

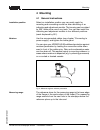

Page 15: 4 Mounting

4 mounting 4.1 general instructions select an installation position you can easily reach for mounting and connecting as well as later retrofitting of an indicating and adjustment module. The housing can be rotated by 330° without the use of any tools. You can also install the indicating and adjustmen...

Page 16

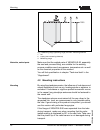

1 3 2 100% 0% fig. 3: measuring range (operating range) and max. Measuring distance 1 full 2 empty (max. Measuring distance) 3 measuring range make sure that the wetted parts of vegapuls 66, especially the seal and process fitting, are suitable for the existing process conditions such as pressure, te...

Page 17

1 2 fig. 4: polarisation marking 1 marking of the polarisation direction 2 vent hole ø 8 mm (0.3 in) do not mount the instruments in or above the filling stream. Fig. 5: inflowing liquid inflowing medium vegapuls 66 standpipe version - foundation fieldbus 17 mounting 28744 -en -070201.

Page 18

5 connecting to voltage supply 5.1 preparing the connection generally note the following safety instructions: l connect only in the complete absence of line voltage l if overvoltage surges are expected, overvoltage arresters should be installed according to foundation fieldbus specification in hazard...

Page 19

In systems without potential equalisation, connect the cable screen directly to ground potential at the power supply unit and at the sensor. In the connection box or t-distributor, the screen of the short stub to the sensor must not be connected to ground potential or to another cable screen. The ca...

Page 20

Fig. 6: connection steps 6 and 7 8 press down the opening levers of the terminals, you will hear the terminal spring closing 9 check the hold of the wires in the terminals by lightly pulling on them 10 connect the screen to the internal ground terminal and the external ground terminal to potential e...

Page 21

1 4 4 4 2 3 fig. 7: material versions, single chamber housing 1 plastic 2 aluminium 3 stainless steel 4 filter element for air pressure compensation of all material versions. Blind stopper with version ip 66/ip 68, 1 bar for aluminium and stainless steel i2c 3 4 5 1 2 display typ: 1 2 5 6 7 8 bus si...

Page 22

I2c display 1 1 2 5 6 7 8 fig. 9: wiring plan, single chamber housing 1 power supply/signal output 5.4 wiring plan, double chamber housing the following illustrations apply to the non-ex as well as to the ex ia version. 1 2 3 4 5 fig. 10: double chamber housing 1 housing cover, connection compartmen...

Page 23

I2c 2 3 1 display typ: 1 2 5 6 7 8 bus sim. Fig. 11: electronics compartment, double chamber housing 1 simulation switch ("on" = mode for simulation release) 2 connection for vegaconnect (i²c interface) 3 internal connection cable to the connection compartment 3 1 2 display 1 2 i²c fig. 12: connecti...

Page 24

I2c 1 1 2 fig. 13: wiring plan, double chamber housing 1 power supply/signal output 5.5 wiring plan, double chamber housing exd information: instruments in exd version with hardware revision …- 01 or higher as well as with national approvals such as e.G. According to fm or csa at a later date. 1 2 3...

Page 25

I2c 2 3 1 display typ: 1 2 5 6 7 8 bus sim. Fig. 15: electronics compartment, double chamber housing 1 simulation switch ("on" = mode for simulation release) 2 connection for vegaconnect (i²c interface) 3 internal connection cable to the connection compartment 1 2 1 2 fig. 16: connection compartment...

Page 26

1 1 2 fig. 17: wiring plan, double chamber housing exd 1 power supply/signal output 5.6 wiring plan, version ip 66/ip 68, 1 bar + - 1 2 fig. 18: wire assignment, connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 screen 5.7 switch-on phase after vegapuls 66 is co...

Page 27: Adjustment Module Plicscom

6 setup with the indicating and adjustment module plicscom 6.1 short description the indicating and adjustment module is used for measured value display, adjustment and diagnosis. It can be mounted in the following housing versions and instruments: l all sensors of the plics ® instrument family, in ...

Page 28

4 screw housing cover with inspection window tightly back on removal is carried out in reverse order. The indicating/adjustment module is powered by the sensor, an additional connection is not necessary. Fig. 19: installation of the indicating and adjustment module note: if you intend to retrofit veg...

Page 29

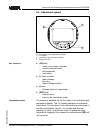

6.3 adjustment system 1.1 2 3 1 fig. 20: indicating and adjustment elements 1 lc display 2 indication of the menu item number 3 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key to select: - menu change - list entry - select editi...

Page 30

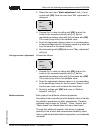

6.4 setup procedure as vegapuls 66 is a distance measuring instrument, the distance from the sensor to the product surface is measured. To have the real product level displayed, an allocation of the measured distance to the percentage height must be made. To carry out this adjustment, the distance i...

Page 31

2 select the menu item "basic adjustment" with [->] and confirm with [ok]. Now the menu item "min. Adjustment" is displayed. Min. Adjustment 0.00 % = 5,000 m(d) 4,000 m(d) 3 prepare the % value for editing with [ok] and set the cursor to the requested position with [->]. Set the requested percentage ...

Page 32

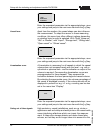

Medium liquid water based acids/bases enter the requested parameter via the appropriate keys, save your settings and jump to the next menu item with the [->] key. Apart from the medium, the vessel shape can also influence the measurement. To adapt the sensor to these measuring conditions, this menu i...

Page 33

Level measurement. A false echo memory should be created with empty vessel so that all potential interfering reflections will be detected. Gating out of false signals change now? Proceed as follows: 1 move from the measured value display to the main menu by pushing [ok]. 2 select the menu item "servi...

Page 34

This function enables reading out parameter adjustment data as well as writing parameter adjustment data into the sensor via the indicating and adjustment module. A description of the function is available in the operating instructions manual "indicating and adjustment module". The following data ar...

Page 35

Extended settings keine unit of measurement m(d) the values of the following functions are not reset to the reset values (see chart) with "reset": function reset value language no reset factory setting like basic setting, in addition special parameters are reset to default values. 6) pointer the min...

Page 36

6.5 menu schematic information: depending on the version and application, the highlighted menu windows are not always available. Basic adjustment 1 ▶ basic adjustment indication diagnostics service info 1.1 min. Adjustment 0.00 % = 10,000 m(d) 8,000 m(d) 1.2 min. Adjustment 100.00 % = 1,000 m(d) 2,0...

Page 37

3.1 pointer distance min.: 0.234 m(d) distance max.: 5.385 m(d) 3.2 meas. Reliability 8 db sensor status ok 3.3 curve selection echo curve 3.4 echo curve presentation of the echo curve service 4 basic adjustment indication diagnostics ▶ service info 4.1 gating out of false signals change now? 4.2 ex...

Page 38

6.6 saving the parameter adjustment data it is recommended noting the adjusted data, e.G. In this operating instructions manual and archive them afterwards. They are hence available for multiple use or service purposes. If vegapuls 66 is equipped with an indicating and adjust- ment module, the most ...

Page 39: Adjustment Programs

7 setup with pactware™ and other adjustment programs 7.1 connecting the pc ~ = power supply vegaconnect 3 pactware / tm >pa 2 3 1 fig. 21: connection directly to the sensor 1 rs232 connection 2 vegapuls 66 3 i²c adapter cable for vegaconnect 3 necessary components: l vegapuls 66 l pc with pactware™ ...

Page 40

All currently available vega dtms are provided in the dtm collection on cd and can be obtained from the responsible vega agency for a token fee. This cd includes also the up-to- date pactware™ version. The basic version of this dtm collection incl. Pactware™ is also available as a free-of- charge do...

Page 41

8 maintenance and fault rectification 8.1 maintenance when used as directed in normal operation, vegapuls 66 is completely maintenance free. 8.2 remove interferences vegapuls 66 offers maximum reliability. Nevertheless faults can occur during operation. These may be caused by the following, e.G.: l se...

Page 42

? Instrument does not appear during connection setup l incorrect termination à check termination at the beginning and end points of the bus and terminate, if necessary, according to the specification l instrument not connected to the segment à check and correct in ex applications, the regulations for...

Page 43

8.3 exchange of the electronics module if the electronics module is defective, it can be replaced by the user. In ex applications, only an instrument and an electronics module with appropriate ex approval may be used. If there is no electronics module available on site, one can be ordered from the v...

Page 44

L clean the instrument and pack it damage-proof l attach the filled in form and if necessary, a safety data sheet to the instrument l please ask the agency serving you for the address of your return shipment. You find the respective agency on our website www.Vega.Com under: "company - vega world- wide...

Page 45: 9 Dismounting

9 dismounting 9.1 dismounting steps warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of chapters "mounting" and "connecting to power supply" and carry out the listed steps in rev...

Page 46: 10 Supplement

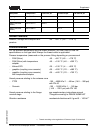

10 supplement 10.1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, wetted parts - process fitting 316l, hastelloy c22 plated - antenna 316l, hastelloy c22 - antenna cone ptfe (tfm 1600), ceramic (99.7 % al 2 o 3 ) - seal, antenna system fkm (viton), kalrez 6375, fep fkm (v...

Page 47

Input variable parameter distance between lower edge of the sensor flange and product surface min. Distance 0 mm measuring range up to 5.85 m 7) reference conditions to measuring accuracy (similar to din en 60770-1) reference conditions according to din en 61298-1 - temperature +18 … +30 °c (+64 … +8...

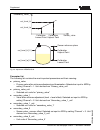

Page 48

0,5 m 5,85 m 20 mm 5 mm -5 mm -20 mm fig. 22: accuracy vegapuls 66 in mm relating to the measuring range in m 1.640 ft 19.19 ft 0.788 in 0.197 in - 0.197 in - 0.788 in fig. 23: accuracy vegapuls 66 in inch relating to the measuring range in ft influence of the ambient temperature to the sensor electr...

Page 49

Gas phase temperature 1 bar/14.5 psi 10 bar/145 psi 50 bar/725 psi hydrogen 20 °c/68 °f -0.01 % 0.10 % 0.61 % hydrogen 200 °c/392 °f -0.02 % 0.05 % 0.37 % water (saturated steam) 100 °c/212 °f 0.20 % - - water (saturated steam) 180 °c/356 °f - 2.1 % - ambient conditions ambient, storage and transpor...

Page 50

Electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 12) - single chamber housing l 1x cable entry m20x1.5 (cable-ø 5 … 9 mm), 1x blind stopper m20x1.5 or: l 1x cloasing cap m20x1.5, 1x blind stopper m20x1.5 or: l 1x closing cap ½ npt, 1x blind plug ½ npt or: l 1x p...

Page 51

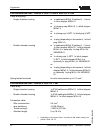

- max. Length 1000 m (3280 ft) - min. Bending radius 25 mm (1 in) at 25 °c (77 °f) - diameter approx. 8 mm - colour - standard pe black - colour - standard pur blue - colour - ex-version blue indicating and adjustment module power supply and data transmission through sensor via gold-plated sliding c...

Page 52

Overvoltage category iii protection class ii approvals 14)15) atex ia atex ii 1g, 1/2g, 2g eex ia iic t6 atex d atex ii 1/2d ip6x t atex ia + d atex ii 1g, 1/2g, 2g eex ia iic t5 + atex ii 1/ 2d ip6x t6 atex d atex ii 1/2g, 2g eexd ia iic t6 atex d + d atex ii 1/2g, 2g eexd ia iic t5 + atex ii 1/ 2d...

Page 53

10.2 foundation fieldbus block diagram, measured value processing the following illustration shows the transducer block and function block in simplified form. T i sim ulate alarm s out pv field-value mode & s tatus pvf-time lo w -cut off l-type out -scal e pv -scale direct indirect indirect sqrt m(d)...

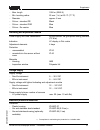

Page 54

Secondary_value_1 calibration lowest point calibration highest point sensor_value cal_level_lo cal_level_hi calibration lowest point calibration highest point sensor reference plane cal_level_lo [%] cal_level_hi [%] fig. 25: adjustment vegapuls 66 parameter list the following list contains the most ...

Page 55

L sensor_value - raw sensor value, i.E. The uncalibrated measurement value from the sensor. Unit derives from 'sensor_range.Unit' l sensor_range - sensor_range.Unit' refers to 'sensor_value', 'max/min_peak_sensor_value', 'cal_poin- t_hi/lo' l simulate_primary_value l simulate_secondary_value_1 l sim...

Page 56

- min./max-adjustment: level at 'cal_point_hi'. When writing 'cal_level_hi' and 'cal_type' = 1 (online) the 'cal_point_hi' is automatically set to the current sensor value. The unit is defined in 'level_unit' l cal_level_lo - min./max.-adjustment: level at 'cal_point_lo'. When writing 'cal_level_lo' ...

Page 57

L first_echo_factor - set up to suit the process conditions. L pulse_velocity_correction - set up to suit the process conditions. L echo_quality - signal/noise ratio l empty_vessel_curve_corr_dist - distance from the sensor to the product surface. Unit derives from 'sensor_range.Unit' l empty_vessel_...

Page 58

10.3 dimensions housing in protection ip 66/ip67 and ip 66/ip 68; 0.2 bar 112mm (4 13 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") 120mm (4 23 / 32 ") ~ 69mm (2 23 / 32 ") ø 77mm (3 1 / 32 ") ~ 69mm (2 23 / 32 ") ~ 116mm (4 9 / 16 ") ~ 87mm (3 27 / 64 ") ø 77mm (3 1 / 32 ") ø 84mm (3 5 / 16 ") ø 8...

Page 59

Vegapuls 66, standpipe version 7 7 / 8 " 1 1 / 32 " 1 3 / 16 " 1 1 / 8 " 8 21 / 32 " 11 7 / 32 " 13 25 / 64 " 15 15 / 16 " 7 1 / 2 " 13 1 / 2 " 6 19 / 64 " 7 3 / 32 " 11 3 / 4 " 14 1 / 4 " 7 1 / 2 " 9 1 / 2 " 9 29 / 64 " 11 39 / 64 " 13 31 / 32 " 6" 9" 11" 16" 1" 15 / 16 " 25 / 32 " 55 / 64 " 15 / 1...

Page 60

10.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte....

Page 61

Supplement vegapuls 66 standpipe version - foundation fieldbus 61 28744 -en -070201.

Page 62

Supplement 62 vegapuls 66 standpipe version - foundation fieldbus 28744 -en -070201.

Page 63

Supplement vegapuls 66 standpipe version - foundation fieldbus 63 28744 -en -070201.

Page 64

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...