- DL manuals

- Vega

- Measuring Instruments

- VEGAPULS 66

- Operating Instructions Manual

Vega VEGAPULS 66 Operating Instructions Manual

Summary of VEGAPULS 66

Page 1

Operating instructions radar sensor for continuous level measurement of liquids vegapuls 66 profibus pa standpipe version document id: 36525.

Page 2: Contents

2 contents vegapuls 66 • profibus pa 36525-en-160224 contents 1 about this document 1.1 function ........................................................................................................................... 4 1.2 target group ...............................................................

Page 3

3 contents vegapuls 66 • profibus pa 36525-en-160224 9.1 maintenance .................................................................................................................. 49 9.2 measured value and event memory ................................................................................

Page 4: 1 About This Document

4 1 about this document vegapuls 66 • profibus pa 36525-en-160224 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup as well as important instruc- tions for maintenance and fault rectification. Please read th...

Page 5: 2 For Your Safety

5 2 for your safety vegapuls 66 • profibus pa 36525-en-160224 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the re...

Page 6

6 2 for your safety vegapuls 66 • profibus pa 36525-en-160224 2.5 ce conformity the device fulfills the legal requirements of the applicable ec guide- lines. By affixing the ce marking, we confirm successful testing of the product. You can find the ce certificate of conformity in the download sectio...

Page 7

7 2 for your safety vegapuls 66 • profibus pa 36525-en-160224 2.8 radio license for usa/canada the instrument is in conformity with part 15 of the fcc regulations. Take note of the following two regulations: • this device may not cause interference, and • the device must be resistant to interference...

Page 8: 3 Product Description

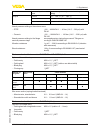

8 3 product description vegapuls 66 • profibus pa 36525-en-160224 3 product description 3.1 configuration the type label contains the most important data for identification and use of the instrument: 2 1 15 13 14 12 11 5 3 6 4 7 8 10 9 fig. 1: layout of the type label (example) 1 instrument type 2 p...

Page 9

9 3 product description vegapuls 66 • profibus pa 36525-en-160224 this operating instructions manual applies to the following instrument versions: • hardware from 2.1.1 • software from 4.5.0 the scope of delivery encompasses: • radar sensor • documentation – quick setup guide vegapuls 66 – instructi...

Page 10

10 3 product description vegapuls 66 • profibus pa 36525-en-160224 foil is also used. Dispose of the packaging material via specialised recycling companies. Transport must be carried out in due consideration of the notes on the transport packaging. Nonobservance of these instructions can cause damag...

Page 11

11 3 product description vegapuls 66 • profibus pa 36525-en-160224 you can find further information in the supplementary instructions "adapter disadapt" (document-id 45250). Plicsmobile t61 is an external gsm/gprs radio unit for transmis- sion of measured values and for remote parameter adjustment o...

Page 12: 4 Mounting

12 4 mounting vegapuls 66 • profibus pa 36525-en-160224 4 mounting 4.1 general instructions on instruments with threaded process fitting, the hexagon must be tightened with a suitable wrench. For the proper wrench size see chapter "dimensions". Warning: the housing must not be used to screw the inst...

Page 13

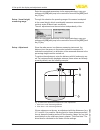

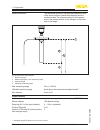

13 4 mounting vegapuls 66 • profibus pa 36525-en-160224 prior to setup you have to replace these protective caps with ap- proved cable glands or close the openings with suitable blind plugs. 4.2 mounting instructions by using the standpipe version, the influence of turbulence and ves- sel installati...

Page 14

14 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 5 connecting to the bus system 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carri...

Page 15

15 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 keep in mind that the cable screening and grounding must be carried out according to the fieldbus specification. In systems with potential equalisation, connect the cable screen directly to ground potential at the power supp...

Page 16

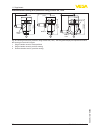

16 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 fig. 2: connection steps 5 and 6 - single chamber housing fig. 3: connection steps 5 and 6 - double chamber housing 6. Insert the wire ends into the terminals according to the wiring plan information: solid cores as well as ...

Page 17

17 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 9. Tighten the compression nut of the cable entry gland. The seal ring must completely encircle the cable 10. Reinsert the display and adjustment module, if one was installed 11. Screw the housing lid back on the electrical ...

Page 18

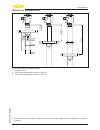

18 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 bus 5 1 2 + ( ) (-) 6 7 8 2 3 4 1 fig. 6: terminal compartment, double chamber housing 1 voltage supply, signal output 2 for display and adjustment module or interface adapter 3 for external display and adjustment unit 4 gro...

Page 19

19 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 5.5 wiring plan, double chamber housing ex d ia 4 1 5 0 0 5 1 6 2 7 3 8 4 9 0 5 1 6 2 7 3 8 4 9 1 0 1 6 7 8 bus 2 3 1 2 + ( ) (-) fig. 8: electronics compartment, double chamber housing ex d ia 1 internal connection to the t...

Page 20

20 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 contact pin colour connection ca- ble in the sensor terminal, electronics module pin 2 white 6 pin 3 blue 7 pin 4 black 8 5.6 double chamber housing with dis-adapt 3 1 2 fig. 11: view to the electronics compartment with disa...

Page 21

21 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 5.7 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 13: wire assignment in permanently connected connection cable 1 brown (+) and blue (-) to power supply or to the processing system 2 shielding 5.8 set instrument address ...

Page 22

22 5 connecting to the bus system vegapuls 66 • profibus pa 36525-en-160224 software addressing is only effective if address 126 or higher is set on the instrument with the address selection switches. The addressing procedure is described in the operating instructions manual "display and adjustment ...

Page 23: Module

23 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 6 set up with the display and adjustment module 6.1 insert display and adjustment module the display and adjustment module can be inserted into the sensor and removed again at any time. You can choose any on...

Page 24

24 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 1 2 fig. 16: installing the display and adjustment module in the double chamber housing 1 in the electronics compartment 2 in the terminal compartment note: if you intend to retrofit the instrument with a di...

Page 25

25 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 – move to the menu overview – confirm selected menu – edit parameter – save value • [->] key: – presentation, change measured value – select list entry – select menu items in the quick setup – select editing...

Page 26

26 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 this menu item is used to select the national language for further pa- rameter adjustment. You can change the selection via the menu item "setup - display, menu language". With the "ok" key you move to the m...

Page 27

27 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 each medium has different reflection properties. With liquids, further interfering factors are fluctuation product surface and foam genera- tion. With bulk solids, these are dust generation, material cone an...

Page 28

28 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 the following features form the basis of the applications: storage tank: • setup: large-volumed, upright cylindrical, spherical • product speed: slow filling and emptying • process/measurement conditions: – ...

Page 29

29 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 – fast to slow filling possible – vessel is filled and emptied very often • vessel: – socket available – large agitator blades of metal – vortex breakers, heating spirals • process/measurement conditions: – ...

Page 30

30 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 – buildup – separation of oil and water possible – overfilling into the antenna possible • properties, sensor: – measurement speed optimized through little averaging – entering the tube inside diameter takes...

Page 31

31 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 – spiders and insects build nests in the antennas – smooth water surface – exact measurement result required – distance to the water surface normally relatively large • properties, sensor: – stable and relia...

Page 32

32 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 enter the requested parameters via the appropriate keys, save your settings with [ok] and jump to the next menu item with the [esc] and the [->] key. Through this selection the operating range of the sensor ...

Page 33

33 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 the actual product level during this adjustment is not important, because the min./max. Adjustment is always carried out without changing the product level. These settings can be made ahead of time without t...

Page 34

34 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 4. Enter the appropriate distance value in m (corresponding to the percentage value) for the full vessel. Keep in mind that the max. Level must lie below the min. Distance to the antenna edge. 5. Save settin...

Page 35

35 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 to damp process-dependent measured value fluctuations, set an integration time of 0 … 999 s in this menu item. Depending on the sensor type, the factory setting is 0 s or 1 s. In this menu item, the pin is a...

Page 36

36 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 in the delivery status, the sensor is set to the ordered national lan- guage. In the menu item "display" you can define which measured value should be presented on the display. The sensor delivers the follow...

Page 37

37 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 when non-contact level sensors are used, the measurement can be influenced by the respective process conditions. In this menu item, the measurement reliability of the level echo is displayed as db value. The...

Page 38

38 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 the "echo curve" shows the signal strength of the echoes over the measuring range in db. The signal strength enables an evaluation of the quality of the measurement. The "false signal suppression" displays t...

Page 39

39 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 the following circumstances cause interfering reflections and can influence the measurement: • high sockets • vessel internals such as struts • agitators • buildup or welded joints on vessel walls note: a fa...

Page 40

40 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 note: check the distance to the product surface, because if an incorrect (too large) value is entered, the existing level will be saved as a false signal. The level would then no longer be detectable in this...

Page 41

41 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 only be assigned once in the profibus pa network. The sensor is only recognized by the control system if the address is set correctly. When the instrument is shipped, address 126 is set. This address can be ...

Page 42

42 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 the following reset functions are available: • delivery status: restoring the parameter settings at the time of shipment from the factory incl. The order-specific settings. A cre- ated false signal suppressi...

Page 43

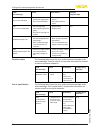

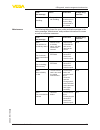

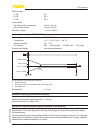

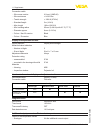

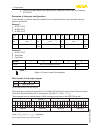

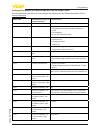

43 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 menu menu item default value setup measurement loop name sensor medium liquid/water bulk solids/crushed stones, gravel application storage tank silo vessel form vessel bottom, dished form vessel top, dished ...

Page 44

44 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 the copied data are permanently saved in an eeprom memory in the display and adjustment module and remain there even in case of power failure. From there, they can be written into one or more sen- sors or ke...

Page 45

45 6 set up with the display and adjustment module vegapuls 66 • profibus pa 36525-en-160224 6.5 saving the parameter adjustment data we recommended noting the adjusted data, e.G. In this operating instructions manual, and archiving them afterwards. They are thus available for multiple use or servic...

Page 46: 7 Setup With Pactware

46 7 setup with pactware vegapuls 66 • profibus pa 36525-en-160224 7 setup with pactware 7.1 connect the pc 3 1 2 fig. 19: connection of the pc directly to the sensor via the interface adapter 1 usb cable to the pc 2 interface adapter vegaconnect 3 sensor 7.2 parameter adjustment for parameter adjus...

Page 47

47 7 setup with pactware vegapuls 66 • profibus pa 36525-en-160224 fig. 20: example of a dtm view all device dtms are available as a free-of-charge standard version and as a full version that must be purchased. In the standard version, all functions for complete setup are already included. An assist...

Page 48

48 8 set up with other systems vegapuls 66 • profibus pa 36525-en-160224 8 set up with other systems 8.1 dd adjustment programs device descriptions as enhanced device description (edd) are available for dd adjustment programs such as, for example, ams™ and pdm. The files can be downloaded at www.Veg...

Page 49

49 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 9 diagnosis, asset management and service 9.1 maintenance if the instrument is used correctly, no maintenance is required in normal operation. 9.2 measured value and event memory the instrument has several memorie...

Page 50

50 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 further echo curves: up to 10 echo curves can be stored in a ring buffer in this memory section. Further echo curves are stored via: • pc with pactware/dtm • control system with edd 9.3 asset management function t...

Page 51

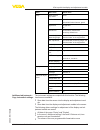

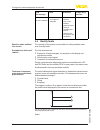

51 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 the following table shows the codes and text messages of the status message "failure" and provides information on causes as well as corrective measures. Code text message cause rectification devspec diagnosis bits...

Page 52

52 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 code text message cause rectification devspec diagnosis bits f260 error in the calibration – error in the calibration carried out in the factory – error in the eeprom – exchanging the elec- tronics – send instrume...

Page 53

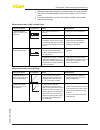

53 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 code text message cause rectification devspec diag- nosis bits s601 overfilling – danger of ves- sel overfilling – make sure that there is no further filling – check level in the vessel bit 20 the following table ...

Page 54

54 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 code text message cause rectification devspec diag- nosis bits m505 no echo available – level echo can no longer be detected – clean the antenna – use a more suitable antenna/sensor – remove possible false echoes ...

Page 55

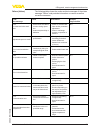

55 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 • whenever the sensor displays a constant value, the reason could also be that the fault setting of the current output is set to "hold value" • if the level indication is too low, the reason could be a line resist...

Page 56

56 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 measurement error during emptying fault description error pattern cause rectification 5. Measured value re- mains unchanged in the close range during emptying level time 0 – false signal larger than the level echo...

Page 57

57 9 diagnosis, asset management and service vegapuls 66 • profibus pa 36525-en-160224 caution: all user-specific settings must be entered again. Hence, you have to carry out a new setup after the electronics exchange. If you have stored the data of the parameter adjustment during the first setup of...

Page 58: 10 Dismount

58 10 dismount vegapuls 66 • profibus pa 36525-en-160224 10 dismount 10.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor- rosive or toxic products etc. Take note of chapters "mounting" an...

Page 59: 11 Supplement

59 11 supplement vegapuls 66 • profibus pa 36525-en-160224 11 supplement 11.1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, wetted parts Ʋ process fitting 316l, alloy c22 (2.4602), alloy 400 (2.4360) Ʋ process seal on site Ʋ antenna 316l, alloy c22 (2.4602) Ʋ antenna im...

Page 60

60 11 supplement vegapuls 66 • profibus pa 36525-en-160224 input variable measured variable the measured quantity is the distance between the end of the sensor antenna (inside the standpipe) and the product surface. The reference plane for the measure- ment is the sealing surface on the hexagon or t...

Page 61

61 11 supplement vegapuls 66 • profibus pa 36525-en-160224 default values Ʋ 1. Fb pv Ʋ 2. Fb sv 1 Ʋ 3. Fb sv 2 current value Ʋ non-ex and ex ia instrument 10 ma, ±0.5 ma Ʋ ex-d-ia instruments 16 ma, ±0.5 ma resolution, digital accuracy (according to din en 60770-1) process reference conditions accor...

Page 62

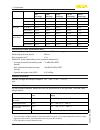

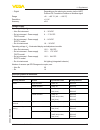

62 11 supplement vegapuls 66 • profibus pa 36525-en-160224 gas phase temperature pressure 1 bar (14.5 psig) 10 bar (145 psig) 50 bar (725 psig) 100 bar (1450 psig) 200 bar (2900 psig) air 20 °c/68 °f 0.00 % 0.22 % 1.2 % 2.4 % 4.9 % 200 °c/392 °f -0.01 % 0.13 % 0.74 % 1.5 % 3.0 % 400 °c/752 °f -0.02 ...

Page 63

63 11 supplement vegapuls 66 • profibus pa 36525-en-160224 seal antenna impedance cone process temperature (measured on the process fitting) graphite ceramic -60 … +250 °c (-76 … +482 °f) ceramic -60 … +300 °c (-76 … +572 °f) ceramic -60 … +400 °c (-76 … +752 °f) vessel pressure relating to the ante...

Page 64

64 11 supplement vegapuls 66 • profibus pa 36525-en-160224 connection cable Ʋ wire cross-section 0.5 mm² (awg 20) Ʋ wire resistance Ʋ tensile strength Ʋ standard length 5 m (16.4 ft) Ʋ max. Length 180 m (590.6 ft) Ʋ min. Bending radius 25 mm (0.984 in) with 25 °c (77 °f) Ʋ diameter approx. 8 mm (0.3...

Page 65

65 11 supplement vegapuls 66 • profibus pa 36525-en-160224 Ʋ digital depending on the electronics version via the hart, profibus pa, foundation fieldbus or modbus signal range -40 … +85 °c (-40 … +185 °f) resolution accuracy ±3 k voltage supply operating voltage u b Ʋ non-ex instrument 9 … 32 v dc Ʋ...

Page 66

66 11 supplement vegapuls 66 • profibus pa 36525-en-160224 protection rating (iec 61010-1) iii approvals instruments with approvals can have different technical specifications depending on the version. For that reason the associated approval documents of these instruments have to be carefully noted....

Page 67

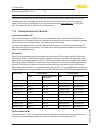

67 11 supplement vegapuls 66 • profibus pa 36525-en-160224 fig. 31: vegapuls 66: block diagram with ai fb 1 … ai fb 3 out values tb transducer block fb 1 … fb 3 function block module of the pa sensors for the cyclic data traffic, vegapuls 66 provides the following modules: • ai fb1 (out) – out value...

Page 68

68 11 supplement vegapuls 66 • profibus pa 36525-en-160224 • long for profibus master only supporting the "identifier format" byte, e.G. Siemens s7-300/400 examplesoftelegramconfiguration in the following you will see how the modules can be combined and how the appendant data tel- egram is structure...

Page 69

69 11 supplement vegapuls 66 • profibus pa 36525-en-160224 coding of the status byte associated with the pa output value you can find further information for the coding of the status byte in the device description 3.02 on www.Profibus.Com. Status code description according to profibusstandard possib...

Page 70

70 11 supplement vegapuls 66 • profibus pa 36525-en-160224 11.3 dimensions the following dimensional drawings represent only an extract of all possible versions. Detailed dimensional drawings can be downloaded at www.Vega.Com/downloads under "drawings". Plastic housing ~ 69 mm (2.72") ø 79 mm (3.11"...

Page 71

71 11 supplement vegapuls 66 • profibus pa 36525-en-160224 aluminium housing with protection rating ip 66/ip 68 (1 bar) 120 mm (4.72") ~ 105 mm (4.13") 116 mm (4.57") ~ 150 mm (5.91") ø 86 mm (3.39") ø 86 mm (3.39") m20x1,5/ ½ npt m16x1,5 2 m20x1,5 m20x1,5 1 fig. 36: housing version with protection ...

Page 72

72 11 supplement vegapuls 66 • profibus pa 36525-en-160224 stainless steel housing with protection rating ip 66/ip 68, 1 bar 117 mm (4.61") ~ 103 mm (4.06") ø 79 mm (3.11") 120 mm (4.72") ~ 105 mm (4.13") ø 86 mm (3.39") m20x1,5 m20x1,5/ ½ npt m16x1,5 ~ 93 mm (3.66") ø 80 mm (3.15") 112 mm (4.41") m...

Page 73

73 11 supplement vegapuls 66 • profibus pa 36525-en-160224 vegapuls 66, standpipe version l ø 52 mm (2.05") ø 8 mm (0.32") ø 56 mm (2.21") 47 mm (1.85") 60 mm (2.36") 180 mm (7.09") 317 mm (12.48") 2 3 1 fig. 39: vegapuls 66, standpipe version 4) 1 standard version 2 for process temperatures up to 2...

Page 74

74 11 supplement vegapuls 66 • profibus pa 36525-en-160224 11.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen un...

Page 75: Index

75 index vegapuls 66 • profibus pa 36525-en-160224 index a adjustment 32, 33 c channel 34 connection 15 copy sensor settings 43 cyclical data traffic 66 d damping 35 data format, output signal 68 date/time 41 deviation 54 displayed value 36 e echo curve – memory 49 – of the setup 38 edd (enhanced de...

Page 76

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 36525-en-160224 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...