- DL manuals

- Vega

- Measuring Instruments

- VEGAPULS 66

- Operating Instructions Manual

Vega VEGAPULS 66 Operating Instructions Manual

Summary of VEGAPULS 66

Page 1

Operating instructions vegapuls 66 profibus pa enamelled version document id: 33335.

Page 2: Contents

2 contents vegapuls 66 • profibus pa 33335-en-170927 contents 1 about this document ............................................................................................................... 4 1.1 function ............................................................................................

Page 3

3 contents vegapuls 66 • profibus pa 33335-en-170927 8.1 maintenance .................................................................................................................. 50 8.2 rectify faults .................................................................................................

Page 4: 1 About This Document

4 1 about this document vegapuls 66 • profibus pa 33335-en-170927 1 about this document 1.1 function this operating instructions manual provides all the information you need for mounting, connection and setup of the instrument. Further - more there are important instructions for maintenance, fault r...

Page 5: 2 For Your Safety

5 2 for your safety vegapuls 66 • profibus pa 33335-en-170927 2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator. During work on and with the device the re...

Page 6

6 2 for your safety vegapuls 66 • profibus pa 33335-en-170927 during the entire duration of use, the user is obliged to determine the compliance of the necessary occupational safety measures with the current valid rules and regulations and also take note of new regula - tions. To avoid any danger, t...

Page 7

7 2 for your safety vegapuls 66 • profibus pa 33335-en-170927 • ic: 3892a-ps6566 modifications not expressly approved by vega will lead to expiry of the operating licence according to fcc. Vegapuls 66 is in conformity with part 15 of the fcc regulations. Take note of the respective operating regulat...

Page 8: 3 Product Description

8 3 product description vegapuls 66 • profibus pa 33335-en-170927 3 product description 3.1 configuration the scope of delivery encompasses: • radar sensor • documentation – quick setup guide vegapuls 66 – instructions for optional instrument features – ex-specific " safety instructions " (with ex v...

Page 9

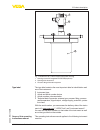

9 3 product description vegapuls 66 • profibus pa 33335-en-170927 3 2 1 fig. 1: vegapuls 66 - enamel version with plastic housing 1 housing cover with integrated plicscom (optional) 2 housing with electronics 3 process fitting with antenna system the type label contains the most important data for i...

Page 10

10 3 product description vegapuls 66 • profibus pa 33335-en-170927 • hardware version ≤ 1.10 • software version ≤ 3.90 3.2 principle of operation vegapuls 66 is a radar sensor in c-band technology for continuous level measurement. The version with enamelled antenna is particularly suitable for measu...

Page 11

11 3 product description vegapuls 66 • profibus pa 33335-en-170927 transport must be carried out in due consideration of the notes on the transport packaging. Nonobservance of these instructions can cause damage to the device. The delivery must be checked for completeness and possible transit damage...

Page 12

12 3 product description vegapuls 66 • profibus pa 33335-en-170927 sensors. Adjustment is carried out via pactware/dtm and the inte - grated usb connection. You can find further information in the supplementary instructions " plicsmobile t61 " (document-id 37700). The protective cover protects the s...

Page 13: 4 Mounting

13 4 mounting vegapuls 66 • profibus pa 33335-en-170927 4 mounting 4.1 general instructions select an installation position you can easily reach for mounting and connecting as well as later retrofitting of a display and adjustment module. The housing can be rotated by 330° without the use of any too...

Page 14

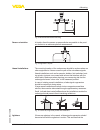

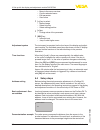

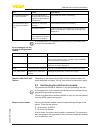

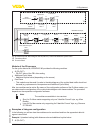

14 4 mounting vegapuls 66 • profibus pa 33335-en-170927 1 3 2 100% 0% 4 fig. 3: measuring range (operating range) and max. Measuring distance 1 full 2 empty (max. Measuring distance) 3 measuring range 4 reference plane information: if the medium reaches the antenna, buildup can form on it and cause ...

Page 15

15 4 mounting vegapuls 66 • profibus pa 33335-en-170927 as process pressure, process temperature as well as the chemical properties of the medium. You can find the specifications in chapter " technical data " and on the nameplate. The instrument is suitable for standard and extended ambient condi - ...

Page 16

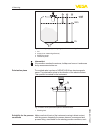

16 4 mounting vegapuls 66 • profibus pa 33335-en-170927 fig. 6: vessel with conical bottom do not mount the instruments in or above the filling stream. Make sure that you detect the product surface, not the inflowing product. Fig. 7: inflowing liquid the socket piece should be dimensioned in such a ...

Page 17

17 4 mounting vegapuls 66 • profibus pa 33335-en-170927 ca. 10 mm fig. 8: recommended socket mounting in liquids, direct the sensor as perpendicular as possible to the prod - uct surface to an achieve optimum measurement. Fig. 9: alignment in liquids the mounting location of the radar sensor should ...

Page 18

18 4 mounting vegapuls 66 • profibus pa 33335-en-170927 interfering reflections from the agitators are saved with the blades in different positions. Fig. 11: agitators through the action of filling, stirring and other processes in the vessel, dense foams which considerably damp the emitted signals m...

Page 19

19 4 mounting vegapuls 66 • profibus pa 33335-en-170927 max. Min. 2 1 fig. 12: pipe antenna system in a tank. The vent hole in the surge pipe must be in one plane with the polarisation marking on the sensor. 1 marking of the polarisation direction 2 vent hole max. ø 5 mm (0.2 in) if possible, the di...

Page 20

20 4 mounting vegapuls 66 • profibus pa 33335-en-170927 100% 0% 1 > 500 mm fig. 13: vegapuls 66 in a bypass tube. The polarisation marking on the process fitting must be in one plane with the tube holes or the tube connection openings. 1 marking of the polarisation direction when the sensor is mount...

Page 21

21 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 5 connecting to power supply 5.1 preparing the connection always keep in mind the following safety instructions: warning: connect only in the complete absence of line voltage. • the electrical connection must only be carried o...

Page 22

22 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 in systems without potential equalisation, connect the cable screen directly to ground potential at the power supply unit and at the sensor. In the connection box or t-distributor, the screen of the short stub to the sensor mu...

Page 23

23 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 fig. 14: connection steps 6 and 7 8. Press down the opening levers of the terminals, you will hear the terminal spring closing 9. Check the hold of the wires in the terminals by lightly pulling on them 10. Connect the screen t...

Page 24

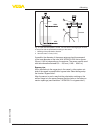

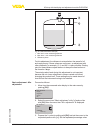

24 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 5 5 5 5 1 2 4 3 fig. 15: material versions, single chamber housing 1 plastic 2 aluminium 3 stainless steel (precision casting) 4 stainless steel (electro-polished) 5 filter element for air pressure compensation of all material...

Page 25

25 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 i2c display 1 1 2 5 6 7 8 fig. 17: wiring plan - single chamber housing 1 voltage supply, signal output 5.4 wiring plan, double chamber housing the following illustrations apply to the non-ex as well as to the ex-ia version. 1...

Page 26

26 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 1 3 2 display 1 2 5 6 7 8 i²c fig. 19: electronics compartment - double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 81 1 2 ...

Page 27

27 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 i2c 1 1 2 fig. 21: wiring plan - double chamber housing 1 voltage supply, signal output 5.5 wiring plan, double chamber housing ex d 1 2 3 4 5 fig. 22: double chamber housing 1 housing cover - connection compartment 2 blind pl...

Page 28

28 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 1 3 2 display 1 2 5 6 7 8 i²c fig. 23: electronics compartment - double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 81 1 2 ...

Page 29

29 5 connecting to power supply vegapuls 66 • profibus pa 33335-en-170927 1 1 2 fig. 25: wiring plan, ex-d-ia double chamber housing 1 voltage supply, signal output 5.6 wiring plan - version ip 66/ip 68, 1 bar 1 2 fig. 26: wire assignment, connection cable 1 brown (+) and blue (-) to power supply or...

Page 30: Module Plicscom

30 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 6 set up with the display and adjustment module plicscom 6.1 short description the display and adjustment module is used for measured value display, adjustment and diagnosis. It can be mounted in th...

Page 31

31 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 fig. 27: insert display and adjustment module note: if you intend to retrofit the instrument with a display and adjustment module for continuous measured value indication, a higher lid with an inspe...

Page 32

32 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 – move to the menu overview – confirm selected menu – edit parameter – save value • [->] key to select: – menu change – select list entry – select editing position • [+] key: – change value of the p...

Page 33

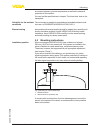

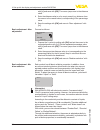

33 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 100% 0% 1,5 m (59.1 ") 15 m (590.6 ") 2 1 3 fig. 29: parameterization example 1 min. Level = max. Measuring distance 2 max. Level = min. Measuring distance 3 reference plane for this adjustment, the...

Page 34

34 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 with [+] and save with [ok] . The cursor jumps now to the distance value. 4. Enter the distance value in m for empty vessel (e.G. Distance from the sensor to the vessel bottom) corresponding to the ...

Page 35

35 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 enter the requested parameters via the appropriate keys, save your settings and jump to the next menu item with the [->] key. Apart from the medium, the vessel shape can also influence the measureme...

Page 36

36 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 caution: note the following if the vegapuls 66 with corresponding approval is used as part of an overfill protection system according to whg (water resources act): if a linearisation curve is select...

Page 37

37 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 in the menu item " display " you can define which value should be indicated on the display. Displayed value pa-out a background lighting integrated by default can be adjusted via the adjustment menu...

Page 38

38 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 information: the trend recording is not activated when being shipped. It must be started by the user via the menu item " start trend curve ". A comparison of the echo curve and the false echo curve ...

Page 39

39 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 from the sensor to the product surface. All false signals in this area are detected by the sensor and saved after confirming with [ok] . Note: check the distance to the product surface, because if a...

Page 40

40 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 • volume • others (no unit, %, ma) in the menu item " pv-out-scale ", the requested numerical value with decimal point is entered for 0 % and 100 % of the measured value. Out-scale-unit pv-out-scale...

Page 41

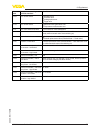

41 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 basic adjustment if the " reset " is carried out, the sensor resets the values of the follow - ing menu items to the reset values (see table): 1) menu item reset value max. Adjustment 0 m(d) min. Ad...

Page 42

42 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 the sensor is already set to the ordered national language. In this menu item you can change the language. The following languages are available, e.G. In software version 3.50: • deutsch • english •...

Page 43

43 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 • display unit • scaling • current output • unit of measurement • language the following safety-relevant data are not read out or written: • hart mode • pin • sil copy sensor data copy sensor data? ...

Page 44

44 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 last change using pc • sensor details, e.G. Approval, process fitting, seal, measuring cell, measuring range, electronics, housing, cable entry, plug, cable length etc. Sensor characteristics displa...

Page 45

45 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 diagnostics basic adjustment 3 display ▶ diagnostics service info peak value indicator 3.1 distance min.: 0.234 m(d) distance max.: 5.385 m(d) meas. Certainty 3.2 15 db sensor status ok curve select...

Page 46

46 6 set up with the display and adjustment module plicscom vegapuls 66 • profibus pa 33335-en-170927 6.10 saving the parameterisation data we recommended writing down the adjustment data, e.G. In this op - erating instructions manual, and archiving them afterwards. They are thus available for multi...

Page 47: Adjustment Programs

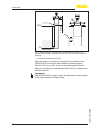

47 7 set up with pactware and other adjustment programs vegapuls 66 • profibus pa 33335-en-170927 7 set up with pactware and other adjustment programs 7.1 connect the pc via vegaconnect 3 1 2 fig. 30: connection of the pc via vegaconnect directly to the sensor 1 usb cable to the pc 2 vegaconnect 3 s...

Page 48

48 7 set up with pactware and other adjustment programs vegapuls 66 • profibus pa 33335-en-170927 • vegaconnect • power supply unit or processing system 7.2 parameter adjustment with pactware for parameter adjustment of the instrument via a windows pc, the configuration software pactware and a suita...

Page 49

49 7 set up with pactware and other adjustment programs vegapuls 66 • profibus pa 33335-en-170927 and echo curves. In addition, there is a tank calculation program as well as a multiviewer for display and analysis of the saved measured value and echo curves. The standard version is available as a do...

Page 50

50 8 maintenance and fault rectification vegapuls 66 • profibus pa 33335-en-170927 8 maintenance and fault rectification 8.1 maintenance if the device is used properly, no special maintenance is required in normal operation. 8.2 rectify faults the operator of the system is responsible for taking sui...

Page 51

51 8 maintenance and fault rectification vegapuls 66 • profibus pa 33335-en-170927 error cause rectification no connection between plc and pa network incorrect adjustment of the bus parameter and the segment coupler-depend - ent baud rate check data and correct, if necessary instrument does not ap -...

Page 52

52 8 maintenance and fault rectification vegapuls 66 • profibus pa 33335-en-170927 information: when loading on site, the order data must first be downloaded from the internet (see operating instructions manual " electronics module "). The electronics modules are adapted to the respective sensor and...

Page 53: 9 Dismount

53 9 dismount vegapuls 66 • profibus pa 33335-en-170927 9 dismount 9.1 dismounting steps warning: before dismounting, be aware of dangerous process conditions such as e.G. Pressure in the vessel or pipeline, high temperatures, cor - rosive or toxic products etc. Take note of chapters " mounting " an...

Page 54: 10 Supplement

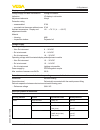

54 10 supplement vegapuls 66 • profibus pa 33335-en-170927 10 supplement 10.1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, wetted parts Ʋ antenna enamel Ʋ antenna cone ptfe (tfm 1600) Ʋ seal, antenna system graphite, ptfe-coated materials, non-wetted parts Ʋ housing pl...

Page 55

55 10 supplement vegapuls 66 • profibus pa 33335-en-170927 reference conditions to measuring accuracy (according to din en 60770-1) reference conditions according to din en 61298-1 Ʋ temperature +18 … +30 °c (+64 … +86 °f) Ʋ relative humidity 45 … 75 % Ʋ air pressure 860 … 1060 mbar/86 … 106 kpa (12...

Page 56

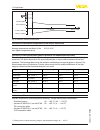

56 10 supplement vegapuls 66 • profibus pa 33335-en-170927 1,0 m (3.28 ft) 35 m (114.8 ft) 20 mm (0.788 in) 10 mm (0.394 in) - 10 mm (- 0.394 in) - 20 mm (- 0.788 in) 0 fig. 33: deviation vegapuls 66 enamel influence of the ambient temperature to the sensor electronics 9) average temperature coeffic...

Page 57

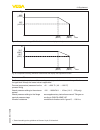

57 10 supplement vegapuls 66 • profibus pa 33335-en-170927 50°c (122°f) 80°c (176°f) 150°c (302°f) 200°c (392°f) t proz t u fig. 34: temperature derating vegapuls 66 enamel without display and adjustment module 50°c (122°f) 70°c (158°f) 150°c (302°f) 200°c (392°f) t proz t u fig. 35: temperature der...

Page 58

58 10 supplement vegapuls 66 • profibus pa 33335-en-170927 electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 11) Ʋ single chamber housing – 1 x cable gland m20 x 1.5 (cable: ø 5 … 9 mm), 1 x blind plug m20 x 1.5 or: – 1 x closing cap m20 x 1.5; 1 x blind plug m20...

Page 59

59 10 supplement vegapuls 66 • profibus pa 33335-en-170927 display and adjustment module voltage supply and data transmission through the sensor indication lc display in dot matrix adjustment elements 4 keys protection rating Ʋ unassembled ip 20 Ʋ mounted into the sensor without cover ip 40 ambient ...

Page 60

60 10 supplement vegapuls 66 • profibus pa 33335-en-170927 housing material version ip-protection class nema protection stainless steel (electro- polished) single chamber ip 66/ip 68 (0.2 bar) type 6p stainless steel (precision casting) single chamber ip 66/ip 68 (0.2 bar) ip 68 (1 bar) type 6p type...

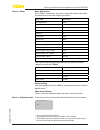

Page 61

61 10 supplement vegapuls 66 • profibus pa 33335-en-170927 m(d) % lin% min-max adjustment linearization profibus pa-output primary value secondary value 2 secondary value 1 target mode failure mode alarms scaling source for scaling t i integration sensor characteristics pa-out tb fb select additiona...

Page 62

62 10 supplement vegapuls 66 • profibus pa 33335-en-170927 • additional cyclic value byte-no. 1 2 3 4 5 6 7 8 9 10 status status status status (fb1) ieee-754- floating point value pa-out (fb1) ieee-754- floating point value additional cyclic value format value example 2 with distance value without a...

Page 63

63 10 supplement vegapuls 66 • profibus pa 33335-en-170927 status code description according to profibus standard possible cause 0 x 0c bad - sensor failure • hardware error • converter error • leakage pulse error • trigger error 0 x 10 bad - sensor failure • measured value generation error • temper...

Page 64

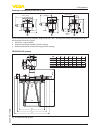

64 10 supplement vegapuls 66 • profibus pa 33335-en-170927 10.3 dimensions housing in protection ip 66/ip 68 (0.2 bar) ~ 69 mm (2.72") ø 77 mm (3.03") 112 mm (4 13 / 32 ") m20x1,5/ ½ npt ~ 69 mm (2.72") ø 77 mm (3.03") 117 mm (4.61" ) m20x1,5/ ½ npt ~ 87 mm (3.43") m16x1,5 ø 84 mm (3.31") 120 mm (4....

Page 65

65 10 supplement vegapuls 66 • profibus pa 33335-en-170927 housing in protection ip 66/ip 68 (1 bar) 117 mm (4.61" ) ~ 103 mm (4.06") ø 77 mm (3.03") 116 mm (4.57" ) ~ 150 mm (5.91") ø 84 mm (3.31") 120 mm (4.72" ) ~ 105 mm (4.13") ø 84 mm (3.31") m20x1,5 2 m20x1,5/ ½ npt m16x1,5 3 m20x1,5 m20x1,5 1...

Page 66

66 10 supplement vegapuls 66 • profibus pa 33335-en-170927 10.4 industrial property rights vega product lines are global protected by industrial property rights. Further information see www.Vega.Com. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte. Nähere informationen un...

Page 67

67 notes vegapuls 66 • profibus pa 33335-en-170927.

Page 68

Printing date: vega grieshaber kg am hohenstein 113 77761 schiltach germany 33335-en-170927 all statements concerning scope of delivery, application, practical use and operat- ing conditions of the sensors and processing systems correspond to the information available at the time of printing. Subjec...