- DL manuals

- Xerox

- Software

- Nuvera 100

- Service Manual

Xerox Nuvera 100 Service Manual

Summary of Nuvera 100

Page 1

General information 1-1 chapter.

Page 2: Chapter 1

1-2 ii linx™ solid inkjet 100 service manual chapter 1 general information this chapter provides information and a general overview of the iilinx solid inkjet 100 printer. Theory of operation, printer specifications and components are presented in the following sections:.

Page 3: General Information

General information 1-3 general information the iilinx solid inkjet 100 printer, shown in figure 1-1, is a user- installable, low maintenance, environmentally friendly, high quality referral image postscript printer. 0388-01 figure 1-1. The iilinx solid inkjet 100 printer (shown with optional auxili...

Page 4

1-4 ii linx™ solid inkjet 100 service manual solid inkjet 100 printer overview the solid inkjet 100 printer is an adobe postscript level 3 (version 3010) grayscale, solid inkjet printer. It supports 409 x 409 dots-per- inch (dpi) resolution at draft mode, and 600 x 600 dpi at high resolution medical...

Page 5

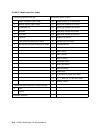

General information 1-5 memory considerations the printer dual frame buffer allows for printing one image while processing a second image (which gives greater printing throughput). With additional ram memory, the printer’s capabilities increase as detailed in table 1-1: table 1-1. Installed ram and ...

Page 6

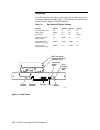

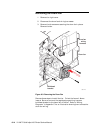

1-6 ii linx™ solid inkjet 100 service manual print engine assemblies internal features of the print engine are illustrated in figure 1-2. 0388-02 ink load assembly x-axis drive and motor paper feed motor paper/ drum heater cap/wipe/purge assembly transfix roller process motor y-axis motor drum print...

Page 7

General information 1-7 seven circuit boards support the printer’s electronics. (refer to figures 1-3 and 1-4). Two boards, called i/o boards, left and right, support the front panel, solenoids and sensors. The main board contains the printer’s cpu processor, ram and rom. The power supply accepts th...

Page 8

1-8 ii linx™ solid inkjet 100 service manual 0388-04 i/o board left power control board printhead drive board optional internal hard drive optional ethernet interface card main board power supply figure 1-4. Circuit boards of the print engine (left rear view).

Page 9

General information 1-9 an internal data bus, called the i 2 c bus, connects all i/o boards to the main board. (refer to figure 1-5.) through this single bus, the main board can “poll” the i/o boards for the state of the printer’s sensors as well as actuate the printer’s solenoids. This data bus gre...

Page 10

1-10 ii linx™ solid inkjet 100 service manual the printer features a printhead maintenance system used to clean the printhead faceplate and clear clogs from the printhead nozzles. (refer to figure 1-6.) the system consists of a vacuum pump assembly, the cap/wipe/purge assembly, the cap/wipe/purge ca...

Page 11

General information 1-11 sensors in the printer provide information to the main board to determine the state of the printer. The printer monitors the positions of some of the movable assemblies, such as the drum, as well as the temperature of many other assemblies, such as the printhead, paper prehe...

Page 12

1-12 ii linx™ solid inkjet 100 service manual drum encoder sensor process gear position sensor drum-home- position sensor drum temperature sensor preheater exit sensor duplex paper sensor transfix exit sensor 0388-34 preheater exit sensor located on inside wall of drum/transfix frame drum transfix r...

Page 13

General information 1-13 caution the actual position of some printer assemblies, such as the printhead or the cap/wipe/purge assembly, cannot be ascertained at all times. The printer records, in nvram, where it last positioned such assemblies each time it moves them. If, after power-down or a power ...

Page 14

1-14 ii linx™ solid inkjet 100 service manual the main board the main board features the printer’s powerpc processor that controls the engine and the postscript processing. Refer to figure 1- 10. Prominent on the main board is the code rom dimm and the ram dimm plug-in modules. The code rom dimm als...

Page 15

General information 1-15 media tray type sensing the combinations of the three tray sensors inform the print engine what type of media tray (a or a4) is installed. These combinations are shown in table 1-2. The print engine does not detect the type of media installed in the tray; it only detects the...

Page 16

1-16 ii linx™ solid inkjet 100 service manual pressing and holding the left arrow while turning off the printer will confirm the printhead is correctly parked by flashing both front panel leds. Turning the printer on with the rear panel dip switch 2 in the “down” position, allows access to the front...

Page 17

General information 1-17 rear panel connectors the rear panel (figure 1-12) of the printer features the host interface connectors to the printer; it includes the following connectors: • standard parallel (high-density connector), ieee 1284c • twisted pair (10baset) ethernet connector • universal ser...

Page 18

1-18 ii linx™ solid inkjet 100 service manual switches four dip switches allow you to reset the printer or place the printer in different operating modes. Figure 1-12 illustrates the rear panel of the printer and location of the dip switches. Table 1-3. Rear panel dip switch settings function switch...

Page 19: Cool Down Mode

General information 1-19 bypass mode (manufacturing mode) bypass mode allows you to access the front panel menus (bypassing the engine and postscript initializing processes) without having to wait for the printhead to warm up. This way, you can observe or change some of the printer settings without ...

Page 20: Accessories

1-20 ii linx™ solid inkjet 100 service manual preparation for moving the solid inkjet 100 printer and accessories it is very important that you follow the correct repacking procedure before shipping the solid inkjet 100 printer. Complete repacking is required. Failure to properly repack the printer ...

Page 21

General information 1-21 1. Use the rear-panel on/off switch to turn off the printer. 2. At the front panel, immediately select quick cool to move printer (you have 4 seconds before the display goes blank). The printer reports the shut down status and takes approximately 15 minutes to cool down. Whi...

Page 22

1-22 ii linx™ solid inkjet 100 service manual 2. Remove the maintenance drawer from the printer. Once you’ve removed the maintenance drawer, keep it level. 1239-59 warning a used maintenance drawer leaks drum fluid if tipped. Keep the maintenance drawer level to prevent spills. Contact with maintena...

Page 23

General information 1-23 repacking the printer and its accessories warning the printer weighs about 36 kg (79 lb.). Do not attempt to lift it without the assistance of another person. 1. Repack the media tray. Remove the media trays and remove all media from the trays. Position the cardboard tray in...

Page 24

1-24 ii linx™ solid inkjet 100 service manual 1239-35b figure 1-13. Repacking the printer.

Page 25

General information 1-25 warning the printer is not permanently attached to the auxiliary feeder unit. When moving the printer or auxiliary feeder unit, move each unit separately to avoid damage or personal injury. The printer weighs about 36 kg (79 lb.). Do not attempt to lift it without the assist...

Page 26: Configuration Page

1-26 ii linx™ solid inkjet 100 service manual configuration page the configuration page, shown on pages 1-27 and 1-28, lists the values the printer stores in its nvram. These values can be informative when troubleshooting the printer, particularly networked operations. The configuration page gives i...

Page 27

General information 1-27.

Page 28

1-28 ii linx™ solid inkjet 100 service manual.

Page 29

General information 1-29 table 1-4. Configuration page settings p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices printer name the current name of the printer as seen on a network yes ii linx sij100 any name defined by the customer up to 32 characters in length. ...

Page 30

1-30 ii linx™ solid inkjet 100 service manual table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices wait timeout amount of time the image processor waits for additional data from a host. Yes 40 seconds any value grea...

Page 31

General information 1-31 table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices handshake setting whether unidirectional or bidirectional communication is used. Yes bi-directional uni-directional u s b language indica...

Page 32

1-32 ii linx™ solid inkjet 100 service manual table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices last config time last date the printer’s configurations were altered yes sysadmin contact name of system administrat...

Page 33

General information 1-33 table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices i p x indicates which ipx frame types the printer accepts ipx networks ethernet 802.2 yes enabled disabled ethernet 802.3 yes enabled dis...

Page 34

1-34 ii linx™ solid inkjet 100 service manual table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices login password indicates whether or not a network password has been set. Yes not set set, not set enable banners pri...

Page 35

General information 1-35 table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices bootp/ dhcp used for setting the printer’s ip address from a boot server yes false true ip address source indicates from what source the ...

Page 36

1-36 ii linx™ solid inkjet 100 service manual table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices language indicates the type of interpreter in use at the system v configured port. Yes postscript filtering interpre...

Page 37

General information 1-37 table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices h t t p indicates if http support has been enabled yes enabled disabled local url address yes http password yes not set set refresh delay...

Page 38

1-38 ii linx™ solid inkjet 100 service manual table 1-4. Configuration page settings (continued) p a r a m e t e r description saved in nvram d e f a u l t limits or alternate choices pop3 polling interval interval printer waits before checking for new mail yes 3 minutes 1 to 32767 printing password...

Page 39: Specifications

General information 1-39 p r i n t e r auxiliary feeder unit c a r t height 38.8 cm (15.3 in.) 12.7 cm (5.0 in.) 47.6 cm (18.75 in.) width 43.2 cm (17.0 in.) 43.2 cm (17.0 in.) 45.7 cm (18.0 in.) d e p t h 59.7 cm (23.5 in.) 59.7 cm (23.5 in.) 55.2 cm (21.75 in.) weight 36.0 kg (79 lbs.) 11.8 kg (26...

Page 40

1-40 ii linx™ solid inkjet 100 service manual functional specifications printing process solid inkjet onto plain paper grayscale ink sticks clear, low-, medium- and high- density ink sticks, each shape- coded print quality selectable 409 x 409, or 600 x 600 dpi (horizontal and vertical) engine print...

Page 41

General information 1-41 electrical specifications warning do not use extension cords of any length or gauge. Primary line voltages 87–132 vac (115 vac nominal) 174–264 vac (220 vac nominal) input voltage range is auto-sensed. Primary voltage 47–63 hz frequency range power consumption 200 watts stan...

Page 42

1-42 ii linx™ solid inkjet 100 service manual caution operate printer only within specified environmental ranges. Environmental specifications warning if combustible fluids are brought into contact with hot elements of the printer, evacuate the area and call for service personnel. Temperature operat...

Page 43

General information 1-43 have any corner raised and dropped 6 cm (2.4 in.) while idle without subsequent impairment of operation. Operating (drop) printer only with the main tray installed; maintenance drawer installed; printhead unlocked; no internal packaging: 0.5 in for one drop on all four botto...

Page 44: Theory of Operation

1-44 ii linx™ solid inkjet 100 service manual theory of operation this topic covers the following subassemblies and diagram within the printer: • functional block diagram • drum/transfix assembly • maintenance drawer • printhead • x-axis movement • printhead tilt mechanism • ink loader • cap/wipe/pu...

Page 45

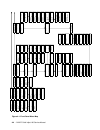

General information 1-45 figure 1-14. Printer functional block diagram drum heater paper preheater i 2 c 10 i 2 c misc 10 ac 8 i 2 c 10 i 2 c 1 1 power supply 15 18 8 ac 6 ac 8 120 120 120 120 network card pci ide hard drive pci cia sdram sdram rom printer id main board cap/w ipe/ purge unit ink loa...

Page 46

1-46 ii linx™ solid inkjet 100 service manual drum/transfix assembly the drum/transfix assembly (figure 1-15) forms the key portion of the printer where imaging takes place. The main features of the drum/transfix assembly (figure 1-16) are the drum and transfix roller. In operation, the image to be ...

Page 47

General information 1-47 840-4-47 home sensor temperature sensor (~55 ° c) drum fan belt drive warning: closed-loop servo drive servo motor paper/drum heater entry assembly encoder encoder disk home flag transfix roller figure 1-16. Drum/transfix assembly an encoder disk and sensor on the left end o...

Page 48

1-48 ii linx™ solid inkjet 100 service manual maintenance drawer the maintenance drawer performs two functions. Its primary function is to create a thin intermediate liquid transfer surface, a layer of silicone oil, on the surface of the drum prior to printing. The oil keeps the ink from sticking to...

Page 49

General information 1-49 felt filter to the oil roller for reuse. As the drum completes one rotation, the rotating cam lowers the oil roller and then a moment later, lowers the blade. A removable nvram chip, mounted on the drawer, stores the number of oiling cycles performed by the maintenance drawe...

Page 50

1-50 ii linx™ solid inkjet 100 service manual figure 1-19 shows a cross-section of the inkjet array and the jet nozzle arrangement. The printhead’s jet stack is fabricated from a stack of chemically etched steel plates which are brazed together to form the ink-jet array. Channels formed by the stack...

Page 51

General information 1-51 ink inlet piezoelectric crystals high * 300 dpi pixels inter- mediate low clear manifolds 22 pixels* 22 pixels 11 pixels* 840-4-49 22 pixels* figure 1-19. Printhead detail the ink-jet array is bonded to a cast aluminum ink reservoir. The reservoir supplies the molten ink to ...

Page 52

1-52 ii linx™ solid inkjet 100 service manual x-axis movement x-axis or lateral movement of the printhead is accomplished using a stepper motor driving a fine-thread leadscrew. The printhead, mounted to the x-axis shaft, moves right and left across the surface of the drum. To find the printhead home...

Page 53

General information 1-53 printhead tilting mechanism to accommodate printhead maintenance, the printhead can be tilted back away from the drum. (refer to figures 1-21 and 1-22.) this creates room for the cap/wipe/purge assembly to be moved into position in front of the printhead faceplate. The print...

Page 54

1-54 ii linx™ solid inkjet 100 service manual a return spring at the top of the tilt arm pulls the printhead toward the drum. In the print position, the tilt arm gear’s missing teeth are positioned at the tilt arm gear’s drive gear. When actuated, a leaf spring pushes against a cam lobe on the backs...

Page 55

General information 1-55 ink loader the ink loader consists of four parallel channels with an ink melting element at the end of each of the four channels. (refer to figure 1-23.) ink sticks, one color loaded in each channel, are pressed by coil-spring pressure into the melting elements. As ink is re...

Page 56

1-56 ii linx™ solid inkjet 100 service manual cap/wipe/purge assembly the cap/wipe/purge assembly is a long, shallow cup with an elastomeric gasket. (refer to figure 1-24.) when raised and pressed against the face of the printhead, it forms an airtight seal. After forming the seal, a partial vacuum ...

Page 57

General information 1-57 the cap/wipe/purge assembly is attached to a pair of parallel belts on a rotating shaft. To perform a printhead maintenance cycle, the printhead is first tilted away from the drum. Then the cap/wipe/purge assembly motor drives the cap/wipe/purge assembly belts, which pull th...

Page 58

1-58 ii linx™ solid inkjet 100 service manual 840-4-51 cap/wipe/purge assembly air valve solenoid vacuum accumulator space vacuum/pump module vacuum pump purge wipe wiper blade flush dab printhead faceplate figure 1-245 cap/wipe/purge assembly and vacuum system.

Page 59

General information 1-59 power supply the power supply has two main, yet interrelated sections: the ac section and the dc section. In the ac section, power is routed to 14 opto-isolated triacs which, under main board logic control, supply ac power to the 14 heaters in the printer. Two fuses provide ...

Page 60

1-60 ii linx™ solid inkjet 100 service manual figure 1-26. Power supply block diagram 840-4-66 f1 +5 v +40 v +54 v -52 v +12 v -12 v drum heater 1 reservoir heater 1 high density ink melter intermediate density ink melter low density ink melter clear ink melter jet stack left paper pre-heater jet st...

Page 61

General information 1-61 print process in operation once an image has been processed and a printing bitmap created, a print cycle begins. The printhead and drum are brought up to their operating temperatures and the ink levels in the ink reservoirs are checked and ink is added from the ink loader, i...

Page 62

1-62 ii linx™ solid inkjet 100 service manual 840-4-55 process motor process drive compound gear cam follower head tilt arm head tilt cam gear head tilt cam gear disengaged from drive gear figure 1-27. Tilting the printhead.

Page 63

General information 1-63 drum preparation to prepare the drum, a thin, intermediate liquid transfer surface is applied to the surface of the drum. (refer to figure 1-28.) first the drum is rotated to a speed of 51 cm per second (20 inches per second). Next, the oil roller and blade of the maintenanc...

Page 64

1-64 ii linx™ solid inkjet 100 service manual 840-4-54 maintenance drawer camshaft electric clutch process drive belt process motor cam pushes oil roller and blade against drum cam lowers oil roller and blade assembly camshaft home position flag drum maintenance drawer camshaft oil on drum blade act...

Page 65

General information 1-65 printing when printing, the printer performs a “four-jet interlace” in which each jet lays down a particular number of pixel columns depending on the print resolution. Each jet lays down one pixel column for each drum rotation; this varies from 30 to 44 rotations (30 @ 409 d...

Page 66

1-66 ii linx™ solid inkjet 100 service manual 1 of 4 2 of 4 3 of 4 4 of 4 1 of 4 2 of 4 3 of 4 4 of 4 output of four side-by-side jets column of pixel dots produced by four adjacent jets are interlaced together for printing. Each jet produces between 30 and 44 pixel columns. Columns of pixel dots pr...

Page 67

General information 1-67 paper pick to pick a sheet of paper, the process motor rotates clockwise, driving the process drive belt and the compound gear counterclockwise. (refer to figure 1-30.) rotating counterclockwise, the compound gear turns and, in turn, engages a gear train that rotates the pic...

Page 68

1-68 ii linx™ solid inkjet 100 service manual exit sensor paper size sensors paper preheater entry sensor paper pick sensor transfix exit sensor preheater exit sensor pick clutch upper feed roller clutch pick roller lower feed roller upper feed roller 840-4-53 deskew fingers figure 1-30. Paper picki...

Page 69

General information 1-69 transfixing, stripping and exiting as the leading edge of the sheet of paper trips the paper preheater exit sensor, it starts the transfix roller being lowered to its transfix position. The process motor rotates clockwise, rotating the process drive compound gear countercloc...

Page 70

1-70 ii linx™ solid inkjet 100 service manual transfix roller transfix cam transfix roller shaft transfix cam solenoid 840-4-52 exit sensor paper preheater transfix exit sensor transfix roller on eccentric shaft transfix roller gear compound gear position sensor process drive compound gear process m...

Page 71: Printer Self-Maintenance

General information 1-71 printer self-maintenance to maintain peak operation, reliability and print quality, the printer has several automatic or semiautomatic maintenance functions. (refer to figure 1-32.) these functions may be started automatically after a certain number of prints or during print...

Page 72

1-72 ii linx™ solid inkjet 100 service manual 840-4-51 cap/wipe/purge assembly air valve solenoid vacuum accumulator space vacuum/pump module vacuum pump purge wipe wiper blade flush dab printhead faceplate figure 1-32. Printhead maintenance cycle.

Page 73

General information 1-73 preparation. Following printer power-up from a cold start or in response to a front panel menu selection, the print engine begins a printhead long cleaning cycle. The first step is to stop any ink melting operation. The printhead is tilted into the standby position. In this ...

Page 74

1-74 ii linx™ solid inkjet 100 service manual following the second flush, the printhead is tilted back and the cap/ wipe/purge assembly is lowered into its standby position. A cap/wipe/ purge home sensor on i/o board right detects when the cap/wipe/ purge assembly is stored in its standby position. ...

Page 75

General information 1-75 transfix roller oiling at the first opportunity after making 50 prints when no prints are queued and the printer is idle, the printer performs a transfix roller oiling cycle. During this cycle, oil is applied to the drum as it would be during a print cycle. Then the transfix...

Page 76

1-76 ii linx™ solid inkjet 100 service manual power control board the power control board functions as a back plane. This circuit board is the point of electrical interface to the print head, main controller, optional ethernet interface card, internal hard disk drive, i/o boards. And power supply. T...

Page 77

General information 1-77 implemented using a cirrus logic cl-cd1284. The parallel port uses a 36 pin ieee 1284 connector on the rear panel. The serial port provides rx and tx only with no handshaking. It is connected via a 5 pin square post 0.1" centers connector recessed into the rear panel. The cl...

Page 78

1-78 ii linx™ solid inkjet 100 service manual optional internal disk drive the internal disk drive board contains a 3.2 gigabyte ide disk drive interfaced to the 32 bit pci bus using a cmd technology pci646 pci to ide data conversion chip. Disk drive data transfer rates are 3.5 mbytes/sec minimum an...

Page 79: Chapter

Error codes and messages 2-1 chapter.

Page 80: Chapter 2

2-2 iilinx™ solid inkjet 100 service manual chapter 2 error codes and messages this chapter provides a description of the error codes and messages. Rear panel leds error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-x.

Page 81: Rear Panel Leds Error Codes

Error codes and messages 2-3 rear panel leds error codes the rear panel leds are located on each side of the rear panel dip switches. Note: all references to right and left are as viewed from the reat of the printer. The left led represents the operation of the postscript firmware. The right led rep...

Page 82

2-4 iilinx™ solid inkjet 100 service manual table 2-1. Main board power-up self-test error codes (continued) left led f l a s h e s long flash=5 short flash=1 2l+ 1s=11 meaning d e t a i l s 9 nvram this test does a walking 1's and a walking 0's test for the last 4 bytes in the vxworks section of th...

Page 83

Error codes and messages 2-5 table 2-1. Main board power-up self-test error codes (continued) left led f l a s h e s long flash=5 short flash=1 2l+ 1s=11 meaning d e t a i l s none 10baset this test verifies the functionality of the ethernet lan controller chip. Any test failures with this component...

Page 84: Service Required Error Codes

2-6 iilinx™ solid inkjet 100 service manual service required error codes following are the service required error codes that are displayed on the front panel. 2,000: sy i/o board 4,000: pc processor control supervisor error codes front panel display software error code meaning 4,001.40 (0x2401) pc_d...

Page 85

Error codes and messages 2-7 4,000: pc processor control supervisor (continued) error codes front panel display software error code meaning 4,006.45 (0x2406) pc-dev_fault_300dpi_cal pc fault: 300 dpi calib calibration failure: target volt-sec area of 300 dpi could not be achieved. Check the hardware...

Page 86

2-8 iilinx™ solid inkjet 100 service manual 4,000: pc processor control supervisor (continued) error codes front panel display software error code meaning 4,015.45 (0x240f) pc_dev_fault_head_adjust_timeout pc fault: head adjust timeout timeout during head adjust. A 20 minute timer elapsed before the...

Page 87

Error codes and messages 2-9 5,000: va drum error codes 6,000: xa x-axis error codes error codes front panel display software error code meaning 5,001.41 (0x2c01) ya_home_fail ya fault: drum home sensor drum home sensor failure: the drum turned one full revolution without seeing the drum home sensor...

Page 88

2-10 iilinx™ solid inkjet 100 service manual 7,000: process motor error codes 8,000: cap drive and web sensors error codes error codes front panel display software error code meaning 7,002.4x (0x3c01) pm_fault_process_motor_stall the process motor stalled during operation. This has several possible ...

Page 89

Error codes and messages 2-11 9,000: ink loader: ink melters and printhead ink level sensors error codes 13,000: head thermals error codes error codes front panel display software error code meaning 9,005.40 (0x4c05) il_fault_low_jam il fault: low density ink-stick jam the low density ink melt heate...

Page 90

2-12 iilinx™ solid inkjet 100 service manual 13,000: head thermals error codes (continued) 14,000: cap thermals error codes error codes front panel display software error code meaning 13,020.52 (0x6d14) tch_js_right_slow tch timer: right jetstack not heating the right jetstack heater is not heating ...

Page 91

Error codes and messages 2-13 15,000: drum thermals error codes 1 6,000: preheat thermals error codes error codes front panel display software error code meaning 15,001.42 (0x7c01) tcd_thermistor_open tcd fault: drum open the drum thermistor appears to be open. 15,002.43 (0x7c02) tcd_thermistor_shor...

Page 92

2-14 iilinx™ solid inkjet 100 service manual 22,lss,tc: media jams error codes l indicates the location of the jam. Ss indicates sensor location. 1 bottom hi-capacity paper feeder 00 usually because of an opened door 2 middle hi-capacity paper feeder 01 bottom high-capacity tray sensors 3 top standa...

Page 93

Error codes and messages 2-15 22,000 jam error codes 31,000 media preheater error codes error codes front panel display software error code meaning 22,703,0c declared jam stall event 22,704,0c declared jam sensor failure 22,705,0c declared jam media jam at exit tray 22,707,0c declared jam media too ...

Page 94

2-16 iilinx™ solid inkjet 100 service manual postscript®-detected error codes note: codes from 24,000 through 24,999 are engine failures reported by postscript. They are not stored in the fault history table in nvram. These are reported when the engine has been stuck in a state for 25 minutes. Error...

Page 95

Error codes and messages 2-17 postscript®-detected error codes (continued) error code meaning 24,017.16 engine is stuck while turning the pick rollers. 24,018.17 engine is stuck while warming up—thermals will not stabilize. 24,019.18 engine is stuck while warming up—thermals are stable. 24,020.10 en...

Page 96: Front Panel Status Messages

2-18 iilinx™ solid inkjet 100 service manual front panel status messages the front panel status messages and solutions are shown in table 2-2. The messages are listed in descending priority order. Table 2-2. Front panel status messages status message solution warming up—please wait the printer is he...

Page 97

Error codes and messages 2-19 table 2-2. Front panel status messages (continued) status message solution standby mode—press any button the printer is in an automatic power-saving mode. Press to return to ready any button to return the printer to ready . Note: pressing help removes standby—so you do ...

Page 98

2-20 iilinx™ solid inkjet 100 service manual table 2-2. Front panel status messages (continued) status message solution close front cover to continue the printer is stopped; close the front cover to resume printing. Close exit cover to continue the printer is stopped; close the exit cover to resume ...

Page 99

Error codes and messages 2-21 table 2-2. Front panel status messages (continued) status message solution media jam—remove upper remove jammed media and reinsert upper media tray. Media tray to clear media jam—remove lower tray remove jammed media and reinsert lower media tray. To clear media jam—rem...

Page 100

2-22 iilinx™ solid inkjet 100 service manual table 2-2. Front panel status messages (continued) status message solution caution! Hot surfaces—insert the printer is stopped. Do not touch hot surfaces! Reinsert maintenance drawer a maintenance drawer a. Maintenance drawer a is the printer is stopped. ...

Page 101: Chapter

Troubleshooting 3-1 chapter.

Page 102: Chapter 3

3-2 ii linx™ solid inkjet 100 service manual chapter 3 troubleshooting this chapter provides troubleshooting assistance as follows: verifying the printer and host connections . . . . . . . . . . . . . . . . . 3-3.

Page 103: System Power-Up Sequence

Troubleshooting 3-3 system power-up sequence the following lists the chain of events that occur when you turn on, reset or initialize the printer. You can follow this list as one means of determining if the printer is operating correctly. The exact chain of events depends upon where the printer “bel...

Page 104

3-4 ii linx™ solid inkjet 100 service manual printhead is in the print position but the cap/wipe/ purge assembly is in some unknown intermediate position: a. If the cap/wipe/purge assembly is not detected in its home position, then the heaters in the printhead and cap/wipe/purge assembly are activat...

Page 105: Its Startup Page

Troubleshooting 3-5 verifying main board cpu operation 1. If the printer does not power up (rear fan is off and power-up diagnostics leds are off), go to the topic, “verifying power supply operation” below. 2. Observe the rear panel leds located on each side of the rear panel dip switches. The left ...

Page 106

3-6 ii linx™ solid inkjet 100 service manual verifying power supply operation required tools: • torx t-20 screwdriver • digital multimeter (dmm) the power supply is divided into two sections: the ac section used for heaters and the dc section for control logic, printhead drivers and motors. Verifyin...

Page 107

Troubleshooting 3-7 3. With a dmm, determine that the fuses on the power supply are functional. Fuse f1 is the ac input fuse for the dc section of the power supply. If f1 opens, the power supply does not function and should be replaced. Caution fuse f2 and fuse f3 are used for the ac heaters within ...

Page 108

3-8 ii linx™ solid inkjet 100 service manual 0388-66 service load connector j 250 warning: ac voltage hazard. Never attempt to plug service load connector here. Figure 3-10. Attaching service load connector to j250 4. Turn on the printer. If the rear panel leds illuminate (indicating power), the pow...

Page 109

Troubleshooting 3-9 testing for a shorted motor 1. Reinstall the power supply if removed in the previous procedure. 2. Disconnect the process motor, the y-axis motor, x-axis motor and the cap/wipe/purge assembly motor wiring harnesses from the power control board. 3. Turn on the printer again to see...

Page 110: Printhead Troubleshooting

3-10 ii linx™ solid inkjet 100 service manual printhead troubleshooting note: the jet test page, which may be printed using the troubleshooting front panel menu and is automatically printed after the cleaning page, contains a localized warning when printed on a4- size paper. The warning message sugg...

Page 111

Troubleshooting 3-11 performance of the cap/wipe/purge assembly and vacuum system. (action steps 4–8.) if you see white “pinstripes” spaced 0.25 cm (0.1 inches) apart across the page (but not present on the test page), the problem is not with the cap/wipe/purge assembly or printhead. Check for somet...

Page 112

3-12 ii linx™ solid inkjet 100 service manual note: the decay time should take about 6 seconds for the peak vacuum to bleed off to 0 cm hg. If there is no decay time (sudden drop to zero), the cap/wipe/ purge gasket is bad. If the decay time is longer than 6 seconds, then something is restricting th...

Page 113

Troubleshooting 3-13 if vacuum is greater than 51 cm hg, the cap/wipe/purge gasket is leaking. Replace the cap/wipe/purge assembly. 9. Install a new cap/wipe/purge assembly.After installing a new cap/wipe/purge assembly, it may take from 4–6 front panel clean cycles before the cap/wipe/purge gasket ...

Page 114

3-14 ii linx™ solid inkjet 100 service manual additional printhead error codes: 13,001.40 and 13,0017.47 open left and right jet stack thermistor. Reseat or replace the data cable. If the error reoccurs, replace printhead. If the new printhead gives the same error, replace the power control board. 1...

Page 115

Troubleshooting 3-15 table 3-1. Printhead troubleshooting action: look for: what next: identify printhead: 1. Get printhead serial number. ❑ 1. Enter serial #: _______________ ❑ go to action 2. Determine problem: 2. Check printhead drive voltage. 3. Rint service test print 2: weak and missing jets. ...

Page 116

3-16 ii linx™ solid inkjet 100 service manual table 3-1. Printhead troubleshooting (cont.) action: look for: what next: check cwp purge performance: 6. Check vacuum and decay time at metal pipe using vacuum "t" during front panel clean cycle. 7. F vacuum is less than 46 cm hg at metal pipe (look for...

Page 117

Troubleshooting 3-17 figure 3-1 shows what a printhead faceplate will look like after a good cap/wipe/purge blade wipe. Notice that there are no smudges or streaks of ink in the nozzle area. Figure 3-1. Good cap/wipe/purge blade wipe figure 3-2 shows a close-up of the printhead faceplate identifying...

Page 118

3-18 ii linx™ solid inkjet 100 service manual figure 3-4 shows a close-up of one of the damaged areas of the cap/ wipe/purge blade used on the printhead shown in figure 3-3. The edge of the blade is pushed inward and flattened which prevents a good wiping action. In most cases you will not be able t...

Page 119

Troubleshooting 3-19 figure 3-7 shows a good purge. Figure 3-7. Good purge figure 3-8 shows a bad printhead data cable. Part of the cable is separated from the connector. Figure 3-8. Bad printhead data cable.

Page 120

3-20 ii linx™ solid inkjet 100 service manual figure 3-9shows the thermistor cable which connects to the driver board disconnected. This can happen while installing the ink loader. Figure 3-9. Thermistor cable unplugged media jams and the paper path required tools: • torx screwdriver and tips • digi...

Page 121

Troubleshooting 3-21 paper-pick errors paper-pick errors occur when the media in the media tray mispicks or the printer double-picks two or more sheets of paper. 1. Fan the media before inserting it in the media tray. 2. In humid environments, keep media sealed in packaging until it is needed for pr...

Page 122

3-22 ii linx™ solid inkjet 100 service manual 4. Check the paper-eject path for obstructions. Ensure no small pieces of paper are trapped around the stripper fingers. If a piece of paper is trapped in the paper preheater, try pushing it out by inserting a stiff piece of cardstock into the paper preh...

Page 123

Troubleshooting 3-23 5. Check the flexible, white paper deskew springs on the inside of the front cover. Ensure none are bent, damaged, or missing. 6. The printer should be installed on a flat, level surface. Printing and print quality problems generally, print problems fall into the following six c...

Page 124

3-24 ii linx™ solid inkjet 100 service manual 7. The x-axis drive is not functioning correctly. If the x-axis drive does not slew the printhead smoothly and evenly during printing, vertical lines appear in the print. Print service test print 11, x-axis calibration, to reveal an x-axis problem. Repla...

Page 125

Troubleshooting 3-25 white portion of image is dark ink on a print where no ink should be printed is often called a latent image. A latent image remains on the drum when it should have been transferred to its sheet of paper. An insufficient amount of oil on the drum, provided by a dirty, defective o...

Page 126

3-26 ii linx™ solid inkjet 100 service manual 3. Replace the power control board. 4. Replace the printhead. Printing too light or too dark perform the procedure, “printhead-to-drum spacing adjustment.” fuzzy text text appears indistinct and difficult to read. 1. Head-to-drum gap is too great. Verify...

Page 127

Troubleshooting 3-27 ghosting drum is too warm. Verify the drum temperature using pc-based diagnostics. Ensure the drum temperature sensor is clean and properly positioned. Ghost of first print on the next print incomplete image transfer is taking place on the first print. 1. Inspect the drum mainte...

Page 128

3-28 ii linx™ solid inkjet 100 service manual poor ink adhesion, poor image durability 1. Verify the paper preheater temperature using pc-based diagnostics. 2. The drum is too cold. Verify the drum temperature using pc- based diagnostics. Ensure the drum temperature sensor is properly positioned and...

Page 129

Troubleshooting 3-29 2. White or dark lines parallel to the long edge of the print, spaced 1.4 mm (0.054 in) in solid fills, using high resolution medical printing mode indicate the x-axis step accuracy is incorrect. Ensure the long spring mounted underneath the printhead is intact and not contamina...

Page 130

3-30 ii linx™ solid inkjet 100 service manual oil streaks on top of print 1. Clean the stripper fingers. 2. Run chase pages through the printer to clean the drum. Use the front panel menu item “remove ink smears” under “troubleshooting.” 3. Clean the maintenance drawer blade or replace the maintenan...

Page 131: Pc-Based Diagnostics

Troubleshooting 3-31 pc-based diagnostics the pc-based diagnostics is provided for interactively testing the operations and functionality of the printer. The diagnostics are provided on a 3-1/2 inch floppy diskette. All of the diagnostic tests are started from the pc and are downloaded to the printe...

Page 132

3-32 ii linx™ solid inkjet 100 service manual 5. Set the pc’s comm port to comm1. Set the baud rate to 19.2 kbaud, 8 data bits, 1 stop bit and no parity. 6. In your dos window, go to the c:\ prompt. 7. To install the diagnostics from a diskette onto your computer, type: a:install /all . 8. Connect t...

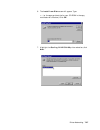

Page 133

Troubleshooting 3-33 the startup screen features the following elements: • a conventional-looking menu bar across the top of the screen; all diagnostic functions are accessible via this menu. • the middle of the screen is a blank gray area; this is a 23 x 80 “tty” in which all interaction takes plac...

Page 134

3-34 ii linx™ solid inkjet 100 service manual alternately, select a test by typing its corresponding letter instead of using arrow keys. • pgup and pgdn – move the display of tests one screen-full at a time. The highlight block generally stays in place on the screen, so this also changes the highlig...

Page 135

Troubleshooting 3-35 diagnostics global help screen • alt-h – opens a small help window to remind which functions are available. Esc or enter (return) make it go away. • f1 – brings up a more complete description about the currently highlighted test. • esc and enter (return) – either key replaces th...

Page 136

3-36 ii linx™ solid inkjet 100 service manual test suite list 1. Press the return key to enter the test group selection window. 2. Use the arrow keys to scroll through the list of tests suites. Press the tab key or the right arrow to select a test suite..

Page 137

Troubleshooting 3-37 once you select a test suite, the individual tests of that suite are displayed. 3. Use the arrow keys to highlight a particular test. 4. Press the space bar to select or deselect a test. You can select as many tests as you like. To run a highlighted test once, press the return k...

Page 138

3-38 ii linx™ solid inkjet 100 service manual 5. After selecting the test(s), press ctrl-r to start the test(s) specifying the number of test cycles to run. The tests run in the order they appear in the menu. Depending on the test, a screen may be displayed to modify how the tests run. The solenoid ...

Page 139

Troubleshooting 3-39 sensor test the sensor test shows you the real-time state of the printer’s sensors. You can manually test the sensors to determine if they operate correctly..

Page 140

3-40 ii linx™ solid inkjet 100 service manual thermal test the thermal tests let you select, start and observe the operation of the printer’s heaters and determine if they are operational. The test displays the real-time temperature of active heaters. A graphic display illustrates if the heater temp...

Page 141

Troubleshooting 3-41 fault history the fault history displays faults as error codes, stored in the printer’s nvram, and the copy count when the fault occurred. Type y to clear the history log..

Page 142

3-42 ii linx™ solid inkjet 100 service manual saving and restoring test selections the current test selection may be saved to a file and later restored, including the completion status of tests which were run earlier. The result of loading a saved test selection file is exactly the same as if the se...

Page 143

Troubleshooting 3-43 view menu provides for changing various screens and major modes of operation for the program. • tests – switches to the 68k window to show results of test running on the print engine. • erase screen – erases all the characters from the currently selected window; it has no affect...

Page 144

3-44 ii linx™ solid inkjet 100 service manual options menu provides for customizing of program operation. Submenus include: • commport – provides for changing the baud rate of the link and for changing the communication port used. The default baud rate is 19.2k. Some diagnostic hosts support rates u...

Page 145: Chapter

Adjustments 4-1 chapter.

Page 146: Chapter 4

4-2 ii linx™ solid inkjet 100 service manual chapter 4 adjustments and calibrations bypass mode (manufacturing mode) . . . . . . . . . . . . . . . . . . . . . . 4-3 cool down mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 hidden service menu . . . . . . . . . . ...

Page 147: Front Panel Menu

Adjustments 4-3 front panel menu the print engine features an interactive menu that allows you to review or change the printer’s stored parameters, as well as initiate test prints and printer service routines. A map of the front panel menu is shown in figure 4-1..

Page 148

4-4 ii linx™ solid inkjet 100 service manual help t opics menu using the ? Button demo and t est p ages t roubleshooting def ault printer settings netw ork settings impro ving print quality print menu map print jet t est p age print quality mode high resolution medical linear ethert alk (toggle) pre...

Page 149

Adjustments 4-5 figure 4-1. Front panel menu map (continured) info service support extended service support (press left arro w printer settings printer identification consumables select to access) f ault history t est prints 1: 32 od le v els (1 page) print quality mode printer name upper p aper cou...

Page 150: Hidden Service Menu

4-6 ii linx™ solid inkjet 100 service manual hidden service menu to access the hidden service menu: 1. Scroll to the service support menu and press the select button. 2. Press and hold the left arrow button. 3. While holding the left arrow button; press the select button. Service support menu previo...

Page 151: Adjustments

Adjustments 4-7 adjustments process belt tension adjustment 1. Turn off the printer and remove the left-side cabinet panel. 2. To adjust the belt tension, loosen the process belt tensioner. With a spring scale, press inward on the tension idler of the process belt with a pressure of 0.7 kg, ± 14 g (...

Page 152

4-8 ii linx™ solid inkjet 100 service manual 0388-28 process belt tensioner press here to set belt deflection figure 4-2. Setting process belt tension 3. Reinstall the left side panel..

Page 153

Adjustments 4-9 exit roller drive belt tension adjustment 1. Turn off the printer and remove the left-side cabinet panel. 2. To adjust the belt tension, loosen the exit roller drive belt tensioner. With a spring scale, press downward on the idler tensioner of the exit roller drive belt with a pressu...

Page 154

4-10 ii linx™ solid inkjet 100 service manual y-axis belts tension adjustment perform this procedure after loosening or removing the y-axis belt drive assembly. (refer to figure 4-4.) 1. Ensure that the three mounting screws that secure the y-axis drive assembly to the chassis are one turn loose and...

Page 155

Adjustments 4-11 attach tension tool to keyholes y-axis belt assembly 0388-30 pull lever arm to set tension tighten screws after setting tension mark the pulleys figure 4-4. Setting the y-axis belt tension.

Page 156

4-12 ii linx™ solid inkjet 100 service manual cold printhead-to-drum spacing adjustment tools required: • printhead-to-drum digital indicator gauge kit • small (3/16 in.) flat-blade screwdriver • 9/64 in. Hex tip • magnetic screwdriver • t-20 torx tip • torque limiting screwdriver • computer running...

Page 157

Adjustments 4-13 3. Remove the ink loader and the metal heat cover. 4. Tilt the printhead to its print position and, if removed, attach the head tilt spring. 5. Torque the mounting screws to 20 in/lbs. 6. Install the digital gap indicator and bracket to the left side of the printer frame and tilt ar...

Page 158

4-14 ii linx™ solid inkjet 100 service manual hot printhead-to-drum spacing adjustment tools required: • printhead-to-drum digital indicator gauge kit • small (3/16 in.) flat-blade screwdriver • 9/64 in. Hex tip • magnetic screwdriver • t-20 torx tip • torque limiting screwdriver • computer running ...

Page 159

Adjustments 4-15 snug in place. 11. Install the digital gap indicator and bracket to the left side of the printer frame and tilt arm as described in the procedure “mounting the digital indicator gauge”. Ensure the digital indicator is set to inches, “in.” note: always move the printhead by moving th...

Page 160

4-16 ii linx™ solid inkjet 100 service manual 19. Terminate the pc-based diagnostics and disconnect the laptop. 20. Reinstall the top cover. 21. Print service test print 12: comb pattern to check alignment. Right tighten locking screws when both left and right adjustments are complete gap tool inser...

Page 161

Adjustments 4-17 occur. Note: some service actions could leave the tilt arm in the wrong location to allow a normal power up. This is especially true in replacing the printhead. When this happens, unusual noise and a loud slam may occur after which the tilt system will recover properly. This happens...

Page 162

4-18 ii linx™ solid inkjet 100 service manual it is flush with the head tilt arm, and then tighten the two screws. The bracket must be flush with the tilt arm. 0388-31 0388-36 upper chassis screw push forward here so bracket is tight against chassis screw and hex screw push forward here so bracket m...

Page 163

Adjustments 4-19 install the gap tools the left and right gap tools must be installed properly to correctly adjust the printhead-to-drum spacing. To install the tools (refer to figure 4-7): 1. Postition the tip of the gap tool between the printhead and the drum. 2. Hook one side of the tool through ...

Page 164

4-20 ii linx™ solid inkjet 100 service manual right 0388-31 hook tool through hold in chassis and over shaft figure 4-7. Installing the gap toolcap/wipe/purge assembly belt adjustments the tension of the cap/wipe/purge assembly belts is factory-set. Do not adjust them unless you remove or replace on...

Page 165

Adjustments 4-21 as long as the belts, cap/wipe/purge assembly motor, and the belt clips (which hold the cap/wipe/purge assembly) are not disturbed, no adjustment is needed. However, if you replace one or both of the belts or the cap/wipe/purge drive motor, you must ensure that the belts are in alig...

Page 166

4-22 ii linx™ solid inkjet 100 service manual unlock index mark on right frame belt lock right cap/wipe/purge assembly belt fan latch lock leave gap between latch and belt tensioner 0388-32 idler pulley left belt lock: align pointer between two index marks for new belt, break off actuator on left-si...

Page 167

Adjustments 4-23 sensor assembly’s encoder wheel groove. This ensures that the encoder wheel is not tensioned and slides easily onto the drum shaft. 2. If not already mounted in place, secure the drum-position sensor assembly onto the drum shaft and secure it to the printer frame. 3. Through the acc...

Page 168

4-24 ii linx™ solid inkjet 100 service manual drum position sensor assembly 0388-33 retaining spring groove gap tool figure 4-9. Setting the drum position encoder gap transfix roller pressure spring adjustment 1. Print the service test print 16: primary solid fills (4 pages). 2. If any of the prints...

Page 169

Adjustments 4-25 6. On the side of the printer corresponding to the wrinkling, tighten the set screw clockwise 1/8 of a revolution, using a 4 mm hex driver. On the side that does not wrinkle, loosen its set screw 1/8 of a revolution. Note: whatever adjustment is added to one side must be taken away ...

Page 170

4-26 ii linx™ solid inkjet 100 service manual x-axis scale adjustment this adjustment sets the gain or rate-of travel of the printhead’s x- axis movement. 1. Allow the printer to warm up to its idle, “ready to print,” state. 2. Enter the “hidden” service menu by scrolling to the service support menu...

Page 171

Adjustments 4-27 adjusting look-up tables the look-up table (lut) menu displays all of the lut resources currently available in the printer. The default lut is indicated with a check mark. The list of available luts is in alphabetic order. If there are contrast values within a family, the menu butto...

Page 172

4-28 ii linx™ solid inkjet 100 service manual paper lut the menu item paper lut customization is found under the menu service support. The paper lut customization setting is a number ranging from 0.5 to 1.0. It affects how built-in look-up tables appear on paper. (user-defined lut families and the l...

Page 173

Adjustments 4-29 setting dmin and dmax adjustments can be made to the dmin and dmax settings in the driver software of the workstation you are sending the data from. Any settings sent by the drivers will overwrite the default settings on the printer for that job. Adjusting dmin will set the lower li...

Page 174

4-30 ii linx™ solid inkjet 100 service manual 4. Print service test print 9. 5. Measure points p1 through p20, and calculate the averages for the boxes having the four different densities: low, medium, high and super high. The values for these densities must be within the following ranges: low 0.13 ...

Page 175: Vacuum Check

Adjustments 4-31 vacuum check tools required: • magnetic screwdriver • vacuum gauge • t-20 torx tip • t-15 torx tip • t-connector for vacuum gauge • pc diagnostics use this check to verify the actions of the vacuum pump and the solenoid valve. In addition, you can determine if the cap/wipe/purge ass...

Page 176

4-32 ii linx™ solid inkjet 100 service manual 0388-35 vacuum guage 40 20 0 60 -76 cap/wipe/purge vacuum hose t-connector vacuum assembly figure 4-12. Connecting the vacuum gauge to the printer 4. Turn on the printer and enable the pc diagnostics as explained in the topic, “pc-based diagnostics.” 5. ...

Page 177: Resetting Nvram

Adjustments 4-33 ink clog in the vacuum tube leading to the cap/wipe/purge assembly. If the vacuum does not bleed off, then the air valve is not opening properly, the 7-mil orifice (a part of the vacuum/pump assembly) is blocked or the vacuum tubing may be clogged. If the printhead is hot, such a co...

Page 178: Calibration

4-34 ii linx™ solid inkjet 100 service manual running reset pe nvram to default or clear ps nvram downloads a file to the printer that performs the indicated reset function; there is no confirmation or cancel function. Calibration x-axis calibration the calibration specification is ± 1 count (0.01) ...

Page 179: Engine Copy Count

Adjustments 4-35 engine copy count the engine copy count maintains the number of pages printed successfully. The total does not include blank cleaning pages nor pages that jam. (the other copy counts, available from the startup page, configuration page, and front panel menu info, do include pages th...

Page 180

4-36 ii linx™ solid inkjet 100 service manual.

Page 181: Chapter

Cleaning and maintenance 5-1 chapter.

Page 182: Chapter 5

5-2 iilinx™ solid inkjet 100 service manual chapter 5 cleaning and maintenance this chapter describes the cleaning procedures to keep the printer in peak operating condition. Some cleaning procedures, such as purging the ink-jets are done automatically when necessary. Other procedures, such as scrub...

Page 183: Cleaning Overview

Cleaning and maintenance 5-3 cleaning overview the printer should be cleaned when any of the following symptoms occur: • light stripes appear in prints. • ink smears or random streaks appear on the front or back of prints. • oily spots appear along the top of prints. • mispicks or multiple picks occ...

Page 184: Cleaning Page

5-4 iilinx™ solid inkjet 100 service manual table 5-1. Problems and cleaning procedures problem type solution light stripes or missing colors missing or light stripes on prints select the automated procedure clean jets from the front panel troubleshooting menu. Ink smears, oil spots or random ink st...

Page 185: Vacuum

Cleaning and maintenance 5-5 vacuum vacuum dust from the top cover, the metal heat shield over the printhead and plastic dust cover under the stripper fingers. Dust should also be vacuumed from the vents, near the fans and anywhere else where it is observed. Drum temperature sensor with a dry swab, ...

Page 186

5-6 iilinx™ solid inkjet 100 service manual the number of remaining cycles can be obtained from the front panel as follows. 1. Allow the printer to warm up to its idle, “ready to print,” state. 2. Scroll to the info selection and press the select button. 3. Repeat for the menus consumables and maint...

Page 187

Cleaning and maintenance 5-7 lubrication tools and supplies required • light oil • grease (nye rheolube 368b) in general, all of the printer’s bearings and motors are lifetime factory-lubricated. However, over time and under certain extreme operating conditions, oil and grease may dry out, causing s...

Page 188

5-8 iilinx™ solid inkjet 100 service manual • loss of traction (tackiness) causing pick or feed failures. Gears: replace gears that show any signs of wear or breakage. Look for these problems: • thinned gear teeth. • bent or missing gear teeth; check especially where a metal gear drives a plastic ge...

Page 189

Cleaning and maintenance 5-9 preventative maintenance checklist ❏ clean feed rollers, exit rollers and guides and stripper fingers only when ink or debris is visible. ❏ clean upper and lower tray pick rollers only when ink or debris is visible. ❏ clean maintenance drawer wiper blade. ❏ clean (dust o...

Page 190

5-10 iilinx™ solid inkjet 100 service manual.

Page 191: Chapter

Removal and replacement 6-1 chapter.

Page 192: Chapter 6

6-2 ii linx™ solid inkjet 100 printer service manual chapter 6 removal and replacement this chapter provides steps to remove and replace key printer field replaceable units (frus). After a brief discussion about the importance of locking the printhead, hardware and then software repair and replace p...

Page 193: Locking The Printhead

Removal and replacement 6-3 locking the printhead during normal power-down, the printer tilts the printhead back and energizes the x-axis drive to move the printhead to the far right. This allows the printhead’s tilt arm, which moves as the printhead moves, to engage a pin protruding from the left-s...

Page 194: Removing The Covers

6-4 ii linx™ solid inkjet 100 printer service manual removing the covers removing the right and left covers 1. Open the front door. 2. Remove the two screws securing the left (or right) cover in place. A sheet-metal screw secures the cover inside the front door. A machine screw secures the cover at ...

Page 195

Removal and replacement 6-5 removing the top cover note: vacuum dust out of the top cover before you remove it. 1. Remove the right cover. 2. Remove the left cover. 3. Open the ink load door and tilt it back. Unclip the ink load door arms from the ink loader’s spring crossarm. 4. Slide the ink loade...

Page 196

6-6 ii linx™ solid inkjet 100 printer service manual removing the rear cover 1. Remove the right cover. 2. Remove the left cover. 3. Remove the top cover. 4. With the top, right and left covers removed, remove the rear cover. Reverse these steps to install the rear cover. 840-4-05 rear cover figure ...

Page 197

Removal and replacement 6-7 removing the front panel 1. Open the exit door. 2. Remove the right and left covers. 3. Remove the three screws securing the front panel. One of the screws is located inside the exit door area. 4. Disconnect the front panel display wiring harness from the right i/o board....

Page 198

6-8 ii linx™ solid inkjet 100 printer service manual removing the front door 1. With a small, flatblade screwdriver, press the release lever on the front door left pivot. The release is located inside a small hole on the left pivot. 2. Slide the door’s right pivot off the right frame post. 3. Remove...

Page 199

Removal and replacement 6-9 removing the exit door and exit roller 1. Remove the right cover. 2. Remove the left cover. 3. At the right side of the printer, remove the cap/wipe/purge electric clutch. Use a small, flatblade screwdriver to release the clutch from the shaft. Also remove the right-side ...

Page 200

6-10 ii linx™ solid inkjet 100 printer service manual 840-4-08 lift release with small screwdriver exit door exit roller lower exit guide exit roller drive pulley left keyed bushing cap/wipe/purge electric clutch right keyed bushing figure 6-6. Removing the exit door and exit roller.

Page 201

Removal and replacement 6-11 removing the ink loader warning even when the printer is turned off, ac line voltages may be present at the printer heaters while the printer is plugged into ac power. 1. Turn off the printer and remove the power cord. Allow the ink loader to cool. Warning hot waste ink ...

Page 202

6-12 ii linx™ solid inkjet 100 printer service manual 840-4-09 ink loader wiring harnesses vacuum/ pump module figure 6-7. Removing the ink loader reverse these steps to install the ink loader. Refer to “wiring diagrams” in appendix c for illustrations showing how to route the ink loader’s wiring ha...

Page 203: Fans

Removal and replacement 6-13 fans removing the left fan 1. Remove the left cover. 2. Disconnect the wiring harnesses leading to the left fan. 3. Remove the two screws securing the left fan to the side frame. Remove the fan. Figure 6-8. Removing the left fan reverse these steps to install the left fa...

Page 204

6-14 ii linx™ solid inkjet 100 printer service manual removing the drum fan 1. Remove the right cover. 2. Disconnect the drum fan’s wiring harnesses. 3. Remove the three screws securing the drum fan in place. Remove the fan. Figure 6-9. Removing the drum fan reverse these steps to install the fan. O...

Page 205: Main Board

Removal and replacement 6-15 main board 1. Power down the printer. Leave the power cord plugged in to provide a ground path for static discharges. Remove the interface cables. 2. Loosen the two rear panel securing screws. 3. Slide out the main board. Refer to figure 6-9. If you are replacing the mai...

Page 206: Power Supply

6-16 ii linx™ solid inkjet 100 printer service manual power supply even when the printer is off, ac line voltage may be present at the printer heaters while the printer is plugged into ac power. 1. Turn off the printer and remove the power cord. 2. Remove the right cover. 3. Remove the left cover. 4...

Page 207

Removal and replacement 6-17 840-4-32 power supply wiring harnesses figure 6-11. Removing the power supply.

Page 208: Power Control Board

6-18 ii linx™ solid inkjet 100 printer service manual power control board 1. Turn off the printer and remove the power cord. 2. Remove the right cover. 3. Remove the left cover. 4. Remove the top cover. 5. Remove the rear cover. 6. Remove the ink loader. 7. Remove the main board. 8. Remove the power...

Page 209

Removal and replacement 6-19 power control board cover plate 840-4-35 figure 6-12. Removing the power control board 11. Disconnect the wiring harnesses leading to the power control board. 12. Remove the four screws securing the power control board cover plate. Remove the plate. 13. Remove the four s...

Page 210: Paper/drum Heater

6-20 ii linx™ solid inkjet 100 printer service manual paper/drum heater warning disconnect the power cord. Ac voltages may be present at the heaters, even with the printer turned off. 1. Remove the right cover. 2. Remove the left cover. Paper / drum heater wiring harness 840-4-16 figure 6-13. Removi...

Page 211: Upper Feed Roller Assembly

Removal and replacement 6-21 5. At the front of the paper/drum heater remove the two screws securing the heater to the inside of the printer frame. Do not confuse the mounting screws with the nearby smaller, brass- colored assembly screws. Reverse these steps to install the paper/drum heater. Upper ...

Page 212

6-22 ii linx™ solid inkjet 100 printer service manual 840-4-13 compound gear slot feed drive belt upper feed roller shaft disconnect head tilt spring upper feed roller electric clutch figure 6-14. Remove the upper feed roller assembly (left side) 6. Front: open the front door and remove the drum mai...

Page 213

Removal and replacement 6-23 9. Disconnect the wiring harness leading from the upper feed roller assembly to the inside the left side of the printer frame. 10. Remove the c-clip located on the left-inside printer frame securing the upper feed roller assembly in place. 11. Remove the upper feed rolle...

Page 214: Drum/transfix Assembly

6-24 ii linx™ solid inkjet 100 printer service manual drum/transfix assembly note: when the drum (see drum/transfix assembly) is replaced, the new drum should be conditioned using the seal drum print suite before the printer is returned to normal service. The seal drum suite is comprised of five cle...

Page 215

Removal and replacement 6-25 840-4-19 exit roller drive belt tensioner exit roller drive belt wiring harness tilt arm spring hex screw compound gear remove drum/transfix assembly screws c-clip figure 6-16. Removing the drum transfix assembly (left side) 12. Right side. Remove the y-axis belt drive a...

Page 216

6-26 ii linx™ solid inkjet 100 printer service manual 17. Remove the five screws securing the right side of the drum/ transfix assembly to the print engine. Note that one screw is removed with a hex key. 18. Carefully, lift and remove the drum/transfix assembly. Protect the drum surface. 840-4-20 le...

Page 217

Removal and replacement 6-27 reverse these steps to install the drum/transfix assembly. Note: upon reassembly, install the hex-keyed screws first; they align the drum/transfix assembly to the engine frame. Make these adjustments after installing a new drum. 1. Ensure the drum position encoder sensor...

Page 218

6-28 ii linx™ solid inkjet 100 printer service manual 840-4-17 mark on the drum shaft to align with the home flag drum home flag drum position encoder wheel figure 6-18. Marking the drum home flag sensor alignment 6. Rotate the tilt gear to orient the gear’s missing teeth to the drum position sensor...

Page 219

Removal and replacement 6-29 840-4-18 screws slide the retaining spring out of the groove groove drum position sensor assembly figure 6-19. Removing the drum position sensor assembly reverse these steps to reinstall the drum position sensor assembly. The drum must be in the same position relative to...

Page 220: Printhead

6-30 ii linx™ solid inkjet 100 printer service manual printhead warning even when the printer is turned off, ac line voltages may be present at the printer heaters while the printer is plugged into ac power. The printhead is hot. 1. Remove the right cover and the left cover. 2. Disconnect the head-t...

Page 221

Removal and replacement 6-31 silicone reservoir plugs 840-4-23 disconnect figure 6-20. Plugging the reservoir holes 8. Rotate the removal tool’s plastic leg into its up position. Slide the removal tool’s standoff locks inward. 9. Place a few sheets of paper between the printhead and the drum to prot...

Page 222

6-32 ii linx™ solid inkjet 100 printer service manual install removal tool 840-4-24 loosen mounting screws slide lock to secure to printhead removal tool leg (in up position) figure 6-21. Removing the printhead installation. If not already in place, install the printhead’s data ribbon cable to the p...

Page 223

Removal and replacement 6-33 3. Torque the mounting screws to 20 in./lbs. 4. Perform a “cold” printhead-to-drum spacing adjustment, followed by a “hot” printhead-to-drum spacing adjustment. X-axis motor and drive assembly reveiw these general operation requirements before servicing the x- axis motor...

Page 224

6-34 ii linx™ solid inkjet 100 printer service manual 4. Remove the two screws securing the x-axis motor and bracket in place. 5. Rotate the black, plastic retainer counter-clockwise. 6. Lift up on the bottom portion of the x-axis drive yoke. Lift up on the yoke and remove the upper portion of the y...

Page 225

Removal and replacement 6-35 reassembly of the x-axis motor and drive assembly for reassembly, apply a small amount of grease on the tip of the nose cone. Apply a small amount, 3 dabs, on the threads of the x-axis shaft. Be sure to rotate the black, plastic retainer so it ends locks the yoke in posi...

Page 226

6-36 ii linx™ solid inkjet 100 printer service manual e790-42-s x-axis drive yoke (install top first) retainer nose cone gear x-axis motor figure 6-23. Installing the x-axis motor and drive assembly 3. Install the upper yoke leg by hooking it into the stiffener tab: pivot toward the side frame until...

Page 227

Removal and replacement 6-37 6. Engage the yoke span and the un-mounted yoke leg by rotating the end tabs of the span to fit through the large rectangular hole of the leg. Orient so the parts are coupled perpendicular to one another. 7. Insert the free span end of this assembly into the upper leg op...

Page 228

6-38 ii linx™ solid inkjet 100 printer service manual 840-4-12 y-axis belt assembly tension screws never remove these screws figure 6-24. Removing the y-axis belt drive assembly 4. Remove the three tension set screws securing the y-axis belt drive assembly to the engine frame. Remove the assembly wi...

Page 229

Removal and replacement 6-39 y-axis (drum) motor and process motor 1. Remove the right cover. 2. Remove the left cover. 3. Remove the front panel. 4. Remove the drum maintenance drawer. 5. If you are removing the y-axis motor, remove the y-axis belt drive assembly. 6. Remove the upper feed roller as...

Page 230

6-40 ii linx™ solid inkjet 100 printer service manual drum transfix assembly y-axis motor process motor 840-4-21 figure 6-25. Y-axis (drum) motor and process motor removing the paper path motor 1. Remove the right cover. 2. Disconnect the paper path motor wiring harness from the power control board....

Page 231

Removal and replacement 6-41 paper path motor remove three screws 840-4-28 figure 6-26. Removing the paper path motor.

Page 232: Cap/wipe/purge Assembly

6-42 ii linx™ solid inkjet 100 printer service manual cap/wipe/purge assembly warning even when the printer is turned off, ac line voltages may be present at the printer heaters while the printer is plugged into ac power. 1. Remove the right cover. 2. Remove the left cover. 3. Disconnect the head-ti...

Page 233

Removal and replacement 6-43 short pin screw cap wipe/ purge assembly vacuum inlet 840-4-43 long pin screw short pin screw figure 6-27. Removing the cap/wipe/purge assembly removing cap/wipe/purge belts 1. Remove the right, left and top covers. 2. Disconnect the head-tilt spring. Tilt back the print...

Page 234

6-44 ii linx™ solid inkjet 100 printer service manual 5. At the right side of the printer, slide the metal vacuum hose out of the cap/wipe/ purge unit. 6. Unlatch the timing belt lock of each belt to free each belt. When installing new belts, reverse these steps and attach each belt so that the poin...

Page 235

Removal and replacement 6-45 removing stripper finger assemblies 1. Remove the right, left and top covers. 2. Upper stripper finger assembly. At the right side of the printer, remove the transfix solenoid bracket. 3. Remove the cutting screw securing the right end of the upper stripper finger assemb...

Page 236: Clutch

6-46 ii linx™ solid inkjet 100 printer service manual 840-4-27 spring unit lower stripper finger assembly upper stripper finger assembly extruded pin cam rider transfix roller cam spring spring bushing bushing c-clip c-clip cutting screw figure 6-29. Removing stripper finger assemblies removing the ...

Page 237

Removal and replacement 6-47 5. Remove the right i/o board. 6. At the right side of the printer, use a small, flatblade screwdriver to unlock the maintenance cam roller flag from the end of the maintenance cam roller. 7. Inside the left-side printer frame, remove the c-clip securing the maintenance ...

Page 238: Assembly

6-48 ii linx™ solid inkjet 100 printer service manual removing maintenance drawer counter connector assembly warning allow the printer to cool for 30 minutes. 1. Remove the right, left and top covers. 2. Remove the ink loader. 3. Remove the maintenance drawer. 4. Disconnect the maintenance drawer co...

Page 239

Removal and replacement 6-49 840-4-64 maintenance drawer counter connector assembly disconnect wiring harness figure 6-31. Removing maintenance drawer counter connector assembly.

Page 240

6-50 ii linx™ solid inkjet 100 printer service manual removing preheater exit sensor warning allow the printer to cool for 30 minutes. 1. Remove the right, left and front covers. 2. Remove the upper feed roller assembly. 3. Remove the paper/drum heater. 4. Disconnect the preheater exit sensor wiring...

Page 241

Removal and replacement 6-51 840-4-65 transfix roller drum remove screw preheater exit sensor in its bracket disconnect wiring harness left i/o board figure 6-32. Removing the preheater exit sensor.

Page 242

6-52 ii linx™ solid inkjet 100 printer service manual removing the drum temperature sensor 1. Remove the right cover, 2. Remove the left cover. 3. Remove the top cover. 4. Remove the ink loader. 5. Unplug the drum temperature sensor from the left i/o board. 6. Remove the screw securing the drum temp...

Page 243: Installing Ram Dimms

Removal and replacement 6-53 installing ram dimms the printer accepts two sdram dimms which are 64 mbyte in size. The printer recognizes any acceptable size sdram dimm in any ram dimm slot. Use the following steps to installing new ram dimms. 1. Power down the printer. Leave the power cord plugged i...

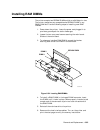

Page 244: Installing The Code Rom Dimm

6-54 ii linx™ solid inkjet 100 printer service manual 840-4-36 main board ram dimms real time clock/nvram printer id code rom dimm figure 6-35. Installing ram dimms installing the code rom dimm the code rom dimm contains both print engine and postscript firmware. Use the following steps to resinstal...

Page 245

Removal and replacement 6-55 4. To install the code rom in the keyed dimm connector, insert the dimm until it locks in place. When properly inserted, a tab on each end of the connector slips into a notch on each end of the rom dimm. 5. Reinstall the main board into the printer. 6. Reconnect the host...

Page 246

6-56 ii linx™ solid inkjet 100 printer service manual installing the optional ethernet network card 1. Power down the printer. Leave the power cord plugged in to provide a ground path for static discharges. Remove the interface cable. 2. Loosen the two securing screws holding the network card or the...

Page 247

Removal and replacement 6-57 installing the internal hard drive 1. Power down the printer. Leave the power cord plugged in to provide a ground path for static discharges. 2. Remove the network card or the network card slot cover plate, whichever is in place. 3. Loosen the two securing screws holding...

Page 248: Upgrading Software

6-58 ii linx™ solid inkjet 100 printer service manual upgrading software the operating system of the solid inkjet 100 printer is capable of reprogramming the embedded software using flash memory technology. When instructed to flash, the os overlays a special boot program, the flash monitor, onto ram...

Page 249: Chapter

Printer networking 7-1 chapter 7.

Page 250: Chapter 3

7-2 ii linx™ solid inkjet 100 printer service manual chapter 3 t of c printer networking this guide provides information to help you quickly install the ii linx™ solid inkjet 100 printer in the following environments: • mac® os (ethertalk) • windows® 95 and windows® 98 • windows nt® • novell® netwar...

Page 251

Printer networking 7-3 before you begin network configuration • set up your printer and physcially connect it to the network. See the iilinx solid inkjet 100 user manual for information about setting up the printer. • install the solid inkjet 100 driver for your printer on every macintosh and pc tha...

Page 252

7-4 ii linx™ solid inkjet 100 printer service manual caution setting the printer’s ip addressing parameters in order to install the printer in a network environment, obtain the information listed in table 3-1. It might be helpful to write down this information so you can refer to it during the confi...

Page 253

Printer networking 7-5 setting ip parameters from the front panel 1. When the front panel displays ready to print , press the down-arrow button until menu is highlighted. Press the select button. 2. Press the down-arrow button until network settings is highlighted. Press the select button. 3. Press ...

Page 254

7-6 ii linx™ solid inkjet 100 printer service manual setting ip parameters—dhcp dynamic host configuration protocol (dhcp) is a system in which windows nt servers can allocate ip addresses dynamically. Under dhcp, the server gives the printer (called a dhcp client) an ip address when the printer is ...

Page 255: Ethernet

Printer networking 7-7 ethernet ® interface built-in ethernet ® connector the printer’s built-in ethernet® connector has the following connections and indicators: 1. Link indicator—on indicates a working connection to a hub; off indicates no connection to a hub. 2. Rcv indicator (green)—blinks while...

Page 256

7-8 ii linx™ solid inkjet 100 printer service manual optional ethernet ® interface card the optional ethernet interface card (figure 7-1) has the following connections and indicators: 1. Tx indicator (yellow)—blinks while the network interface is transmitting. 2. Rx link indicator (green)—blinks whi...

Page 257

Printer networking 7-9 ethernet ® cables and termination note: to fully comply with emi (electro-magnetic interference) specifications, the use of shielded or screened cables may be required. “shielded” describes ibm-defined cables used with the db-9 connector. “screened” describes cables that are e...

Page 258: Mac

7-10 ii linx™ solid inkjet 100 printer service manual mac ® os: ethertalk configuration note: the printer’s appletalk connection works with macintosh system software 7.0, 7.1, 7.5, 7.6, 8.0, 8.1, and 8.5. Finding the printer’s name in the chooser 1. From the apple menu, select chooser. 2. In the lef...

Page 259: Novell