- DL manuals

- Makita

- Saw

- EA3200S

- Instruction Manual

Makita EA3200S Instruction Manual

Summary of EA3200S

Page 1

Instruction manual original instruction manual ea3200s ea3201s ea3202s ea3203s important: read this instruction manual carefully before putting the chain saw into operation and strictly observe the safety regulations! Keep this instruction manual!.

Page 2

2 thank you for purchasing a makita product! Congratulations on choosing a makita chain saw! We are confi‑ dent that you will be satisfied with this modern piece of equipment. The ea3200s, ea3201s, ea3202s, ea3203s are very handy and robust chain saws with a new design. The automatic chain lubricati...

Page 3

3 4 5 6 3 2 1 delivery inventory 1. Chain saw 2. Guide bar 3. Saw chain 4. Chain protection cover 5. Universal wrench 6. Screwdriver for carburetor adjustment 7. Instruction manual (not shown) in case one of the parts listed should not be included in the delivery inventory, please consult your sales...

Page 4

4 4 5 6 7 1 2 3 1 4 3 2 safety precautions intended use power chain saws this power chain saw may be used only for sawing wood out of doors. It is intended for the following uses depending on its class: - professional and mid-class: use on small, medium and large trees: felling, limb removal, cuttin...

Page 5

5 stop on stop on 6 5 7 9 8 fuels / refuelling ‑ stop the engine before refuelling the chain saw. ‑ do not smoke or work near open fires (5). ‑ let the engine cool down before refuelling. ‑ fuels can contain substances similar to solvents. Eyes and skin should not come in contact with mineral oil pr...

Page 6

6 10 12 13 14 11 kickback ‑ when working with the chain saw dangerous kickbacks may occur. ‑ kickback occurs when the upper part of the end of the guide bar inadvertently touches wood or other hard objects (10). ‑ this causes the saw to be thrown back toward the user with great force and out of cont...

Page 7

7 b a b 15 16 17 18 19 45 o 45 o 2 1 / 2 ‑ be careful when cutting splintery wood. Cut pieces of wood may be pulled along (risk of injuries). ‑ when cutting with the upper edge of the guide bar, the chain saw may be pushed in the direction of the user if the chain gets clamped. For this reason use t...

Page 8

8 20 21 22 23 vibration individuals with poor circulation who are exposed to excessive vibration may experience injury to blood vessels or the nervous system. Vibration may cause the following symptoms to occur in the fingers, hands or wrists: “falling asleep” (numbness), tingling, pain, stabbing se...

Page 9

9 ea3200s ea3201s ea3202s ea3203s stroke volume cm 3 32 bore mm 38 stroke mm 28.2 max. Power at speed kw / 1/min 1.35 / 10,000 max. Torque at speed nm / 1/min 1.6 / 7,000 idling speed / max. Engine speed with bar and chain 1/min 2,800 / 12,800 clutch engagement speed 1/min 4,100 sound pressure level...

Page 10

10 2 3 1 4 6 5 7 9 13 14 11 12 10 8 16 15 17 18 19 20 22 23 21 24 25 26 1 handle 2 cover 3 hood lock 4 tubular handle 5 hand guard (release for chain brake) 6 muffler 7 spike bar 8 chain tensioning screw 9 retaining nuts 10 chain catcher 11 sprocket guard 12 adjusting screw for oil pump (bottom side...

Page 11

11 5 7 6 5 4 1 2 3 put on the guide bar (7). Make sure that the pin (5) of the chain tensioner engages in the hole in the guide bar. Mounting the guide bar and saw chain use the universal wrench delivered with the chain saw for the following work. Put the chain saw on a stable surface and carry out ...

Page 12

12 2 4 12 3 2 10 8 9 9 11 replace the sprocket guard (3). Important: lift the saw chain over the chain catcher (12). Tighten the nuts (2) only hand‑tight to begin with. Lift the chain (9) over the sprocket (8). Caution: do not insert the chain between the chain sprocket and the disc. Guide the chain...

Page 13

13 2 4 checking the chain tension the tension of the chain is correct if the chain rests against the bottom side of the guide bar and can still be easily turned by hand. While doing so the chain brake must be released. Check the chain tension frequently ‑ new chains tend to get longer during use! Wh...

Page 14

14 1 2 3 7 5 6 5 4 lift the chain (6) over the sprocket (5). Caution: do not insert the chain between the chain sprocket and the disc. Guide the chain from above about halfway into the groove (7) on the guide bar. Caution: note that the cutting edges along the top of the chain must point in the dire...

Page 15

15 2 4 2 10 6 8 9 3 2 pull the chain (6) around the sprocket nose (8) of the guide bar in the direction of the arrow. Replace the sprocket guard (3). Important: lift the saw chain over the chain catcher (9). Tighten the nuts (2) only hand‑tight to begin with. Tensioning the saw chain turn the quicks...

Page 16

16 6 5 1 2 4 3 9 7 8 mounting the guide bar and saw chain place the saw on a stable surface and perform the following work steps in order to install the guide bar and saw chain: release the chain brake by pulling the hand guard (1) in direction of arrow. Fold up the sprocket guard quick tensioner (2...

Page 17

17 12 11 4 3 2 15 8 10 pull the chain (8) around the sprocket nose (10) of the guide bar in the direction of the arrow. Tightening the saw chain simultaneously push in hard on the sprocket guard quick tensioner (2) and turn it clockwise to screw the sprocket guard on, but do not yet tighten it. Rais...

Page 18

18 1 1 2 2 4 2 checking the chain tension the tension of the chain is correct if the chain rests against the bottom side of the guide bar and can still be easily turned by hand. While doing so the chain brake must be released. Check the chain tension frequently ‑ new chains tend to get longer during...

Page 19

19 fuel caution: this saw is powered by mineral-oil products (gasoline and oil). Be especially careful when handling gasoline. Do not smoke. Keep tool well away from open flames, spark, or fire (explosion hazard). Fuel mixture this tool is powered by a high‑performance air‑cooled two‑stroke engine. ...

Page 20

20 filling fuel and chain oil follow the safety precautions! Be careful and cautious when handling fuels. The engine must be switched off! Thoroughly clean the area around the caps, to prevent dirt from getting into the fuel or oil tank. Unscrew the tank cap (use the universal wrench if necessary, s...

Page 21

21 2 3 + - 1 checking the chain lubrication never work with the chain saw without sufficient chain lubri ‑ ca tion. Otherwise the service life of the chain and guide bar will be reduced. Before starting work check the oil level in the tank and the oil feed. Check the oil feed rate as described below...

Page 22

22 1 2 4 5 3 on starting the engine do not start the chain saw until after it is completely assembled and checked! Move at least 3 meters / 10 feet away from the place where the chain saw was fuelled. Make sure you have a secure footing, and place the saw on the ground in such a way that the guide b...

Page 23

23 6 checking the chain brake the chain brake must be checked before every use of the saw! Start the engine as described above (have a secure footing, place the chain saw on the ground so that the chain and guide bar are not near anything). Hold the front handle firmly, with your other hand on the r...

Page 24

24 service adjusting the carburetor caution: carburetor adjustment may only be done by a specialist makita service center! Do not undertake any adjustments to adjusting screws (h) and (l) without a tachometer! Incorrect adjustment can lead to engine damage! A tachometer is needed for adjustments to ...

Page 25

25 α α β β min. 3 mm (0.11”) the sharpening angle (α) must be identical for all cutters! 30° for chain type 092, 290 the teeth will have the proper angle (ß) automatically if the proper round file is used. 80° for chain type 092, 290 different angles result in a roughly, irregularly running chain, i...

Page 26

26 1 2 4/5 chain type 092 290 files and how to work with them use a special saw chain round file for sharpening. Standard round files are unsuitable. See “extract from the spare parts list”. Type 092: saw chain round file, dia. 4.0 mm. Type 290: saw chain round file, dia. 4.5 mm. The file should cut...

Page 27

27 1 3 2 4 5 cleaning the inside of the sprocket guard caution: before doing any work on the guide bar or chain, always switch off the engine and pull the plug cap off the spark plug (see “replacing the spark plug”). Always wear protective gloves! Caution: start the chain saw only after having as- s...

Page 28

28 11 9 12 8 check the sprocket before mounting a new chain. Worn out sprockets (8) may damage the new chain and must therefore be replaced. Remove the sprocket guard (see “putting into opera‑ tion”). Remove the chain and guide bar. Remove circlip (9). Caution: the circlip will pop out of the groove...

Page 29

29 3 1 2 4 7 5 4 5 3 4 6 5 cleaning the air filter caution: to prevent eye injury, always wear eye protec- tion when cleaning the filter with compressed air! Do not use fuel to clean the air filter. Loosen the scew (1) counter‑clockwise and remove the hood (2). Push up the combination switch (3) (ch...

Page 30

30 8 0.5 mm 10 9 13 11 12 replacing the spark plug caution: do not touch the spark plug or plug cap if the engine is running (high voltage). Switch off the engine before starting any maintenance work. A hot engine can cause burns. Wear protective gloves! The spark plug must be replaced in case of da...

Page 31

31 7 2 8 11 6 5 13 3 9 12 10 14 1 4 replacing the starter cable/ replacing the return spring pack/replacing the starter spring unscrew three screws (1). Remove fan housing (2). Remove the air guide (3) from the fan housing. Careful! Injury hazard! Do not unscrew screw (7) if the return spring is und...

Page 32

32 16 replacing the suction head the felt filter (16) of the suction head can become clogged. It is recommended to replace the suction head once every three months in order to ensure unimpeded fuel flow to the carburetor. To remove the suction head for replacement, pull it out through the tank fille...

Page 33

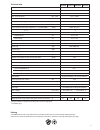

33 instructions for periodic maintenance to ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be performed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform the ...

Page 34

34 service, spare parts and guarantee maintenance and repair the maintenance and repair of modern engines as well as all safety devices require qualified technical training and a special work‑ shop equipped with special tools and testing devices. Any work not described in this manual may be performe...

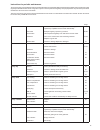

Page 35

35 trouble shooting malfunction system observation cause chain does not run chain brake engine runs chain brake actuated. Engine does not start or only with difficulty ignition system ignition spark malfunction in fuel supply system, compression system, mechanical malfunction. No ignition spark stop...

Page 36

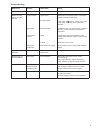

36 26 27 28 29 32 30/31 25 10 8 9 7 22 20 6 4 19 1 2 3 14 17 15 16 18 13 11 12 21 ea3200s, ea3201s ea3202s, ea3203s extract from the spare parts list use only original makita parts. For repairs and replacement of other parts, see your makita service center..

Page 37

37 extract from the spare parts list use only original makita parts. For repairs and replacement of other parts, see your makita service center. Ea3200s, ea3201s ea3202s, ea3203s pos. Qty. Denomination 1 1 sprocket nose bar 3/8”, 30 cm, 1.3 mm (12”) 1 sprocket nose bar 3/8”, 35 cm, 1.3 mm (14”) 1 sp...

Page 38

38 for european countries only 12. Ec declaration of conformity we makita corporation as the responsible manufacturer declare that the following makita machine(s): designation of machine: petrol chain saw model no./ type: ea3200s, ea3201s specifications: see “technical data” table. Are of series pro...

Page 39

39.

Page 40

Makita corporation anjo, aichi, japan 884987a228 www.Makita.Com ala.