- DL manuals

- Vacon

- DC Drives

- 100 INDUSTRIAL

- Applications Manual

Vacon 100 INDUSTRIAL Applications Manual

Summary of 100 INDUSTRIAL

Page 1

Vacon 100 hvac drives application manual ®.

Page 3

Vacon • 0 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com table of contents document id: dpd00491h order code: doc-app02456+dluk rev. H revision release date: 7.5.13 corresponds to application package fw0065v021.Vcx 1. Vacon 100 - startup ...................................................

Page 4

Vacon • 1 tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.11 group 3.9: protections .................................................................................................... 66 3.6.12 group 3.10: automatic reset ...........................................................................

Page 5

Vacon 100 - startup vacon • 2 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 1 1. V acon 100 - s tartup 1.1 startup wizard in the startup wizard , you will be prompted for essential information needed by the drive so that it can start controlling your process. In the wizard, you will n...

Page 6

1 vacon • 3 vacon 100 - startup tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 push the ok button unless you want to set all parameter values manually. Now the startup wizard is done. The startup wizard can be re-initiated by activating the parameter restore factory defaults (parameter p6.5.1) in ...

Page 7

Vacon 100 - startup vacon • 4 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 1 if one of the analogue input signals is selected the question 9 appears. Otherwise you will be taken to question 11. If either of the options keypad setpoint 1 or 2 is chosen the question 10 will appear. If ...

Page 8

1 vacon • 5 vacon 100 - startup tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 after this, the keypad will show the digital input and relay output configuration done by the application (graphical keypad only). Write these values down for future reference. 1.4 fire mode wizard the fire mode wizard ...

Page 9

Keypad of the drive vacon • 6 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2. K eypad of the drive the control keypad is the interface between the vacon 100 frequency converter and the user. With the control keypad it is possible to control the speed of a motor, to supervise the st...

Page 10

2 vacon • 7 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.1 vacon keypad with graphical display the graphical keypad features an lcd display and 9 buttons. 2.1.1 keypad display the keypad display indicates the status of the motor and the drive and any irregularities in motor...

Page 11: Or:

Keypad of the drive vacon • 8 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 figure 3. Editing values on graphical keypad 2.1.2.2 resetting fault instructions for how to reset a fault can be found in chapter 3.8.1 on page 111. 2.1.2.3 local/remote control button the loc/rem button is...

Page 12

2 vacon • 9 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4. The display will return to the same location as it was when the loc/rem button was pushed. However, if the remote control place was changed to local (keypad) you will be prompted for keypad reference. Figure 4. Chang...

Page 13

Keypad of the drive vacon • 10 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.1.2.4 copying parameters note! This feature is available in graphical keypad only. The parameter copy function can be used to copy parameters from one drive to another. The parameters are first saved to t...

Page 14

2 vacon • 11 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.1.2.5 help texts the graphical keypad features instant help and information displays for various items. All parameters offer an instant help display. Select help and press the ok button. Text information is also avai...

Page 15

Keypad of the drive vacon • 12 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.2 vacon keypad with text segment display you can also choose a keypad with text segment display (text keypad) for your user interface. It has mainly the same functionalities as the keypad with graphical d...

Page 16

2 vacon • 13 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.2.2 using the keypad 2.2.2.1 editing values change value of a parameter following the procedure below: 1. Locate the parameter. 2. Enter the edit mode by pressing ok. 3. Set new value with the arrow buttons up/down. ...

Page 17

Keypad of the drive vacon • 14 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 changing control places change of control place from remote to local (keypad). 1. Anywhere in the menu structure, push the loc/rem button. 2. Using the arrow buttons, select local/remote and confirm with th...

Page 18

2 vacon • 15 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.3 menu structure click on and select the item you wish to receive more information about (electronic manual). Table 1. Keypad menus quick setup see chapter 3.4. Monitor multi-monitor* basic timer functions pid contro...

Page 19

Keypad of the drive vacon • 16 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.3.1 quick setup the quick setup menu includes the minimum set of most commonly used parameters during installation and commissioning. More detailed information on the parameters of this group you will fin...

Page 20

2 vacon • 17 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.3.3 parameters through this submenu, you can reach the application parameter groups and parameters. More information on parameters in chapter 3. 2.3.4 diagnostics under this menu, you can find active faults , reset f...

Page 21

Keypad of the drive vacon • 18 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.3.4.4 total counters table 2: diagnostics menu, total counters parameters index parameter min max unit default id description v4.4.1 energy counter varies 2291 amount of energy taken from supply network. ...

Page 22

2 vacon • 19 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.3.4.5 trip counters 2.3.4.6 software info table 3: diagnostics menu, trip counters parameters index parameter min max unit default id description p4.5.1 energy trip counter varies 2296 resettable energy counter. Note...

Page 23

Keypad of the drive vacon • 20 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.3.5 i/o and hardware various options-related settings are located in this menu. 2.3.5.1 basic i/o monitor here the statuses of inputs and outputs. 2.3.5.2 option board slots the parameters of this group d...

Page 24

2 vacon • 21 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.3.5.3 real time clock 2.3.5.4 power unit settings fan the fan operates in optimized or always-on mode. In the optimized mode, fan speed is controlled according to the drive‘s internal logic that receives data from te...

Page 25

Keypad of the drive vacon • 22 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.3.5.5 keypad * only available with graphical keypad table 9: power unit settings, sine filter index parameter min max unit default id description p5.6.4.1 sine filter 0 1 0 2507 0 = disabled 1 = enabled t...

Page 26

2 vacon • 23 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.3.5.6 fieldbus parameters related to different fieldbus boards can also be found in the i/o and hardware menu. These parameters are explained in more detail in the respective fieldbus manual. Submenu level 1 submenu ...

Page 27

Keypad of the drive vacon • 24 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 rs-485 bacnet ms/tp parameters baud rate autobauding mac address instance number communication timeout monitoring fieldbus protocol status communication status actual instance number fault code control word...

Page 28

2 vacon • 25 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 * will appear only after connection has been established table 11: rs-485 common settings index parameter min max unit default id description p5.8.1.1 protocol 0 9 0 2208 0 = no protocol 4 = modbus rtu 5 = n2 9 = bacne...

Page 29

Keypad of the drive vacon • 26 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 table 15: n2 monitoring (this table is only visible when p5.8.1.1 protocol = 5/n2) table 16: bacnet mstp parameters (this table is only visible when p5.8.1.1 protocol = 9/ bacnetmstp) table 17: bacnet mstp ...

Page 30

2 vacon • 27 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 table 19: fixed ip table 20: modbus tcp common settings table 21: bacnet ip settings table 22: bacnet ip monitoring index parameter min max unit default id description p5.9.1.2.1 ip address 192.168.0.10 2529 the parame...

Page 31

Keypad of the drive vacon • 28 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.3.6 user settings 2.3.6.1 parameter backup table 23: user settings menu, general settings index parameter min max unit default id description p6.1 language selections varies varies varies 802 depends on l...

Page 32

2 vacon • 29 keypad of the drive tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.3.7 favourites note! This menu is not available in text keypad. Favourites are typically used to collect a set of parameters or monitoring signals from any of the keypad menus. You can add items or parameters to the ...

Page 33

Vacon hvac application vacon • 30 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3. V acon hvac a pplication the vacon hvac drive contains a preloaded application for instant use. The parameters of this application are listed in chapter 3.6 of this manual and explained in more detail...

Page 34

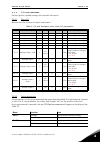

3 vacon • 31 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.2 example of control connections table 27. Connection example, standard i/o board standard i/o board terminal signal default 1 +10 v ref reference output 2 ai1+ analogue input, voltage or current * * selectable wi...

Page 35

Vacon hvac application vacon • 32 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 table 28. Connection example, relay board 1 relay board 1 default terminal signal 21 ro1/1 nc relay output 1 run 22 ro1/2 cm 23 ro1/3 no 24 ro2/1 nc relay output 2 fault 25 ro2/2 cm 26 ro2/3 no 32 ro3/1 ...

Page 36

3 vacon • 33 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.3 isolating digital inputs from ground the digital inputs (terminals 8-10 and 14-16) on the standard i/o board can also be isolated from ground by setting the dip switch on the control board to position off . See ...

Page 37

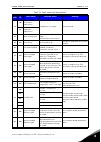

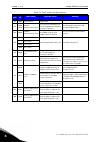

Vacon hvac application vacon • 34 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.4 hvac application - quick setup parameter group the quick setup parameter group is a collection of parameters that are most commonly used during installation and commissioning. They are collected in t...

Page 38

3 vacon • 35 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 * = the parameter is only visible on the graphical keypad. ** = the parameter is only visible on the graphical and the text keypad. P1.17 pid mini-wizard * 0 1 0 1803 0 = inactive 1 = activate see chapter 1.2. P1.18...

Page 39

Vacon hvac application vacon • 36 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.5 monitor group vacon 100 ac drive provides you with a possibility to monitor the actual values of parameters and signals as well as statuses and measurements. Some of the values to be monitored are cu...

Page 40

3 vacon • 37 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 v2.2.18 last active fault 37 the fault code of latest activated fault that has not been reset. V2.2.19 fire mode status 1597 0 = disabled 1 = enabled 2 = activated (enabled + di open) 3 = test mode v2.2.20 din statu...

Page 41

Vacon hvac application vacon • 38 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.5.3 timer functions monitoring here you can monitor values of timer functions and the real time clock. Table 32: monitoring of timer functions code monitoring value unit id description v2.3.1 tc 1, tc ...

Page 42

3 vacon • 39 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.5.4 pid1 controller monitoring 3.5.5 pid2 controller monitoring 3.5.6 multi-pump monitoring table 33: pid1-controller value monitoring code monitoring value unit id description v2.4.1 pid1 setpoint varies 20 proce...

Page 43

Vacon hvac application vacon • 40 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.5.7 fieldbus data monitoring table 36: fieldbus data monitoring code monitoring value unit id description v2.8.1 fb control word 874 fieldbus control word used by application in bypass mode/format. Dep...

Page 44

3 vacon • 41 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.5.8 temperature inputs monitoring this menu is only visible if there is an option card installed having temperature measurement inputs, such as the opt-bj option cards. Table 37: temperature inputs monitoring inde...

Page 45

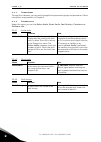

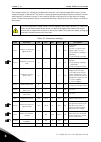

Vacon hvac application vacon • 42 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6 vacon hvac application - application parameter lists find the parameter menu and the parameter groups as guided below. The hvac application embodies the following parameter groups: table 38. Paramete...

Page 46

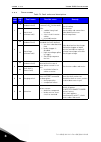

3 vacon • 43 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.1 column explanations code = location indication on the keypad; shows the operator the parameter number. Parameter = name of parameter min = minimum value of parameter max = maximum value of parameter unit = uni...

Page 47

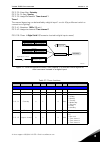

Vacon hvac application vacon • 44 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.2 parameter programming the programming of digital inputs in vacon hvac application is very flexible. There are no digital terminals assigned only for certain function. You can choose the terminal of...

Page 48

3 vacon • 45 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 example: you want to connect the control signal 2 a (parameter p3.5.1.2) to digital input di2 on standard i/o board. 3.6.2.1 example programming with graphical keypad 1 locate the parameter control signal 2 a (p3.5....

Page 49

Vacon hvac application vacon • 46 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.2.2 example programming with text keypad 1 locate the parameter control signal 2 a (p3.5.1.2) on the keypad. 2 enter the edit mode by pressing ok. The initial character starts to blink. Change the va...

Page 50

3 vacon • 47 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.2.3 descriptions of signal sources: table 39. Descriptions of signal sources source function slot0 1 = always false, 2-9 = always true slota number corresponds to digital input in the slot. Slotb number correspo...

Page 51

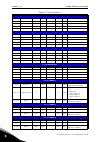

Vacon hvac application vacon • 48 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.3 group 3.1: motor settings 3.6.3.1 basic settings table 40: basic motor settings index parameter min max unit default id description p3.1.1.1 motor nominal voltage varies varies v varies 110 find th...

Page 52

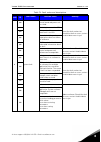

3 vacon • 49 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.3.2 motor control settings table 41: advanced motor settings index parameter min max unit default id description p3.1.2.1 switching frequency 1.5 varies khz varies 601 motor noise can be minimised using a high s...

Page 53

Vacon hvac application vacon • 50 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 index parameter min max unit default id description p3.1.2.18 energy optimization 0 1 0 666 the drive searches for the minimum motor current in order to save energy and to lower the motor noise. This fun...

Page 54

3 vacon • 51 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.4 group 3.2: start/stop setup start/stop commands are given differently depending on the control place. Remote control place (i/o a): start, stop and reverse commands are controlled by 2 digital inputs chosen wi...

Page 55

Vacon hvac application vacon • 52 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.5 group 3.3: control reference settings the requency reference source is programmable for all control places except pc , which always takes the reference from the pc tool. Remote control place (i/o a...

Page 56

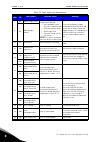

3 vacon • 53 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.3.8 keypad reference copy 0 2 1 181 selects function for run state & reference copy when changing to keypad control: 0 = copy reference 1 = copy ref & run state 2 = no copying p3.3.9 fieldbus control reference se...

Page 57

Vacon hvac application vacon • 54 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.3.22 reverse direction 0 1 0 15530 this parameter enables or disables the function to run the motor in reverse direction. This parameter shall be set to reverse prevented if there is a risk of causing...

Page 58

3 vacon • 55 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.6 group 3.4: ramp & brakes setup two ramps are available (two sets of acceleration time, deceleration time and ramp shape). The second ramp can be activated by a digital input. Note! Ramp 2 always has higher pri...

Page 59

Vacon hvac application vacon • 56 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.7 group 3.5: i/o configuration 3.6.7.1 digital inputs digital inputs are very flexible to use. Parameters are functions that are connected to the required digital input terminal. The digital inputs a...

Page 60

3 vacon • 57 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.5.1.23 pid2 start signal digin slot0.2 1049 false = pid2 in stop mode true = pid2 regulating this parameter will have no effect if pid2 controller is not enabled in the basic menu for pid2 p3.5.1.24 pid2 select s...

Page 61

Vacon hvac application vacon • 58 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.7.2 analogue inputs table 46: analogue input settings index parameter min max unit default id description p3.5.2.1 ai1 signal selection anin slota.1 377 connect the ai1 signal to the analogue input o...

Page 62

3 vacon • 59 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.5.2.29 ai5 custom. Max -160.00 160.00 % 100.00 192 custom range max setting p3.5.2.30 ai5 signal inversion 0 1 0 198 0 = normal 1 = signal inverted p3.5.2.31 ai6 signal selection anin slot0.1 199 see p3.5.2.13. P...

Page 63

Vacon hvac application vacon • 60 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.7.3 digital outputs, slot b (basic) table 47: digital output settings on standard i/o board index parameter min max unit default id description p3.5.3.2.1 basic r01 function 0 39 2 11001 function sel...

Page 64

3 vacon • 61 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.7.4 expander slots d and e digital outputs 3.6.7.5 analogue outputs, slot a (standard) table 48: slot d/e digital outputs index parameter min max unit default id description application dynamic output list shows...

Page 65

Vacon hvac application vacon • 62 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.7.6 expander slots d to e analogue outputs table 50: slot d/e analogue outputs index parameter min max unit default id description application dynamic output list shows only parameters for existing o...

Page 66

3 vacon • 63 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.8 group 3.6: fieldbus data mapping fieldbus process data out values to monitor through fieldbus are: table 51: fieldbus data mapping index parameter min max unit default id description p3.6.1 fieldbus data out 1...

Page 67

Vacon hvac application vacon • 64 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.9 group 3.7: prohibit frequencies in some systems it may be necessary to avoid certain frequencies due to mechanical resonance problems. By setting up prohibit frequencies it is possible to skip thes...

Page 68

3 vacon • 65 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.10 group 3.8: limit supervisions choose here: 1. One or two (p3.8.1/p3.8.5) signal values for supervision. 2. Whether the low or high limits are supervised (p3.8.2/p3.8.6) 3. The actual limit values (p3.8.3/p3.8...

Page 69

Vacon hvac application vacon • 66 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.11 group 3.9: protections parameters of motor thermal protection (p3.9.6 to p3.9.10) the motor thermal protection is to protect the motor from overheating. The drive is capable of supplying higher th...

Page 70

3 vacon • 67 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 the torque values for setting the underload curve are set in percentage which refers to the nominal torque of the motor. The motor's name plate data, parameter motor nominal current and the drive's nominal current i...

Page 71

Vacon hvac application vacon • 68 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.9.12 stall current 0.00 2*i h a i h 710 for a stall stage to occur, the current must have exceeded this limit. P3.9.13 stall time limit 1.00 120.00 s 15.00 711 this is the maximum time allowed for a s...

Page 72

3 vacon • 69 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.12 group 3.10: automatic reset table 56: autoreset settings index parameter min max unit default id description p3.10.1 automatic reset 0 1 0 731 0 = disabled 1 = enabled p3.10.2 restart function 0 1 1 719 the s...

Page 73

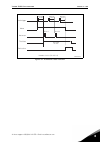

Vacon hvac application vacon • 70 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.13 group 3.11: timer functions the time functions (time channels) in the vacon 100 give you the possibility to program functions to be controlled by the internal rtc (real time clock). Practically ev...

Page 74

3 vacon • 71 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 timers timers can be used to set a time channel active during a certain time by command from a digital input (or a time channel). Figure 16. Activation signal comes from a digital input or " a virtual digital input"...

Page 75

Vacon hvac application vacon • 72 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.11.2.3: from day: saturday p3.11.2.4: to day: sunday p3.11.2.5: assigntochannel: time channel 1 timer 1 the manual bypassing can be handled by a digital input 1 on slot a (by a different switch or con...

Page 76

3 vacon • 73 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.11.2 interval 2 p3.11.2.1 on time 00:00:00 23:59:59 hh:mm:ss 00:00:00 1469 see interval 1 p3.11.2.2 off time 00:00:00 23:59:59 hh:mm:ss 00:00:00 1470 see interval 1 p3.11.2.3 from day 0 6 0 1471 see interval 1 p3....

Page 77

Vacon hvac application vacon • 74 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.14 group 3.12: pid-controller 1 3.6.14.1 basic settings table 58: index parameter min max unit default id description p3.12.1.1 pid gain 0.00 1000.00 % 100.00 118 if the value of the parameter is set...

Page 78

3 vacon • 75 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.14.2 setpoints table 59: index parameter min max unit default id description p3.12.2.1 keypad setpoint 1 varies varies varies 0 167 p3.12.2.2 keypad setpoint 2 varies varies varies 0 168 p3.12.2.3 setpoint ramp ...

Page 79

Vacon hvac application vacon • 76 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.12.2.10 setpoint 1 wake-up mode 0 1 0 15539 select if wake up level should work as absolute level or as relative setpoint. 0 = absolute level 1 = relative setpoint p3.12.2.11 setpoint 1 boost -2.0 2.0...

Page 80

3 vacon • 77 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.14.3 feedbacks table 60: index parameter min max unit default id description p3.12.3.1 feedback function 1 9 1 333 1 = only source1 in use 2 = sqrt(source1);(flow=constan t x sqrt(pressure)) 3 = sqrt(source1- so...

Page 81

Vacon hvac application vacon • 78 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.14.4 feedforward feedforward usually needs accurate process models, but in some simple cases a gain + offset type of feedforward is enough. The feedforward part does not use any feedback measurements...

Page 82

3 vacon • 79 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.14.6 pressure loss compensation table 63: index parameter min max unit default id description p3.12.6.1 enable setpoint 1 0 1 0 1189 enables pressure loss compensation for setpoint 1. 0 = disabled 1 = enabled p3...

Page 83

Vacon hvac application vacon • 80 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.15 group 3.13: pid-controller 2 3.6.15.1 basic settings for more detailed information, see chapter 3.6.14. 3.6.15.2 setpoints table 64: index parameter min max unit default id description p3.13.1.1 e...

Page 84

3 vacon • 81 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.15.3 feedbacks for more detailed information, see chapter 3.6.14. 3.6.15.4 process supervision for more detailed information, see chapter 3.6.14. Table 66: index parameter min max unit default id description p3....

Page 85

Vacon hvac application vacon • 82 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.16 group 3.14: multi-pump the multi-pump functionality allows you to control up to 4 motors (pumps, fans) with pid controller 1. The ac drive is connected to one motor which is the "regulating" motor...

Page 86

3 vacon • 83 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.17 group 3.16: fire mode drive ignores all commands from keypad, fieldbuses and pc tool and runs at preset frequency when activated. If activated, alarm sign is shown on the keypad and warranty is void . In orde...

Page 87

Vacon hvac application vacon • 84 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6.18 group 3.17: application settings 3.6.19 group 3.18: kwh pulse output settings m 3.16.11 fire mode counter 0 4 294 967 295 0 1679 fire mode counter tells how many times fire mode has been activated...

Page 88

3 vacon • 85 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.7 hvac application - additional parameter information due to its user-friendliness and simplicity of use, the most parameters of the vacon hvac application only require a basic description which is given in the pa...

Page 89

Vacon hvac application vacon • 86 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.1.2.15 o vervoltage controller p3.1.2.16 u ndervoltage controller these parameters allow the under-/overvoltage controllers to be switched out of operation. This may be useful, for example, if the mai...

Page 90

3 vacon • 87 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 19. I/o a start/stop logic = 0 explanations: selection number selection name note 0 cs1: forward cs2: backward the functions take place when the contacts are closed. 1 control signal (cs) 1 activates causing ...

Page 91

Vacon hvac application vacon • 88 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 20. I/o a start/stop logic = 1 explanations: selection number selection name note 1 cs1: forward (edge) cs2: inverted stop 1 control signal (cs) 1 activates causing the output frequency to rise. T...

Page 92

3 vacon • 89 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 21. I/o a start/stop logic = 2 explanations: selection number selection name note 2 cs1: forward (edge) cs2: backward (edge) shall be used to exclude the possibility of an unintentional start. The start/stop ...

Page 93

Vacon hvac application vacon • 90 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 22. I/o a start/stop logic = 3 selection number selection name note 3 cs1: start cs2: reverse explanations: 1 control signal (cs) 1 activates causing the output frequency to rise. The motor runs f...

Page 94

3 vacon • 91 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 23. I/o a start/stop logic = 4 selection number selection name note 4 cs1: start (edge) cs2: reverse shall be used to exclude the possibility of an unintentional start. The start/stop contact must be opened b...

Page 95

Vacon hvac application vacon • 92 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.3.10 p reset frequency mode you can use the preset frequency parameters to define certain frequency references in advance. These references are then applied by activating/inactivating digital inputs c...

Page 96

3 vacon • 93 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 24. Acceleration/deceleration (s-shaped) p3.4.12 f lux braking instead of dc braking, flux braking is a useful way to raise the braking capacity in cases where additional brake resistors are not needed. When ...

Page 97

Vacon hvac application vacon • 94 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.5.2.2 ai1 signal filter time when this parameter is given a value greater than 0 the function that filters out disturbances from the incoming analogue signal is activated. Note! Long filtering time ma...

Page 98

3 vacon • 95 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.9.2 r esponse to external fault an alarm message or a fault action and message is generated by an external fault external fault signal in one of the programmable digital inputs (di3 by default) using parameters p...

Page 99

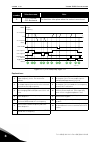

Vacon hvac application vacon • 96 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 26. Motor thermal current i t curve p3.9.9 m otor thermal time constant the time constant is the time within which the calculated thermal stage has reached 63% of its final value. The bigger the f...

Page 100

3 vacon • 97 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 27. Motor temperature calculation p3.9.12 s tall current the current can be set to 0.0…2*i l . For a stall stage to occur, the current must have exceeded this limit. See figure 28. If parameter p3.1.1.7 motor...

Page 101

Vacon hvac application vacon • 98 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 29. Stall time count p3.9.16 u nderload protection : f ield weakening area load the torque limit can be set between 10.0-150.0 % x t nmotor. This parameter gives the value for the minimum torque a...

Page 102

3 vacon • 99 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.9.18 u nderload protection : t ime limit this time can be set between 2.0 and 600.0 s. This is the maximum time allowed for an underload state to exist. An internal up/down counter counts the accumulated underloa...

Page 103

Vacon hvac application vacon • 100 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 32. Automatic reset function 11104.Emf fault trigger autoreset trial time wait time p3.10.3 reset 1 reset 2 trial time p3.10.4 fault active alarm number of trials: (p3.10.5 = 2) wait time p3.10.3...

Page 104

3 vacon • 101 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.12.1.9 d ead band hysteresis p3.12.1.10 d ead band delay the pid controller output is locked if the actual value stays within the deadband area around the reference for a predefined time. This function will prev...

Page 105

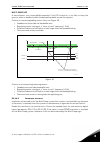

Vacon hvac application vacon • 102 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.12.2.7 s leep frequency limit 1 p3.12.2.8 s leep delay 1 p3.12.2.9 w ake - up level 1 this function will put the drive into sleep mode if the frequency stays below the sleep limit for a longer time t...

Page 106

3 vacon • 103 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 35. Feedforward control p3.12.5.1 e nable process supervision figure 36. Process supervision upper and lower limits around the reference are set. When the actual value goes above or below these a counter sta...

Page 107

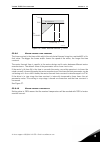

Vacon hvac application vacon • 104 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 pressure loss compensation figure 37. Position of pressure sensor if pressurizing a long pipe with many outlets, the best place for the sensor would probably be halfway down the pipe (position 2). Howev...

Page 108

3 vacon • 105 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 p3.12.6.1 e nable setpoint 1 p3.12.6.2 s etpoint 1 max compensation the sensor is placed in position 1. The pressure in the pipe will remain constant when we have no flow. However, with flow, the pressure will drop...

Page 109

Vacon hvac application vacon • 106 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 multi-pump use a motor/motors are connected/disconnected if the pid controller is not able to keep the process value or feedback within the defined bandwith around the setpoint. Criteria for connecting/...

Page 110

3 vacon • 107 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 example of the interlock logic: if the motor starting order is 1 -> 2 -> 3 -> 4 -> 5 now, the interlock of motor 3 is removed, i.E. The value of parameter p3.5.1.27 is set to false, the order changes to: 1 -> 2 -> ...

Page 111

Vacon hvac application vacon • 108 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 40. Selection 1, enabled: if the regulating motor needs to be included in the autochange or interlock logic make the connection according to figure 41 below. Every motor is controlled with one re...

Page 112

3 vacon • 109 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 41. M m m k1 k1.1 k2 k2.1 k3 k3.1 11113.Emf k1 k1.1 k1.1 k1 k2 k3 k2 k3 k2 k2.1 k2.1 k2 k1 k3 k1 k3 k3 k3.1 k3.1 k3 k2 k1 k2 k1 mains motor 1 motor 2 motor 3 motor 1 control from relay motor 2 control from r...

Page 113

Vacon hvac application vacon • 110 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 p3.14.4 a utochange example: in the autochange sequence after the autochange has taken place, the motor with the highest priority is placed last and the others are moved up by one place: starting order/...

Page 114

3 vacon • 111 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.8 hvac application - fault tracing when an unusual operating condition is detected by the ac drive control diagnostics, the drive initiates a notification visible, for example, on the keypad. The keypad will show...

Page 115

Vacon hvac application vacon • 112 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.8.2 fault history in menu m4.3 fault history you find the maximum number of 40 occurred faults. On each fault in the memory you will also find additional information, see below. ( 0 ) ( 39 ) id: m4.1 ...

Page 116

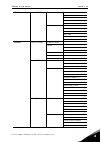

3 vacon • 113 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.8.3 fault codes table 74. Fault codes and descriptions fault code fault id fault name possible cause remedy 1 1 overcurrent (hardware fault) ac drive has detected too high a current (>4*i h ) in the motor cable: ...

Page 117

Vacon hvac application vacon • 114 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 8 600 system fault communication between control board and power unit has failed. Reset the fault and restart. Should the fault re-occur, contact the distributor near to you. 602 watchdog has reset the ...

Page 118

3 vacon • 115 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 9 80 undervoltage (fault) dc-link voltage is under the voltage limits defined. • most probable cause: too low a supply voltage • ac drive internal fault • defect input fuse • external charge switch not closed note!...

Page 119

Vacon hvac application vacon • 116 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 19 180 power overload (short-time supervision) drive power is too high. Decrease load. 181 power overload (long-time supervision) 25 motor control fault start angle identification has failed. Generic mo...

Page 120

3 vacon • 117 vacon hvac application tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 51 1051 external fault digital input. 52 1052 1352 keypad communication fault the connection between the control keypad and frequency converter is broken. Check keypad connection and possible keypad cable. 53 1053 ...

Page 122

Document id: rev. H manual authoring: documentation@vacon.Com vacon plc. Runsorintie 7 65380 vaasa finland subject to change without prior notice © 2013 vacon plc. Find your nearest vacon office on the internet at: www.Vacon.Com.