- DL manuals

- Vacon

- DC Drives

- 100 INDUSTRIAL

- Installation Manual

Vacon 100 INDUSTRIAL Installation Manual

Summary of 100 INDUSTRIAL

Page 1

Vacon 100 ac drives installation manual enclosed drives ®.

Page 3: Preface

Preface document id: dpd01666a date: 9.1.2015 about this manual this manual is copyright of vacon plc. All rights reserved. Preface vacon · 3 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com.

Page 4

Vacon · 4 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 5: Table of Contents

Table of contents preface about this manual 3 1 approvals 7 2 safety 9 2.1 the safety symbols used in the manual and the drive 9 2.2 warning 9 2.3 caution 10 2.4 earthing and earth fault protection 11 2.5 using an rcd or an rcm device 12 3 receiving the delivery 13 3.1 package label 13 3.2 type desi...

Page 6

7.4 installation in an it system 46 7.4.1 the emc jumper in mr8 47 7.4.2 the emc jumper in mr9 48 7.4.3 the emc jumper in mr10 50 7.5 maintenance 51 7.5.1 maintenance intervals 51 7.5.2 replacing the filters of the ac drive 52 7.5.3 replacing the fans of the ac drive 53 7.5.4 replacing the power uni...

Page 7: Approvals

1 approvals here are the approvals that have been granted to this vacon product. Find the ec declaration of conformity on the next page. Approvals vacon · 7 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 1.

Page 8

Ec declaration of conformity we manufacturer’s name: vacon oyj manufacturer’s address: p.O. Box 25 runsorintie 7 fin-65381 vaasa finland hereby declare that the product product name: vacon 100 ac drive model designation: wall-mounted drives: vacon 0100 3l 0003 5...0310 5 vacon 0100 3l 0003 4...0310 ...

Page 9: Safety

2 safety 2.1 the safety symbols used in the manual and the drive this manual contains warnings and cautions, which are identified with safety symbols. The warnings and cautions give important information on how to prevent injury and damage to the equipment or your system. Read the warnings and cauti...

Page 10

Warning! Do not touch the motor terminals u, v, w or the brake resistor terminals when the drive is connected to mains. These terminals are live when the drive is connected to mains, also when the motor does not operate. Warning! Do not touch the relay outputs or the i/o terminals. They can have a d...

Page 11

Caution! Make sure that there is reinforced protective ground connection. It is mandatory, because the touch current of the ac drives is more than 3.5 ma ac (refer to en 61800-5-1). See chapter 2.4 earthing and earth fault protection. Caution! Do not use spare parts that are not from the manufacture...

Page 12

Table 2: protective earthing conductor cross-section cross-sectional area of the phase conductors (s) [mm 2 ] the minimum cross-sectional area of the protective earthing conductor in question [mm 2 ] s ≤ 16 s 16 16 35 s/2 the values of the table are valid only if the protective earthing conductor is...

Page 13: Receiving The Delivery

3 receiving the delivery before a vacon ® ac drive is sent to the customer, the manufacturer makes many tests on the drive. However, after you remove the packaging, examine the drive for transport damages. If the drive was damaged during the shipping, speak to the cargo insurance company or the carr...

Page 14

3.2 type designation code the type designation code of vacon is made of standard codes and optional codes. Each part of the type designation code agrees to the data in your order. The code can have this format, for example: vacon0100-3l-0385-5-ed table 3: the description of the parts in the type des...

Page 15

3.5 removing the packaging and lifting the ac drive 3.5.1 weight of the ac drive the weights of ac drives of different frames are very different. It can be necessary for you to use a lifting device to move the drive from its package. Table 4: the default weight of the enclosed drive and some options...

Page 16

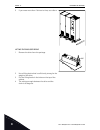

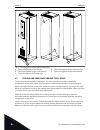

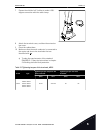

5 if you move more than 1 drive at a time, use rollers. Lifting the enclosed drive 1 remove the drive from the package. >60° 2 use a lifting device that is sufficiently strong for the weight of the drive. 3 put the lifting hooks in the holes on the top of the cabinet. 4 the minimum angle between the...

Page 17

5 lift the drive into a vertical position. >60° >60° 3.6 "product modified" label in the accessories bag, there is also a "product modified" label. The function of the label is to tell the service personnel about the changes that are made in the ac drive. Attach the label on the side of the ac drive...

Page 18: Mounting

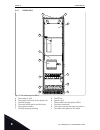

4 mounting 4.1 dimensions of the cabinet install the ac drive in a vertical position. Attach the drive with screws to the wall and/or the floor. 406 Ø13 Ø13 Ø13 335 663 399 354 602 605 2100.5 2135.5 2155.5 120.5 100 200 fig. 2: the dimensions of the cabinet (without options), mr8 vacon · 18 mounting...

Page 19

606 Ø13 Ø13 Ø13 535 663 599 555 600 604 2100.5 2135.5 2155.5 120.5 100 200 fig. 3: the dimensions of the cabinet (without options), mr9 and mr10 4.2 installation of the cabinet to attach the cabinet to the floor, there are 3 alternatives. • use the 4 fixing points at the bottom of the cabinet. • use...

Page 20

A b d e c fig. 4: the fixing points of the cabinet, mr8-mr10 a. The 4 fixing points at the bottom b. The 2 fixing points at the front bottom c. The 2 fixing points at the rear top d. The 2 fixing points in the fixing bracket e. The 2 fixing points at the front bottom 4.3 cooling and free space aroun...

Page 21

The power loss of the ac drive can change very much, when the load, the output frequency or the switching frequency changes. It is useful to know the power loss, when you plan the cooling equipment in an electrical room. Use this formula to calculate the approximate power loss of the drive in nomina...

Page 22

Fig. 6: the back channel using the back channel for cooling 1 make an opening in the wall. 2 attach the back channel components to the cabinet. 3 move the cabinet adjacent to the wall. 4 make sure that you seal the openings correctly. Vacon · 22 mounting 4 tel. +358 (0)201 2121 · fax +358 (0)201 212...

Page 23: Power Cabling

5 power cabling 5.1 cable and fuse sizes we recommend the fuse type gg/gl (iec 60269-1) for mains fuses (-f1). Use only fuses that have a sufficient voltage rating according to the mains voltage. Do not use larger fuses than what is recommended in table 6. The fuses are selected for short circuit pr...

Page 24

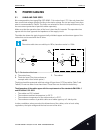

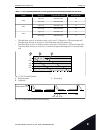

3 3 3 3 3 -f1 3 -fc1 -ta1 -t fig. 8: the fuses in mr8, mr9 and mr10 table 6: the recommended mains cables and fuses in 380 v-500 v frame type il [a] mains fuse (gg/gl) [a] mains and motor cable (cu/ai) [mm2] mains terminal, bolt size earth terminal, bolt size mr8 0140 2 0140 5 140 160 (3x70+35) (cu)...

Page 25

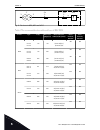

Table 7: drive fuses, 380-500 v, mersen frame type i l [a] catalogue number of the fuse fuse rating [a] number of fuses needed fuse size mr8 0140 2 0140 5 140 nh1ud69v250pv 250 3 1 0170 2 0170 5 170 nh1ud69v350pv 350 3 1 0205 2 0205 5 205 nh1ud69v400pv 400 3 1 mr9 0261 2 0261 5 261 nh2ud69v500pv 500...

Page 26

Table 8: drive fuses, 380-500 v, bussmann frame type i l [a] catalogue number of the fuse fuse rating [a] number of fuses needed fuse size mr8 0140 2 0140 5 140 170m3817d 315 3 1 0170 2 0170 5 170 170m3818d 350 3 1 0205 2 0205 5 205 170m3819d 400 3 1 mr9 0261 2 0261 5 261 170m5810d 500 3 2 0310 2 03...

Page 27

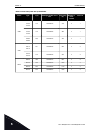

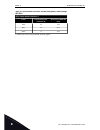

5.2 brake resistor cables table 9: brake resistor cables, 380-500 v frame type il [a] brake resistor cable [mm 2 ] mr8 0140 2 0140 5 140 3x70+35 (cu) 3x95+29 (al) 0170 2 0170 5 170 3x95+50 (cu) 3x150+41 (al) 0205 2 0205 5 205 3x120+70 (cu) 3x185+57 (al) mr9 0261 2 0261 5 261 3x185+95 (cu) 2x3x120+41...

Page 28

5.3 preparing for the cable installation • before you start, make sure that none of the components of the ac drive is live. Read carefully the warnings in chapter 2 safety. • make sure that the motor cables are sufficiently far from other cables. • the motor cables must cross other cables at an angl...

Page 29

5.4 cable installation 5.4.1 frames mr8 to mr9 1 connect the cables. The picture shows an example of good cabling. A) connect the phase conductors of the mains cable and of the motor cable into the correct terminals. If you use a brake resistor cable, connect its conductors into the correct terminal...

Page 30

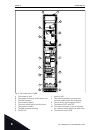

A b d e f g h i j k l m n c p o fig. 9: the inside layout of mr8 a. The output air grill b. The control connector of the power unit c. The emc jumpers d. The contactor option e. The main switch option and the fuses f. The mains terminals g. The 360-degree grounding h. The pe bar i. Input air grill j...

Page 31

O. The main fan p. The cable entry plate for i/o cables a b d e f g h i j k l m n c p o fig. 10: the inside layout of mr9 a. The output air grill b. The control connector of the power unit c. The emc jumpers d. The contactor option e. The main switch option and the fuses f. The mains terminals g. Th...

Page 32

L. The options capt and cpif m. The motor terminals, if you do not have the common mode and/or the du/dt filter n. The internal fan for ip54 o. The main fan p. The cable entry plate for i/o cables 1 if you use many cables on one connector, put the cable lugs on top of each other. A c b a. The first ...

Page 33

Table 11: tightening torques of the terminals, mr8 and mr9 frame type tightening torque: the power and motor terminals tightening torque: the emc grounding clamps tightening torque: the earth terminals [nm] lb-in. [nm] lb-in. [nm] lb-in. Mr8 0140 2-0205 2 0140 5-0205 5 30-44 * 266-389 * 1.5 13.3 20 ...

Page 34

5.4.2 frame mr10 a b d e f g h i j c l k fig. 11: the inside layout of mr10 a. The output air grill b. The control connector of the power unit c. The emc jumper d. The main switch option and the fuses e. The mains terminals f. The 360-degree grounding g. The pe bar h. Input air grill i. The terminal...

Page 35

1 strip the motor cable and the mains cable. A) keep the earth conductor as short as possible, but so that it reaches the grounding bar. 2 strip the brake resistor cable. A) keep the earth conductor as short as possible, but so that it reaches the grounding bar. 3 open the cabinet door. 4 cut the gr...

Page 36

5 connect the stripped cables. A) connect the phase conductors of the mains cable and of the motor cable into the correct terminals. If you use a brake resistor cable, connect its conductors into the correct terminals. B) attach the earth conductor of each cable to an earth terminal with a clamp. C)...

Page 37

7 expose the shield of all 3 cables to make a 360- degree connection with the cable clamp. 8 attach the terminal cover, and then the extension box cover. 9 close the cabinet door. 10 make sure that the earth conductor is connected to the motor and also to the terminals that are identified with . A) ...

Page 38: Control Compartment

6 control compartment 6.1 the control compartment of the enclosed drive the enclosed drive has a door-mounted control compartment, separated from the cabinet section, for the main power supply terminals and the motor output cable terminals. You can have an access to the control compartment through a...

Page 39

C b a d i k l m n o p q j e g h f fig. 12: the control compartment of the cabinet a. Insulation fault sensor (+cpif) b. 24 v dc power supply (+capd) c. Emergency stop cat 1 (+cps1) d. Mcbs for aux. Devices e. The control unit f. A 230 v ac socket (+caps) g. Extended i/o terminals (+ctid) h. Terminal...

Page 40

C d f a b e fig. 13: the ethernet and rs485 connections a. Rs485 terminal a = data - b. Rs485 terminal b = data + c. The dip switches d. The ethernet terminal e. The i/o terminals f. The grounding bar 6.2.1 using fieldbus through an ethernet cable table 13: ethernet cable data item description the p...

Page 41

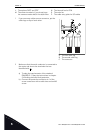

Ethernet cabling 1 connect the ethernet cable to its terminal. 2 put the cover of the drive back. Keep the distance between the ethernet cable and the motor cable at a minimum of 30 cm. See more in the installation manual of the fieldbus that you have. 6.2.2 using fieldbus through an rs485 cable tab...

Page 42

2 connect the cable to the standard i/o board of the drive, in terminals a and b. • a = negative • b = positive 3 attach the shield of the cable to the frame of the drive with a cable clamp to make a grounding connection. Vacon · 42 control compartment 6 tel. +358 (0)201 2121 · fax +358 (0)201 212 2...

Page 43

4 if the drive is the last device on the fieldbus line, set the bus termination. A) find the dip switches on the left side of the control unit of the drive. B) set the dip switch of the rs485 bus termination to the on position. C) biasing is built in the bus termination resistor. The termination res...

Page 44

Note! If you do power-down to the last device, there is no bus termination. Vacon · 44 control compartment 6 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 45: Commissioning and Additional

7 commissioning and additional instructions 7.1 commissioning safety before you start the commissioning, read these warnings. Warning! Do not touch the internal components or the circuit boards of the drive when the drive is connected to mains. These components are live. A contact with this voltage ...

Page 46

7.2 operation of the motor 7.2.1 checks before starting the motor before you start the motor, do these checks. • make sure that all the start and stop switches that are connected to the i/o terminals are in the stop position. • make sure that you can start the motor safely. • activate the start-up w...

Page 47

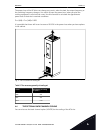

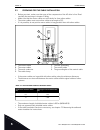

Caution! Before you connect the ac drive to mains, make sure that the emc level of the drive is correct. An incorrect emc level can cause damage to the drive. 7.4.1 the emc jumper in mr8 change the emc protection of the ac drive from level c3 to level c4. 1 open the cover of the ac drive. 2 find the...

Page 48

4 find the grounding arm and push it down. A b a. The grounding arm is up b. The grounding arm is down (level c3) 5 after the change, write "the emc level was changed" and the date on the "product changed" label. If the label is not attached at this time, attach it on the drive near the name plate. ...

Page 49

2 loosen the screws of the cover plate and remove it. 3 remove the emc jumper. 4 if you change the emc level, write "the emc level was changed" and the date on the "product changed" label. If the label is not attached at this time, attach it on the drive near the name plate. Product modified date: d...

Page 50

2 find the 2 emc jumpers on the emc board. They are not adjacent to each other. Remove the emc jumpers. A a. The emc jumpers 3 if you change the emc level, write "the emc level was changed" and the date on the "product changed" label. If the label is not attached at this time, attach it on the drive...

Page 51

2 find the emc jumper between the terminals l2 and l3. 3 remove the emc jumper. 4 if you change the emc level, write "the emc level was changed" and the date on the "product modified" label. If the label is not attached at this time, attach it on the drive near the name plate. Product modified date:...

Page 52

Table 15: the maintenance intervals and tasks maintenance interval maintenance task regularly do a check of the tightening torques of the terminals. Do a check of the filters. 6-24 months (the interval is different in different envi- ronments.) do a check of the input and output terminals and the co...

Page 53

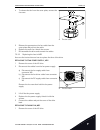

Replacing the filter on the cabinet door 1 to remove the cover of the filter, pull it out and up. 2 clean or replace the filter. 3 put the cover of the filter back. 7.5.3 replacing the fans of the ac drive 7.5.3.1 replacing the fans in mr8 here are the instructions on how to replace the fans of the ...

Page 54

2 disconnect the cables from the fan power supply. A) disconnect the fan supply cable from connector x81. B) disconnect the fan driver cable from connector x61. C) disconnect the dc supply cable from connector x8. Remove the 4 screws that hold the fan power supply. X81 x61 x8 a a a. The 4 screws 3 l...

Page 55

4 to release the fan from the cover plate, remove the 4 screws. A a. The fan cable 5 release the grommet on the fan cable from the cover plate and pull out the cable. 6 replace the main fan. Attach the screws. 7 re-assemble the drive and connect the cables. 7.5.3.2 replacing the fans in mr9 here are...

Page 56

2 disconnect the cables from the fan power supply. 3 remove the 12 screws from the fan cover plate. Use the handle to lift off the main fan unit. 1 2 2 3 3 4 to release the fan from the cover plate, remove the 4 screws. A a. The fan cable 5 release the grommet on the fan cable from the cover plate a...

Page 57

Replacing the main fan assembly, mr10 1 loosen the 8 screws and lift off the service lid. 2 disconnect the cables from each fan power supply. A) disconnect the fan driver cable from connector x61. B) disconnect the dc supply cable from connector x8. Remove the 5 screws. X61 x8 x61 x8 a a a a. The 5 ...

Page 58

Replacing the fan power supplies, mr10 you can replace only 1 or both the fan power supplies. 1 remove the main fan assembly. See the previous instructions. 2 a) disconnect the fan supply cable from connector x81. B) disconnect the fan driver cable from connector x61. C) disconnect the dc supply cab...

Page 59

2 remove the 2 screws from the top of the power unit. Commissioning and additional instructions vacon · 59 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 7.

Page 60

3 remove the 6 screws from the bottom of the power unit. 4 pull the power unit out carefully until it is possible to use the front lifting holes. Vacon · 60 commissioning and additional instructions 7 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 61

5 attach the lifting hooks to the front lifting holes and lift the power unit out of the cabinet. 7.5.4.2 replacing the power unit, mr9 1 disconnect all the power cables from the bottom of the power unit. Commissioning and additional instructions vacon · 61 24-hour support +358 (0)201 212 575 · emai...

Page 62

2 remove the 2 screws from the top of the power unit. Also remove the lifting lugs. You will re-attach them later. Vacon · 62 commissioning and additional instructions 7 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 63

3 remove the 8 screws from the bottom of the power unit. 4 pull the power unit out carefully until it is possible to re-attach the lifting lugs. Commissioning and additional instructions vacon · 63 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 7.

Page 64

5 re-attach the lifting lugs. You can use the extra nut that is on the screw. Remove the nut and attach it to the other side of the lifting lug. Vacon · 64 commissioning and additional instructions 7 tel. +358 (0)201 2121 · fax +358 (0)201 212 205.

Page 65

6 attach the lifting hooks to the lifting lugs and lift the power unit out of the cabinet. Commissioning and additional instructions vacon · 65 24-hour support +358 (0)201 212 575 · email: vacon@vacon.Com 7.

Page 66

7.5.4.3 replacing the power unit, mr10 1 remove the 4 screws of the lower cover of the power unit and remove the cover. 2 disconnect all the power cables from the bottom of the power unit. 3 remove the 2 screws from the top of the power unit. Vacon · 66 commissioning and additional instructions 7 te...

Page 67

4 remove the 2 screws from the bottom of the power unit. 5 pull the power unit out carefully until the front lifting holes are available. 6 attach the lifting hooks to the front lifting holes and lift the power unit out of the cabinet. Commissioning and additional instructions vacon · 67 24-hour sup...

Page 68: Technical Data, Vacon

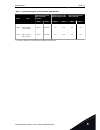

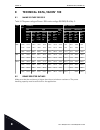

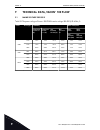

8 technical data, vacon ® 100 8.1 mains voltage 380-500 v table 16: the power ratings of vacon ® 100 in mains voltage 380-500v, 50-60 hz, 3~ fram e drive type loadability motor shaft power low high max curre nt i s 2s 400 v mains 480 v mains contin uous curre nt i lin [a] contin uous curre nt i lout...

Page 69

Table 17: the recommended brake resistor types and the calculated resistance of the drive frame duty cycle type of brake resistor resistance [Ω] mr8 light duty brr 0105 ld 5 6.5 heavy duty brr 0105 hd 5 6.5 mr9 light duty brr 0300 ld 5 3.3 heavy duty brr 0300 hd 5 3.3 mr10 light duty brr 0520 ld 5 1...

Page 70

Table 18: the minimum resistance and the brake power, mains voltage 380-500 v mains voltage 380-500 v, 50/60 hz, 3~ frame the minimum brake resistance [Ω] brake power* @845 vdc [kw] mr8 6.5 109.9 mr9 3.3 216.4 mr10 1.4 573 * = when you use recommended resistor types. Vacon · 70 technical data, vacon...

Page 71

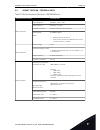

8.3 vacon ® 100 - technical data table 19: the technical data of the vacon ® 100 ac drive technical item or function technical data mains connection input voltage u in 380-500 v, -10%…+10% input frequency 50-60 hz, -5...+10% connection to mains once per minute or less frequently starting delay 8 s (...

Page 72

Table 19: the technical data of the vacon ® 100 ac drive technical item or function technical data ambient conditions ambient operating tem- perature i l current: -10°c (no frost)...+40 °c i h current: -10°c (no frost)...+40 °c maximum operating temperature: +50 °c with derat- ing (1.5%/1°c) storage...

Page 73

Table 19: the technical data of the vacon ® 100 ac drive technical item or function technical data emc (at default settings) immunity fulfils en61800-3, 1 st and 2 nd environment emissions en61800-3, category c3. The drive can be changed to c4 for it type mains. See chapter 7.4 installation in an it...

Page 74: Technical Data, Vacon

9 technical data, vacon ® 100 flow 9.1 mains voltage 380-500 v table 20: the power ratings of vacon ® 100 flow in mains voltage 380-500 v, 50-60 hz, 3~ frame drive type loadability motor shaft power continuous current i lin [a] continuous current i lout [a] 10% overload current [a] max current i s 2...

Page 75

9.2 vacon ® 100 flow - technical data table 21: the technical data of the vacon ® 100 flow ac drive technical item or function technical data mains connection input voltage u in 380-500 v, -10%…+10% input frequency 50-60 hz, -5...+10% connection to mains once per minute or less frequently starting d...

Page 76

Table 21: the technical data of the vacon ® 100 flow ac drive technical item or function technical data ambient conditions ambient operating tem- perature i l current: -10°c (no frost)…+40 °c maximum operating temperature: +50 °c with derat- ing (1.5%/1°c) storage temperature -40 °c…+70 °c relative ...

Page 77

Table 21: the technical data of the vacon ® 100 flow ac drive technical item or function technical data emc (at default settings) immunity fulfils en61800-3, 1 st and 2 nd environment emissions en61800-3, category c3. The drive can be changed to c4 for it type mains. See chapter 7.4 installation in ...

Page 78

10 technical data on control connections 10.1 technical data on control connections table 22: the standard i/o board standard i/o board terminal signal technical information 1 reference output +10 v, +3%, maximum current: 10 ma 2 analogue input, voltage or cur- rent analogue input channel 1 0...+10 ...

Page 79

Table 22: the standard i/o board standard i/o board terminal signal technical information 11 common a for din1-din6 digital inputs can be disconnected from ground, see chapter isolation of digital inputs from ground in the installation man- ual. 12 24 v aux. Voltage +24 v, ±10%, max volt. Ripple max...

Page 80

Table 23: the standard relay board (+sbf3) terminal signal technical information 21 relay output 1 * change-over contact (spdt) relay. 5.5 mm isolation between channels. Switching capacity • 24 vdc/8 a • 250 vac/8 a • 125 vdc/0.4 a minimum switching load • 5 v/10 ma 22 23 24 relay output 2 * change-...

Page 81

Table 24: the optional relay board (+sbf4) terminal signal technical information 21 relay output 1 * change-over contact (spdt) relay. 5.5 mm isolation between channels. Switching capacity • 24 vdc/8 a • 250 vac/8 a • 125 vdc/0.4 a minimum switching load • 5 v/10 ma 22 23 24 relay output 2 * change-...

Page 82: Options

11 options 11.1 the codes of the options table 25: the codes and names of the options name code motor heater control +camh cabinet heater +cach cabinet light +cacl aux voltage transformer +capt 24 vdc power supply +capd 230 vac socket +caps signal lights + push buttons +cdlp extended i/o terminals +...

Page 84

Document id: rev. A manual authoring: documentation@vacon.Com vacon plc. Runsorintie 7 65380 vaasa finland subject to change without prior notice © 2015 vacon plc. Sales code: doc-ins100ed+dluk find your nearest vacon office on the internet at: www.Vacon.Com.