- DL manuals

- KEB

- Recording Equipment

- COMBIVERT F5

- Instruction Manual

KEB COMBIVERT F5 Instruction Manual

Summary of COMBIVERT F5

Page 1

Combivert mat.No. Rev. 00f50eb-kw00 1c stop read instruction manual part 1 first ! Gb instruction manual combivert f5 power unit housing w 200…400 kw.

Page 2

This instruction manual describes the power circuits of the series keb combivert f5 housing size w. It is only valid together with the instruction manuals part 1 and part 3. Both instruction manuals must be made available to the user. Be- fore working with the unit the user must become familiar with...

Page 3

Gb - 3 table of contents 1. General ......................................................4 1.1 product description ........................................ 4 1.2 specifiedapplication ...................................... 4 1.3 unitidentification ............................................ 5 1.4 i...

Page 4

Gb - 4 general 1. General 1.1 product description in selecting the keb combivert you have acquired a frequency inverter with the highest demands on quality and dynamic. This instruction manual describes the following units: unit type: frequency inverter series: combivert f5 power range: 200…400 kw v...

Page 5

Gb - 5 general 1.3 unitidentification 28.F5. A 0 w- 9 0 0 a cooling 0 heat sink with cooling fan at special/customer unit consecutive numbering a heat sink with cooling fan (varnished) c water cooling (varnished) d through-mount version h water cooling (second version) encoder interface 0 none at sp...

Page 6

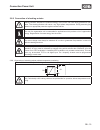

Gb - 6 general 1.4 installation instructions 1.4.1 cooling systems the keb combivert f5 is available for different cooling systems: heat sink with cooling fan (mounted version) the standard version is delivered with heat sink and cooling fan. Special versions the dissipation of power loss must be gu...

Page 7

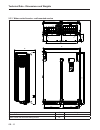

Gb - 7 general 1.4.3 control cabinet installation mounting distances dimension distance in mm distance in inch c a b d d a 150 6 b 100 4 c 30 1.2 d 30 1.2 x 1) 50 2 1) distance to preceding elements in the cabinet door. Direction of the cooling fins front and side view of the coolant inlet coolant o...

Page 8

Gb - 8 general 1.5 installation of water-cooled units in continuous operation water-cooled inverters are operated with lower temperature than air-cooled inverters. This has positive effects on lifetime-relevant components such as fan and dc link circuit capacitors and power mo- dules (igbt). Also th...

Page 9

Gb - 9 general 1.5.3 requirements on the coolant the requirements on the coolant are depending on the ambient conditions, as well as from the used cooling sy- stem. General requirements on the coolant: standards trinkwv 2001, din en 12502 part 1-5, din 50930 part 6, dvgw work sheet w216 vgb cooling ...

Page 10

Gb - 10 general chemical procedures. 1.5.5 coolant temperature and moisture condensation the inlet temperature may not exceed 40°c. The maximum heat sink temperature is 60 °c or 90 °c depending on the power unit and overload capacity (see „technical data“). To ensure a safe operation the coolant out...

Page 11

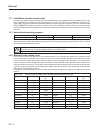

Gb - 11 general 1.5.6 coolantheatingdependingonpowerlossandflowratewithwater 0 1 2 3 4 5 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 pv [kw] Δt [k] 100 l/min 50 l/min 40 l/min 30 l/min 20 l/min 10 l/min 5 l/min 1.5.7 typicallyfallofpressuredependingontherateofflow bar 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0...

Page 12

Gb - 12 technical data 2. Technical data 2.1 operating conditions standard standard/ class instructions definitionaccordingto en 61800-2 inverter product standard: ratedspecifications en 61800-5-1 inverter product standard: general safety site altitude max. 2000 m above sea level with site altitudes...

Page 13

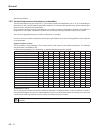

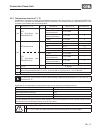

Gb - 13 technical data of the 400 v class inverter size 28 29 30 31 32 housing size w phases 3 2x3 3 2x3 2x3 2x3 2x3 output rated power [kva] 256 319 395 436 492 max. Rated motor power [kw] 200 250 315 355 400 output rated current [a] 370 460 570 630 710 max. Short time current 1) [a] 463 575 713 78...

Page 14

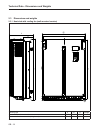

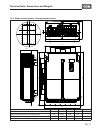

Gb - 14 technical data - dimensions and weights 2.3 dimensions and weights 2.3.1 heat sink with cooling fan (wall mounted version) a1 940 a 910 630 670 b housing type a a1 b weight standard with sub construction 368 155.5 Ø13 standard with sub construction (heightened) 362.5 150 Ø13.

Page 15

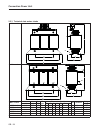

Gb - 15 technical data - dimensions and weights 2.3.2 heat sink with cooling fan (through-mount version) 670 a1 2 940 a 25 55 Ø25 1020 720 100 300 500 700 100 100 100 100 100 100 100 100 100 100 b housing type a a1 b weight through-mount version 2 fans (standard) 368 155.5 Ø 9 through-mount version ...

Page 16

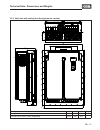

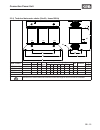

Gb - 16 technical data - dimensions and weights 2.3.3 water-cooled inverter - wall mounted version 368 129,5 560 2 g g 287,5 287,5 630 670 13 940 630 15,5 13 910 housing type g weight water-cooled heat sink 1/2“ water-cooled heat sink with braking resistor 1/2“.

Page 17

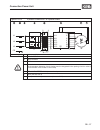

Gb - 17 technical data - dimensions and weights 2.3.4 water-cooled inverter - through-mount version 670 2 214,5 a1 100 300 500 700 200 400 600 800 1000 1020 a 720 675 975 12,5 12,5 g g b housing type a a1 b g weight water-cooled heat sink 370 155.5 Ø 9 1/2“ water-cooled heat sink with braking resist...

Page 18

Gb - 18 connection terminals 2.4 terminal strips of the power circuit all terminal strips following the requirements of the en 60947-7-1 (iec 60947-7-1) 2.4.1 mains input the keb combivert is dependent on the input rectifier suitable for 3-phase mains supply (b6-rectifier-circuit) or 6-phase (b12-re...

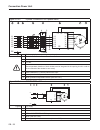

Page 19

Gb - 19 connection terminals picture2.4.1.Cmainsinput6-phase(b12rectifier) l3.2 l2.2 l1.2 l3.1 l2.1 l1.1 name function l1.1, l1.2 6-phase or 2 x 3-phase mains connection l2.1, l2.2 l3.1, l3.2 stay bolt 16 mm for ring thimble; tightening torque 25 nm (220 lb inch) picture 2.4.1.D mains input dc witho...

Page 20

Gb - 20 connection terminals motor terminal strip x1b u u v v w w name function no. U, u 3-phase motor connection 1 v, v w, w connection for protective earth conductor 2 the motor lines must be parallel passed and con- nected with the respective cross section (see tech- nical data). Permissible cabl...

Page 21

Gb - 21 connection terminals terminal strip for motor temperature detection and braking transistor monitoring x1d k1 k2 t1 t2 name function no. K1, k2 braking transistor monitoring (optional) 1 t1, t2 connection for temperature detec- tion (see chapter " temperature detec- tion t1, t2") permissible ...

Page 22

Gb - 22 connection power unit 2.5 accessories 2.5.1 filter and chokes the following table describes the possible modes of connection, which results from combivert and phases. Mode of connection inverter phases mains phases connection picture 3~ –> 3~ 3-phase (b6 rectifier) 3-phase 1 6~ –> 3~ 6-phase...

Page 23

Gb - 23 connection power unit 2.5.2 technicaldatafilter picture 1 picture 2 260 235 210 300 390 240 l1 inverter 3x480v +5% ac/50-60hz hf-filter 30.E4.T60-1001 karl e. Brinkmann gmbh d-32677 barntrup 650a @ t=45 c hpf:-25 c - +85 c line 6xø12 m12 l2 l3 20 200 240 1000 m10 line inver ter 3x480v +5% a ...

Page 24

Gb - 24 connection power unit 2.5.3 technical data mains choke picture 2 b l1 l2 d1 v1 u1 u2 w1 v2 w2 h t l3 picture 3 t l3 d1 d2 l2 l1 b h c u1 v1 w1 u2 v2 w2 mat. Number l i n p v fi- gure dimensions [mm] pe terminal weight mh [a] [w] b t h l1 l3 d1 d2 [kg] 24drb18-1541 0.15 200 168 2 267 215 310 ...

Page 25

Gb - 25 connection power unit 2.5.4 technical data motor choke (uk=4%; fmax=100 hz) picture 3 t l3 d1 d2 l2 l1 b h c u1 v1 w1 u2 v2 w2 mat. Number l i n p v fi- gure dimensions [mm] pe terminal weight mh [a] [w] b t h l1 l3 d1 d2 [kg] 25drc18-5831 0.058 210 400 3 352 230 350 328 121 10x16 30x3 m8 – ...

Page 26

Gb - 26 connection power unit 2.6.2 mains and motor connection exchanging mains and motor connection leads to immediate destruction of the unit. Pay attention to the supply voltage and the correct polarity of the motor ! Figure 2.6.2.A 3-phase combivert at 3-phase mains l1 l2 l3 pe 7 8 pe u v w pe p...

Page 27

Gb - 27 connection power unit figure 2.6.2.B 6-phase combivert at 3-phase mains l1 l2 l3 pe 7 8 pe u v w pe pe t1 t2 l1.1 l2.1 l3.1 l1.2 l2.2 l3.2 u u v v w w legend 1 mains supply 3-phase 2 mains fuse 3 mains contactor 4 hf filter 5 mains chokes (the temperature detection of both chokes must be int...

Page 28

Gb - 28 connection power unit figure 2.6.2.C 6-phase combivert at 6-phase mains pe 7 8 pe u v w pe pe t1 t2 l1' l2' l3' l1 l2 l3 l1.1 l2.1 l3.1 l1.2 l2.2 l3.2 u u v v w w legend 1 mains supply 6-phase (earthing star point yn) 2 mains fuse 3 mains contactor 4 hf filter 5 mains chokes (the temperature...

Page 29

Gb - 29 connection power unit 2.6.3 selection of the motor cable correct selection and wiring of the motor cable is very important for high motor ratings: • lower abrasion of the motor bearings by leakage currents • improved emc characteristics • lower symmetrical operating capacities • less losses ...

Page 30

Gb - 30 connection power unit picture 2.6.4.1 motor connection in star connection u1 v1 w1 w2 u2 v2 pe 3 picture 2.6.4.2 motor connection in delta connection u1 v1 w1 w2 u2 v2 pe 3.

Page 31

Gb - 31 connection power unit 2.6.7 temperature detection t1, t2 parameter in.17 displays in high byte the installed temperature input of the inverter. As a standard the keb com- bivert f5 is delivered with switchable kty84/ptc evaluation. The desired function is adjusted with pn.72 and operates in ...

Page 32

Gb - 32 connection power unit 2.6.7.1 use of the temperature input in kty mode picture 2.6.7.1 connection of a kty sensor t1 t2 kty sensors may not be combined in connection with other sensings. Otherwise this causes wrong measurements. Examples for the arrangement and programming of a temperature c...

Page 33

Gb - 33 connection power unit 2.6.8 connection of a braking resistor braking resistors dissipate the produced energy of the motor into heat during generatoric ope- ration. Thus braking resistors can cause very high surface temperatures. During assembly pay attention to appropriate protection against...

Page 34

Gb - 34 connection power unit 2.6.8.2 braking resistor with over-heat protection and gtr7 monitoring (water-cooled inverter) this circuit offers a direct protection with defective gtr7 (braking transistor). At defective braking transistor an integrated relay opens the terminals k1/k2 and error „e.Pu...

Page 35

Gb - 35 connection power unit 2.6.8.3 braking resistor with over-heat protection without gtr7 monitoring (air-cooled inverter) this circuit offers a direct protection with defective gtr7 (braking transistor). The braking resistor overheats and opens the oh terminals with defective gtr7. The oh termi...

Page 36

Gb - 36 appendix 3. Appendix 3.1 overload characteristic time [s] characteristic 1 time [s] characteristic 2 30 60 90 120 150 180 210 240 270 300 0 105 110 115 120 125 130 135 140 145 150 160 170 180 190 200 210 220 30 60 90 120 150 180 210 240 270 300 0 105 110 115 120 125 130 135 140 145 150 load ...

Page 37

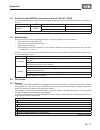

Gb - 37 appendix 3.4 protection with mccb in accordance with ul 489 (ul: divq) authorized manufacturers of mccb´s with the specified rated currents of the mccb´s described in chapter 2.2 and 2.3: manufacturer ul-file type siemens part number siemens e10848 vl 400 ul, jg-frame 3vl41 40-xke30-zzzz 1) ...

Page 38

Gb - 38 appendix • increase variable transformer slowly to indicated input voltage (>1 min) and remain at least on the specified time. Voltage class input voltage residence time 400 v 0…280 v 15 rpm 280…400 v 15 rpm 400…500 v 1 h storage period > 3 years • input voltages as before, however double th...

Page 39

Gb - 39 notes.

Page 40

Keb antriebstechnik austria gmbh ritzstraße 8 • a-4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • b-9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technolog...