C o m b i v e r t instruction manual encoder interface channel 1 biss + 1vpp translation of original manual document part version date 20097260 gbr 00 0115.

3 table of contents table of contents 1. Preface ............................................................................................................. 4 1.1 information on special measures .......................................................................................4 1.2 documentat...

4 preface 1. Preface the described hard- and software are developments of the karl e. Brinkmann gmbh. The enclosed documents correspond to conditions valid at printing. Misprint, mistakes and techni- cal changes reserved. 1.1 information on special measures the used pictograms have following signifi...

5 preface selection of our units in view of their suitability for the intended use must be done generally by the user. Tests can only be done within the application by the machine manufacturer. They must be repeated, even if only parts of hardware, software or the unit adjustment are modi- fied. Dan...

6 preface 1.5 pay attention to markings info pay attention to markings functional fs safety pay special attention to units with one of these markings on the nameplate..See documentation for special installation or operation requirements!.

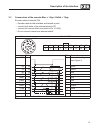

7 product description 2. Product description x3a channel 1 x3a channel 1 ttl, biss + 1vpp, endat + 1vpp figure 1: encoder interface 2.1 general the instruction covers the installation of the interface card, the connection as well as the start-up of a suitable encoder. Further information and the par...

8 product description 57: biss-c hengstler singleturn with 1 vpp-signal 58: biss-c hengstler multiturn 59: biss-c without electronic type plate 67: biss-c kübler singleturn 68: biss-c kübler multiturn 72: biss-c without electronic type plate with 1 vpp signals detection of the encoder manufacturer i...

9 product description if the encoder has 1vpp signals, the encoder must support 2048 increments per revolution . The numbers of increments must be set on 2048 in parameter ec.01. If 1vpp signals are detected during initialization, they are also tested for encoder breakage. If none signals are detect...

10 product description 2.4 scope of delivery (option or replacement delivery) • encoder interface • instruction manual • fixing bolt • packing material 2.5 mechanical installation all kind of works on the inverter may be carried out by authorized personnel in accordance with the emc and safety rules...

11 description of the interface 3. Description of the interface 3.1 voltage supply u int 24 vdc internal voltage supply of combivert x2a x3a 24v 5v u int uext 100ma 500ma u ext control terminal strip (x2a) of the combivert with exter- nal voltage supply 24…30 vdc. 24 v voltage output of encoder inte...

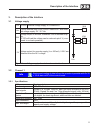

12 description of the interface 3.2.2 description of x3a line length dependent on baud rate 2 4 6 8 10 12 14 16 18 1 3 5 7 9 11 13 15 17 encoder pin inc-ttl biss and endat 1 a+ cos+ 2 a- cos- 3 b+ sin+ 4 b- sin - 5 n+ data+ 6 n- data- 7 clock- 8 9 clock+ 10 11 12 13 gnd gnd 14 gnd gnd 15 16 5v 5v 17...

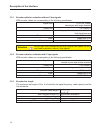

13 description of the interface 3.3 connenction of the encoder biss + 1 vpp / endat + 1 vpp encoder cable at terminal x3a • encoder cable double-shielded and twisted in pairs • connect both sides of the external shield to pe • connect the internal shield one-sided to pin 14 (x3a) • do not connect in...

14 description of the interface 3.3.1 encoder cable for evaluation without 1 vpp-signals keb encoder cables are corresponding to the following specification: signal lines (2 x 2 x 0,15 mm² twisted pair and single shielded supply line 2 x 0,38 mm²) particularities trailing capable, oil resistand, sui...

15 description of the interface 3.3.4 tested encoders the following encoders have been tested by keb on it application: biss-c: hengstler acuro ad58, ad36, ad34, kübler sendix 5853, endat: heidenhain roq 437, eci 1317, eqn 1125 info however, this does not restrict the use of rotary encoder with same...

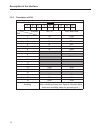

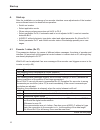

16 start-up 4. Start-up after the installation or exchange of an encoder interface some adjustments of the inverter/ servo software have to be done before operation: • switch on inverter • select application mode • when using synchronous motors set ud.02 to f5-s • select parameter ec.38; if automati...

17 start-up value description 69 for encoder with incremental signals, the incremental counted position is com- pared with the absolute position (e. G. Zero signal or position via biss/endat). If there is a difference, which cannot be corrected the following error is triggered. The following status ...

18 notizen / notes.

19 notizen / notes.

Keb antriebstechnik austria gmbh ritzstraße 8 • a-4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • b-9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technolog...