- DL manuals

- KEB

- Recording Equipment

- COMBIVERT F5

- Instruction Manual

KEB COMBIVERT F5 Instruction Manual

Summary of COMBIVERT F5

Page 1

C o m b i v e r t gb instruction manual combivert f5 standard and interface operator translation of original manual document part version 20104044 gbr 00

Page 3: Table of Contents

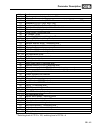

Gb - 3 table of contents 1. Preface ............................................................................................................. 5 1.1 general .................................................................................................................................5 1.2 valid...

Page 4

Gb - 4 5. Error assistance ........................................................................................... 69 6. Quick guide .................................................................................................. 76 6.1 quick guide for operating mode „general“ ...................

Page 5

Gb - 5 preface 1. Preface 1.1 general the described hard- and software are developments of the karl e. Brinkmann gmbh. The enclosed documents correspond to conditions valid at printing. Misprint, mistakes and tech- nical changes reserved. The instruction manual must be made available to the user. Pr...

Page 6

Gb - 6 preface if single regulations should be or become void, invalid or impracticable, the effectivity of all other regulations or agreements is not affected. 1.3 copyright the customer may use the instruction manual as well as further documents or parts from it for internal purposes. Copyrights a...

Page 7

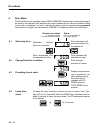

Gb - 7 connection and operation 2. Connection and operation 2.1 operation without operator a special hsp5 cable (part no. 00f50c0-0010) is available for the operation of the keb combivert without operator. The cable is connected between hsp5 interface x4a and serial rs232 pc interface (com1 or com2)...

Page 8

Gb - 8 connection and operation principally during a change, parameter values are immediately accepted and stored non-vol- atile. However, with some parameters it is not useful that the adjusted value is accepted im- mediately. In these cases the adjusted value is accepted and stored non-volatile by...

Page 9

Gb - 9 connection and operation 2.3 interface operator (part number 00f5060-2000) interface operator (mat.No. 00f5060-2000) the interface operator corre- sponds to the functional range of the digital operator. However, it is extended by a serial rs232/485 interface and a diagnosis-/pa- rameter inter...

Page 10

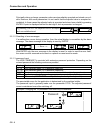

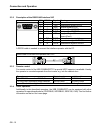

Gb - 10 connection and operation 2.3.2 description of the rs232/485 interface x6c pin rs485 signal meaning 5 4 3 2 1 9 8 7 6 5 4 3 2 1 9 8 7 6 1 - - reserved 2 - txd transmission signal rs232 3 - rxd receive signal rs232 4 a‘ rxd-a receive signal a rs485 5 b‘ rxd-b receive signal b rs485 6 - vp supp...

Page 11

Gb - 11 connection and operation 3. Customer parameters (cp-mode) 3.1 general once the development stage of a machine is completed, usually only a few parameters are required for the adjustment or the control of the inverter. To make the handling easier and the user documentation more understandable...

Page 12

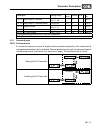

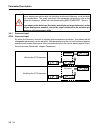

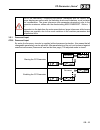

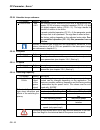

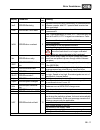

Gb - 12 parameter description 3.3 factory setting for operating mode „general“ parameter setting range reso- lution default unit e based on cp.00 password input 0…9999 1 - - - ud.01 cp.01 actual frequency display -400…400 0,0125 0 hz - ru.03 cp.02 set frequency display -400…400 0,0125 0 hz - ru.01 c...

Page 13

Gb - 13 parameter description parameter setting range reso- lution default unit e based on cp.32 relay output 2 / function 0…100 b/c: 0…84 1 27 - e do.03 cp.33 relay output 2 / switching level ±30000,00 0,01 4 - - le.03 cp.34 rotation source 0…10 b/c: 0…9 1 2 - e op.01 cp.35 an1 interface selection ...

Page 14

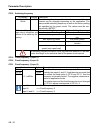

Gb - 14 parameter description 3.3.2 operating display the parameters below serve for the controlling of the frequency inverter during operation. Cp.01 actual frequency display co-domain description 0…±400 hz display of the actual output frequency in hz. Additionally the operator display "nop" and "l...

Page 15

Gb - 15 parameter description cp.04 apparent current co-domain description 0…±6553.5 a display of the actual apparent current in ampere. Cp.05 apparent current / peak value co-domain description 0…±6553.5 a cp.05 makes is possible to recognize the max. Apparent current. For that the highest value of...

Page 16

Gb - 16 parameter description 3.3.3 basic adjustment of the drive the following parameters determine the fundamental operating data of the drive. They should be checked and/or adapted to the application. Cp.10 min. Frequence co-domain setting description 0.0…400.0 hz 0 hz with ths frequence the inve...

Page 17

Gb - 17 parameter description cp.13 deceleration time co-domain setting description -0.01…300.00 s 5.00 s the parameter determines the time needed to decelerate from 100 hz to 0 hz. The actual deceleration time is pro- portional to the frequency change. At deceleration time = -0,01 see cp.12 (displa...

Page 18

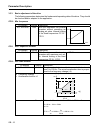

Gb - 18 parameter description cp.14 s-curve time co-domain setting description 0.00 (off)…5.00 s 0.00 s (off) for some applications it is of advantage when the drive starts and stops jerk-free. This is achieved through a straightening of the acceleration and deceleration ramps. The straightening tim...

Page 19

Gb - 19 parameter description cp.16 rated frequency co-domain setting description 0.00…400.00 hz 50 hz with the adjusted frequency the inverter reaches in controlled operation a maximal output voltage. The adjustment of the rat- ed motor frequency is typical in this case. Motors can overheat when th...

Page 20

Gb - 20 parameter description cp.18 switching frequency co-domain setting description 2 / 4 / 8 / 12 / 16 khz ltk the switching frequency with which the power modules are clocked can be changed depending on the application. The max.Possible switching frequency as well as the factory setting are spec...

Page 21

Gb - 21 parameter description cp.22 dc braking mode during the dc braking the motor is not decelerated over the ramp. Fast braking occurs via dc voltage which is applied to the motor winding. This parameter determines how the dc braking is triggered. The selection must be confirmed with „enter“. Val...

Page 22

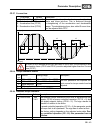

Gb - 22 parameter description cp.23 dc braking time co-domain setting description 0.00…100.00 s 10 s if the braking time depends on the actual frequency (cp.22 = 2…7), it is calculated as follows: cp.23 x f b t b = ––––––––– 100 hz f t 100 hz f b t b cp.23 t b : real braking time f b : actual freque...

Page 23

Gb - 23 parameter description co-domain setting description l: utilization t t t las t sll fr cp.24 cp.25 fs 1 0 0 1 l las: ramp stop active sll: constant current limit (stall) active fr: actual frequency fs: set frequency cp.26 speed search condition when connecting the frequency inverter onto a de...

Page 24

Gb - 24 parameter description cp.27 quick stop dec time co-domain setting description 0.00…300.00 s 2.00 s the fast-stop function is activated depending on cp.28. The parameter determines the time needed to decelerate from 100 hz to 0 hz. The actual deceleration time is pro- portional to the frequen...

Page 25

Gb - 25 parameter description cp.29 anout1 function cp.29 defines the function of analog output 1. The selection must be confirmed with „en- ter“. Value setting reaction output 0 absolute actual frequency (cp.01) 100 hz = 100 % 1 absolute set frequency (cp.02) 100 hz = 100 % 2 x actual frequency (cp...

Page 26

Gb - 26 parameter description cp.30 anout1 gain co-domain setting description -20,00…20,00 1,00 with the amplification the output voltage of the analog output can be tuned the signal to be given out. An ampli- fication of 1 corresponds to ±100 % = ±10 v. Example: the analog output shall give out +10...

Page 27

Gb - 27 parameter description cp.31 relay output 1 / function cp.32 relay output 2 / function cp.31 and cp.32 determine the function of the two outputs. The values must be confirmed with „enter“. Value setting function 0 off 1 on 2 run signal; also by dc braking 3 no error 4 cp.31 error message 5 fa...

Page 28

Gb - 28 parameter description value setting function 39 amount ru.58 „angle difference“ > switching level (observe only in posi- or synchronous mode / scaling factor of the le-parameters for incre- ments) 40 absolute value anout1 > level 1) 41 modulation on 42 output of the analog signal anout 3 or ...

Page 29

Gb - 29 parameter description value setting function 59 60 61 62 function switching condition met if: and all selected inputs are active or at least one of selected inputs is active nand at least one of selected inputs is not active nor all selected inputs are not active the selection of inputs to b...

Page 30

Gb - 30 parameter description value setting function 80 the output is set, if the distance to be covered to the target is larger than the adjusted level. 81 amount ru.09 „encoder 1 speed“ or ru.10 „encoder 2 speed“ > switch- ing level. 82 83 hsp5 bus synchronizes; corresponds status word bit 9 (sy.5...

Page 31

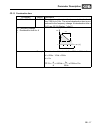

Gb - 31 parameter description cp.33 relay output 2 / switching level co-domain setting description -30000,00…30000,00 4,00 this parameter determines the switching level for the re- lay output 2 (cp.32). After the switching of the relay, the value can move within a window (hysteresis), without the re...

Page 32

Gb - 32 parameter description cp.35 an1 interface selection description the setpoint input 1 (an1) can be triggered by various signal levels. In order to correctly evaluate the signal, this parameter must be adapted to the signal source. The selection must be confirmed with „enter“. Val- ue setting ...

Page 33

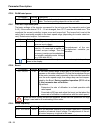

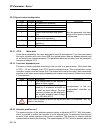

Gb - 33 parameter description 3.4 factory setting for operating mode „multi“ parameter setting range reso- lution default unit e based on cp.00 password input 0…9999 1 – – – ud.01 cp.01 encoder 1 speed ±4000 0,125 0 rpm – ru.09 cp.02 set value display ±4000 0,125 0 rpm – ru.01 cp.03 inverter state 0...

Page 34

Gb - 34 parameter description due to the calculation / measuring accuracies, tolerances with the current and torque displays as well as with the switching levels and limitations, must be taken into consideration. The given tolerances (see parameter description) refer to the respective maximum values...

Page 35

Gb - 35 parameter description 3.4.2 operating display the parameters below serve for the controlling of the frequency inverter during operation. Cp.01 encoder 1 speed co-domain description 0…±4000 rpm display of actual motor speed (incremental encoder 1). For control rea- sons the encoder speed is d...

Page 36

Gb - 36 parameter description cp.04 apparent current co-domain description 0…±6553.5 a display of the actual apparent current in ampere. Cp.05 apparent current / peak value co-domain description 0…±6553.5 a cp.05 makes is possible to recognize the max. Apparent current. For that the highest value of...

Page 37

Gb - 37 parameter description 3.4.3 basic adjustment of the drive the following parameters determine the fundamental operating data of the drive and must be adjusted for the initial start-up (see chapter "start-up" ). They should be checked and/or adapted to the application. Cp.10speedcontrolconfigu...

Page 38

Gb - 38 parameter description cp.16 dasm rated power co-domain setting description 0.35…1000 kw see 3.4.5 adjustment of the rated motor power according to the name plate. The factory setting depends on the unit size. Cp.17 load mot. Dependent para. The basic settings of the inverter correspond to th...

Page 39

Gb - 39 parameter description co-domain setting description u a f 100% cp. 19 motors can overheat when the rated frequency is incorrectly adjusted. During reg- ulated operation (cp.10 = 4 or 5) this parameter has no function. Cp.20 encoder 1 (inc/r) co-domain setting description 1…16383 inc 2500 inc...

Page 40

Gb - 40 parameter description cp.22 maximum speed co-domain setting description 0…4000 rpm 2100 rpm a maximum speed must be preset in order to limit the setpoint value. This limit value is the basis for further setpoint calcu- lations and for the determination of setpoint characteristics. The maximu...

Page 41

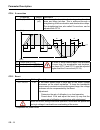

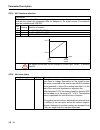

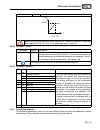

Gb - 41 parameter description cp.25 acc. Time forward co-domain setting description 0.00…300.00 s 5.00 s defines the time needed to accelerate from 0 to 1000 rpm. The actual acceleration time is proportional to the speed change (∆ n). ∆n speed change t [s] cp.25 n [rpm] 1000 800 300 0 0,5 1 1,5 2 ∆ ...

Page 42

Gb - 42 parameter description cp.26 deceleration time co-domain setting description -0.01…300.00 s 5.00 s defines the time needed to accelerate from 1000 to 0 rpm. The actual deceleration time is proportional to the speed change (∆ n). At a deceleration time of -1 the value from cp.25 is used (displ...

Page 43

Gb - 43 parameter description cp.27 s-curve time co-domain default description 0.00 (off)…5.00 s 0.00 s (off) for some applications it is of advantage when the drive starts and stops jerk-free. This is achieved through a straightening of the acceleration and deceleration ramps. The straightening tim...

Page 44

Gb - 44 parameter description cp.30 kp speed co-domain setting description 0…32767 300 the proportional factor of the speed controller is adjusted in these parameters (see chapter 3.4.6 „start-up“). Cp.31 ki speed co-domain setting description 0…32767 100 the integral factor of the speed controller ...

Page 45

Gb - 45 parameter description value function 11 overtemperature alert signal interior ohi 12…19 only application mode 20 actual value = set value (cp.03 = fcon; rcon; not at nop, ls, error, ssf) 21 accelerate (cp.03 = facc, racc, las) 22 decelerate (cp.03 = fdec, rdec, lds) 23 real direction of rota...

Page 46

Gb - 46 parameter description cp.35 limit switch / stopping mode this parameter determines the response of the drive to the terminal „ f“ or „r“. These termi- nals are programmed as hardware limit switches. The reaction of the drive is shown in the table below. Val- ue setting display reaction resta...

Page 47

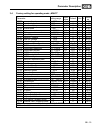

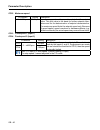

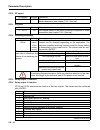

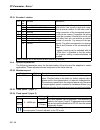

Gb - 47 parameter description 3.4.5 factory settings in the table below the factory settings for the size-dependent parameter values are listed. Parameter cp.11 cp.12 cp.13 cp.14 cp.15 cp.16 — cp.29 unit size/ voltage class rated motor speed rated motor frequency rated motor current rated motor volt...

Page 48

Gb - 48 parameter description parameter cp.11 cp.12 cp.13 cp.14 cp.15 cp.16 — cp.29 unit size/ voltage class rated motor speed rated motor frequency rated motor current rated motor voltage rated motor cos(phi) rated motor power rated motor torque maximum torque [rpm] [hz] [a] [v] cos(phi) [kw] [nm] ...

Page 49

Gb - 49 parameter description parameter cp.11 cp.12 cp.13 cp.14 cp.15 cp.16 — cp.29 unit size/ voltage class rated motor speed rated motor frequency rated motor current rated motor voltage rated motor cos(phi) rated motor power rated motor torque maximum torque [rpm] [hz] [a] [v] cos(phi) [kw] [nm] ...

Page 50

Gb - 50 parameter description start │ preset positive setpoint speed ref 1 (terminals x2a.1 / x2a.2) ◄───── remove cause of error ┐ │ │ activate control release (terminal x2a.16) ├◄────────────────────────────┐ direction of rotation of the motor (forward) correct ? ─ no─► exchange motor phases yes ├...

Page 51

Gb - 51 parameter description 3.4.7 adjustment speed controller 1. Open control release => frequency inverter in status „nop“ 2. Select closed loop operation => parameter cp.10 = 4 problem very long transient process problem very long speed overshoot solution increase kp speed (cp.30); even- tually ...

Page 52

Gb - 52 cp-parameter „servo“ 3.5 factory setting for operating mode „servo“ parameter setting range reso- lution default unit e based on cp.00 password input 0...9999 1 - - - ud.01 cp.01 encoder 1 speed ±4000 0,125 0 rpm - ru.09 cp.02 set value display ±4000 0,125 0 rpm - ru.01 cp.03 inverter state ...

Page 53

Gb - 53 cp-parameter „servo“ due to the calculation / measuring accuracies, tolerances with the current and torque displays as well as with the switching levels and limitations, must be taken into consideration. The given tolerances (see parameter description) refer to the respective maximum values ...

Page 54

Gb - 54 cp-parameter „servo“ 3.5.2 operating display the parameters below serve for the controlling of the frequency inverter during operation. Cp.01 encoder 1 speed co-domain description 0…±4000 rpm display of actual motor speed (incremental encoder 1). For control rea- sons the set speed is displa...

Page 55

Gb - 55 cp-parameter „servo“ cp.05 apparent current / peak value co-domain description 0…±6553.5 a cp.05 makes is possible to recognize the max. Apparent current. For that the highest value of cp.04 is stored in cp.05. The peak value memory can be cleared by pressing the up, down or enter key or ove...

Page 56

Gb - 56 cp-parameter „servo“ cp.10speedcontrolconfiguration value setting function description 0 x off (open-loop operation) with this parameter the basic setting of the speed controller is determined. 1 -reserved- 2 -reserved- 3 off (open-loop operation) 4 speed control(closed-loop opera- tion) 5 t...

Page 57

Gb - 57 cp-parameter „servo“ engine runs manual in clockwise direction. If this is not the case, the direction of rotation can be changed with cp.21. If the correct direction of rotation is displayed, it can be started with the adjustment. • the connected motor must rotate free. • open control relea...

Page 58

Gb - 58 cp-parameter „servo“ cp.21 encoder 1 rotation bit val- ue function description 0 encoder rotation at manual rotation the actual speed at for- ward rotation has a positive sign and a neg- ative at reverse rotation. In the other case a wrong connection of the incremental encod- er can be the r...

Page 59

Gb - 59 cp-parameter „servo“ cp.25 acc. Time forward co-domain setting description 0.00…300.00 s 5.00 s defines the time needed to accelerate from 0 to 1000 rpm. The actual acceleration time is proportional to the speed change (∆ n). ∆n speed change t [s] cp.25 n [rpm] 1000 800 300 0 0,5 1 1,5 2 ∆ t...

Page 60

Gb - 60 cp-parameter „servo“ cp.26 deceleration time co-domain setting description -0.01…300.00 s 5.00 s defines the time needed to accelerate from 1000 to 0 rpm. The actual deceleration time is proportional to the speed change (∆ n). At a deceleration time of -1 the value from cp.25 is used (displa...

Page 61

Gb - 61 cp-parameter „servo“ cp.27 s-curve time co-domain setting description 0.00 (off)…5.00 s 0.00 s (off) for some applications it is of advantage when the drive starts and stops jerk-free. This is achieved through a straightening of the acceleration and deceleration ramps. The straightening time...

Page 62

Gb - 62 cp-parameter „servo“ cp.29 absolute torque reference co-domain setting description +10000.00 nm see 4.4.5 the absolute torque reference of the drive is adjusted with pa- rameter cp.29 in torque controlled operation (cp.10 = 5) and with digital setpoint setting (cp.28 = 2). The sign stands fo...

Page 63

Gb - 63 cp-parameter „servo“ cp.33 relay output 1 / function cp.34 relay output 2 / function cp.33 and cp.34 determine the function of the two outputs. The values must be confirmed with „enter“. Value function 0 off 1 on 2 run signal; also by dc braking 3 no error 4 error message 5 error without aut...

Page 64

Gb - 64 cp-parameter „servo“ value function 53 n-control limit active 54…62 only application mode 63 absolute value anout1 > level 1) 64 absolute value anout2 > level 1) 65 anout1 > switching level 1) 66 anout2 > switching level 1) 67…69 only application mode 70 driver vcc active (safety relay) 71…7...

Page 65

Gb - 65 cp-parameter „servo“ cp.36 reaction to external fault with the external error monitoring external units can take direct influence on the drive. This parameter determines the response of the drive to a signal at terminal „ i3“, according to following table. Val- ue setting display reaction re...

Page 66

Gb - 66 cp-parameter „servo“ parameter cp.11 cp.12 cp.13 cp.14 cp.15 cp.16 cp.17 cp.18 cp.29 unit size/ voltage class default motor rated motor torque rated motor speed rated motor frequen - cy rated motor current dsm emk voltage constant winding inductance winding resistance stand still current max...

Page 67

Gb - 67 cp-parameter „servo“ 3.5.7 adjustment speed controller with the pc software keb combivis (scope) setpoint and real speed can be displayed. If one of the following real speed curves occurs at acceleration, the speed controller (cp.30, cp.31) should be adjusted according to the notes. Problem ...

Page 68

Gb - 68 drive mode 4. Drive mode the drive mode is an operating mode of keb combivert that permits the manual starting of the drive by the operator. After switching the control release the set value and rotation setting occurs only via keyboard. In order to activate the drive mode the corresponding ...

Page 69

Gb - 69 error assistance 5. Error assistance error messages at keb combivert are always displayed with "e." and the appropriate er- ror code in the display. Error messages cause the immediate deactivation of the modulation. Restart possible only after reset or autoreset. Malfunction are represented ...

Page 70

Gb - 70 error assistance display combivis val- ue meaning pna positioning not accessible 123 the specified position cannot be reached within the preset ramps. The abort of the positioning can be pro- grammed. Poff power off 78 depending on the programming of the function the inverter restarts automa...

Page 71

Gb - 71 error assistance display combivis val- ue meaning e.Bus errorwatchdog 18 adjusted monitoring time (watchdog) of communication between operator and pc / operator and inverter has been exceeded. E.Cdd errorcalc. Drive data 60 error: during the automatic motor stator resistance measurement. E.D...

Page 72

Gb - 72 error assistance display combivis val- ue meaning e.Ndoh no error drive over- heat 11 motor temperature switch or ptc at the terminals t1/t2 is again in the normal operating range. The error can be reset now. E.Noh no e. Overheat pow.Mod. 36 temperature of the heat sink is again in the permi...

Page 73

Gb - 73 error assistance display combivis val- ue meaning e.Ol2 error overload 2 19 occurs if the standstill constant current is exceeded (see technical data in the power circuit manual). The error can only be reset if the cooling time has elapsed and e.Nol2 is displayed. E.Op error overpotential 1 ...

Page 74

Gb - 74 error assistance display combivis val- ue meaning e.Up error underpotential 2 error: undervoltage (dc-link circuit) occurs, if dc-link voltage falls below the permissible value. Causes: input voltage too low or instable inverter rating too small voltage losses through wrong cabling the suppl...

Page 75

Gb - 75 error assistance display combivis val- ue meaning a. Oh abn.Stop overheat pow. Mod. 89 a level can be defined, when it is exceeded this warning is output. The response to this warning can be pro- grammed. A.Oh2 abn.Stop motor protect. 97 warning: electronic motor protective relay has tripped...

Page 76

Gb - 76 parameter description 6. Quick guide 6.1 quick guide for operating mode „general“ parameter setting range resolu- tion unit e customer setting cp.00 password input 0…9999 1 - - cp.01 actual frequency display -400…400 0,0125 hz - cp.02 set frequency display -400…400 0,0125 hz - cp.03 inverter...

Page 77

Gb - 77 parameter description cp.32 relay output 2 / function 0…100 b/c: 0…84 1 - e cp.33 relay output 2 / switching level ±30000,00 0,01 - - cp.34 rotation source 0…10 b/c: 0…9 1 - e cp.35 an1 interface selection 0…2 1 - e cp.36 an1 zero clamp -10,0…10,0 0,1 % - ltk=depending on power unit; e=enter...

Page 78

Gb - 78 parameter description 6.2 quick guide for operating mode „multi“ parameter setting range reso- lution unit e customer set- ting cp.00 password input 0...9999 1 – – cp.01 encoder 1 speed ±4000 0,125 rpm – cp.02 set value display ±4000 0,125 rpm – cp.03 inverter state 0...255 1 – – cp.04 appar...

Page 79

Gb - 79 parameter description 6.3 factory setting for operating mode „servo“ parameter setting range reso- lution unit e customer setting cp.00 password input 0...9999 1 - - cp.01 encoder 1 speed ±4000 0,125 rpm - cp.02 set value display ±4000 0,125 rpm - cp.03 inverter state 0...255 1 - - cp.04 app...

Page 80

Gb - 80 passwords 7. Passwords read only read/write drive mode 100 200 500

Page 81

Gb - 81 notes.

Page 82

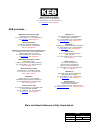

Keb antriebstechnik austria gmbh ritzstraße 8 • a-4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • b-9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technolog...