- DL manuals

- KEB

- Recording Equipment

- COMBIVERT F5

- Installation Manual

KEB COMBIVERT F5 Installation Manual

Summary of COMBIVERT F5

Page 1

C o m b i v e r t gb the general emc and safety directions at www. Keb.De have to be observed ! Mat.No. Rev. 00f5sem-ka03 1j installation manual housing a.

Page 2

Gb - 49 this manual describes the keb combivert f5. Particular attention is paid to the installation, the connection as well as the basic operation. Due to the various application and programming possibilities, the application-specific connection and/or wiring diagram, the parameter adjustment as we...

Page 3: Table of Contents

Gb - 3 table of contents 1. Safety and operating instructions....................................................................................4 2. Product description ...........................................................................................................5 2.1 intended use........

Page 4: For Drive Converters

Gb - 51 1. General in operation, drive converters, depending on their degree of protection, may have live, uninsulated, and possibly also moving or rotating parts, as well as hot surfaces. In case of inadmissible removal of the required covers, of improper use, wrong installation or maloperation, th...

Page 5: Product Description

Gb - 5 product description 2. Product description 2.1 intended use the digital servo controller keb combivert f5-servo serves exclusively for the control and regulation of synchronous servo motors. The operation of other electric consumers is prohibited and can lead to the destruction of the unit. O...

Page 6: Product Description

Gb - 6 2.3 technical data product description inverter size 05 07 housing size a phases 1 3 1 3 output rated power [kva] 0,9 1,6 output rated current [a] 2,3 4 output rated current ul [a] 2 4,1 stand still current [a] 2,5 4,4 max. Short time current 1) [a] 4,6 8 oc-tripping current [a] 5,5 9,6 rated...

Page 7

Gb - 7 inverter size 05 07 09 housing size a phases 3 3 3 output rated power [kva] 0,9 1,8 2,8 output rated current [a] 1,3 2,6 4,1 output rated current ul [a] 1,0 1,8 3,4 stand still current [a] 1,4 2,9 4,5 max. Short time current 1) [a] 2,6 5,2 8,2 oc-tripping current [a] 3,1 6,2 9,8 rated switchi...

Page 8

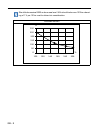

Gb - 8 site altitude maximal 2000 m above sea level. With site altitudes over 1000 m a derat- ing of 1 % per 100 m must be taken into consideration. Overload function 0 50 100 150 200 250 300 s 100 120 140 160 180 200 %.

Page 9: Product Description

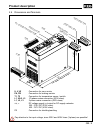

Gb - 9 product description 2.4 dimensions and terminals pel1 l2 l3 ++-- pel1 n/l2l3 ++-- wa ein fe schutz s ist als a llei schutz maßna nicht zu lÌässig die ko entlad beträg t2 t1 pb pa w v u pe 185 175 144 158 76 5 u, v, w connection for servo motor pa, pb connection for braking resistor t1, t2 con...

Page 10: Installation and Connection

Gb - 10 installation and connection 3. Installation and connection 3.1 control cabinet installation 3.2 emc-conform installation installation position and min. Distances 150 mm 30 mm 100 mm start stop func. Speed enter f/r antriebstechnik start stop func. Speed enter f/r antriebstechnik 6 inch 1 inc...

Page 11: Installation and Connection

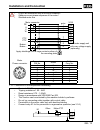

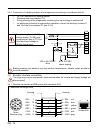

Gb - 11 7 l1l2 l3 ++ -- e installation and connection 3.3 connection of power circuit 3.3.1 wiring instructions • core cross-section 1,5 mm² • strip 7 mm • optional use of wire-end ferrule • after arresting the cable by removing the screwdriver absolutely check for a firm fit attach / remove termina...

Page 12: Installation and Connection

Gb - 12 installation and connection ++ -- l1 pe n/l2 l3 l1 pe n mains connection 230 v 1-phase ++ -- l1 pe n/l2 l3 l1 pe l2 l3 ++ -- l1 pe l2 l3 l1 pe l2 l3 ++ -- l1 pe n/l2 l3 + - ++ -- l1 pe l2 l3 + - 1 x 230 v ac 3 x 1.5 mm² mains connection 230 v 3-phase 3 x 230 v ac 4 x 1.5 mm² mains connection...

Page 13: Installation and Connection

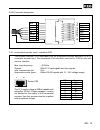

Gb - 13 installation and connection • plug in all connectors only in off-circuit condition ! • observe correct phase sequence of the motor ! • shielded motor line ptc ptc brake + brake – motor power connector a b c d 1 2 3 4 pe u v w ext. Brake supply unit with own voltage supply (optionally) apply ...

Page 14

Gb - 14 1 2 3 4 5 6 7 8 9 10 11 12 3.4.1 resolver connection at keb motors with connector x3a 3.4 encoder interface connection 1 8 the plugs may only be connected / disconnected when the inverter and supply voltage are disconnected ! Motor resolver plug socket x3a • maximum line length 50 m 3.3.6 co...

Page 15

Gb - 15 1 8 3.4.2 incremental encoder input / -emulation x3b the encoder interface x3 is switchable from an incremental encoder emulation to an in- cremental encoder input. The increments of the emulation are fixed to 1024 for units with resolver interface. Max. Input frequency: signals: rs 422 / 2 ...

Page 16: Installation and Connection

Gb - 16 installation and connection 3.5 control board servo 3.5.1 control terminal strip x2a 1 2 5 7 8 10 11 12 13 24 25 26 16 18 19 21 22 • tightening torque 0.22…0.25 nm (2 lb inches) • use shielded/drilled cables • lay shield on one side of the inverter onto earth potential • npn control is not p...

Page 17: Installation and Connection

Gb - 17 installation and connection 3.5.2 connection of the control terminal strip set value potentiometer 3…10 kΩ external voltage supply 20…30 v dc ±0 % 1 a set value signal 0…±10 v dc analog output ±10 v dc max. 5 ma 1) connect potential equalizing line only if a potential difference of > 30 v ex...

Page 18: Operation of The Unit

Gb - 67 operation of the unit 4. Operation of the unit 4.1 operation accessories 4.1.1 with hsp5 cable and without operator a special cable (part number 00f50c0-0001) is necessary for the control of the keb combivert without operator. It is connected between the hsp5-interface x4a and a serial rs232...

Page 19: Operation of The Unit

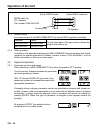

Gb - 68 operation of the unit 4.1.4 remote control for remote control of the keb combivert f5 a special hsp5 operator is available. Operator cable the last three digits of the part number indicate the length of the cable in dm. 00f5060-9000 00f50c0-2xxx 00f5060-9001 00f50c0-3xxx 4.1.5 other operator...

Page 20: Operation of The Unit

Gb - 69 4.2.2 resetting error messages if a malfunction occurs during operation, then the actual display is overwritten by the alarm message. The alarm message in the display is reset by enter. — error —> enter f/r with enter only the error message in the display is reset. In order to reset the erro...

Page 21: Cp-Parameter

Gb - 80 cp-parameter 4.3 parameter description for f5 servo display parameter setting range resolution default unit enter based on cp.00 password input 0...9999 1 - - - ud.01 cp.01 encoder 1 speed ±4000 0.125 0 rpm - ru.09 cp.02 setpoint display ±4000 0.125 0 rpm - ru.01 cp.03 inverter state 0...255...

Page 22: Cp-Parameter

Gb - 81 cp-parameter cp.10 speedcontrolconfiguration this parameter activates the speed or the torque control. Cp.10 description 4 speed control 5 torque control 6 speed / torque control cp.19 load motor dependent parameter the factory settings of the servo correspond to the size of the unit and the...

Page 23: Cp-Parameter

Gb - 82 cp-parameter the signals a(+) and a(-) must be changed for units with sin/cos encoder. Should this involve too much effort then you can achieve a rotation reversal of encoder 1 by means of this parameter. Cp.21 meaning 0 tracks not exchanged 1 track exchanged 2…3 reserved for initiator input...

Page 24: Cp-Parameter

Gb - 83 cp-parameter value function 63 absolut value anout1 > switching level 1) 64 absolut value anout2 > switching level 1) 65 anout1 > switching level 1) 66 anout2 > switching level 1) 70 driver voltage activ (safety relay) 73 absolut active power > switching level 1) 74 active power > switching ...

Page 25: Annex A

Annex a gb - 84 a. Annex a a.1 overload characteristic release time [s] 105 110 120 130 140 150 160 100 150 200 250 300 30 50 170 180 190 200 210 220 load [%] on exceeding a load of 105% the overload integrator starts. When falling below the inte- grator counts backwards. Error e.Ol is triggered if ...

Page 26: Annex A

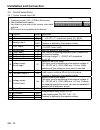

Gb - 85 annex a cycle function constant pay attention to unusual noises of the motor (e.G. Vibrations) as well as of the frequency inverter (e.G. Fan). Pay attention to unusual smells of the motor or frequency inverter (e.G. Eva- poration of capacitor electrolyte, braise of the motor winding) monthl...

Page 27: Annex A

Annex a gb - 86 storage period > 3 years • input voltages as before, however double the times per year. Eventually change capacitors. Eventually change capacitors. After expiration of this start-up the keb combivert can be operated on nominal rating conditions or delivered to a new storage. A.5 chan...

Page 28: Annex B

Annex b gb - 28 b. Annex b b.1 ce-marking ce marked frequency inverter and servo drives were developed and manufactured to comply with the regulations of the low-voltage directive 2006/95/ec. The inverter or servo drive must not be started until it is determined that the installation complies with t...

Page 29: Annex B

Gb - 29 annex b • integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must be provided in accordance with the manufacturer in- structions, national electrical code and any additional local codes, or the equivalent. Table for input fusin...

Page 30: Annex B

Annex b gb - 30 use of modular drive system 07f5a1a-3e2f: • for 480 v models, f5-a, modular drive system, consisting of two drive units, cat. No. 07f5a1a-3e2f: "suitable for use on a circuit capable of delivering not more than 10000 rms symmetrical amperes, 480 volts maximum, when protected by class...

Page 31: Annex B

Gb - 31 annex b b.3 additional manuals you find supplementary manuals and instructions for the download under www.Keb.De > service > downloads general instructions • part 1 emc-and safety instructions unit-specific instructions • part 2 power circuits • dpart 3 control circuit service notes download...

Page 32: Keb Worldwide…

Keb antriebstechnik austria gmbh ritzstraße 8 • a-4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • b-9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technolog...