- DL manuals

- KEB

- Recording Equipment

- COMBIVERT F5

- Instruction Manual

KEB COMBIVERT F5 Instruction Manual

Summary of COMBIVERT F5

Page 1

Combivert original manual mat.No. Rev. 00f50eb-kb00 1c gb instruction manual housing b 0.37...2.2 kw 230 v 0.37...4.0 kw 400 v.

Page 3: Table of Contents

3 table of contents table of contents 1. Preface ............................................................................................................. 5 1.1 information on special measures .......................................................................................5 1.2 documentat...

Page 4: List of Figures

4 table of contents a. Annex a ......................................................................................................... 27 a.1 overload characteristic .....................................................................................................27 a.2 overload protection in t...

Page 5

5 preface 1. Preface the described hard and software are developments of the keb automation kg. The en- closed documents correspond to conditions valid at printing. Misprint, mistakes and technical changes reserved. 1.1 information on special measures the used pictograms have following significance:...

Page 6

6 preface step 3 the entire documentation associated with the device will be displayed, in- cluding the instruction manuals in german and english. If available, other translations are also indicated. Make sure that the user understands the pro- vided language. Should you be unable to read or underst...

Page 7

7 preface keb ® , combivert ® , keb combicontrol ® and combivis ® are registered trademarks of keb automation kg. Other wordmarks or/and logos are trademarks (™) or registered trademarks (®) of their re- spective owners and are listed in the footnote on the first occurrence. When creating our docume...

Page 8

8 preface 1.7 unitidentification 09 . F5 . B 1 b - 3 9 0 0 cooling a: heat sink b: flat rear encoder interface 0: none switching frequency; short time current limit; overcurrent limit 5: 4 khz; 150 %; 180 % 9: 4 khz; 180 %; 216 % a: 8 khz; 180 %; 216 % b: 16 khz; 180 %; 216 % input identification 0:...

Page 9

9 1.8 installation instructions 1.8.1 cooling systems the keb combivert f5 is available for different cooling systems: heat sink with cooling fan (mounted version) the standard version is delivered with heat sink and cooling fan. Special versions the dissipation of power loss must be guaranteed by t...

Page 10

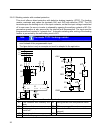

10 1.8.2 control cabinet installation mounting distances dimen- sions distance in mm distance in inch c a b d d a 150 6 b 100 4 c 30 1.2 d 0 0 x 1) 50 2 1) distance to preceding control elements in the con- trol cabinet door. Direction of the cooling fins front and side view of the coolant inlet coo...

Page 11

11 safety and application notes 1. General in operation, drive converter depending on their degree of protection, may have live, uninsulated and possibly also moving or rotating parts, as well as hot surfaces. In case of inadmissible removal of the required covers, of improper use, wrong installatio...

Page 12

12 technical data 2. Technical data 2.1 operating conditions standard standard/ class instructions definitionacc. En 61800-2 inverter product standard ratedspecifications en 61800-5-1 inverter product standard: general safety site altitude max. 2000 m above sea level (with site altitudes over 1000 m...

Page 13

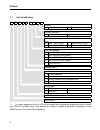

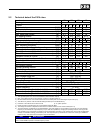

13 2.2 technical data of the 230v class inverter size 05 07 09 10 housing size b phases 1 3 1 3 1 3 1 3 output rated power [kva] 0.9 1.6 2.8 4 max. Rated motor power [kw] 0.37 0.75 1.5 2.2 output rated current [a] 2.3 4 7 10 max. Short time current 1) [a] 4.1 7.2 12.6 18 oc-tripping current [a] 5 8....

Page 14

14 2.3 technical data of the 400v class inverter size 05 07 09 10 12 housing size b phases 3 output rated power [kva] 0.9 1.8 2.8 4 6.6 max. Rated motor power [kw] 0.37 0.75 1.5 2.2 4 output rated current [a] 1.3 2.6 4.1 5.8 9.5 max. Short time current 1) [a] 2.3 4.7 7.4 10.4 17 oc-tripping current ...

Page 15

15 info note pole pairs the technical data are for 2/4-pole standard motors. With other pole numbers the inverter must be dimen- sioned onto the rated motor current. Contact keb for special or medium frequency motors. Warning input rated voltage no braking resistor may be connected for control type ...

Page 16

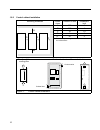

16 2.5 dimensions and weights 2.5.1 dimensions mounted version (representation with optional mounting kit) 75,85 173,5 90 220 159,5 69 266 5 210 5 90 161 weight: 2 kg figure 3: dimensions mounted version.

Page 17

17 2.5.2 dimensions flat rear (representation with optional mounting kit) 128 91 139,5 250 281,4 235 7,5 50 Ă 5,5 weight: 1.8 kg figure 4: dimensions flat rear.

Page 18

18 2.5.3 mounted version with/without operator figure 5: mounted version with/without operator 2.5.4 flat rear mit/ohne operator figure 6: flat rear with/without operator.

Page 19

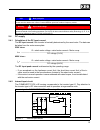

19 2.6 terminal strips of the power circuit caution observe input voltage, since 230 v and 400 v class possible info all terminal strips meet the requirements according to en 60947-7-1 (iec 60947-7-1) name function cable cross-sections terminals no. L1, n 1-phase mains connection 1 l1, l2, l3 3-phas...

Page 20

20 2.7 accessories 2.7.1 filter and chokes voltage class inverter size filter mains choke 50 hz (4 % uk) motor choke 100 hz (4 % uk) 230 v 1-phase 05 10e5t60-0001 05z1b02-1000 – 07 07z1b02-1000 – 09 09z1b02-1000 – 10 10z1b02-1000 – 230 v 3-phase 05 10e5t60-1001 05z1b03-1000 – 07 07z1b03-1000 – 09 12...

Page 21

21 2.8 connection power unit 2.8.1 mains and motor connection caution incorrect connection possible! • absolutely pay attention to the supply voltage of the keb combivert. A 230 v unit at 400 v mains is destroyed immediately. • exchanging mains and motor connection leads to immediate destruction of ...

Page 22

22 2.8.1.2 mains connection 3-phase l1 l2 l3 pe l1 7 8 l2 l3 u v w pe u v w pe pe t1 t2 figure 9: mains connection 3-phase legend 1 mains supply 2 mains fuses 3 mains contactor 4 mains choke 5 hf filter 6 keb combivert f5 7 motor (see also 2.8.3) 8 motor protection temperature sensor (also see 2.8.4...

Page 23

23 2.8.2 selection of the motor cable the correct selection and wiring of the motor cable is very important: • lower abrasion of the motor bearings by leakage currents • improved emc characteristics • lower symmetrical operating capacities • less losses by transient currents 2.8.3 connection of the ...

Page 24

24 2.8.4 temperature detection t1, t2 in.17 function of t1, t2 pn.72 (dr33) resistance display ru.46 (f6 => ru28) error/warn- ing 1) 5xh ptc (in accord- ance with din en 60947-8) 1 t1-t2 closed – 0.75…1.65 kΩ (reset resistance) undefined – 1.65…4 kΩ (tripping resistance) undefined x > 4 kΩ t1-t2 ope...

Page 25

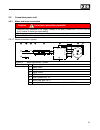

25 2.8.5 connection of a braking resistor warning very high surface temperatures braking resistors dissipate the produced energy of the motor into heat during generatoric operation. Thus braking resistors can cause very high surface temperatures. During assem- bly pay attention to appropriate protec...

Page 26

26 2.8.5.2 braking resistor with overheat protection this circuit offers a direct protection with defective braking transistor (gtr7). The braking resistor overheats and opens the terminals oh1 and oh2 with defective gtr7. The oh terminals open the holding circuit of the input contactor, so that the...

Page 27

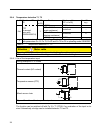

27 annex a a. Annex a a.1 overload characteristic time [s] 30 60 90 120 150 180 210 240 270 300 0 105 110 115 120 125 130 135 140 145 150 160 170 180 190 200 210 220 load [%] in this range the characteristic declines dependent on the overcurrent limit (see unit identification). Figure 15: overload c...

Page 28

28 annex a a.3 calculation of the motor voltage the motor voltage for dimensioning of the drive is depending on the used components. The mains voltage reduces according to the following table: mains choke uk 4 % example: inverter open-loop 4 % closed-loop inverter with mains- and motor choke at non-...

Page 29

29 annex a storage period • start-up without special measures storage period 1…2 years • operate frequency inverter one hour without modulation storage period 2…3 years • remove all cables from the power circuit; especially of braking resistor or module • open control release • connect variable tran...

Page 30

30 annex b b. Annex b b.1 certification b.1.1 ce marking ce marked frequency inverter and servo drives were developed and manufactured to comply with the regulations of the low-voltage directive 2006/95/ec. The inverter or servo drive must not be started until it is determined that the installation ...

Page 31

31 annex b • integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must be provided in ac- cordance with the manufacturer instructions, national electrical code and any additional local codes, or the equivalent. Branch circuit protection ...

Page 32

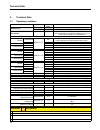

32 annex b cat. No. Drive input rating # self protected manual motor con- troller type and manufacturer self protected manual motor controller rating 05f5 480v/3ph pkzmo–10e, eaton industries 480y/277v, 7.5 hp 07f5 480v/3ph pkzmo–10e, eaton industries 480y/277v, 7.5 hp 09f5 480v/3ph pkzmo–10e, eaton...

Page 33

33 annex c c. Annex c c.1 changing the response threshold of the braking transistor (not valid for control type „basic“) to avoid a premature switching of the brake transistor at an input rated voltage of 480 vac, the response threshold must be controlled or adjusted according to the following graph...

Page 34

Keb antriebstechnik austria gmbh ritzstraße 8 • 4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • 9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technology (s...