- DL manuals

- Oki

- Printer

- CX3641 MFP

- Service & Troubleshooting Manual

Oki CX3641 MFP Service & Troubleshooting Manual

ES3640MFP / CX3641MFP

Service & Troubleshooting Guide

© 2008 OkiData Americas, Inc.

Disclaimer

Every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The manufacturer assumes no responsibility

for the results of errors beyond its control. While all reasonable efforts have been made to make this document accurate and helpful as possible, we make no

warranty of any kind, expressed or implied, as to the accuracy or completeness of the information contained herein. For the most up-to-date service information

available, visit our website at

www.okidata.com

© Okidata Americas, Inc. 2008

Summary of CX3641 MFP

Page 1

Es3640mfp / cx3641mfp service & troubleshooting guide © 2008 okidata americas, inc. Disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The manufacturer assumes no responsibility for the results of errors beyond its control. Wh...

Page 2: Contents

Contents chapter 1 printer maintenance procedures 1.1 service maintenance procedures 1.2 cleaning the printer 1.3 cleaning the imaging unit contacts 1.4 cleaning the led heads 1.5 cleaning the feed rollers.

Page 3: Chapter 2

Chapter 2 user menu and adjustments 2.1 accessing the user menu main menus sub menus configuration print page count • finisher count • supplies life network • paper size in tray • system print pages print pages suspend printing resume printing print secure job print secure job menus tray configurati...

Page 4: Chapter 3

Chapter 3 troubleshooting print quality 3.1 an overview of print-quality problems print-quality problems overview defects associated with specific printer components 3.2 generating and analyzing test prints generating and analyzing control panel test prints generating and analyzing service test prin...

Page 5: Chapter 4

Chapter 4 troubleshooting paper jams 4.1 paper jam error code table 4.2 jam troubleshooting code 370: paper jam occurred in the duplex (rear) code 371: paper jam occurred in the duplex (middle) code 372: paper jam occurred in the duplex (front cover) code 373: paper jam occurred in the duplex (rear)...

Page 6: Chapter 5

Chapter 5 troubleshooting self diagnostic codes 5.1 self diagnostic error codes self diagnostic error codes (printer) self diagnostic error codes (scanner/adf) self diagnostic error codes (finisher) self diagnostic error codes (other codes) 5.2 general troubleshooting no control panel display contro...

Page 7: Chapter 1

Chapter 1 printer maintenance procedures 1.1 service maintenance procedures perform the following procedures whenever you check, service, or repair the printer. Cleaning the printer, as outlined in the following steps, assures proper operation of the printer and reduces the probability of having to ...

Page 8

1.2 cleaning the printer perform the following general cleaning steps as indicated by the printer’s operating environment. Caution never apply alcohol or other chemicals to any parts in the printer. Never use a damp cloth to clean up toner. If you remove the image drum units, place them in a light p...

Page 9

1.4 cleaning the led heads clean the led head if a vertical white band or white stripe appears on the print. Caution always use a soft, dry, lint-free cloth to clean the led heads. Never use solvents to clean the lens. 1. Open the top cover. 2. Clean each led head with a clean, lint- free cloth. 1.5...

Page 10: Chapter 2

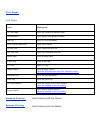

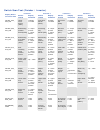

Chapter 2 user menu and adjustments 2.1 accessing the user menu press the menu up arrow to access the user menu. User mode menus main menus sub menus configuration print page count • finisher count • supplies life network • paper size in tray • system print pages print pages suspend printing resume ...

Page 11

Configuration print page count item description total page * displays the total number of printed pages. Must be enabled in printer service mode. Color page displays the number of color printed pages converted to letter equivalent. Monochrome page displays number of monochrome printed pages converte...

Page 12

Network the items and settings displayed are specific to your system. Full details are given in the configuration guide. Information given is also available on the printed configuration sheets. Paper size in tray item description tray displays detected paper size of selected tray mp tray displays de...

Page 13

Print pages print pages item description ps test page prints the postscript sample page. Configuration prints printer configuration details. Job log prints efi job log details. Color charts (disk only) prints color charts. Ps font list prints postscript font list. Pcl font list prints pcl emulation ...

Page 14

Print secure job print secure job item description enter password enter a password to use secure printing. Not found use a secure printing job (secure job) or a job stored to hdd when printing. When you print a secure document, it is deleted from the hdd. When you print a document stored to hdd, it ...

Page 15

System adjust item description (printer defaults are indicated in blue ) power save time sets the period after which power save mode starts. 5 min, 15 min, 30 min, 60 min , 240 min clearable warning when online is selected, you must manually clear the warning by pressing the online button. Change to...

Page 16

Transparency color setting as for paper color setting above. The range is -2 to +2. Default is 0. Smr setting (new) allows for minor corrections in print anomalies such as "smearing" due to environmental conditions (temperature & humidity) bg setting (new) allows for minor corrections in print anoma...

Page 17

Calibration exit calibration item description exit calibration select “enter” to exit the calibration screen auto density mode item description auto density mode *on / off – turns on or off the auto density mode auto bg adjust mode item description auto bg adjust mode *on / off – turns on or off the...

Page 18

Calibrate item description *6x6 dot screen print meas. Pg. *yes / no see “calibrating the printer” in chapter 2 12x6 dot screen print meas. Pg. *yes / no see “calibrating the printer” in chapter 2 12x6 line screen print meas. Pg. *yes / no see “calibrating the printer” in chapter 2 12x12 dot screen ...

Page 19

Reset counter item description reset counter *no / yes – not used at this time change password item description change password *new password – enter new 4 digit password.

Page 20

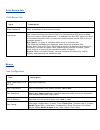

Service modes & adjustments 2.2 accessing service mode enter service mode by holding down the menu up / menu down and help buttons at the same time while powering up the machine. (this may take up to 60 seconds.) the system maintenance menu will appear. Service mode menus there are 4 menus under sys...

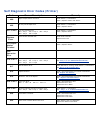

Page 21

Button function _____________________________________________________________________ back returns to the prior higher level menu structure, if available. If help text is displayed, pressing back restores the current menu item. ________________________________________________________________________...

Page 22

Using the motor & clutch test enter service mode by holding down the menu up / menu down and help buttons at the same time while powering up the machine. (this may take up to 60 seconds.) from diagnostic mode down arrow to “motor & clutch test” and press “enter” from this menu, pressing the down arr...

Page 23

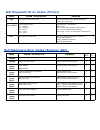

Fan tests item tested remark fan id runs black image drum fan for 10 seconds fan belt runs the transfer belt fan for 10 seconds fan fuser runs the fuser fan for 10 seconds fan pu-board runs the pu board fan for 10 seconds fan power runs the power supply fan for 10 seconds inverter tests item tested ...

Page 24

Using the switch scan test enter service mode by holding down the menu up / menu down and help buttons at the same time while powering up the machine. (this may take up to 60 seconds.) the system maintenance menu will appear. From diagnostic mode, down arrow to “switch scan” and press “enter” from t...

Page 25

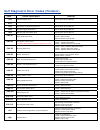

Mpt pe_ hop_cvo_home mpt-paper- end sensor port level h, l mpt- hopping h:on l:off cover-mpt h - open l - close mpt home position h - open l – close tray1 pe_ pne_cvo 1st-paper- end port level h, l 1st-paper- near-end port level h, l cover-1st h - open l – close tray1 hop_lift 1st-hopping sensor por...

Page 26

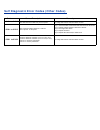

Switch scan test (finisher / inverter) location 1 location 2 location 3 location 4 display detail on printer lcd sensor tested display condition sensor tested display condition sensor tested display condition sensor tested display condition fin s01_s02_ s03_s04 upper cover sensor [pi23] h:open l:clo...

Page 27

2.6 service adjustments removing the calibration for the copier screen 1. Press the down arrow button until calibration is highlighted, then press the enter button 2. Press the down arrow button until remove calibration is highlighted, then press the enter button 3. Press the down arrow button until...

Page 28

6. Press the enter button in the next window to print out the colorcal measurement page 7. Press the enter button again to accept the choice to measure the colorcal page that was just printed 8. Once the following screen appears: place the q-13 strip face down on the glass in the top left corner. Ne...

Page 29

9. Once the q-13 and colorcal page are on the copier glass, press the enter button 10. In the next window choose whether or not to print a comparison page and press enter 11. When asked to apply the calibration, press the enter button 12. In the final window select yes, and press the enter button in...

Page 30

Using command workstation to calibrate the scanner tools needed q-13 gray scale, part number 70051001. Reasons that a calibration should be done 1. On initial setup, there is no copier calibration stored in the mfp unit so calibration is required. 2. Colors are off when making a copy, but are fine w...

Page 31

Diagram: standard calibrator utility diagram: expert calibrator utility the scanner unit can be calibrated via both the standard and expert calibrator processes (shown above). This article will use the standard calibrator to demonstrate the process for the remainder of the document. The instructions...

Page 32

In check print settings (item 2 of the following window), select copier screen as shown below. In generate measurement page (item 3 of the above window), press the print button. The following colorcal measurement page will be printed..

Page 33

In get measurements (item 4 of the following window), press the measure button. The following screen will appear. Select “yes” in the above window. The following screen will appear..

Page 34

Press the print button in the above screen. The following page will be printed..

Page 35

The following screen will appear. Place the kodak gray scale and kodak color control patches on to the scanner calibration page as shown below. Now place the kodak gray scale, kodak color control patches and scanner calibration page face down on the scanner glass and press the continue button in the...

Page 36

Press the continue button in the previous information window. The following screen will appear. Place the kodak gray scale strip face down on the scanner glass and place the colorcal measurement page face down on top of the strip (as shown below)..

Page 37

Press the continue button in the place patch page window (shown in instruction 11). The following screens will appear sequentially. Press the ok button in the above measurement window. The following screen will appear..

Page 38

Press the apply button in the above window. The following will appear. Press the ok button in the above information window. The following will appear..

Page 39

Press the done button in the above window. The scanner and the printer have now been successfully calibrated..

Page 40

Calibrating the auto media detection sensor the auto media adjustment procedure is a two step process. There is a rough and fine adjustment that needs to be made. Both of these steps should be performed when doing the calibration. Tools needed pre-measured transparency pack p/n 42527801 reasons that...

Page 41

Fine adjustment re-enter service mode using the above procedure. Press the menu down button to "diagnostic mode" and select “enter”. Press the menu up button to "media weight adj pa" and select “enter”. The display should now read "edit thickness data" , select “enter”. "thickness sample page p=3" s...

Page 42

Last press the on line button to change from the tens column to the hundreds (ex. T= 1 10) column and once again use the menu up & menu down buttons to change the value. Once the t value for p=1 is set correctly press the enter button to exit the value adjustment. Press the menu up button to change ...

Page 43: Chapter 3

Chapter 3 troubleshooting print quality 3.1 print-quality problems overview print-quality defects can be attributed to printer components, consumables, media, internal software, external software applications, and environmental conditions. To successfully troubleshoot print-quality problems, elimina...

Page 44

Defects associated with specific printer components some print-quality problems can be associated with specific assemblies, the most common problems and the associated assemblies are listed below. Also, refer to the printer’s troubleshooting print-quality problems pages or a specific print- quality ...

Page 45

3.2 generating and analyzing control panel test prints control panel test prints must first be enabled in service mode. Enter service mode by holding down the menu up / menu down and help buttons at the same time while powering up the printer unit. (this may take up to 60 seconds.) select “maintenan...

Page 46

Things to observe when analyzing the id check pattern test page include: • streaks in process direction (in the direction of feed, parallel with paper travel) • banding in scan direction (across the page, perpendicular to paper travel) • uneven density • voids • repeating defects • mis-registration ...

Page 47

Generating and analyzing service test prints generating and analyzing 100% solid fill test pages these prints consist of 100% solid fill in cmyk. Each color can be selected individually or in combinations. Enter service mode by holding down the menu up / menu down and help buttons at the same time w...

Page 48

Page down to “color”- select “on” select “on line” key. Screen will appear where you can select each color to print. Use the “on line” key to turn off all colors you do not wish to print. Example: for a “magenta” print, turn off “yellow”, “cyan”, and “black”. To turn “on” / “off” the individual colo...

Page 49

Page down to “print execute” – select “enter” to print selected test page things to observe when analyzing the 100% fill test page include: 2 wrinkling 3 creases 4 roller marks 5 scratches 6 repeating defects or banding 7 missing color(s) 8 streaks 9 voids 1. Consistent fills in each color. Each col...

Page 50

Generating and analyzing print engine test prints analyzing the ps test pattern analyzing the demo page compare with previous demo page that was left with the service log during the previous service visit and observe the following: • consistent fills in all colors. • thin white lines • dark lines • ...

Page 51

3.3 print-quality troubleshooting practices initial actions to perform prior to using any of these troubleshooting procedures. Ask specific questions of the operator to determine actual problem generate configuration pages to ascertain if all updates are installed, consumable life and to use for ref...

Page 52

Light prints in all colors the overall image density is too light in all colors. If the image is light in only one color, see "light print in only one color". Initial actions to perform perform initial actions from print quality troubleshooting practices verify the media used is supported by this pr...

Page 53

Light print in only one color only one color; yellow, magenta, cyan, or black, is too light on the printed image. Initial actions to perform perform initial actions from print quality troubleshooting practices verify that color calibration has been performed prior to using this troubleshooting proce...

Page 54

Blank prints initial actions perform initial actions from print quality troubleshooting practices run a test print to help isolate the problem between the fiery control board and the engine control board. Areas of the printer that apply to blank prints imaging unit led head engine control board trou...

Page 55

Mottled or splotchy prints the print image has a mottled appearance. Note: this defect is known to occur when manually duplexing, at low humidity, and when printing on heavy weight media. Initial actions perform initial actions from print quality troubleshooting practices areas of the printer that a...

Page 56

Unexpected colors the colors produced by the printer are dramatically different from the color expected. Initial actions perform initial actions from print quality troubleshooting practices areas of the printer that apply to unexpected colors imaging unit hvps engine control board troubleshooting st...

Page 57

Repeating bands, lines, marks, or spots this is usually caused by a damaged roller. In some instances, the spots may be dark instead of white and are repeated. Initial actions perform initial actions from print quality troubleshooting practices print the color test pages to identify the color causin...

Page 58

Random bands, lines, marks, or missing spots there are areas of the image extremely light or are missing entirely and do not appear to be a repeating defect or in a single color. Caution leaving an imaging unit exposed to light for periods in excess of 10 minutes can quickly degrade its performance ...

Page 59

Random spots there are spots of toner randomly scattered across the page. Toner melting off the fuser thermistors can also place random spots onto prints. Initial actions perform initial actions from print quality troubleshooting practices verify the imaging unit, fuser, and transfer unit are not at...

Page 60

Background there is a very light covering of toner across the entire page. Background contamination can appear in one of the primary colors or gray. The printer displays no error code. Note depending on the type of paper and environmental conditions, some light amount of random background spotting i...

Page 61

Ghosting or hot offset there are faint, ghostly images appearing on the page. The images may be either from a previous page or from the current page. This type of artifact can be related to the percent coverage called out in the file being printed. If the colors are offset by less than 10 mm, this r...

Page 62

Incomplete fusing or cold offset the fuser temperature is set too low for the media loaded in the tray causing improper fusing resulting in the toner rubbing off easily. Initial actions: perform initial actions from print quality troubleshooting practices verify the correct media type is set at the ...

Page 63

Mis-registration, color layers not correctly registered the image appears blurred and the primary colors are not aligning correctly into one image. For a page oriented long-edge feed, the following applies: if the colors are shifted from left to right, this is mis-registration in the process directi...

Page 64

12. Are the led head ribbon cables undamaged, properly routed and seated? Yes – go to step 13. No - reseat, correctly route or replace the wiring harness. 13. Swap the led head of the problem color with any other led head. Print a supplies page. Has the problem moved with the led head? Yes – replace...

Page 65

Toner on back of print there is toner on the back of the printed sheet of paper. Initial actions: perform initial actions from print quality troubleshooting practices areas of the printer that apply to toner on back of print imaging unit transfer unit troubleshooting steps resolution 1. Check and cl...

Page 66

Image not centered or positioned correctly the image is not centered on the page correctly initial actions: perform initial actions from print quality troubleshooting practices areas of the printer that apply to image not centered or positioned correctly imaging unit transfer unit troubleshooting st...

Page 67

Process direction bands, voids, or streaks there are areas of the image that are extremely light or missing entirely. These missing areas form wide bands that run along the page parallel to the leading edge of the paper . Initial actions: perform initial actions from print quality troubleshooting pr...

Page 68

Scan direction bands, voids, or streaks there are areas of the image that are extremely light or are missing entirely. The missing areas form bands that run along the page from the leading edge to the trailing edge in the direction of paper travel. Initial actions: perform initial actions from print...

Page 69

Scan direction dark streaks there are dark lines running parallel with the leading edge of the print. Initial actions: perform initial actions from print quality troubleshooting practices areas of the printer that apply to scan direction dark streaks imaging unit transfer unit belt troubleshooting s...

Page 70

Process direction lines or streaks there are dark lines running along the page in the direction of paper travel from the leading edge to the trailing edge. This is generally due to fuser, paper path roller and/or exit guides contaminated with toner debris. Initial actions: perform initial actions fr...

Page 71: Chapter 4

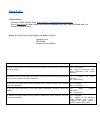

Chapter 4 troubleshooting paper jams 4.1 paper jam error code table *note - when a jam occurs, to display the error code, press the help button. Error code contents of the operator panel display area where the jam has occurred 370 : paper jam occurred around the duplex unit. Duplex unit (rear area) ...

Page 72

Errors in the 6xx range are user clearable errors. These errors indicate locations where paper remains in the printer after a jam. These errors do not reference the actual jam, which is referenced by 3xx errors. 631: tray 1 side cover 632: tray 2 side cover 633: tray 3 side cover 634: tray 4 side co...

Page 74

4.2 jam troubleshooting 370: paper jam condition paper jam 370 occurs when the paper is inverted for double-sided printing. 1. The dup-in1 sensor does not change to off-state within the predefined time after it changed to on-state. 2. The dup-in2 sensor does not change to on-state within the predefi...

Page 75

371: paper jam condition paper jam 371 occurs when paper jams in the middle area of the duplex unit. 1. The dup-r sensor does not return to off-state within the predefined time after it changed to on-state. 2. The dup-f sensor does not change to on-state within the predefined time after the dup-r se...

Page 76

372 :paper jam condition error 372 occurs when paper jams in the front area of the duplex unit. 1. The in2 sensor does not change to on-state within the predefined time after paper has exited from the duplex unit. The printer stops printing immediately when the jam occurs. Cause 1. Transport rollers...

Page 77

373: paper jam condition paper jam 373 occurs when the paper is inverted for double-sided printing. 1. The dup-in2 sensor does not change to off-state within the predefined time after the dup-r sensor changed to on-state. The printer stops printing immediately when the jam occurs. Cause 1. Transport...

Page 78

380: paper jam condition paper jam that occurred while the paper was being transported by the registration roller after it was hopped normally. 1. The in2 sensor does not change to on-state within the predefined time after the registration roller started to rotate. 2. The wr sensor does not change t...

Page 79

381 : paper jam condition paper jam has occurred while the paper was being transported by the registration roller, the belt unit or the fuser. 1. The exit sensor does not change to on-state within the predefined time after the wr sensor changed to on-state. 2. The in2 sensor does not return to off-s...

Page 80

382: paper jam condition jam near the fuser unit 1. The exit sensor does not return to off-state within the predefined time after it changed to on-state. The printer stops printing immediately when the jam occurs. Cause 1. Fuser unit is not transporting paper. 2. A piece of paper, foreign substance,...

Page 81

383 : paper jam condition paper jam in the fuser or near the entrance to the duplex unit 1. The dup-in1 sensor does not change to on-state within the predefined time after the exit sensor changed to on-state. The printer stops printing immediately when the jam occurs. Cause 1. Paper path switch sepa...

Page 82

384: paper jam condition jam near the exit area 1. When the printer is turned on, or the cover is opened and closed, job-off sensor has changed to on-state. The printer stops printing immediately when the jam occurs. Cause 1. Transport rollers cannot transport paper because they have become dirty wi...

Page 83

390 : paper jam condition this is a multi purpose tray mis-feed. 1. Even after the printer tries hopping operation three times, mpt hp sensor does not change to on-state. 2. Even after the printer tries hopping operation three times, in2 sensor does not change to on-state, then, off-state. The print...

Page 84

Close the cover - slide the paper guide to the center - return cover to the original position. While lifting mp tray, insert the white lever in the arm that supports mp tray, and lock it by lowering the white lever. (both sides) move the paper guide outward, close the paper supporter, and close the ...

Page 85

391, 392, 393, 394, paper jam condition paper has misfed from tray 1, 2, 3, 4. 1. Even after the printer tries hopping operation three times, tray 1 to 4hp sensors do not change to on-state. 2. The in1 sensor does not return to off-state within the predefined time after the tray1 to 4 hp sensor chan...

Page 86

400: paper size error / 401: multiple sheet feed error condition error indicating that the detected size is not the specified size. The printer ejects the paper, then, displays the error. * error 401 may occur along with error 400 when the paper is fed from the tray. Cause there are several possible...

Page 87: Chapter 5

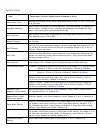

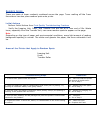

Chapter 5 troubleshooting self diagnostic codes 5.1 self diagnostic error codes (printer) code cause/description remedy 001 to 007 cpu exception 001 = asp pcb key chip error 002 = unauthorized hdd copy 003 = unauthorized software configuration 004 = eeprom missing power off/on. Replace fiery pcb (mu...

Page 88

Self diagnostic error codes (printer) code cause/description remedy 052 image processor driver error replace fiery pcb (must replace eeprom) 060 parallel interface driver error replace fiery pcb (must replace eeprom) 062 usb drive error replace fiery pcb (must replace eeprom) 063 network communicati...

Page 89

Self diagnostic error codes (printer) code cause/description remedy 111 to 117 an optional unit for another model is detected 111 = duplex 112 = 2 nd tray 113 = 3 rd tray 114 = 4 th tray 115 = 5 th tray 116 = finisher 117 = inverter install option / check connections replace engine control board see...

Page 90

Self diagnostic error codes (printer) code cause/description remedy 167 to 169 167 = thermistor slope error 168 = compensation thermistor error 169 = upper side thermistor error see “fuser failure” 170 to 176 fuser thermistor short circuit / open circuit high temperature / low temperature see “fuser...

Page 91

Self diagnostic error codes (printer) code cause/description remedy 310 the printer engine top cover is open see “top cover open error” 320 fuser unit is detected as missing see “fuser unit detected as missing” 321 motor overheated see “ motor overheating error” 323 to 326 open cover paper thickness...

Page 92

Self diagnostic error codes (printer) code cause/description remedy 480 paper output stacker full error check sensor / connections check / replace stacker full sensor 490 mp tray out of paper error check sensor / connections check / replace sensor 491 to 495 tray out of paper error 491 = tray 1 492 ...

Page 93

Self diagnostic error codes (printer) code cause/description remedy 930 sub cpu clock frequency error check connections of the engine pcb (s2m) replace the engine pcb 931 to 935 clock frequency error 931 = duplex 932 = inverter 933 = tray 2 934 = tray 3 935 = tray 4 check sensor / connections replac...

Page 94

Self diagnostic error codes (finisher) code cause/description remedy 090 finisher stapler error see finisher service manual 091 finisher tray elevator error see finisher service manual 092 finisher bin 2 exit belt motor error see finisher service manual 093 finisher jogging motor error see finisher ...

Page 95

Self diagnostic error codes (other codes) code cause/description remedy 0101 to 0104 the data stored in hdd may be corrupted re-image hard drive with the latest version. 0201 to 0223 the communication between a scanner and a printer is disrupted step 1 . Check all cable connections between scanner &...

Page 96

5.2 general troubleshooting no control panel display troubleshooting procedure initial actions: 1. Remove and reseat the fiery control board. 2. Print an engine test print. 3. Replace the fiery control board. 4. See “dc power supply troubleshooting”. Control panel led is on, no control panel display...

Page 97

Troubleshooting dc power supply troubleshooting procedure initial actions: 1. Perform the ac power supply troubleshooting procedure. 2. Replace the low voltage power supply (lvps). Troubleshooting ram memory failures troubleshooting procedure initial actions: check that the ram devices are making po...

Page 98: Fuser Failure

3.3 troubleshooting error codes fuser failure the fuser temperature regulation has failed. Error codes that apply 167 to 169 and 170 to 176 initial troubleshooting actions to take 1. Reseat the fuser. 2. Cycle the printer's power. 3. Test wall voltage parts of the printer that apply 1. Fuser 2. Lvps...

Page 99

Environmental sensor failure the environmental sensor has failed. Error codes that apply 123 and 124 initial troubleshooting actions to take 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. Parts of the printer that apply 1. Environmental sensor 2. Environmental s...

Page 100

Imaging unit motor overheating failure error codes that apply 321 initial troubleshooting actions to take 1. Ensure that the temperature and installation clearances of the printer are at specifications. 2. Clean all fan ducts. 3. Turn the printer off and allow a minimum of 30 minutes for cooling. 4....

Page 101

Engine control board failure error codes that apply 102 to 106 and 200 to 202 initial troubleshooting actions to take 1. Cycle the printers power 2. If the problem persists follow the procedure below. Parts of the printer that apply 1. Engine control board eeprom 2. Engine control board troubleshoot...

Page 102

Lvps power supply failure error codes that apply n/a initial troubleshooting actions to take 1. Cycle the printers power 2. If the problem persists follow the procedure below. Parts of the printer that apply 1. Lvps troubleshooting procedure steps action taken yes no 1 visually inspect the lvps for ...

Page 103

Fiery controller fan failure 1. Cycle the printers power 2. If the problem persists follow the procedure below. 1. Fiery control board fan steps action taken yes no 1 test the cooling fan for proper operation and adequate airflow. Run the motor clutch fan test . Does the fan operate correctly? Repla...

Page 104

Power supply fan failure 1. Clear any obstructions from the lvps fan vent. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Lvps fan 2. Lvps 3. Engine control board steps action taken yes no 1 test the lvps fan. Run the motor clutch test fan power does the fan ...

Page 105

Fan failure 1. Ensure that the temperature and installation clearances of the printer are at specifications. 2. Clean all fan ducts. 3. Turn the printer off and allow a minimum of 30 minutes for cooling. 4. Restart the printer. 5. If the problem persists follow the procedure below. 1. Fan associated...

Page 106

Duplex interface failure 1. Reseat the duplex unit 2. Cycle the printers power 3. If the problem persists follow the procedure below. 1. Duplex unit 2. Motor driver board steps action taken yes no 1 check the duplex unit connector for damage. Is the connector damaged? Replace the connector. Replace ...

Page 107

Tray 1, 2, 3, 4 communication errors 1. Cycle the printers power 2. If the problem persists follow the procedure below. 1. High capacity feeder control board 2. Engine control board steps action taken yes no 1 check the hi cap connector for damage. Is the connector damaged? Replace the connector. Go...

Page 108

Inverter unit interface failure 1. Reseat the finisher connections. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Inverter control board 2. Finisher power cord 3. Engine control board steps action taken yes no 1 check the following for evidence of fault or d...

Page 109

Cyan, magenta, yellow, black led failure 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Led head 2. Ledpwr harness 3. Led relay board 4. Yk led data harness 5. Cm led data harness 6. Led relay board 7. Engine control board steps action taken yes no 1 check le...

Page 110

Fuser fan failure 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 2 fuser fan 3 fuser fan harness 4 engine control board steps action taken yes no 1 test the cooling fan for proper operation and adequate airflow. Run the motor clutch fan test . Does the fan opera...

Page 111

Fuser 110v/220v mismatch error 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Fuser 2. Engine control board steps action taken yes no 1 ensure the proper fuser (110v vs. 220v) is installed in the printer. Is the correct fuser installed? Replace the engine con...

Page 112

Unsupported duplex unit rom 1. Reseat the duplex unit 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Duplex unit 2. Engine control board steps action taken yes no 1 check the following for evidence of fault or damage: duplex connector is there any damage? Rep...

Page 113

Fuse cut error (fuser) 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Fuser 2. Engine control board steps action taken yes no 1 test the fuser fuse. Is the fuse cut? Replace the engine control board go to step 2. 2 replace the fuser. Cycle the power. Does the...

Page 114

Fuse cut error (transfer belt unit) 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Transfer unit 2. Hvps cover 3. Hvps 4. Engine control board steps action taken yes no 1 test the condition of the fuse. Is the fuse cut? Replace the engine control board go to ...

Page 115

Fuse cut error c, m, y, k imaging drum unit 1. Reseat the indicated imaging unit 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. C, m, y, k imaging unit 2. Imaging unit sensor board 3. Engine control board steps action taken yes no 1 check the affected imaging...

Page 116

Fiery controller to engine board communication failure 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Fiery control pcb 2. Engine control board steps action taken yes no 1 cycle power to the printer. Does the error persist? Go to step 2. Complete 2 reseat the...

Page 117

Finisher interface error 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Finisher control board 2. Finisher interface cable 3. Finisher power cord 4. Engine control board steps action taken yes no 1 check the following for evidence of fault or damage: finisher...

Page 118

Inverter power supply failure 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Inverter power supply 2. Inverter interface cable 3. Inverter power cord 4. Engine control board steps action taken yes no 1 check the following for evidence of fault or damage: inve...

Page 119

Control panel communication failure 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Control panel 2. Control panel interface cable 3. Engine control board steps action taken yes no 1 check the control panel connection. Is the control panel harness connected to...

Page 120

Error in the transfer belt 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Transfer unit 2. Transfer unit motor 3. Belt rotation sensor 4. Engine control board steps action taken yes no 1 test the belt rotation sensor. Run the switch scan test and test the hal...

Page 121

C, m, y, k imaging drum unit failure 1. Reseat the indicated image drum unit 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. C, m, y, k imaging drum unit 2. C, m, y, k unit motor 3. Imaging drum unit sensor board 4. Imaging drum unit up/down mechanism 4. Engin...

Page 122

5 test the indicated imaging unit motor 1. Remove the affected imaging unit. 2. Close the interlock switches. 3. Run the motor clutch test for the affected motor. Does the motor function correctly? Go to step 6. Replace the motor. If the error persists, go to step 6. Check the up/down mechanism and ...

Page 123

Engine board flash memory error 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Engine control board steps action taken yes no 1 cycle power to the printer. Does the error reappear? Replace the engine control board complete error codes that apply initial troub...

Page 124

Unsupported rom 1. Reseat the unit in question 2. Cycle the printers power 3. If the problem persists follow the procedure below. 1. Unit indicated by the code 2. Engine control board steps action taken yes no 1 check for evidence of fault or damage to the indicated unit. Is there damage evident? Re...

Page 125

1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Toner cartridge 2. Image drum unit 3. Toner motor 4. Imaging drum unit sensor board 5. Engine control board steps action taken yes no 1 check the following for evidence of fault or damage: toner cartridge imaging...

Page 126

Mt home position detection error 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Mpt home position sensor 2. Home position sensor harness 3. Registration motor 4. Engine control board steps action taken yes no 1 check the mpt lift plate by printing a job from ...

Page 127

Toner feed switch error/toner lock lever error 1. Ensure that the toner cartridges are fully seated and locked into position 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Toner cartridge 2. Image drum unit 3. Rfid antenna 4. Rfid reader board 5. Engine contr...

Page 128

Color up/down error 1. Cycle the printer's power. 2. If the problem persists follow the procedure below. 1. Up/down motor 2. Front up/down mechanism 3. Rear up/down mechanism 4. Engine control board steps action taken yes no 1 test the up/down sensor. Run the scan switch test to test the up/down sen...

Page 129

Top cover open error 1. Ensure that the top cover latch is free of obstructions and fully closed. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Top cover interlock switch 2. Hvps 3. Engine control board steps action taken yes no 1 check the following for evi...

Page 130

Fuser unit detected as missing 1. Ensure that the fuser latch is free of obstructions and fully engaged. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Fuser 2. Fuser release sensor 3. Engine control board steps action taken yes no 1 check the following for e...

Page 131

Id unit life error 1. Print a configuration page to verify remaining life. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. C, m, y, k imaging unit , 2. Engine control board steps action taken yes no 1 generate a configuration page and check the indicated drum ...

Page 132

Fuser life error 1. Replace the fuser. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Fuser unit , 2. Engine control board steps action taken yes no 1 generate a configuration page and check the indicated fuser life counter under “supply life”. Does the count...

Page 133

Belt life error 1. Replace the transfer unit. 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Transfer unit , 2. Engine control board steps action taken yes no 1 generate a configuration page and check the indicated belt life counter under “supply life”. Does ...

Page 134

Toner out error 1. Replace the effected cartridge 2. Cycle the printer's power. 3. If the problem persists follow the procedure below. 1. Toner cartridge 2. Rfid harness 3. Rfid reader board 4. Engine control board 5. Lvps steps action taken yes no 1 check toner cartridge installation. Are the toner...