- DL manuals

- Vega

- Transmitter

- VEGAPULS 62

- Operating Instructions Manual

Vega VEGAPULS 62 Operating Instructions Manual

Summary of VEGAPULS 62

Page 1

Operating instructions vegapuls 62 4 ... 20 ma/hart.

Page 2: Contents

Contents 1 about this document 1.1 function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.2 target group . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1.3 symbolism used . . . . . . . . . . . . . . . . . . . . . . . 5 2 for your safety 2.1 authorised personnel. . . . . . . . ...

Page 3

6.3 adjustment system . . . . . . . . . . . . . . . . . . . . . 35 6.4 adjustment system . . . . . . . . . . . . . . . . . . . . . 36 6.5 setup procedure . . . . . . . . . . . . . . . . . . . . . . . 37 6.6 menu schematic . . . . . . . . . . . . . . . . . . . . . . . 43 6.7 saving the parameter adju...

Page 4

Supplementary operating instructions manuals information: vegapuls 62 is available in different versions and is supplied specifically acc. To the order. Depending on the selected version, supplementary operating instructions man- uals come with the shipment. The supplementary operating instructions ar...

Page 5: 1 About This Document

1 about this document 1.1 function this operating instructions manual has all the information you need for quick setup and safe operation. Please read this manual before you start setup. 1.2 target group this operating instructions manual is directed to trained, qualified personnel. The contents of t...

Page 6: 2 For Your Safety

2 for your safety 2.1 authorised personnel all operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the operator. For safety and warranty reasons, any internal work on the instruments must be carried out only by personnel a...

Page 7

L emc: en 61326: 2004 - emission: class b - susceptibility: industrial areas l r & tte directive: i-ets 300-440 expert opinion no. 0043052-02/see, notified body no. 0499 l lvd: en 61010-1: 2002 2.6 compatibility acc. To namur ne 53 vegapuls 62 meets namur recommendation ne 53. Vega instruments are ge...

Page 8

List or having a gain greater than 33 db are strictly prohibited for use with this device. The required antenna impedance is 50 ohm. 2.8 safety information for ex areas please note the ex-specific safety information for installation and operation in ex areas. These safety instructions are part of the...

Page 9

L make sure that the cable gland is tight and strain-relieved. The outer diameter of the connection cable must be adapted to the cable gland. Tighten the pressure screw of the cable gland carefully. L cover unused openings for cable glands tightly l mount the instrument in such a position that the s...

Page 10: 3 Product Description

3 product description 3.1 configuration the vegapuls 62 radar sensor is available in two electronics versions: l standard electronics type ps60k l electronics with increased sensitivity type ps60s the respective version can be determined by means of the type label on the electronics. The electronics ...

Page 11

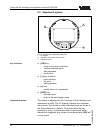

2 1 3 fig. 1: vegapuls 62, threaded version with plastic housing 1 housing cover with integrated plicscom (optional) 2 housing with electronics 3 process fitting with horn antenna 3.2 principle of operation vegapuls 62 is a radar sensor in k-band (emitting frequency approx. 26 ghz) for continuous lev...

Page 12

Proportional to the distance and hence to the level. The determined level is converted into an appropriate output signal and outputted as measured value. Two-wire electronics 4 … 20 ma/hart for power supply and measured value transmission on the same cable. The voltage supply range can differ dependi...

Page 13

The packaging of standard instruments consists of environ- ment-friendly, recyclable cardboard. For special versions, pe foam or pe foil is also used. Dispose of the packaging material via specialised recycling companies. L storage and transport temperature see "supplement - technical data - ambient...

Page 14: 4 Mounting

4 mounting 4.1 general instructions select an installation position you can easily reach for mounting and connecting as well as later retrofitting of an indicating and adjustment module. The housing can be rotated by 330° without the use of any tools. You can also install the indicating and adjustmen...

Page 15

Information: if the medium reaches the antenna, buildup can be caused which can lead to faulty measurements later on. Fig. 3: measuring range (operating range) and max. Measuring distance 1 full 2 empty (max. Measuring distance) 3 measuring range the process fitting must be sealed if there is gauge o...

Page 16

3 insert the antenna from below into the vessel socket and secure it against falling off 4 retighten the antenna with hexagon screws to the antenna socket; torque max. 10 nm (7.5 lbf ft) note: vegapuls 62 with purging air connection or with antenna extension has a notch on the antenna socket. This no...

Page 17

2 hold the connection piece (3) with a wrench sw 22 on the flattenings 3 unscrew the locknut (2) with sw 36 against the antenna 4 unscrew the compression nut (1) with a wrench sw 41 against the antenna 5 remove the parabolic antenna (4) axially 6 mount sensor flange to the adapter flange and clamp it 7...

Page 18

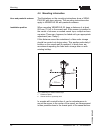

4.4 mounting information the illustrations on the mounting instructions show a vega- puls 62 with horn antenna. The mounting instructions also apply to vegapuls 62 with parabolic antenna. When mounting vegapuls 62, keep a distance of at least 200 mm (7.9 in) to the vessel wall. If the sensor is inst...

Page 19

Fig. 7: vessel with conical bottom do not mount the instruments in or above the filling stream. Make sure that you detect the product surface and not the inflowing product. Fig. 8: inflowing material socket pieces should be dimensioned such that the antenna end protrudes at least 10 mm (0.4 in) out of ...

Page 20

Ca. 10 mm fig. 9: recommended socket mounting if the reflective properties of the medium are good, you can mount vegapuls 62 on sockets higher than the antenna length. You will find recommended values for socket heights in the following illustration. The socket end should be smooth and burr-free, if p...

Page 21

Fig. 11: orientation in liquids the radar sensor should be installed at a location where no installations cross the microwave signals. Vessel installations such as, for example, ladders, limit switches, heating spirals, struts, etc. Can cause false echoes that get superimposed on the useful echo. Ma...

Page 22

Fig. 13: agitators through the action of filling, stirring and other processes in the vessel, dense foams which considerably damp the emitted signals may form on the product surface. If foams lead to measurement errors, you should use the biggest possible radar antennas and low frequency radar sensor...

Page 23

Max. Min. 2 1 fig. 14: pipe antenna systems in a tank 1 marking of the polarisation direction 2 vent holde max. ø 5 mm (0.2 in) if possible, the antenna diameter of the sensor should correspond to the inner diameter of the tube. With vegapuls 62 this is approx. 40 mm (1.6 in). The sensor can be used...

Page 24

100% 0% 1 > 300 mm fig. 15: vegapuls in a bypass tube 1 marking of the polarisation direction when mounting the sensor on a bypass tube, the distance of vegapuls 62 to the upper tube connection should be approx. 300 mm (12 in) or more. In case of extremely rough tube inner walls, you should use an i...

Page 25

5 connecting to power supply 5.1 preparing the connection always observe the following safety instructions: l connect only in the complete absence of line voltage l if overvoltages are expected, overvoltage arresters should be installed tip: we recommend using vega overvoltage arresters Üs-f-lb-i an...

Page 26

Caution: no grease should be used when screwing the npt cable gland or steel tube into the threaded insert. Standard grease can contain additives affecting the connection between threaded insert and housing. This will influence the stability of the connection and the tightness of the housing. If scree...

Page 27

Fig. 16: connection steps 6 and 7 8 press the opening lever of the terminals downward, you will hear the terminal spring closing 9 check the hold of the wires in the terminals by lightly pulling on them 10 connect the screen to the internal ground terminal and the external ground terminal to potenti...

Page 28

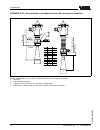

1 4 4 4 2 3 fig. 17: material versions, single chamber housing 1 plastic 2 aluminium 3 stainless steel 4 filter element for pressure compensation or blind stopper with version ip 66/ ip 68, 1 bar i2c display 1 2 5 6 7 8 3 4 1 2 fig. 18: electronics and connection compartment, single chamber housing ...

Page 29

I2c display 1 1 2 5 6 7 8 fig. 19: wiring plan, single chamber housing 1 power supply/signal output 5.4 wiring plans, double chamber housing the following illustration apply to non-ex as well as ex ia versions. The exd version is described in the next subchapter. 1 2 3 4 5 fig. 20: double chamber ho...

Page 30

1 3 2 display 1 2 5 6 7 8 i2c fig. 21: electronics compartment, double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 61 3 1 2 display 1 2 i2c fig. 22: connection compartment, double chamber housing 1...

Page 31

I2c 1 1 2 fig. 23: wiring plan, double chamber housing 1 power supply/signal output 5.5 wiring plans, double chamber housing exd 1 2 3 4 5 fig. 24: double chamber housing 1 housing cover, connection compartment 2 blind stopper or plug m12x1 for vegadis 61 (option) 3 housing cover, electronics compar...

Page 32

1 3 2 display 1 2 5 6 7 8 i2c fig. 25: electronics compartment, double chamber housing 1 plug connector for vegaconnect (i²c interface) 2 internal connection cable to the connection compartment 3 terminals for vegadis 61 1 2 1 2 fig. 26: connection compartment, double chamber housing exd 1 spring-lo...

Page 33

1 1 2 fig. 27: wiring plan, double chamber housing exd 1 power supply/signal output 5.6 wiring plans, version ip 66/ip 68, 1 bar + - 1 2 fig. 28: wire assignment, connection cable 1 br (+) and bl (-) for power supply or to the processing system 2 screen 5.7 switch-on phase after vegapuls 62 is conne...

Page 34: Adjustment Module Plicscom

6 setup with the indicating and adjustment module plicscom 6.1 short description the indicating and adjustment module plicscom is used for measured value display, adjustment and diagnosis. It can be mounted in the following housing versions and instruments: l all sensors of the plics ® instrument fa...

Page 35

4 screw housing cover with inspection window tightly back on removal is carried out in reverse order. Plicscom is powered by the sensor, an additional con- nection is not necessary. Fig. 29: installation of plicscom note: if you intend to retrofit vegapuls 62 with a plicscom for continuous measured v...

Page 36

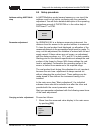

6.3 adjustment system 1.1 2 3 1 fig. 30: indicating and adjustment elements 1 lc display 2 indication of the menu item number 3 adjustment keys l [ok] key: - move to the menu overview - confirm selected menu - edit parameter - save value l [->] key to select: - menu change - list entry - editing posi...

Page 37

6.4 setup procedure in hart-multidrop mode (several sensors on one input) the address must be set before continuing with the parameter adjustment. You will find a detailed description in the operating instructions manual of plicscom or in the online help of pactware™ or dtm. Hart mode standard addres...

Page 38

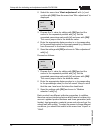

2 select the menu item "basic adjustment" with [->] and confirm with [ok]. Now the menu item "min. Adjustment" is displayed. Min. Adjustment 0.00 % = 5.000 m(d) 4.000 m(d) 3 prepare the % value for editing with [ok] and set the cursor to the requested position with [->]. Set the requested percentage ...

Page 39

Medium liquid according to the conductivity and the dielectric value of liquids, the reflection properties can differ considerably. Therefore additional options such as "solvent", "chem. Mixture" and "water based" are offered below the menu item liquid. With solids, you can choose between "powder/dust"...

Page 40

Measured value with a corresponding delay. In general, a time of a few seconds is sufficient to smooth the measured value display. Damping 0 s enter the requested parameter via the appropriate keys, save your settings and jump to the next menu item with the [->] key. A linearization is necessary for a...

Page 41

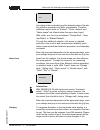

Ment. A false echo storage detects and marks these false echoes, so that they are no longer taken into account for the level measurement. A false echo memory should be created with empty vessel so that all potential interfering reflections will be detected. False signal suppression change now? Procee...

Page 42

L displayed value l display unit l scaling l current output l units of measurement l language the following safety-relevant data are not read out or written: l hart mode l pin l sil copy sensor data copy sensor data? Basic adjustment if the "reset" is carried out, the sensor resets the values of the...

Page 43

Function reset value lighting no reset language no reset sil no reset hart mode no reset factory setting like basic setting, in addition special parameters are reset to default values. 10) peak values the min. And max. Distance values are reset to the current value. Additional adjustment and diagnos...

Page 44

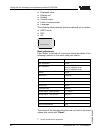

6.5 menu schematic information: depending on the version and application, the highlighted menu windows are not always available. Basic adjustment 1 ▶ basic adjustment display diagnostics service info 1.1 min. Adjustment 0.00 % = 10.000 m(d) 8.000 m(d) 1.2 max. Adjustment 100.00 % = 1.000 m(d) 2.000 ...

Page 45

3.1 peak values distance-min.: 0.234 m(d) distance-max.: 5.385 m(d) 3.2 meas. Reliability 8 db sensor status ok 3.3 choose curve echo curve 3.4 echo curve presentation of the echo curve service 4 basic adjustment display diagnostics ▶ service info 4.1 false signal suppression change now? 4.2 extende...

Page 46

6.6 saving the parameter adjustment data it is recommended noting the adjusted data, e.G. In this operating instructions manual and archive them afterwards. They are hence available for multiple use or service purposes. If vegapuls 62 is equipped with an indicating and adjust- ment module plicscom, ...

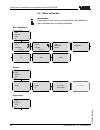

Page 47: Adjustment Programs

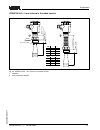

7 setup with pactware™ and other adjustment programs 7.1 connecting the pc ~ = power supply vegaconnect 3 pactware / tm >pa 2 3 1 fig. 31: pc connected directly to the sensor 1 rs232 connection 2 vegapuls 62 3 i²c adapter cable for vegaconnect 3 necessary components: l vegapuls 62 l pc with pactware...

Page 48

2 3 1 4 ~ = power supply vegaconnect 3 pactware / tm fig. 32: connecting the pc to the signal cable 1 rs232 connection 2 vegapuls 62 3 hart adapter cable for vegaconnect 3 4 hart resistance 250 ohm necessary components: l vegapuls 62 l pc with pactware™ and suitable vega-dtm l vegaconnect 3 with har...

Page 49

Detailed description is available in the online help of pactware™ and the vega-dtms. Note: keep in mind that for setup of vegapuls 62, dtm-collection 06/2003 or a newer version must be used. All currently available vega-dtms are provided in the dtm collection on cd and can be obtained from the respo...

Page 50

8 maintenance and fault rectification 8.1 maintenance when used as directed in normal operation, vegapuls 62 is completely maintenance-free. 8.2 fault rectification vegapuls 62 offers maximum reliability. Nevertheless faults can occur during operation. These may be caused by the following, e.G.: l sens...

Page 51

L no voltage supply à check cables for line break, repair, if necessary l supply voltage too low or load resistance too high à check and adapt, if necessary ? Current signal greater than 22 ma or less than 3.6 ma l electronics defective à exchange instrument or return it for repair in ex application...

Page 52

In ex applications, only an instrument and an electronics module with appropriate ex approval may be used. If there is no electronics module available on site, one can be ordered from the vega agency serving you. The order data of the sensor must be downloaded into the new electronics module. This c...

Page 53

Www.Vega.Com under: "services – downloads – forms and certificates – repair form". By doing this you help us carry out the repair quickly and without having to call back for needed information. L print and fill out one form per instrument l clean the instrument and pack it damage-proof l attach the co...

Page 54: 9 Dismounting

9 dismounting 9.1 dismounting procedure warning: before dismounting, be aware of dangerous process con- ditions such as e.G. Pressure in the vessel, high temperatures, corrosive or toxic products etc. Take note of the instructions in chapters "mounting" and "connecting to power supply" and carry out...

Page 55: 10 Supplement

10 supplement 10.1 technical data general data 316l corresponds to 1.4404 or 1.4435 materials, non-wetted parts - housing plastic pbt (polyester), alu-die casting pow- der-coated, 316l - seal ring between housing and housing cover nbr (stainless steel housing), silicone (alu/ plastic housing) - insp...

Page 56

Output variable output signal 4 … 20 ma/hart resolution 1.6 µa fault signal current output unchanged; 20.5 ma; 22 ma; current limitation 22 ma load see load diagram in power supply integration time (63 % of the input variable) 0 … 999 s, adjustable fulfilled namur recommendation ne 43 input variable ...

Page 57

Characteristic curve deviation and measurement characteristics 11) average temperature coefficient of the zero signal (temperature error) 0.03 %/10 k resolution, general max. 1 mm frequency k-band (26 ghz technology) interval approx. 1 s adjustment time 12) >1 s (dependent on the parameter adjustment)...

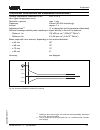

Page 58

1,0 m 30 m 30 mm 15 mm -15 mm -30 mm fig. 34: accuracy vegapuls 62 with horn antenna and increased sensitivity beam angle with parabolic antenna 4° accuracy with parabolic antenna see diagram 2,0 m 30 m 40 mm 3 mm -3 mm -40 mm fig. 35: accuracy vegapuls 62 with parabolic antenna 2,0 m 30 m 40 mm 15 ...

Page 59

Ambient conditions ambient, storage and transport temperature - without indicating and adjustment module -40 … +80°c (-40 … +176°f) - with indicating and adjustment module -20 … +70°c (-4 … +158°f) process conditions process temperature (measured on the process fitting), depending on the seal of the ...

Page 60

32 145 232 psi 122 -40 212 302 392 ˚f fig. 38: din flange pn 16 temperature derating in psi/°f vessel pressure relating to din flange pn 40 (note nominal pressure stage of the flange and temperature derating!) 0 -40 20 bar 34,4bar dn150 29,4bar dn200 26,4bar dn250 50 100 150 200 ˚c 30 40 10 37 34 40,0b...

Page 61

56 64 0 -40 50 bar 54,0bar dn100 64,0bar dn80 50,4bar dn150 44,0bar dn200 39,6bar dn250 50 100 150 200 ˚c 60 70 40 10 20 30 fig. 41: din flange pn 64 temperature derating in bar/°c 290 435 580 145 812 928 -40 725 psi 783,2psi dn100 928,2psi dn80 731,0psi dn150 638,2psi dn200 574,4psi dn250 870 1015 3...

Page 62

-40 150 lbs./sq.In. 2"…10" 32 122 212 302 392 ˚f fig. 44: ansi flange 150 lbs temperature derating based on °f vessel pressure relating to ansi flange 300 lbs (note nominal pressure stage of the flange and temperature derating!) 0 -40 200 lbs./sq.In. 50 100 150 200 ˚c 300 100 2"…10" fig. 45: ansi flange...

Page 63

-40 500 lbs./sq.In. 2"…10" 600 400 32 122 212 302 392 ˚f fig. 48: ansi flange 600 lbs temperature derating based on °f vessel pressure relating to ansi flange 900 lbs (note nominal pressure stage of the flange and temperature derating!) 0 -40 lbs./sq.In. 2"… 6" 50 100 150 200 ˚c 700 800 900 8"…10" 1 2 ...

Page 64

Data on rinsing air connection pressure max. 6 bar (87 psi) air flow - with 0.5 bar (7.3 psi) approx. 50 l/min - with 3.0 bar (43.5 psi) approx. 100 l/min air flow with reflux valve - with 0.55 bar (8.0 psi) approx. 20 l/min - with 3.0 bar (43.5 psi) approx. 85 l/min thread g⅛a catch - with non-ex dust...

Page 65

Electromechanical data - version ip 66/ip 67 and ip 66/ip 68; 0.2 bar cable entry/plug 14) - single chamber housing l 1x cable entry m20x1.5 (cable-ø 5 … 9 mm), 1x blind stopper m20x1.5 or: l 1x closing cap ½ npt, 1x blind plug ½ npt or: l 1x plug (depending on the version), 1x blind plug m20x1.5 - ...

Page 66

Connection cable - configuration four cores, one suspension cable, one breather capillary, screen braiding, foil, mantle - wire cross section 0.5 mm² - wire resistance - tensile load >1200 n (270 pounds force) - standard length 5 m (16.4 ft) - max. Length 1000 m (3280 ft) - min. Bending radius 25 mm ...

Page 67

Permissible residual ripple - u ss - 100 hz … 10 khz u ss load see diagram 1000 750 500 250 14 18 16 20 22 24 26 28 30 32 34 36 Ω v 4 1 2 3 fig. 51: voltage diagram 1 hart load 2 voltage limit eex ia instrument 3 voltage limit non-ex/exd instrument 4 voltage supply voltage supply - version with incr...

Page 68

1000 750 500 250 15 18 16 20 22 24 26 28 30 32 34 36 Ω v 4 1 2 3 fig. 52: voltage diagram for version with increased sensitivity 1 hart load 2 voltage limit eex ia instrument 3 voltage limit non-ex/exd instrument 4 supply voltage electrical protective measures protection - plastic housing ip 66/ip 6...

Page 69

Approvals 17) atex ia atex ii 1g, 1/2g, 2g eex ia iic t6; atex ii 1g, 1/2g, 2g eex ia iic t5+atex ii 1/2d ip6x t6 atex d atex ii 1/2 d ip6x t atex ia + d atex ii 1g, 1/2g, 2g eex ia iic t5+atex ii 1/ 2d ip6x t6 atex d atex ii 1/2g, 2g eexd ia iic t6 atex d + d atex ii 1/2g, 2g eexd ia iic t5+atex ii...

Page 70

10.2 dimensions housing versions in protection ip 66/ip67 and ip 66/ip 68, 0.2 bar 112mm (4 13 / 32 ") 117mm (4 39 / 64 ") 116mm (4 9 / 16 ") 120mm (4 23 / 32 ") ~ 69mm (2 23 / 32 ") ø 77mm (3 1 / 32 ") ~ 69mm (2 23 / 32 ") ~ 116mm (4 9 / 16 ") ~ 87mm (3 27 / 64 ") ø 77mm (3 1 / 32 ") ø 84mm (3 5 / ...

Page 71

Vegapuls 62 - horn antenna in threaded version mm inch 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ") 118mm (4 41 / 64 ") 46mm (1 13 / 16 ") 3 15 / 16 " ø1 37 / 64 " ø1 57 / 64 " ø2 61 / 64 " ø3 47 / 64 " 4 23 / 32 " 8 1 / 2 " 16 59 / 64 " x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1...

Page 72

Vegapuls 62 - horn antenna in threaded version with rinsing air connection mm inch 3 15 / 16 " 4 23 / 32 " 8 1 / 2 " 16 59 / 64 " ø1 37 / 64 " ø1 57 / 64 " ø2 61 / 64 " ø3 47 / 64 " x y 100 ø40 120 ø48 216 ø75 430 ø95 1½" 2" 3" 4" x y 1½" 2" 3" 4" 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ")...

Page 73

Vegapuls 62 - horn antenna in threaded version with antenna extension mm inch 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ") 118mm (4 41 / 64 ") 7 7 / 8 " ø1 37 / 64 " ø1 57 / 64 " ø2 61 / 64 " ø3 47 / 64 " 8 21 / 32 " 12 7 / 16 " 20 55 / 64 " 46mm (1 13 / 16 ") x y g1½a / 1½ npt x y > 200 ø40...

Page 74

Vegapuls 62 - horn antenna in flange version 60mm (2 23 / 64 ") 140mm (5 33 / 64 ") 4xø 3 / 4 " 4xø 3 / 4 " 8xø 55 / 64 " 8xø 3 / 4 " 8xø 7 / 8 " 4xø 45 / 64 " 8xø 45 / 64 " 8xø 45 / 64 " 4 3 / 4 " 4 59 / 64 " 6 19 / 64 " 2 61 / 64 " 3 47 / 64 " 3 47 / 64 " 16 59 / 64 " 16 59 / 64 " 1 57 / 64 " 4 23 ...

Page 75

Vegapuls 62 - horn antenna in flange version with rinsing air connection d k x d b y 1 2 140mm (5 33 / 64 ") 4xø 3 / 4 " 4xø 3 / 4 " 8xø 55 / 64 " 8xø 3 / 4 " 8xø 7 / 8 " 4xø 45 / 64 " 8xø 45 / 64 " 8xø 45 / 64 " 4 3 / 4 " 4 59 / 64 " 6 19 / 64 " 2 61 / 64 " 3 47 / 64 " 3 47 / 64 " 16 59 / 64 " 16 59...

Page 76

Vegapuls 62 - parabolic antenna in threaded version 38mm (1 1 / 2 ") 22mm ( 55 / 64 ") 22mm ( 55 / 64 ") 118mm (4 41 / 64 ") 128mm (5 3 / 64 ") ø 243mm (9 9 / 16 ") 46mm (1 13 / 16 ") g1½a / 1½ npt 2 1 fig. 60: vegapuls 62 - parabolic antenna in threaded version 1 standard 2 with temperature adapter...

Page 77

Vegapuls 62 - parabolic antenna in flange version d mm b k d dn 50 pn 40 165 20 125 4xø18 dn 80 pn 40 200 24 160 8xø18 dn 100 pn 16 220 20 180 8xø18 dn 150 pn 16 285 22 240 8xø22 2" 150 lb 152,4 19,1 120,7 4xø19,1 3" 150 lb 190,5 23,9 152,4 4xø19,1 4" 150 lb 228,6 23,9 190,5 8xø19,1 6" 150 lb 279,4 2...

Page 78

10.3 industrial property rights vega product lines are global protected by industrial property rights. Further information see http://www.Vega.Com. Only in u.S.A.: further information see patent label at the sensor housing. Vega produktfamilien sind weltweit geschützt durch gewerbliche schutzrechte....

Page 79

Supplement vegapuls 62 - 4 ... 20 ma/hart 79 28435 -en -060317.

Page 80

Vega grieshaber kg am hohenstein 113 77761 schiltach germany phone +49 7836 50-0 fax +49 7836 50-201 e-mail: info@de.Vega.Com www.Vega.Com iso 9001 all statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the...