- DL manuals

- Xerox

- Software

- DocuPrint 180

- Operator's Manual

Xerox DocuPrint 180 Operator's Manual

Summary of DocuPrint 180

Page 1

Version 51.Xx, october 2006 701p25101 docutech 128/155/180 highlight color operator guide.

Page 2

Prepared by: xerox corporation global knowledge and language services 800 phillips road bldg. 845-17s webster, new york 14580 usa ©2006 by xerox corporation. All rights reserved. Copyright protection claimed includes all forms and matters of copyrightable material and information now allowed by stat...

Page 3

Docutech 128/155/180 highlight color operator guide i product recycling and disposal if you are managing the disposal of your xerox product, please note that the product contains lead, mercury and other materials whose disposal may be regulated due to environmental considerations in certain countrie...

Page 4

I i docutech 128/155/180 highlight color operator guide.

Page 5: 1 Safety Notices

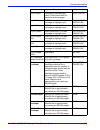

Docutech 128/155/180 highlight color operator guide iii 1 safety notices system safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6: 4 Problem Solving

I v docutech 128/155/180 highlight color operator guide waste containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27 wire module removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30 cleaning ...

Page 7: 6 Service and Supplies

Docutech 128/155/180 highlight color operator guide v stock satisfaction guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 using non-standard stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1...

Page 8

V i docutech 128/155/180 highlight color operator guide.

Page 9: Introduction

Docutech 128/155/180 highlight color operator guide vii introduction the docutech 128/155/180 hlc operator guide is one of a number of publications that make up the xerox document services platform series. About this guide the guide is intended for xerox docutech 128/155/180 hlc operators whose job ...

Page 10: Conventions

V i ii docutech 128/155/180 highlight color operator guide introduction • “technical information” contains the hardware and software capacity guidelines for the docutech 128/155/180 hlc systems. • “supplies” lists the supplies that you might want to keep in stock, and the information you need to ord...

Page 11: Safety Notices

Docutech 128/155/180 highlight color operator guide 1-1 1 safety notices system safety it is your responsibility to ensure your xerox equipment is safe at all times. This section includes equipment safety notices related to laser safety, ozone safety, and operation safety. Laser safety warning: use ...

Page 12

1 - 2 docutech 128/155/180 highlight color operator guide safety notices ozone safety this product produces ozone during normal operation. The ozone produced is dependent on copy volume and is heavier than air. Providing the proper environmental parameters as specified in the xerox installation inst...

Page 13

Docutech 128/155/180 highlight color operator guide 1- 3 safety notices – the power cable is damaged or frayed. – liquid is spilled into the system. – the system is exposed to water. – any part of the system is damaged. • always use materials and supplies specifically designed for your xerox equipme...

Page 14

1 - 4 docutech 128/155/180 highlight color operator guide safety notices warning: this system is certified manufactured and tested in compliance with strict safety and radio frequency interference regulations. Any unauthorized alteration which includes the addition of new functions or the connection...

Page 15

Docutech 128/155/180 highlight color operator guide 1- 5 safety notices in the event of problems, you should contact your local xerox representative in the first instance. The product has been tested to and is complaint with tbr21, a specification for terminal equipment for use on analogue switched ...

Page 16

1 - 6 docutech 128/155/180 highlight color operator guide safety notices check your understanding please review the questions and answers that follow to ensure that you understand the electricity at work regulation in england and wales. Question what is the electricity at work regulation? Answer the...

Page 17: Additional Queries

Docutech 128/155/180 highlight color operator guide 1- 7 safety notices must be carried out only by persons who possess the relevant skill, knowledge and experience to carry out such tests. Please contact the xerox europe customer service organization for further information. The use of inappropriat...

Page 18

1 - 8 docutech 128/155/180 highlight color operator guide safety notices.

Page 19: 2 System Components

Docutech 128/155/180 highlight color operator guide 2-1 2 system components the xerox docutech hlc printers are electronic reprographics systems. They are high volume printers available in multiple configurations. These versatile, high performance printing systems enable personal computers and other...

Page 20: Functional Overview

2 - 2 docutech 128/155/180 highlight color operator guide system components optional components • inverter feeder/stacker and up to 3 feeder/stackers • 2-tray interposer and finisher (production publisher configuration) note: the initial release of the production publisher (interposer and finisher) ...

Page 21

Docutech 128/155/180 highlight color operator guide 2- 3 system components data formats supported the xerox docutech 128/155/180 hlc can print the following data formats: • ascii • lcds* • ipds* • pcl • pdf • postscript • tiff • ppml note: * not supported on the production publisher configuration at...

Page 22: Paper Weights

2 - 4 docutech 128/155/180 highlight color operator guide system components stock specifications the success of any print run depends on proper selection, care, and handling of the paper or other stock that is used. It is very important to select, store, condition, and load print media properly in o...

Page 23

Docutech 128/155/180 highlight color operator guide 2- 5 system components • predrilled paper: has holes for use in binders or binder rings. Before loading predrilled paper, fan it to remove any loose plugs that could cause paper jams. • perforated paper: have been pierced with one or more rows of h...

Page 24

2 - 6 docutech 128/155/180 highlight color operator guide system components system software and job flow this section describes how the system software processes are used as a typical job flows through the system. Note: there are no job flow differences between the high volume printer and the produc...

Page 25: Printer Overview

Docutech 128/155/180 highlight color operator guide 2- 7 system components output queue after decomposition, the job is stored in the output queue. Printer the marker transfers the job from the output queue to the printer. After the job has successfully printed, it is removed from the output queue a...

Page 26

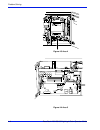

2 - 8 docutech 128/155/180 highlight color operator guide system components high volume printer the components, special features, and configurations of the xerox docutech 128/155/180 hlc printer are shown in the following figures. Figure 2-2. Printer with inverter feeder/stacker + feeder/ stacker (s...

Page 27

Docutech 128/155/180 highlight color operator guide 2- 9 system components processor feeder/ paper trays two processor feeder/paper trays (trays 1 and 2) are located in the main part of the printer. Trays 1 and 2 can handle paper sized from 8 by 10 inches / 203 by 254 mm to 9.02 by 14.02 inches / 23...

Page 28

2 - 1 0 docutech 128/155/180 highlight color operator guide system components paper level indicators display the approximate quantity of paper in the tray. Each display shows paper by quarter reams up to one ream, and then by full reams. The green indicator appears above its paper level indicator. S...

Page 29

Docutech 128/155/180 highlight color operator guide 2- 11 system components inverter feeder/stacker note: high volume printer configuration only each output feeder/stacker has offsetting capability and a capacity of 2500 sheets of 20 pound or 80 gsm paper. This capacity does not apply to 11 by 17 in...

Page 30

2 - 1 2 docutech 128/155/180 highlight color operator guide system components figure 2-5. High capacity stacker bin control panel 1. Ready to unload indicator on stacker bins 2. Please wait indicator on stacker bins 3. Bin unload button on stacker 4. In use indicator on stacker bin ready to unload i...

Page 31

Docutech 128/155/180 highlight color operator guide 2- 13 system components high-capacity stackers the high-capacity stacker (hcs) bins are located in the top half of the feeder/stacker modules, accessed through double doors. Two high-capacity stacker bins are standard, with up to two additional bin...

Page 32

2 - 1 4 docutech 128/155/180 highlight color operator guide system components production publisher the standard base components, special features, and configurations of the xerox docutech 180 hlc production publisher printer are shown in the following figures. Figure 2-8. Production publisher: print...

Page 33

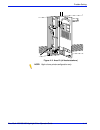

Docutech 128/155/180 highlight color operator guide 2- 15 system components interposer note: production publisher configuration only the two-tray interposer module is located between the print engine and the finisher. The interposer inserts blank or preprinted sheets as required. Figure 2-9. Interpo...

Page 34

2 - 1 6 docutech 128/155/180 highlight color operator guide system components finisher note: production publisher configuration only figure 2-10. Finisher in the finisher, prints can be collated, and stitched or bound, as required for a job. The following lists the finisher components: 1. Bindexer 2...

Page 35

Docutech 128/155/180 highlight color operator guide 2- 17 system components the stacker note: production publisher configuration only the stacker collects unfinished or finished stitched or bound jobs. When the stacker is full, or the job is completed, the stacker door opens and the stacker drawer t...

Page 36

2 - 1 8 docutech 128/155/180 highlight color operator guide system components dfa support the bypass transport meets the xerox document feeding and finishing architecture (dfa) specifications. The system software supports dfa. However, in order for the bypass transport to function correctly, you nee...

Page 37

Docutech 128/155/180 highlight color operator guide 2- 19 system components high volume printer paper path the following figure shows the path the paper takes through the high volume printer. Figure 2-11. Route of paper through the high volume printer 1. Processor feeder tray 1 2. Processor feeder t...

Page 38

2 - 2 0 docutech 128/155/180 highlight color operator guide system components 4. High-capacity feeder tray 4 a. Side 1 of sheet leaving feeder tray b. Drilled holes (on right edge) c. Origin 0,0: portrait orientation 5. Paper inverter 6. Duplex inverter 7. Sample tray 8. High-capacity stacker bin a ...

Page 39

Docutech 128/155/180 highlight color operator guide 2- 21 system components production publisher paper path the following figure shows the path the paper takes through the production publisher. Figure 2-12. Route of paper through the production publisher 1. Processor feeder tray 1 2. Processor feede...

Page 40

2 - 2 2 docutech 128/155/180 highlight color operator guide system components high volume printer bypass transport paper path figure 2-13. Bypass transport paper path (high volume printer configuration shown) 1. Sheet path 2. Exit rollers 3. Floor.

Page 41: The System

Docutech 128/155/180 highlight color operator guide 2- 23 system components the system system hardware the basic hardware components of the docutech 128/155/180 hlc systems are the docusp controller and the printer. The docusp controller the docusp controller is the connection between you and the sy...

Page 42

2 - 2 4 docutech 128/155/180 highlight color operator guide system components accessing docusp remotely (remote workflow) remote workflow, a remote graphical user interface (gui), is available for installation from a cd. Remote workflow allows you to manage your docusp-based printers from a single p...

Page 43

Docutech 128/155/180 highlight color operator guide 2- 25 system components the docusp tape client software enables transmission of data from a cartridge or open reel tape to the docusp controller via the socket gateway. The 4 gb external scsi quarter inch cartridge (qic) tape drive is an external d...

Page 44

2 - 2 6 docutech 128/155/180 highlight color operator guide system components figure 2-15. Peripheral cabinet 1. 9-track magnetic tape drive 2. 18/36-track cartridge tape drive paper sizing and print speed the printer paper trays have edge guide sensors that detect paper length and width. The system...

Page 45

Docutech 128/155/180 highlight color operator guide 2- 27 system components long and short edge feeding to feed through the printer, the leading edge of the paper must be at least 10 inches long. Therefore, the following standard sizes of paper must be loaded so that sheets feed long edge first: • 7...

Page 46

2 - 2 8 docutech 128/155/180 highlight color operator guide system components.

Page 47: Routine Maintenance

Docutech 128/155/180 highlight color operator guide 3-1 3 routine maintenance this section describes the routine activities you perform to maintain the reliability and productivity of your printer. Cleaning and maintenance overview some printer components need to be cleaned periodically to help keep...

Page 48

3 - 2 docutech 128/155/180 highlight color operator guide routine maintenance approved or recommended by xerox. If you use other supplies, you may damage the system. • keep supplies in stock as listed in the service and supplies chapter. • whenever you use or remove a part from the system, handle th...

Page 49: Paper

Docutech 128/155/180 highlight color operator guide 3- 3 routine maintenance paper you can add the same kind of paper to a tray when the supply is low without stopping the printer. You must have the same paper or stock loaded in two trays for the system to continue printing while you are loading the...

Page 50

3 - 4 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-2 recommended temperature and humidity for paper storage conditioning paper because temperature and humidity affect paper performance in the printer, you need to condition paper before using it. To condition paper...

Page 51

Docutech 128/155/180 highlight color operator guide 3- 5 routine maintenance table 3-1. Paper conditioning example: if you want to move ten cartons of paper from a storage area with a temperature of 90 o f. To an operating area with a temperature of 70 o f. (a 20 o difference), you should do so at l...

Page 52

3 - 6 docutech 128/155/180 highlight color operator guide routine maintenance adding paper to tray 1 or 2 the following steps must be performed to add paper to tray 1 or 2. 1. Press the tray unlock button on the front of the tray. Wait for the red "please wait" light to go off. 2. When the green "re...

Page 53

Docutech 128/155/180 highlight color operator guide 3- 7 routine maintenance for stock outside the recommended limits, refer to the "technical information" chapter in this guide. Figure 3-4 positioning the stack 8. Move the rear guide forward until it touches the edge of the stack. 9. Lower the feed...

Page 54

3 - 8 docutech 128/155/180 highlight color operator guide routine maintenance in u.S. Markets – 11.1 to 11.4 inches/282 to 290 mm – 11.8 to 12.1 inches/300 to 307 mm – 13 to 13.5 inches/330 to 343 mm in non-u.S. Markets – 11.1 inches to 11.4 inches/282 to 290 mm – 11.8 inches to 12.1 inches/300 to 3...

Page 55

Docutech 128/155/180 highlight color operator guide 3- 9 routine maintenance adjusting for paper curl each sheet of paper has a natural curve called the curl. Storing or using the paper under humid conditions may increase the curl. When too much curl causes paper handling problems, adjust the decurl...

Page 56

3 - 1 0 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-6 measuring the paper curl note: corners of the sheets of paper should not exceed curl shown in this chart. Image move green decurler lever move green decurler lever.

Page 57

Docutech 128/155/180 highlight color operator guide 3- 11 routine maintenance adjusting the decurler lever perform the following steps to adjust the decurler lever. Caution: do not use any paper that is not suitable for system use. 1. Open the right door of the processor. 2. Locate the decurler leve...

Page 58: Maintaining The Printer

3 - 1 2 docutech 128/155/180 highlight color operator guide routine maintenance maintaining the printer a screen message is displayed when it is necessary to replace system supplies. To ensure that the system runs efficiently, replace the supplies as soon as possible. Replacing the black dry ink bot...

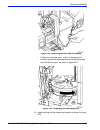

Page 59

Docutech 128/155/180 highlight color operator guide 3- 13 routine maintenance figure 3-8 removing the empty bottle 4. To insert a new bottle, place the bottle on the edge of the bottle guide. A. With a slow, firm motion push the bottle into the dispense position over the hopper. B. Turn a new bottle...

Page 60

3 - 1 4 docutech 128/155/180 highlight color operator guide routine maintenance paper seal by pulling it toward you with the other hand. Discard the seal along with the drop cloth. Figure 3-10 removing the paper seal 5. Close the processor access door. Note: if any dry ink should get on your skin, w...

Page 61

Docutech 128/155/180 highlight color operator guide 3- 15 routine maintenance 3. Remove the empty container by grasping its handle. With a slow, firm motion, remove the container. Figure 3-11 highlight color container 4. Pull the container out until it stops. 5. Remove the container and discard it. ...

Page 62

3 - 1 6 docutech 128/155/180 highlight color operator guide routine maintenance changing the highlight color customer changeable units the highlight color customer changeable unit (ccu) consists of the color dry ink bottle and supporting equipment. In order to change the highlight color or to servic...

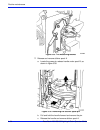

Page 63

Docutech 128/155/180 highlight color operator guide 3- 17 routine maintenance c. When the hlc unit is level, tighten the lock nut. Figure 3-12 leveling the cart 7. Push down firmly on the cart pedal until you hear or feel the pedal catch. The pedal should stay locked down. The pallet within the cart...

Page 64

3 - 1 8 docutech 128/155/180 highlight color operator guide routine maintenance 5. Then, turn the yellow ccu handle a quarter turn clockwise. Figure 3-13 unlatching the ccu 9. Using the metal flange of the color ccu, pull the ccu out of the printer until it is completely in the cart. The flange is l...

Page 65

Docutech 128/155/180 highlight color operator guide 3- 19 routine maintenance the cart. If the pallet does not move, check that the ccu is all the way out of the printer and push down on the pedal again. Figure 3-15 closing the top cover 11. Close the top cover and store it. Inserting a ccu to inser...

Page 66

3 - 2 0 docutech 128/155/180 highlight color operator guide routine maintenance 4. Push down firmly on the cart pedal until you hear or feel the pedal catch. The pedal should stay locked down. The pallet containing the ccu is raised. 5. Using the ccu metal flange, firmly push the ccu into the printe...

Page 67

Docutech 128/155/180 highlight color operator guide 3- 21 routine maintenance storing the cart and ccu note: if any dry ink gets on your hands, wash them with soap and cold water. Heat sets the ink permanently. If any dry ink gets on your clothes, brush them with a dry paper towel or a stiff bristle...

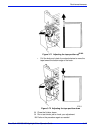

Page 68

3 - 2 2 docutech 128/155/180 highlight color operator guide routine maintenance 5. Slide the stand toward the machine to engage the pins with the holes and the slot. The end of the service stand may need to be lifted slightly to ensure pin engagement. 6. With the service stand in position against th...

Page 69

Docutech 128/155/180 highlight color operator guide 3- 23 routine maintenance 6. Then, turn the yellow ccu handle a quarter turn clockwise. Figure 3-20 removing the ccu from the printer 11. Using the metal flange of the color ccu, pull the ccu out of the printer until it is completely in the stand. ...

Page 70

3 - 2 4 docutech 128/155/180 highlight color operator guide routine maintenance caution: fuser lubricant for other printers is not compatible. Do not use docutech and docuprint fuser agent in a docutech hlc system. Do not use docutech hlc fuser shield in a docutech 61xx or docuprint 1xx system. The ...

Page 71

Docutech 128/155/180 highlight color operator guide 3- 25 routine maintenance figure 3-22 preparing to add fuser blend warning: fuser lubricant spills cause the floor to be slippery. If any fuser lubricant is spilled onto the floor, it must be removed immediately. C. Open a new box of fuser lubrican...

Page 72

3 - 2 6 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-23 adding the fuser blend e. Replace the reservoir cap by turning it clockwise approximately one full turn. Do not overtighten the cap. F. Inspect the area around the fuser to ensure no fuser blend was spilled. ...

Page 73

Docutech 128/155/180 highlight color operator guide 3- 27 routine maintenance 7. Close the processor doors. The fuser blend message disappears after the system makes approximately 20 prints. Waste containers the waste containers in the dt 128/155/180 hlc collect dry ink and developer after it has be...

Page 74

3 - 2 8 docutech 128/155/180 highlight color operator guide routine maintenance 4. Insert the new waste hlc developer waste container into the transport assembly. Push the retainer out of the way with your thumb. Continue seating the new waste container onto the tray and release the container latch....

Page 75

Docutech 128/155/180 highlight color operator guide 3- 29 routine maintenance figure 3-27 flat cap on waste bottle 4. Place the flat cap on the round bottle opening and snap it down. This prevents spillage when discarding the bottle. 5. Discard the waste material and container by placing the contain...

Page 76

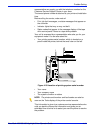

3 - 3 0 docutech 128/155/180 highlight color operator guide routine maintenance wire module removal and replacement replace the wire module only when directed to by the customer support center. Caution: in the following instructions, do not pull on the locating arm of the developer housing. A bent o...

Page 77

Docutech 128/155/180 highlight color operator guide 3- 31 routine maintenance 1. Position the wire module on the hlc developer module. 2. Snap the wire module retainer springs behind the tabs. 3. Slide the hlc developer module into the machine. 4. Latch the ccu into place. 5. Remove the cart or serv...

Page 78

3 - 3 2 docutech 128/155/180 highlight color operator guide routine maintenance cleaning the system and its components note: follow the procedures in this section only when directed by xerox customer support center personnel. Cleaning tasks consist of the following: • cleaning the 18/36-track cartri...

Page 79

Docutech 128/155/180 highlight color operator guide 3- 33 routine maintenance cleaning the 26-track cartridge tape drive the 26-track, or quarter inch cartridge (qic) tape drive heads should be cleaned at least once a week. If you use the drive for eight hours or more per day, then you should clean ...

Page 80

3 - 3 4 docutech 128/155/180 highlight color operator guide routine maintenance cleaning the sensors and the reflecting surfaces caution: never use abrasive materials or strong solvents when cleaning sensors. The following is a list of sensors to clean: • q850 and q861 sensor • q1011/1009 sensor and...

Page 81

Docutech 128/155/180 highlight color operator guide 3- 35 routine maintenance figure 3-30 area 4 and green handle 3. Locate the q850 and q861 sensor. Figure 3-31 q850 and q861 sensor.

Page 82

3 - 3 6 docutech 128/155/180 highlight color operator guide routine maintenance 4. Place a dry cleaning pad on the sensor and move it from left to right to clean the sensor. 5. Lower the area 4 green handle. 6. Close the printer doors. Cleaning the q1011/1009 sensor and mirror 1. Open the right and ...

Page 83

Docutech 128/155/180 highlight color operator guide 3- 37 routine maintenance figure 3-33 q1106 and q1166 sensors cleaning the q1107 sensor note: high volume printer configuration only to access sensor q1107, open the top cover of the high capacity stacker. To clean the sensor: 1. Brush or wipe the ...

Page 84

3 - 3 8 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-34 q1107 sensor cleaning the q1164 sensor note: high volume printer configuration only to access sensor q1164, open the top cover of the last feeder/ stacker module, the one containing the purge tray. To clean t...

Page 85

Docutech 128/155/180 highlight color operator guide 3- 39 routine maintenance figure 3-35 q1164 sensor cleaning the display the display should be cleaned as required. Clean the display with a soft, lint-free cloth dampened with a glass or lens and mirror cleaner. Do not spray the liquid directly ont...

Page 86

3 - 4 0 docutech 128/155/180 highlight color operator guide routine maintenance clearing or cleaning the finisher sensors note: production publisher configuration only clearing the finisher sensors should be performed only when directed by a customer support center representative. Note: the finisher...

Page 87

Docutech 128/155/180 highlight color operator guide 3- 41 routine maintenance figure 3-37 locating the q1201 sensor 3. Brush a folded sheet of paper under the sensor to clear any obstructions. 4. Close the processor cover. Clearing the q1202 and q1203 sensors note: production publisher configuration...

Page 88

3 - 4 2 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-38 locating the q1202 and q1203 sensors 3. Brush a folded sheet of paper under each sensor to clear any obstructions, as shown in figure 3-39. Figure 3-39 clearing the q1202 and q1203 sensors 4. Close the finish...

Page 89

Docutech 128/155/180 highlight color operator guide 3- 43 routine maintenance cleaning the q1222 and q1210 sensors note: production publisher configuration only cleaning the q1222 and the q1210 sensors should be performed only when directed by a customer support center representative. 1. Open the fi...

Page 90

3 - 4 4 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-41 locating the q1222 and q1210 sensors 4. Wipe each sensor gently with a soft cloth to clean them. 5. Close the finisher top cover. Clearing the q1205, q1206, and q1207 sensors note: production publisher config...

Page 91

Docutech 128/155/180 highlight color operator guide 3- 45 routine maintenance figure 3-42 locating the q1205, q1206, and q1207 sensors 4. Brush a folded sheet of paper across each sensor to clear any obstruction. 5. Close the bindexer and finisher doors. Clearing the q1213 sensor note: production pu...

Page 92

3 - 4 6 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-43 q1213 sensor 4. Brush a folded sheet of paper across the sensor to clear any obstruction. 5. Close the binder drawer and the finisher doors. Clearing the q1221, q1218, and q1227 sensors note: production publi...

Page 93

Docutech 128/155/180 highlight color operator guide 3- 47 routine maintenance figure 3-44 locating the q1221, q1218, and q1227 sensors cleaning the binder note: production publisher configuration only keep the binder clean to prevent binder tape jams. Clean the binder once a week, or as needed, and ...

Page 94

3 - 4 8 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-45 opening the binder drawer 3. Perform the following steps: a. Locate and remove the plastic binder platen cleaner from the binder tape reel, as shown in the following figure. Figure 3-46 binder platen cleaner ...

Page 95

Docutech 128/155/180 highlight color operator guide 3- 49 routine maintenance d. Continue to move the cleaner in the same manner until the 2-sided tabs break. Note: note: ensure that the following cleaning procedures are performed in the order listed. Cleaning the binder tape guides note: production...

Page 96

3 - 5 0 docutech 128/155/180 highlight color operator guide routine maintenance 2. Ensure that the glue is removed from the grooves on the binder platen surface, which align with the top and bottom edges of the book. Figure 3-48 cleaning the binder platen cleaning the flappers note: production publi...

Page 97

Docutech 128/155/180 highlight color operator guide 3- 51 routine maintenance figure 3-49 cleaning the flappers cleaning the calipers note: production publisher configuration only using the binder platen cleaner, clean the binder caliper surfaces until all the glue is removed..

Page 98

3 - 5 2 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-50 cleaning the calipers closing the binder note: production publisher configuration only perform the following steps to close the binder. 1. Push in the binder drawer until it stops. 2. Close the finisher doors...

Page 99

Docutech 128/155/180 highlight color operator guide 3- 53 routine maintenance 1. Open the finisher doors. 2. Lift the stitcher panel, which is located directly above the stitcher spools. 3. Pull the green stitcher head release handle forward and up until it latches into place, as shown in figure 3-5...

Page 100

3 - 5 4 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-52 removing the stitcher wire plug 5. Perform one of the following steps: • if there is no wire on the spool, use the wire cutters to pull the remaining wire carefully out of the tubing, as shown in figure 3-53....

Page 101

Docutech 128/155/180 highlight color operator guide 3- 55 routine maintenance figure 3-53 removing the wire from the tubing • if there is wire on the spool, hold it on the spool and carefully rewind the remaining wire out of the tubing and onto the stitcher spool, as shown in figure 3-54. Figure 3-5...

Page 102

3 - 5 6 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-55 the measuring bracket 7. Release and remove stitcher spool a. A. Locate the green pin release handle under spool b, as shown in figure 3-56. Figure 3-56 removing the stitcher spool pin b. Pull and hold the ha...

Page 103

Docutech 128/155/180 highlight color operator guide 3- 57 routine maintenance 8. Install the new stitcher spool. A. Slide the new stitcher spool into position with the paper wrapper still in place. B. Replace the stitcher spool pin. Push it down until it locks into place, as shown in figure 3-57. Fi...

Page 104

3 - 5 8 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-58 removing the paper wrapper note: hold the wire between the thumb and forefinger of both hands. 10. Feed the wire slowly into the tubing until the wire extends from the stitcher plug, as shown in figure 3-59. ...

Page 105

Docutech 128/155/180 highlight color operator guide 3- 59 routine maintenance 12. Slowly and carefully pull about 3 feet (1 meter) of wire from the spool. 13. Cut the wire, leaving about 2 inches (51mm) of wire extending from the end of the stitcher plug. 14. Insert the plug into the measuring brack...

Page 106

3 - 6 0 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-60 storing binder tape in a cool, dry place perform the following steps to store the binder tape wheels. 1. Always store binder tape in a dry place cooler than 90°f (32°c). 2. Keep stored rolls in their original...

Page 107

Docutech 128/155/180 highlight color operator guide 3- 61 routine maintenance replacing the binder tape reel note: production publisher configuration only use this procedure to replace the binder tape in the system. To ensure proper binding and to reduce binder tape jams, do not leave binder tape in...

Page 108

3 - 6 2 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-63 removing the tape b. Rewind the tape onto the tape reel. 4. Slide the tape reel off the tape reel drive. A. Move the reel retainer in the center of the reel to the horizontal unlocked position. Figure 3-64 un...

Page 109

Docutech 128/155/180 highlight color operator guide 3- 63 routine maintenance note: note: the tape will not feed properly if the retainer is not locked. B. Move the reel retainer to the locked position. Figure 3-65 locking the reel note: note: ensure that the tape passes through the binder tape sens...

Page 110

3 - 6 4 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-67 threading the tape to the pressure roll 8. Turn the green knob clockwise until the tape extends at least 2 inches (51mm) beyond the tape guides. Figure 3-68 feeding the tape manually 9. Cut the tape. A. Lift ...

Page 111

Docutech 128/155/180 highlight color operator guide 3- 65 routine maintenance b. Remove the cut piece of tape. Figure 3-69 cutting the tape 10. Close the binder drawer. 11. Close the finisher doors. Adjusting the binder tape registration note: production publisher configuration only the binder tape ...

Page 112

3 - 6 6 docutech 128/155/180 highlight color operator guide routine maintenance figure 3-70 locating the binder tape knob the knob is spring loaded and moves in increments to change the location of the binder tape. Each increment equals a change of 0.1mm, up or down, on the edge of the book. One ful...

Page 113

Docutech 128/155/180 highlight color operator guide 3- 67 routine maintenance figure 3-71 adjusting the tape position up • pull the knob and rotate it counterclockwise to move the tape toward the bottom edge of the book. Figure 3-72 adjusting the tape position down 8. Close the finisher doors. 9. Ru...

Page 114

3 - 6 8 docutech 128/155/180 highlight color operator guide routine maintenance.

Page 115: Problem Solving

Docutech 128/155/180 highlight color operator guide 4-1 4 problem solving the system is designed to help you find and solve problems as they happen. The system detects hardware and software problems, displays error or fault messages and screens, and sounds an alert tone (if it is enabled) when a pro...

Page 116

4 - 2 docutech 128/155/180 highlight color operator guide problem solving when a fault occurs when a fault occurs in the printer an indicator appears on the docusp print services window and a printer faults message appears. Note: the printers also have an attention light on top of the finisher modul...

Page 117

Docutech 128/155/180 highlight color operator guide 4- 3 problem solving paper path jams • check the area where the jams are occurring to ensure that the paper path is clear of paper and other obstructions. • if a jammed sheet of paper tears when being removed, ensure that you have removed all of th...

Page 118

4 - 4 docutech 128/155/180 highlight color operator guide problem solving missing sheets in a set immediately after a jam. After recovering from a jam, an incomplete set may be purged and the set reprinted. Check the prints to ensure that you are not confusing the purged output with the completed se...

Page 119

Docutech 128/155/180 highlight color operator guide 4- 5 problem solving processor power is off unexpectedly the processor or the docusp controller may have an electrical problem. If the docusp controller has an electrical problem, it may shut off the power to the processor. 1. Determine if the docu...

Page 120

4 - 6 docutech 128/155/180 highlight color operator guide problem solving solving print quality problems a print quality problem means that the job was submitted successfully, but does not print correctly. Note: if the image quality parameters are changed, you must restart or reboot the docusp softw...

Page 121

Docutech 128/155/180 highlight color operator guide 4- 7 problem solving clearing paper jams in printer areas 2 through 10 for both configurations in the following figures, the printer jam clearance areas have arrows pointing to them or circles drawn around them. Figure 4-1 area 2 figure 4-2 area 3.

Page 122

4 - 8 docutech 128/155/180 highlight color operator guide problem solving figure 4-3 area 4 figure 4-4 area 5.

Page 123

Docutech 128/155/180 highlight color operator guide 4- 9 problem solving figure 4-5 area 6 figure 4-6 area 7.

Page 124

4 - 1 0 docutech 128/155/180 highlight color operator guide problem solving figure 4-7 area 8 note: if a jammed sheet rips as you are removing it from area 8, you may have to use the pinch lever in area 9 to remove the paper. Refer to the note following the area 14 figure for additional instructions...

Page 125

Docutech 128/155/180 highlight color operator guide 4- 11 problem solving figure 4-8 area 9 to clear jams from area 9: 1. Lower and pull out tray 1 to give you better access to area 9. 2. Pull the area 9 green lever toward you to unlatch it. Be sure to relatch the lever after you have cleared any pa...

Page 126

4 - 1 2 docutech 128/155/180 highlight color operator guide problem solving figure 4-9 area 10 figure 4-10 area 11 (all feeder/stackers) note: high volume printer configuration only.

Page 127

Docutech 128/155/180 highlight color operator guide 4- 13 problem solving figure 4-11 area 12 (all feeder/stackers) note: high volume printer configuration only.

Page 128

4 - 1 4 docutech 128/155/180 highlight color operator guide problem solving clearing paper jams in the feeder/stackers figure 4-12 area 13 note: figures 4-12 and 4-13 applicable on the high volume printer configuration only. Figure 4-13 area 14.

Page 129

Docutech 128/155/180 highlight color operator guide 4- 15 problem solving note: you may sometimes find paper lying on top of area 14, even though there is no message indicating a jam in this area. Discard the paper. Figure 4-14 area 15 note: high volume printer configuration only.

Page 130

4 - 1 6 docutech 128/155/180 highlight color operator guide problem solving figure 4-15 area 16 note: high volume printer configuration only.

Page 131

Docutech 128/155/180 highlight color operator guide 4- 17 problem solving figure 4-16 area 17 note: if your printer has frequent jams in this area, you may need to clean the q1106 sensor. Note: high volume printer configuration only.

Page 132

4 - 1 8 docutech 128/155/180 highlight color operator guide problem solving figure 4-17 area 18 points to note for clearing jams in area 18: • sometimes the controller messages direct you to discard the last sheet delivered to the stack following a jam in area 18. Check for this message when clearin...

Page 133

Docutech 128/155/180 highlight color operator guide 4- 19 problem solving figure 4-18 area 19 3. Remove any paper from the exposed area. 4. Press the green lever to the left until the latch catches. 5. Press the area 20 green lever in the direction of the arrow printed on it..

Page 134

4 - 2 0 docutech 128/155/180 highlight color operator guide problem solving figure 4-19 area 20 6. Remove any paper from the exposed area. 7. Press the green lever down and to the left until the latch catches. 8. Close the bypass transport module door. Clearing a misfeed (feeder tray fault) note: hi...

Page 135

Docutech 128/155/180 highlight color operator guide 4- 21 problem solving 3. For the processor feeder trays, press the green lever to unlatch the paper feeder assembly. Figure 4-21 4. Remove and discard any partially fed paper. Ensure that: • the paper supply is neatly stacked. • the stack is not hi...

Page 136

4 - 2 2 docutech 128/155/180 highlight color operator guide problem solving figure 4-22 6. Slide the tray back into the printer until the tray latches and press the continue button to resume printing. 7. Discard any pages sent to the sample tray, purge tray, or unused stacker bin when the misfeed wa...

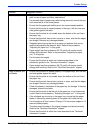

Page 137

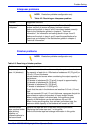

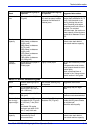

Docutech 128/155/180 highlight color operator guide 4- 23 problem solving interposer problems note: production publisher configuration only table 4-2. Resolving an interposer problem finisher problems note: production publisher configuration only problem suggested solutions repeated jams in interpos...

Page 138

4 - 2 4 docutech 128/155/180 highlight color operator guide problem solving binder tape not positioned correctly on the top edge of the output prints adjust the binder tape registration using the procedure, "adjusting the binder tape registration," in this guide. Binder tape is too long or too short...

Page 139

Docutech 128/155/180 highlight color operator guide 4- 25 problem solving binder tape fault note: production publisher configuration only to clear a binder tape fault: 1. Open the finisher doors. 2. Open the top cover. Warning: the binder tape adhesive is hot, approximately 425°f (218°c). Allow the ...

Page 140

4 - 2 6 docutech 128/155/180 highlight color operator guide problem solving 11. Ensure that area 18 is clear of all binder tape adhesive. If it is not, clean the binder using the procedure, "cleaning the binder," in the "routine maintenance" chapter. 12. Close the finisher doors. 13. Close the top c...

Page 141

Docutech 128/155/180 highlight color operator guide 4- 27 problem solving figure 4-24 removing the stitcher wire plug 5. Remove the stitcher wire plug. • the stitcher wire plug is located above the binder area, as shown in figure 4-24. • press and hold down the release clip. • pull the plug out of t...

Page 142

4 - 2 8 docutech 128/155/180 highlight color operator guide problem solving figure 4-25 cutting the wire 7. Insert the plug into the measuring bracket, as shown in figure 4-26. Figure 4-26 the measuring bracket 8. Feed the wire until the wire touches the back of the measuring bracket. 9. Remove any ...

Page 143

Docutech 128/155/180 highlight color operator guide 4- 29 problem solving • fold a piece of copy paper in half lengthwise. Place the folded sheet of copy paper under the stitcher head, as shown in figure 4-27. • pull out the stitcher knob and allow it to snap back into place to free any stitcher wir...

Page 144: Customer Support Center

4 - 3 0 docutech 128/155/180 highlight color operator guide problem solving checking paper curl you can adjust the decurler lever to correct most paper curl problems. Refer to the paper curl chart, later in this chapter, to determine the amount of curl in the paper stock. Perform the following to me...

Page 145

Docutech 128/155/180 highlight color operator guide 4- 31 problem solving representative can supply you with the telephone number for the customer service support center in your area. The correct phone number is attached to your printer at installation time. Before calling for service, make note of:...

Page 146

4 - 3 2 docutech 128/155/180 highlight color operator guide problem solving.

Page 147: 5 Technical Information

Docutech 128/155/180 highlight color operator guide 5-1 5 technical information this section contains the hardware and software capacity guidelines for the docutech hlc systems. It includes the printer specifications, the satisfaction guides for paper trays and stock, and tips on storing paper and i...

Page 148

5 - 2 docutech 128/155/180 highlight color operator guide technical information tray 1 stock sizes us letter (8 1/2 x 11 inches) us legal (8 1/2 x 14 inches) 9 x 11 inches a4 8 1/2 x 13 inches 223 x 297 mm custom (width = 8 to 9 inches (203 to 229 mm), length = 10 to 14 inches (254 to 356 mm)) capac...

Page 149

Docutech 128/155/180 highlight color operator guide 5- 3 technical information us ledger (17 x 11 inches) 9 x 11 inches a3 a4 8 1/2 x 13 inches 223 x 297 mm iso b4 jis b4 custom (width = 8 to 17 inches (203 to 432 mm), length = 10 to 14.33 inches (254 to 364 mm)) capacity 550 sheets, substance 20 (7...

Page 150: Printer Satisfaction Guides

5 - 4 docutech 128/155/180 highlight color operator guide technical information capacity 3000 sheets (1500 inboard and 1500 outboard), substance 20 (75 g/m2) stitcher stock sizes 8 x 10 inches to 9 x 14 inches (203 x 254 mm to 229 x 356 mm) capacity 2 to 70 sheets, substance 20 (75 g/m2) stitches pe...

Page 151

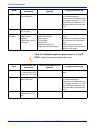

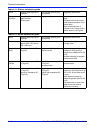

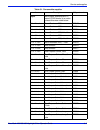

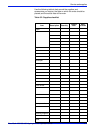

Docutech 128/155/180 highlight color operator guide 5- 5 technical information the curl in the paper, refer to the “routine maintenance” and “problem solving” sections of this guide. Stock satisfaction guides table 5-1. Satisfaction guide for paper trays 1 and 2 table 5-2. Satisfaction guide for pap...

Page 152

5 - 6 docutech 128/155/180 highlight color operator guide technical information table 5-3. Satisfaction guide for paper trays 3, 4, 5, and 6 note: high volume printer configuration only weight substance 16 to 110 (60 to 200 g/m2) weights outside the limits shown are not recommended. Substance 110 (2...

Page 153

Docutech 128/155/180 highlight color operator guide 5- 7 technical information table 5-4. Satisfaction guide for 2-sided printing using various stocks the following table lists stock that have been evaluated and tested for use in this system. There are many other stocks available, some of which may ...

Page 154

5 - 8 docutech 128/155/180 highlight color operator guide technical information table 5-5. Satisfaction guide for various stocks stock type instructions for use substance 13 (49 g/m2) paper use trays 3,4,or 5. Do not run 2-sided prints. Load the paper with seam side down into tray 3. Optimum satisfa...

Page 155

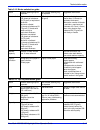

Docutech 128/155/180 highlight color operator guide 5- 9 technical information 3 hole drilled, edge reinforced, 4024 dp paper do not stitch or bind. Do not run with tabs. Tabs can be inserted off-line. For optimum satisfaction, use the paper trays 1 and 2 plate assembly. The plate assembly can be or...

Page 156

5 - 1 0 docutech 128/155/180 highlight color operator guide technical information do not use the following stocks: • multipart forms • stocks outside of the recommended size and weight ranges using non-standard stock using stock of non-standard width or length in the printer may have a negative impa...

Page 157

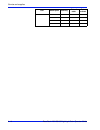

Docutech 128/155/180 highlight color operator guide 5- 11 technical information table 5-7. Stock length impact on system performance paper stock rotation this section identifies the limitations on the rotation of paper stock in the docutech 128/155/180 hlc bypass transport when using a third-party f...

Page 158

5 - 1 2 docutech 128/155/180 highlight color operator guide technical information displayed on the docusp controller to warn the print services operator that the paper stock to be rotated will not fit in the bypass transport. The signature booklet maker attached to a docutech 128/155/ 180 hlc printe...

Page 159

Docutech 128/155/180 highlight color operator guide 5- 13 technical information *although the diagonal meets the 18-inch (457 mm) rotation limit, the paper stock long dimension exceeds the processor path width. The sheet must stay in the short-edge feed orientation throughout the paper path. Note: n...

Page 160

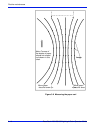

5 - 1 4 docutech 128/155/180 highlight color operator guide technical information figure 5-1. Rotatable and non-rotatable sizes (“as loaded” media size sizes whose dimensions are located on the left of the curve or on the line itself have a diagonal that is less than or equal to 18.0 inches (457 mm)...

Page 161

Docutech 128/155/180 highlight color operator guide 5- 15 technical information set or stack size substance 16 to 20 (60 to 75 g/m2) over substance 20 (75 g/ m2) stock as sets or stacks increases the likelihood of bindexer jams. When using copy paper heavier than substance 20 (75 g/m2), limit the st...

Page 162

5 - 1 6 docutech 128/155/180 highlight color operator guide technical information type or condition xerographic bond paper in good condition drilled paper slightly curled paper do not use excessively curled paper. Transparencies must contain some opaque sheets to avoid finisher jams. Stock not defin...

Page 163

Docutech 128/155/180 highlight color operator guide 5- 17 technical information set size limits maximum collated: 125 sheets of substance 20 (75 g/m2) or equivalent thickness minimum collated: 15 sheets of substance 20 (75 g/m2) (7 sheets with index covers) or equivalent thickness maximum uncollated...

Page 164

5 - 1 8 docutech 128/155/180 highlight color operator guide technical information type or condition xerographic bond paper in good condition drilled paper these may yield stacking registration problems: slightly curled paper precut tabs cannot be sent to the top tray. Do not use excessively curled p...

Page 165: Service and Supplies

Docutech 128/155/180 highlight color operator guide 6-1 6 service and supplies after the installation of your printer, there are a few ongoing tasks that must be performed. These tasks may include all or some of the following: • maintaining an adequate inventory of consumable supplies • overseeing r...

Page 166

6 - 2 docutech 128/155/180 highlight color operator guide service and supplies the key to effective use of the support center is correct identification of the problem. Before calling the support center, it is helpful to have the following information available: • a list of any error messages • an ex...

Page 167

Docutech 128/155/180 highlight color operator guide 6- 3 service and supplies your sales representative can help you submit the initial order of supplies needed for installation. These items include paper, dry ink, fuser blend, and developer. Once your printer volume is established, planning ahead a...

Page 168

6 - 4 docutech 128/155/180 highlight color operator guide service and supplies routine maintenance there are a number of routine maintenance tasks that must be performed to ensure maximum efficiency of your printer. These tasks include the following: • adding dry ink • cleaning the exterior surfaces...

Page 169

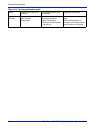

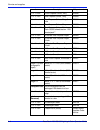

Docutech 128/155/180 highlight color operator guide 6- 5 service and supplies table 6-1. Consumable supplies item description u.S. Part number paper xerox paper quantities are 10 reams (5,000 sheets) to a carton unless otherwise noted below 8.5 x 11 inch xerox business 4200 3r2047 a4 xerox business ...

Page 170

6 - 6 docutech 128/155/180 highlight color operator guide service and supplies 8.5 x 14 inch dual purpose colors, ivory 3r3096 8.5 x 11 inch dual purpose colors, gray 3r3066 8.5 x 11 inch dual purpose colors, gray, 3- hole 3r3802 8.5 x 14 inch dual purpose colors, gray 3r3098 8.5 x 11 inch** dual pu...

Page 171

Docutech 128/155/180 highlight color operator guide 6- 7 service and supplies dry ink black packaged 3 cartridges per carton. 220k/carton with 6% black only area coverage 6r206 (us/ca) dry ink blue 300k/carton with 1.5% area coverage as highlight color 6r1191 (us/ca) 6r90343 (eu) dry ink red 300k/ca...

Page 172

6 - 8 docutech 128/155/180 highlight color operator guide service and supplies caution: *do not use dt/dp fuser agent 8r2955 in a dt hlc printer. Do not use dt hlc fuser blend in other docutech or docuprint systems. Caution: *fuser blend and fuser shield are not interchangeable. Contact your xerox r...

Page 173

Docutech 128/155/180 highlight color operator guide 6- 9 service and supplies use the following table to help record the supplies and accessories you require, the date on which the order should be placed, and the actual date of the order. Table 6-2. Supplies checklist item description quantity date ...

Page 174

6 - 1 0 docutech 128/155/180 highlight color operator guide service and supplies item description quantity date of order date ordered.